System for detecting fracture splitting notch of connecting rod of automobile based on machine vision

A technology for automotive connecting rods and detection systems, applied in optical device exploration, etc., can solve problems such as low accuracy of manual identification, reduced cracking success rate, failure of connecting rod cracking, etc., to achieve improved interface, practicability, and excellent stability and correct rate, reduce the effect of workers' workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

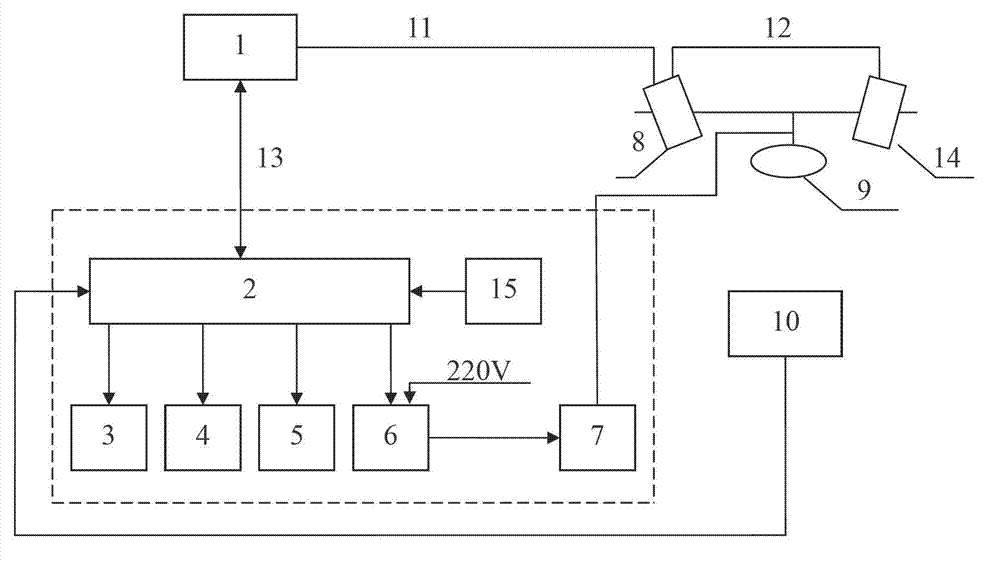

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

[0023] The automobile connecting rod cracking groove detection system based on machine vision of the present invention uses the machine vision method to realize accurate detection of the automobile connecting rod cracking groove. Since the automobile connecting rod cracking tank detection system based on machine vision of the present invention is mainly used in industrial sites, each component should try to select devices with strong anti-interference ability and applicable to harsh environments.

[0024] The car connecting rod cracking tank detection system based on machine vision of the present invention is mainly composed of a computer 1, a programmable logic controller 2, an output success indicator 3, an output failure indicator 4, an output alarm lamp 5, a relay 6, Light source controller 7, No. 1 camera 8, light source 9, photoelectric switch 10, No. 1 connection line 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com