Special oil-sludge cracking device and oil-sludge cracking process

A cracking device and oil sludge technology, which is applied in the petroleum industry, pyrolysis reaction, and hydrocarbon oil treatment, etc., can solve the problems of oil and gas leakage, cracking equipment and process can not realize automatic and continuous feeding, and low work efficiency, so as to improve High efficiency, high working efficiency, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

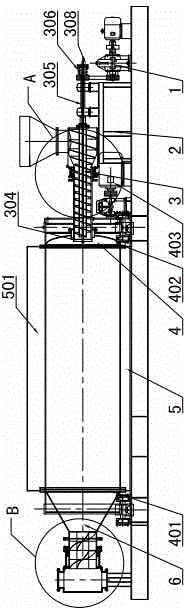

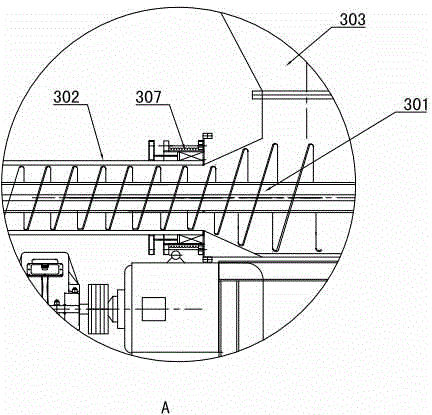

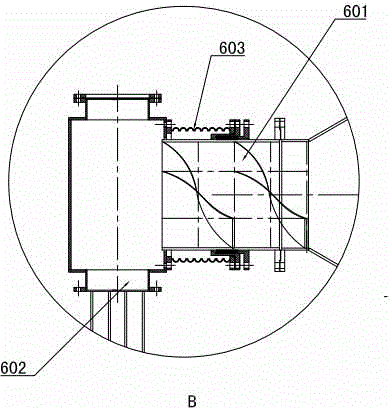

[0029] Figure 1-3 It is the best embodiment of the special cracking device and cracking process for this oil sludge, the following will be combined with the attached Figure 1-3 The present invention will be further described.

[0030] Refer to attached Figure 1-3 : Special cracking device for oil sludge, including feeding system, cracking furnace body 4, heating system 5 and discharging system 6, feeding system includes transmission device 1 and screw feeding mechanism 3, screw feeding mechanism 3 is fixedly installed on support device 2 In the upper part, the screw feeding mechanism 3 includes a conical screw propeller 301. The conical screw propeller 301 has a spiral cone section whose diameter gradually decreases. A sealing sleeve 307 is provided at the end of the outer ring of the feeding cylinder 302 . One end of the conical screw propeller 301 is driven by the transmission device 1 , and the other end extends into the cracking furnace body 4 , and a hopper 303 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com