Cover tape

一种盖带、基材层的技术,应用在薄膜/薄片状的粘合剂、应用、电气元件等方向,能够解决防静电性能下降、很难得到防静电性能、很难维持防静电性能等问题,达到稳定防静电性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

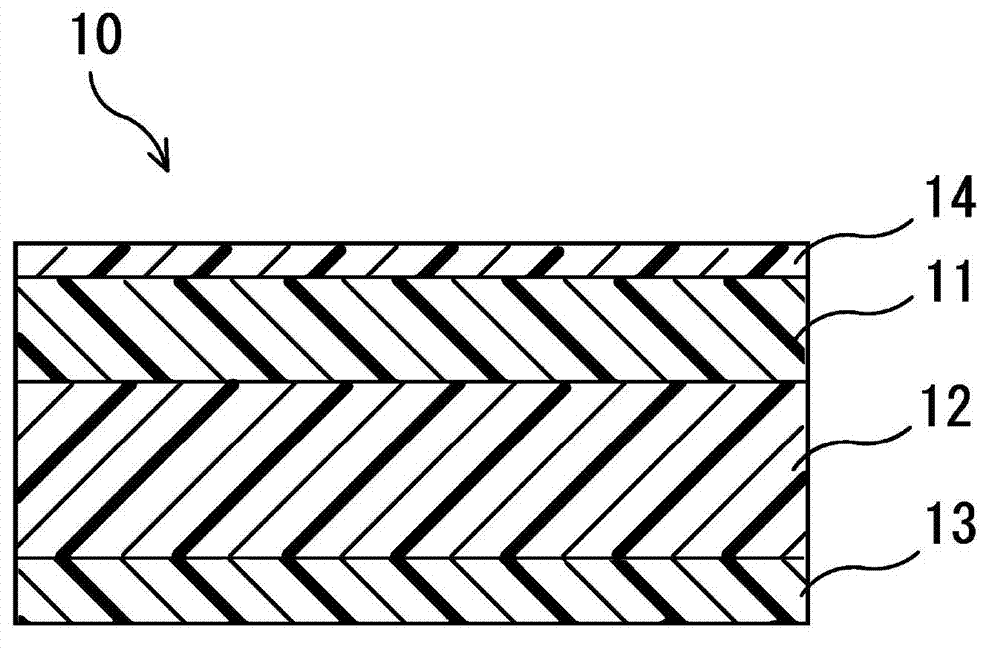

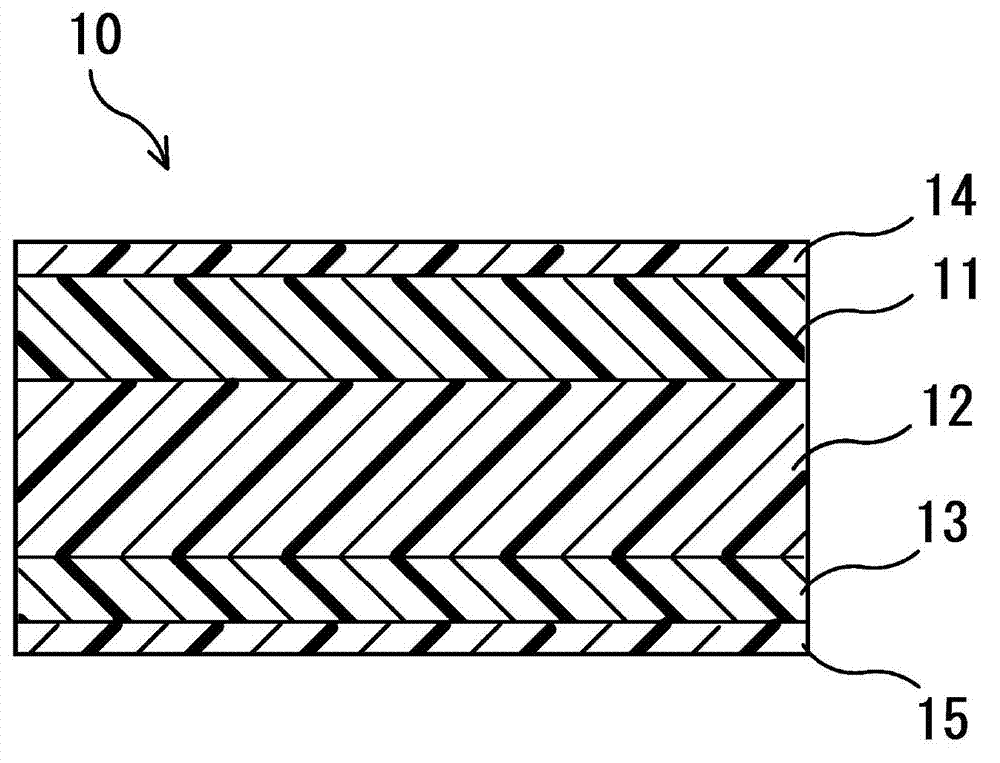

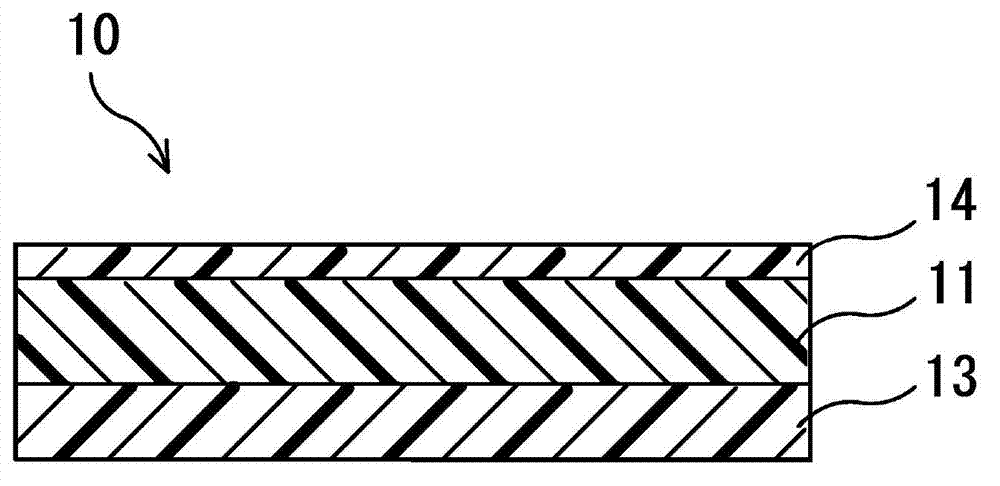

[0090] 42.5% by mass of styrene-butadiene block copolymer "CLEAREN" (manufactured by Denki Kagaku Kogyo Co., Ltd.) and 22.5% by mass of styrene-butadiene block copolymer "TR-2000" (manufactured by JSR Corporation) , Ethylene-α-olefin random copolymer "Tafmer-A" (manufactured by Mitsui Chemicals Co., Ltd.) 25% by mass, high-impact polystyrene: Toyo Styrene "E640N" (manufactured by Toyo Styrene Co., Ltd.) 10% by mass , pre-mixed with a tumbler, using a single-screw extruder with a diameter of 40mm to stir at 210°C, and a line speed of 20m per minute to form an adhesive layer ( figure 2 Medium, 13) resin composition. Using the resin composition for the adhesive layer, a film was formed with an extrusion blow molding machine to obtain a film having a thickness of 15 μm constituting the adhesive layer. Furthermore, a roll coater is used to form the substrate layer ( figure 2 Medium, 11) Biaxially stretched polyethylene terephthalate film (thickness 12μm) is coated with two-comp...

Embodiment 2~9、 comparative example 1~9

[0092] In addition to forming an antistatic layer according to the composition ratio as described in Table 1 and Table 2 ( figure 2 In the same manner as in Example 1 except for middle and 14), the cover tapes in Examples 2 to 3 of the present invention and the cover tapes in Comparative Examples 1 and 3 to 9 were produced. In addition, in addition to forming an antistatic layer according to the composition ratios described in Table 1 and Table 2, an adhesive layer was formed from an acrylic resin "EC-242" (manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) ( figure 2 In the same manner as in Example 1 except for middle and 13), the cover tapes in Examples 4 to 9 of the present invention and the cover tape in Comparative Example 2 were produced.

[0093] For the cover tapes in Examples 1 to 9 and Comparative Examples 1 to 9, the above-mentioned various characteristics were obtained. All the results are summarized in Table 1 and Table 2.

[0094] 【Table 1】

[0095]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com