Mono-component aqueous metal baking paint and preparation method thereof

A single-component, water-based technology, applied in the field of coatings, can solve problems such as the reduction of organic volatile matter content, and achieve the effects of excellent water resistance, high hydroxyl value, and low baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

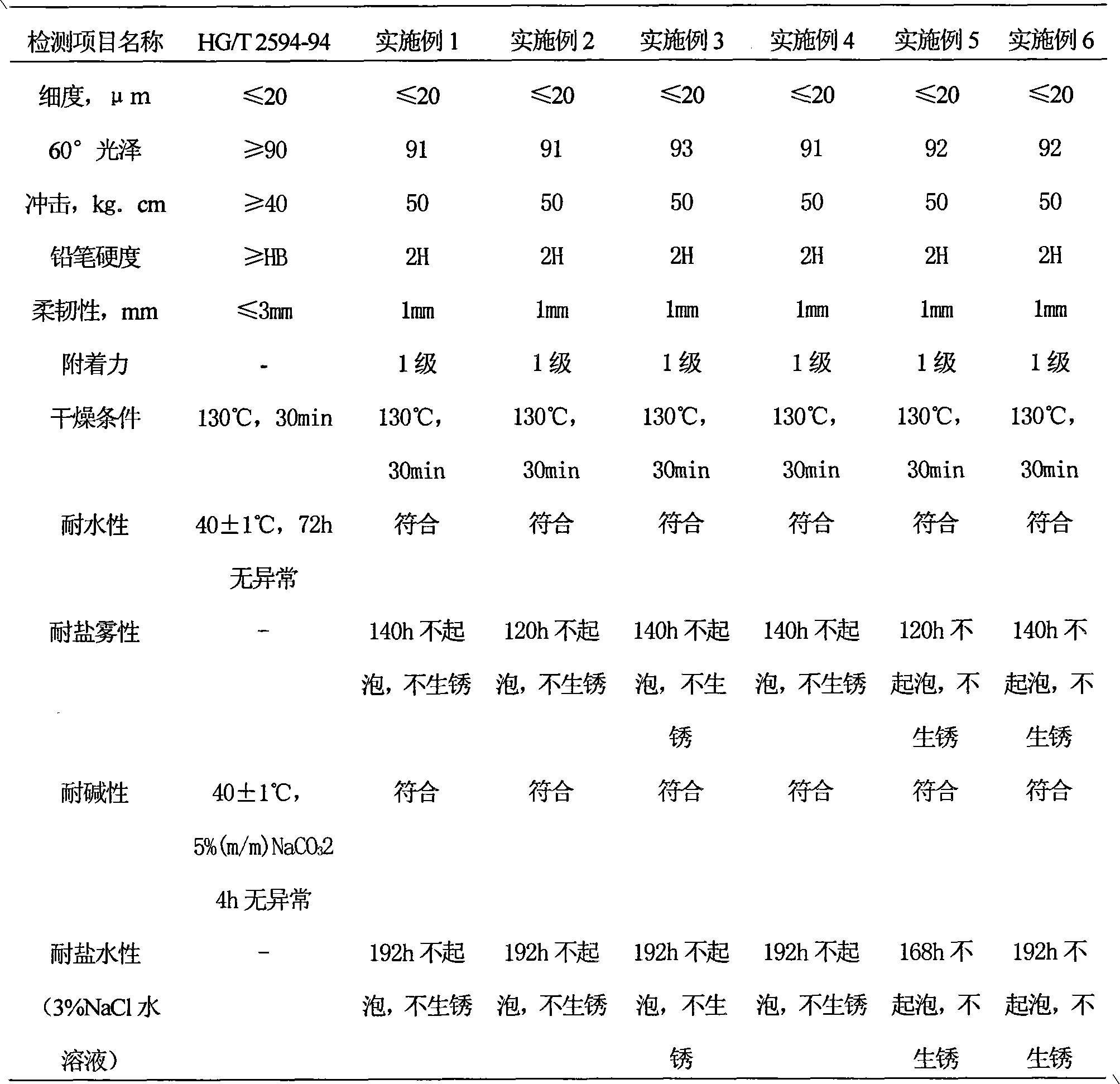

Examples

Embodiment 1

[0031]The formula of one-component water-based metal baking coating is: tap water 44.65Kg (44.65%), water-based acrylic modified polyester resin (HD-MB019, Beijing Jinhuili Applied Chemical Products Co., Ltd.) 30.48Kg (30.48%), amino resin (Luwipal 072, BASF Applied Chemicals Co., Ltd.) 7.62Kg (7.62%), rutile titanium dioxide (CR-826, Kemeiji Chemical Company) 11.88Kg (11.88%), iron oxide red (ZH162, Guangzhou Crystal Color Pigment Co., Ltd.) 2.86Kg (2.86%), amine regulator (DMEA, BASF Applied Chemicals Co., Ltd.) 1.2 (1.2%), wetting and dispersing agent A (X-405, Dow Chemical Company) 0.19Kg (0.19%), Wetting and dispersing agent B (731A, U.S. Rohm and Haas Company) 0.19Kg (0.19%), defoamer (810, Dego Company) 0.03Kg (0.03%), thickener (112, Ciba Company) 0.5Kg (0.5%), leveling agent (3580, EFKA company) 0.4Kg (0.4%)

[0032] Preparation:

[0033] 1) Under the condition of stirring at a speed of 500r / min, according to the total weight of the formula, add 30% of tap water, 0....

Embodiment 2

[0036] The formula of one-component water-based metal baking coating is: tap water 41.27Kg (41.27%), water-based acrylic modified polyester resin (HD-MB019, Beijing Jinhuili Applied Chemical Products Co., Ltd.) 28Kg (28%), amino resin ( Luwipal 072, BASF Applied Chemicals Co., Ltd.) 7.2Kg (7.2%), rutile titanium dioxide (CR-826, Kemeiji Chemical Company) 21Kg (21%), amine regulator (DMEA, BASF Applied Chemicals Co., Ltd.) 1.12 (1.2%), wetting and dispersing agent A (X-405, Dow Chemical Company) 0.2Kg (0.2%), wetting and dispersing agent B (731A, U.S. Rohm and Haas Company) 0.2Kg (0.2%), disinfectant Foaming agent (810, Dego Company) 0.01Kg (0.01%), thickener (WT-105A, Deqian Chemical Co., Ltd.) 0.8Kg (0.8%), leveling agent (3580, EFKA Company) 0.2Kg (0.2%) )

[0037] Preparation:

[0038] 1) Under the condition of stirring at 400r / min, according to the total weight of the formula, add 30% of tap water, 0.72% of amine regulator, 0.2% of wetting and dispersing agent A, 0.2% of...

Embodiment 3

[0041] One-component water-based metal baking paint formula is: tap water 51.4Kg (51.4%), water-based acrylic modified polyester resin (HD-MB019, Beijing Jinhuili Applied Chemical Products Co., Ltd.) 32Kg (32%), amino resin ( Luwipal 072, BASF Applied Chemical Co., Ltd.) 8Kg (8%), iron oxide red (4110, Bayer company) 2.5Kg (2.5%), iron oxide black (4330, Bayer company) 2.5Kg (2.5%), amine regulator (DMEA, BASF Applied Chemical Co., Ltd.) 1.36 (1.36%), wetting and dispersing agent A (X-405, Dow Chemical Company) 0.15Kg (0.15%), wetting and dispersing agent B (731A, U.S. Rohm and Haas Company) 0.19Kg (0.19%), defoamer (805, Dego company) 0.1Kg (0.1%), thickener (112, Ciba company) 1.2Kg (1.2%), leveling agent (3580, EFKA company )0.6Kg (0.6%)

[0042] Preparation:

[0043] 1) Under the condition of stirring at 600r / min, according to the total weight of the formula, add 30% of tap water, 0.72% of amine regulator, 0.15% of wetting and dispersing agent A, 0.19% of wetting and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com