Wear-resistant sole of male boot and preparation method thereof

A technology of soles and parts by weight, which is applied in the field of shoes, can solve the problems of needing improvement, limited improvement, single and limited improvement of wear resistance, etc., and achieve good vulcanization effect, easy combination, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A wear-resistant sole for men's boots, in parts by weight, its raw material components are shown in Table 1.

[0055] Among them, the coupling agent is KH-550, the length of the aramid fiber is 5mm, the antioxidant is the antioxidant 2246S, and the vulcanization accelerator is the accelerator TT.

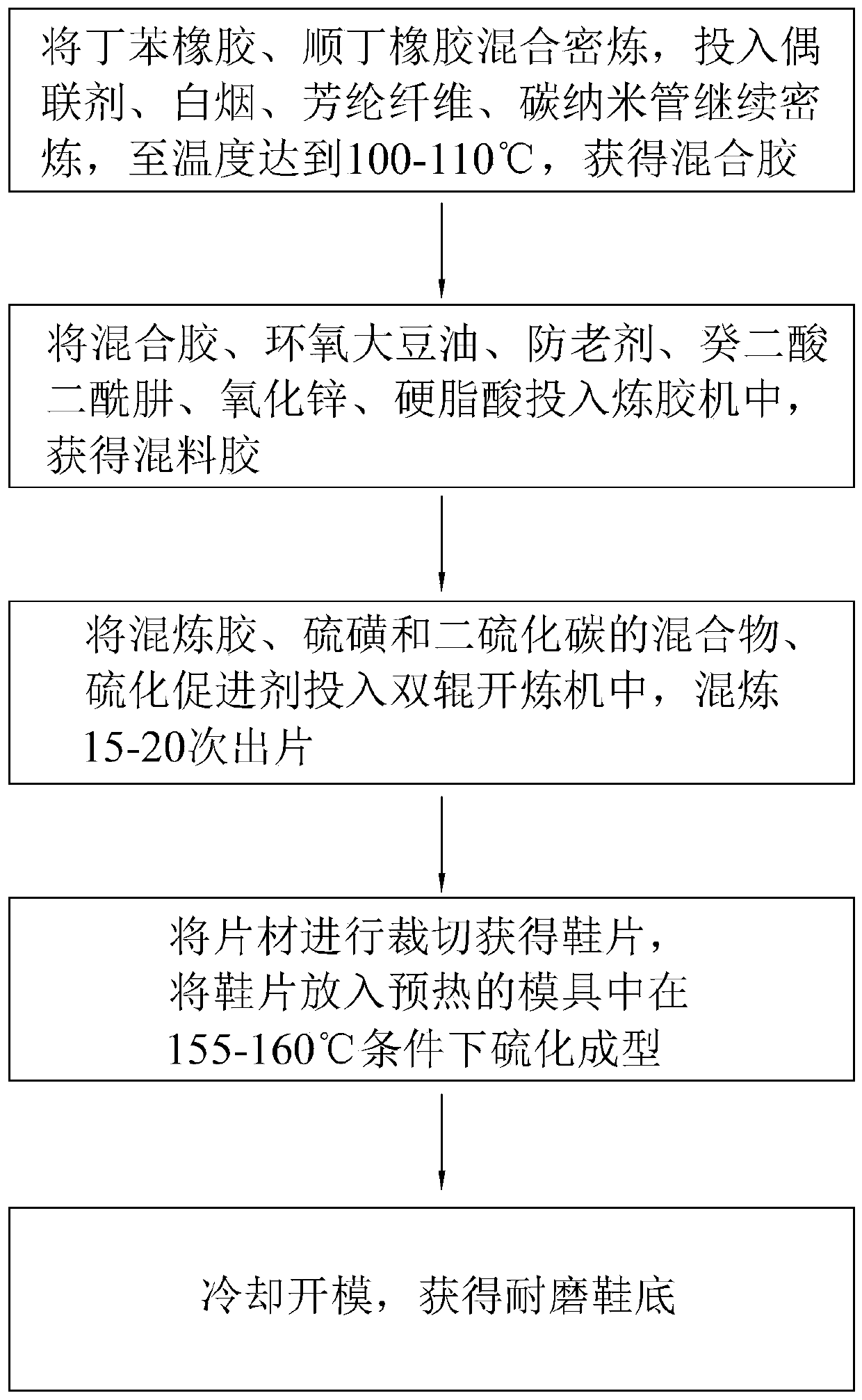

[0056] like figure 1 As shown, the preparation method of this wear-resistant sole comprises the following steps:

[0057]S1, mixing and banburying styrene-butadiene rubber and cis-butadiene rubber, adding coupling agent KH-550, white smoke, aramid fiber, and carbon nanotubes, and continuing banburying until the temperature reaches 100-110°C, to obtain a mixed rubber;

[0058] S2, put mixed glue, epoxidized soybean oil, anti-aging agent 2246S, sebacic acid dihydrazide, zinc oxide, and stearic acid into a rubber mixing machine to obtain a mixed rubber;

[0059] S3, put the mixed rubber, the mixture of sulfur and carbon disulfide, and the accelerator TT into the twin-roll mill...

Embodiment 2

[0063] A wear-resistant sole for men's boots, in parts by weight, its raw material components are shown in Table 1.

[0064] Among them, the coupling agent is KH-550, the length of the aramid fiber is 5mm, the antioxidant is the antioxidant 2246S, and the vulcanization accelerator is the accelerator TT.

[0065] The preparation method of the wear-resistant sole comprises the following steps:

[0066] S1, mixing and banburying styrene-butadiene rubber and cis-butadiene rubber, adding coupling agent KH-550, white smoke, aramid fiber, and carbon nanotubes, and continuing banburying until the temperature reaches 100-110°C, to obtain a mixed rubber;

[0067] S2, put mixed glue, epoxidized soybean oil, anti-aging agent 2246S, sebacic acid dihydrazide, zinc oxide, and stearic acid into a rubber mixing machine to obtain a mixed rubber;

[0068] S3, put the mixed rubber, the mixture of sulfur and carbon disulfide, and the accelerator TT into the twin-roll mill, and knead for 15-20 tim...

Embodiment 3

[0072] A wear-resistant sole for men's boots, in parts by weight, its raw material components are shown in Table 1.

[0073] Among them, the coupling agent is KH-550, the length of the aramid fiber is 5mm, the antioxidant is the antioxidant 2246S, and the vulcanization accelerator is the accelerator TT.

[0074] The preparation method of the wear-resistant sole comprises the following steps:

[0075] S1, mixing and banburying styrene-butadiene rubber and cis-butadiene rubber, adding coupling agent KH-550, white smoke, aramid fiber, and carbon nanotubes, and continuing banburying until the temperature reaches 100-110°C, to obtain a mixed rubber;

[0076] S2, put mixed glue, epoxidized soybean oil, anti-aging agent 2246S, sebacic acid dihydrazide, zinc oxide, and stearic acid into a rubber mixing machine to obtain a mixed rubber;

[0077] S3, put the mixed rubber, the mixture of sulfur and carbon disulfide, and the accelerator TT into the twin-roll mill, and knead for 15-20 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com