Graphene conductive powder coating before wooden product coating as well as preparation and application thereof

A technology of conductive powder and graphene, which is applied in the direction of powder coating, conductive coating, epoxy resin coating, etc., can solve the problem that it cannot be well adapted to the collinear spraying production of wood products of various specifications, and cannot realize the complete porosity of wood product substrates. Sealing, product coating quality problems and other problems, to achieve bright color, shorten the baking time, and improve the coating strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

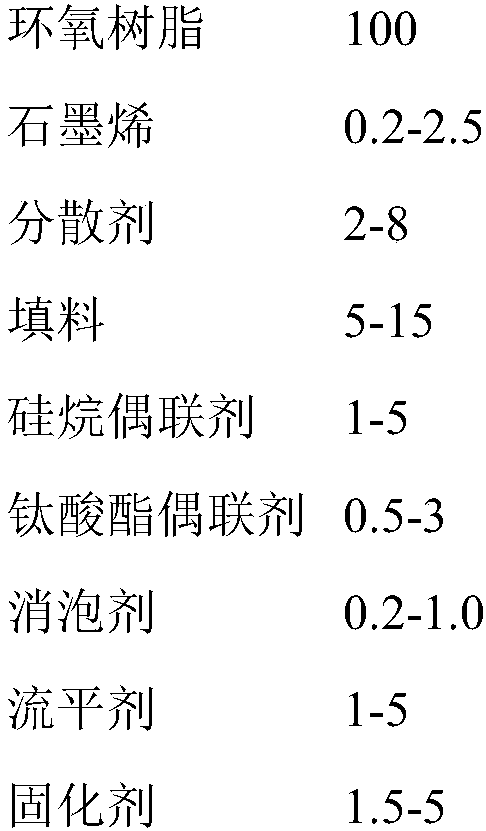

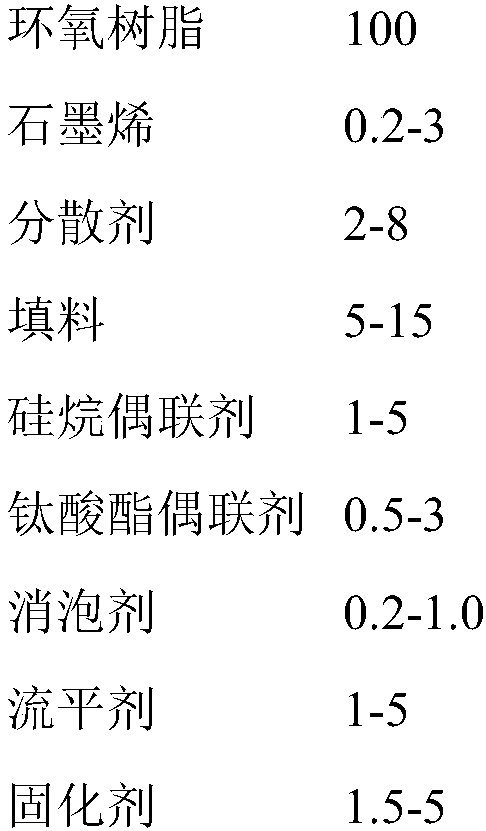

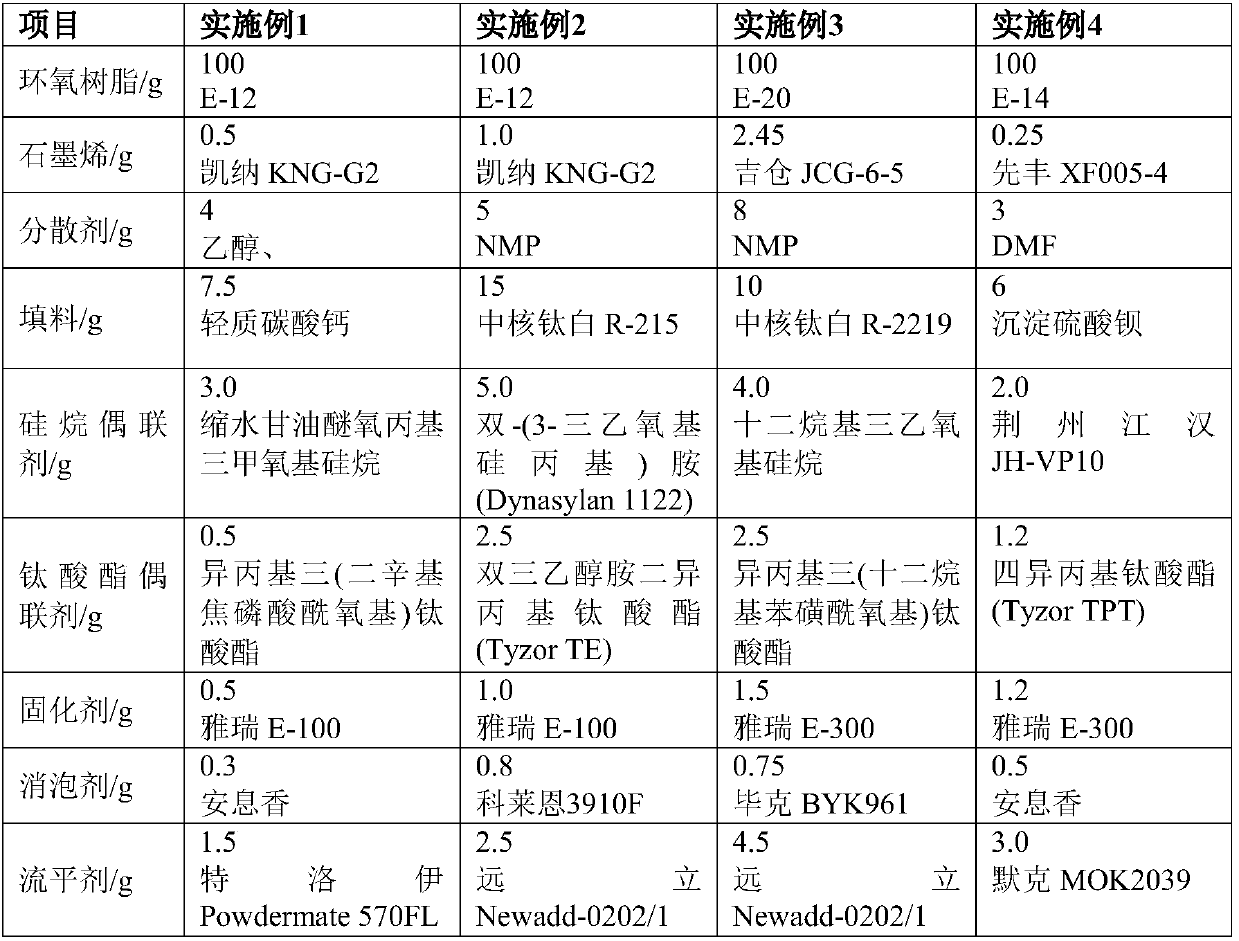

[0030] The content of each component of the raw materials of the graphene conductive powder coating before the wood product painting is shown in Table 1, and the preparation method is as follows:

[0031] (1) Pre-pulverizing the epoxy resin can be used after passing through a 200-mesh screen;

[0032] (2) ultrasonicating the dispersant for graphene for 15-60min to prepare a dispersion slurry for use; avoid secondary stacking and agglomeration of graphene.

[0033] (3) Mixing and grinding the silane coupling agent and titanate coupling agent for the filler to form a slurry for use;

[0034] (4) adding the material obtained in steps 1 to 3 and the remaining components into the mixer, and after mixing for 20-30min, transfer to a material bucket for use;

[0035] (5) Add the mixed material in the material barrel into the twin-screw extruder, melt, mix and extrude at 85-100 ° C, and after cooling and tableting, crush, pulverize, classify and sieve to obtain the conductive powder c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com