Test system and method for asphalt foaming performance

A foaming performance and testing system technology, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problem of inability to observe the size distribution of asphalt foam and its changing trend, high requirements for test equipment, and reduced measurement accuracy and other problems, to achieve the effect of eliminating too much subjectivity, avoiding asphalt pollution, and facilitating testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

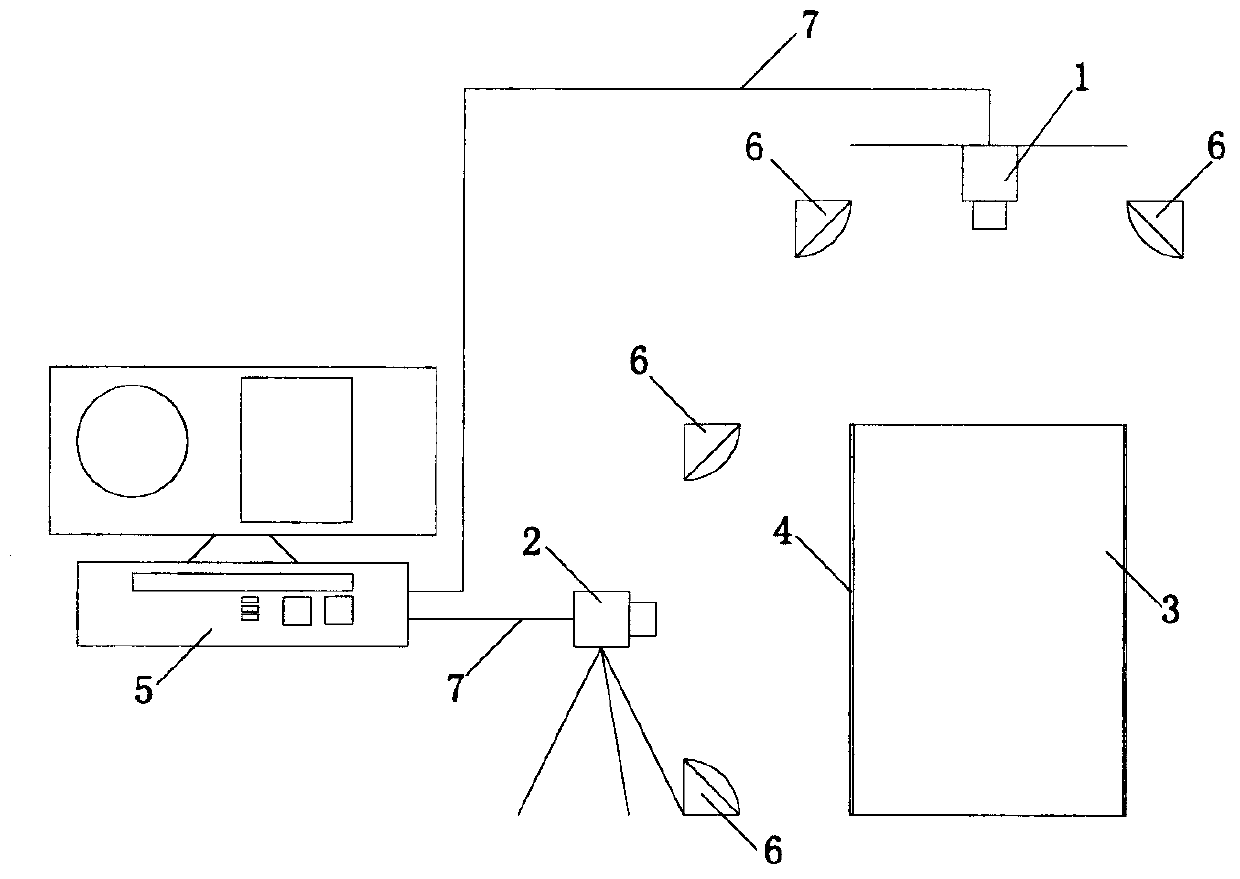

[0065] The measurement system and method of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0066] The materials and instruments used in this embodiment include: 1. Three types of asphalt: a sufficient amount of Korean Ssangyong 70# asphalt, Sinopec 70# asphalt, and PetroChina 70# asphalt. 2. One WLB 10 foam testing machine. 3. Two high-speed industrial cameras from Basler, Germany. Four 4.50W white LED floodlights. 5. A cylinder with a diameter of 275mm and a height of 350mm is made of transparent glass fiber reinforced plastic barrel with high temperature resistance and heat preservation. 6. Sufficient amount of transparent asphalt release agent - butter. 7. One oven. 8. Two data transmission lines. 9. An electronic computer and a set of built-in digital image analysis software.

[0067] figure 1 The measurement system for asphalt foaming performance proposed by the present invention includes a foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com