Rubber/acetylene black conductive material as well as preparation method and application thereof

A technology of acetylene carbon black and conductive materials, which is applied in conductive materials dispersed in non-conductive inorganic materials, electrical recording technology applying charge patterns, equipment for electrical recording technology applying charge patterns, etc. Technology and production capacity, high price of chloroether rubber, and high processing temperature, to achieve the effect of good mechanical properties, stable electrical conductivity, and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

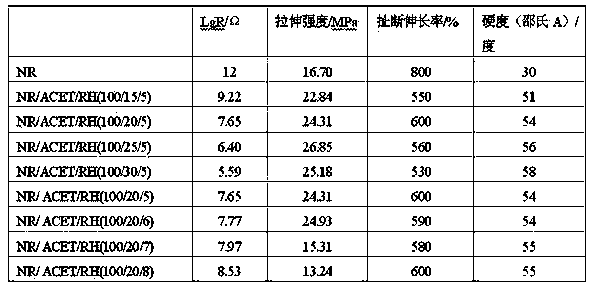

[0053]Natural rubber (NR) is selected, and the formula (mass ratio, the same below) is as follows: NR 100, acetylene carbon black (ACET) and resorcinol and hexamethylenetetramine complex (RH) values are shown in Table 1 , is a variable; stearic acid 2, ZnO 4, accelerator TMTM 1.5, accelerator DM 0.5, antioxidant 4010NA 1, sulfur 1.5. It is mixed at room temperature on a Φ160 open mill, and then vulcanized on a 25-ton flat vulcanizer at a vulcanization temperature of 143°C. Table 1 lists the electrical conductivity and mechanical properties of NR / ACET / RH conductive composite vulcanizates. It can be seen from the table that with the increase of the amount of ACET in the NR / ACET / RH system, the electrical conductivity and tensile strength of the vulcanized rubber increased to a certain extent, and the hardness showed an upward trend. After adding RH, the electrical conductivity of the material decreased to a certain extent, but the spray The frost phenomenon is effectively solv...

Embodiment 2

[0057] The rubber is nitrile rubber (NBR), and the formula is as follows: NBR 100, resorcinol and hexamethylenetetramine complex (RH), acetylene carbon black (ACET) as variables, stearic acid 2, ZnO 5, Accelerator CZ 1.5, accelerator DM 0.5, antioxidant 4010NA 1, sulfur 2. It is mixed at room temperature on a Φ160 open mill, and then vulcanized on a 25-ton flat vulcanizer at a vulcanization temperature of 170°C.

[0058] Table 2: Electrical conductivity and mechanical properties of NBR / ACET / RH vulcanizate

[0059]

[0060] It can be seen from Table 2 that with the increase of the amount of ACET, the conductivity and tensile strength of the conductive composite material have been improved, but compared with Table 1, in the case of a small filling amount, it can be seen that NBR / ACET / RH The conductivity and mechanical properties of the system are not as good as those of NR / ACET / RH system.

Embodiment 3

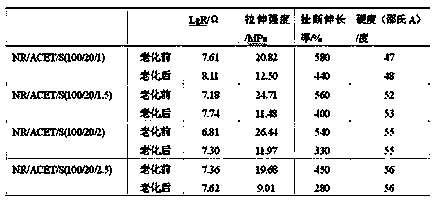

[0062] The rubber is natural rubber, and the formula is as follows: NR 100, ACET20, resorcinol and hexamethylenetetramine complex (RH) 5, insoluble S variable, ZnO 5, stearic acid 2, accelerator (TMTM) 1 , Antiaging agent (4010NA) 1. The flakes were kneaded at room temperature in an open mill, and then vulcanized on a flat vulcanizer. The vulcanization condition was 143°C x normal vulcanization time (min). Table 3 shows the electrical conductivity and mechanical properties of the natural rubber / acetylene carbon black conductive composite material system with different vulcanizing agent additions. It can be seen that the increase in the amount of insoluble S can improve the electrical conductivity and mechanical properties of the composite material to a certain extent, but when the amount is too large, excessive cross-linking will destroy the conductive network structure, aging (70 。 C, 72h), the material can maintain good electrical conductivity and mechanical properties.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com