Coal ash activating agent and low-cost cement prepared through same

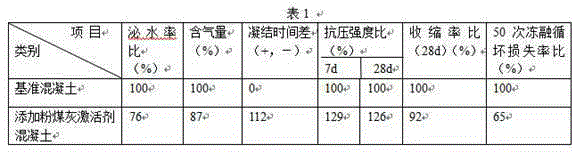

A technology of fly ash and activator, applied in the field of fly ash activator and low-cost cement, can solve the problems of concrete shrinkage and cracking, affecting concrete performance, reducing concrete strength, etc., to enhance construction performance, good activation function, prevent frosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0011] Fly ash activator embodiment 2, prepare raw material according to following proportioning: 30 kilograms of sodium sulfate, 40 kilograms of potassium aluminum sulfate, 3 kilograms of triethanolamine, 5 kilograms of sodium gluconate, 1.5 kilograms of citric acid and 35 kilograms of silicon powder; With embodiment 1.

Embodiment 3

[0012] Fly ash activator embodiment 3, prepare raw material according to following proportioning: 40 kilograms of sodium sulfate, 50 kilograms of potassium aluminum sulfate, 4.5 kilograms of triethanolamine, 5 kilograms of sodium gluconate, 2 kilograms of citric acid and 20 kilograms of silicon powder; With embodiment 1.

Embodiment 4

[0013] Fly ash activator embodiment 4, prepare raw material according to following proportioning: 35 kilograms of sodium sulfate, 60 kilograms of potassium aluminum sulfate, 5 kilograms of triethanolamine, 4 kilograms of sodium gluconate, 1.8 kilograms of citric acid and 33 kilograms of silicon powder; With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com