Methods for producing polarizing laminate film and polarizing plate

A manufacturing method and a technology for laminating films, applied in polarizing elements, optics, instruments, etc., can solve problems such as poor film handling and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

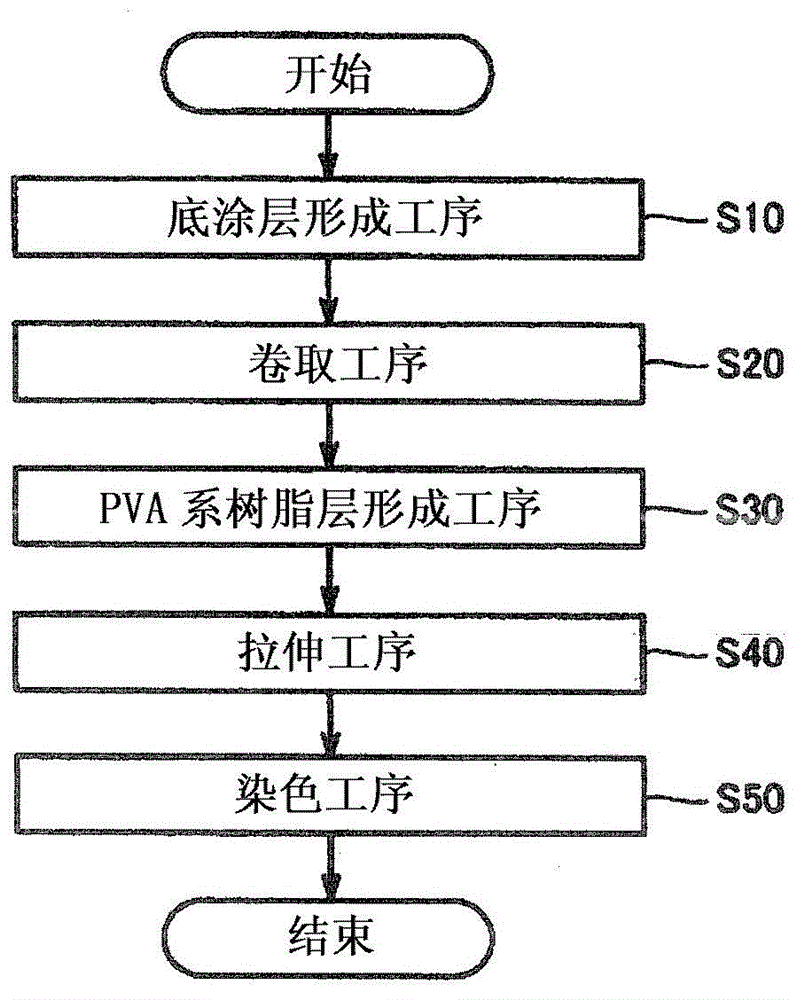

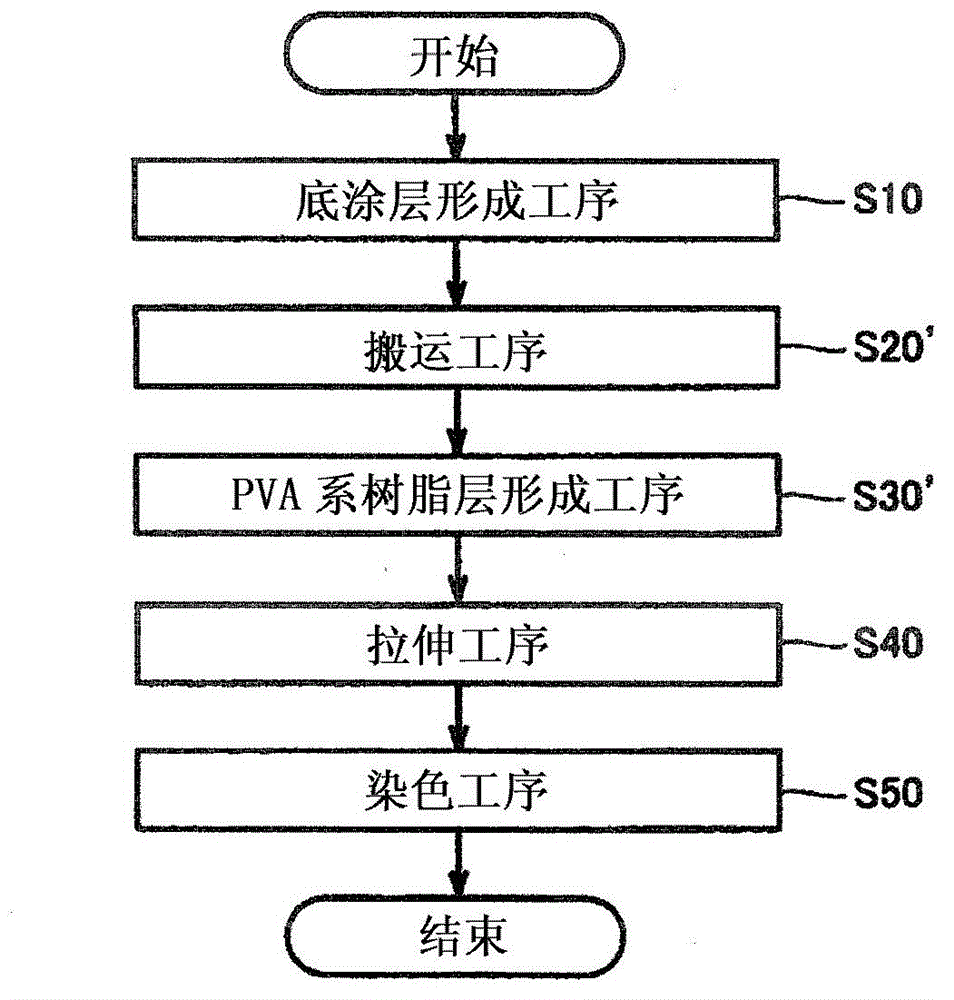

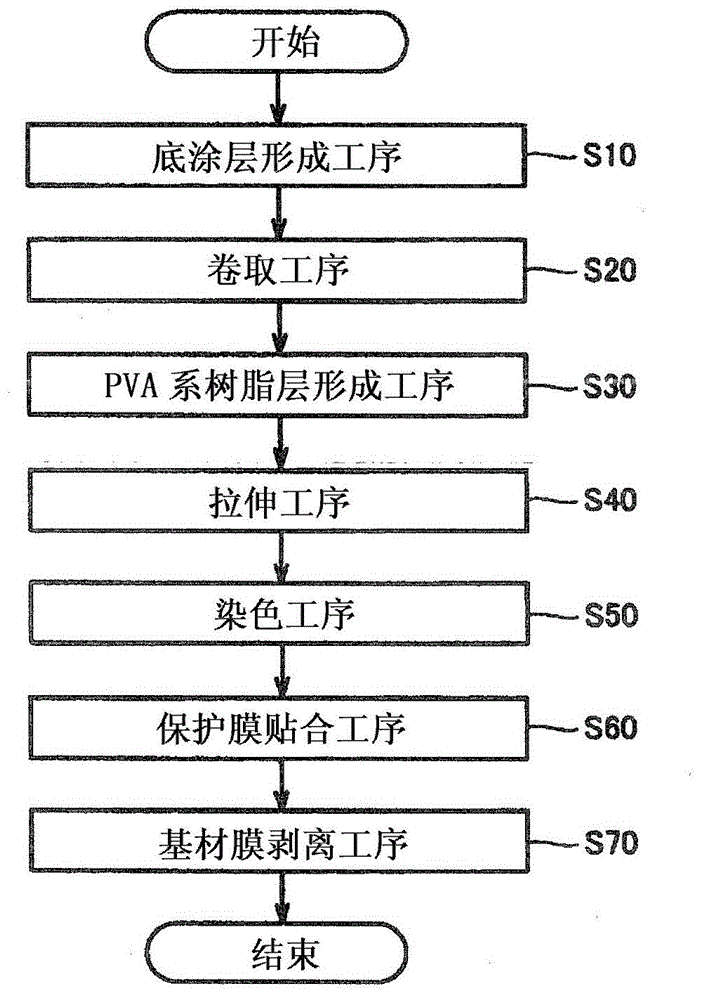

Method used

Image

Examples

Embodiment 1

[0174] according to figure 2 The manufacturing method shown produces a polarizing plate.

[0175] (undercoat layer formation process)

[0176] As the base film, an unstretched polypropylene (PP) film having a thickness of 100 μm was used.

[0177] As a primer solution not containing a crosslinking agent, polyvinyl alcohol powder (manufactured by Nippon Gosei Chemical Industry Co., Ltd., saponification degree 99.5 mol%, trade name: Z-200) was dissolved in hot water at 95°C to prepare An aqueous solution in which the weight ratio of water: polyvinyl alcohol powder is 100:3. The obtained primer solution was coated on the corona-treated substrate film, and dried at 80° C. for 10 minutes to form a primer layer with a thickness of 0.3 μm.

[0178]The experiment shown below was performed about the base film in which this undercoat layer was formed, and the degree of blocking was confirmed.

[0179]

[0180] (1) A film coated with an undercoat layer having a size of 300 mm×220 ...

Embodiment 2

[0203] As the base film, an unstretched polypropylene film having a thickness of 100 μm was used in the same manner as in Example 1.

[0204] Polyvinyl alcohol powder (manufactured by Nippon Synthetic Chemical Industry Co., Ltd., saponification degree 99.5 mol%, trade name: Z-200) was dissolved in hot water at 95°C to prepare water: The weight ratio of polyvinyl alcohol powder was 100: The aqueous solution of 3, and then, add and mix the epoxy-based cross-linking agent solution (Sumika Chemtex Co. , Ltd., trade name: Sumirez (registered trademark) Resin 650, aqueous solution with a solid content concentration of 30% by weight), and prepared as a primer solution. At this time, the concentration of the epoxy-based crosslinking agent (solid content) in the primer solution was 0.04% by weight.

[0205] The obtained primer solution was coated on the corona-treated substrate film, and dried at 80° C. for 10 minutes to form a primer layer with a thickness of 0.2 μm.

[0206] (Adhes...

Embodiment 3

[0225] In this example, as a cross-linking agent for the primer solution, "Orgatics-TC310 (trade name)" (manufactured by Matsumoto Pharmaceutical Co., Ltd., active ingredient (Chem. Structure: (HO) 2 Ti[OCH(CH 3 )COOH] 2 ) 44% by weight, isopropanol 40% by weight and water 16% by weight solution).

[0226] First, solution A was prepared by mixing water, isopropanol, and "Orgatics TC-310" so that the weight ratio of water:isopropanol:TC-310 was 85:15:7.5. Here, the weight ratio of TC-310 refers to the weight of the entire solution containing the organometallic compound.

[0227] In addition, 15 parts by weight of polyvinyl alcohol powder (manufactured by Kuraray Co., Ltd., saponification degree: about 80 mol%, trade name: KL506) was dissolved in 100 parts by weight of water at 80°C to prepare an aqueous solution of polyvinyl alcohol ( Solution B).

[0228] Solution A and solution B were mixed so that the weight ratio of solution A:solution B was 1.3:4 to prepare a primer s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com