Continuous poriferous titanium dioxide fiber and the technique of preparing the same

A technology of porous titanium dioxide and preparation process, applied in titanium dioxide, titanium oxide/hydroxide, chemical instruments and methods, etc., can solve the problems of TiO2 shedding, reduction of photocatalytic efficiency and activity, reduction of catalyst specific surface area, etc., and achieve production costs. Low cost, saving the cost of sewage degradation treatment, and easy to industrialize the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

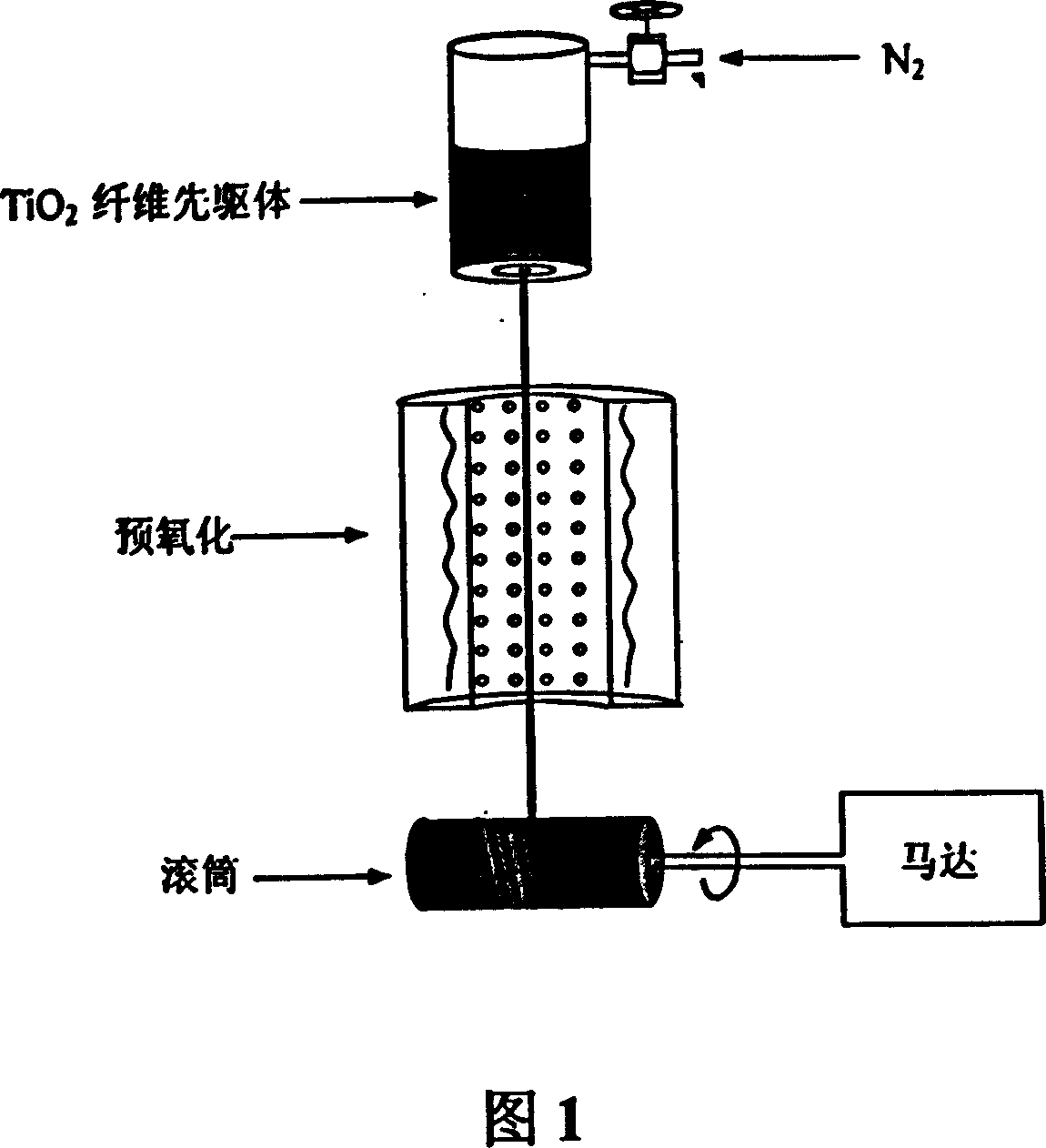

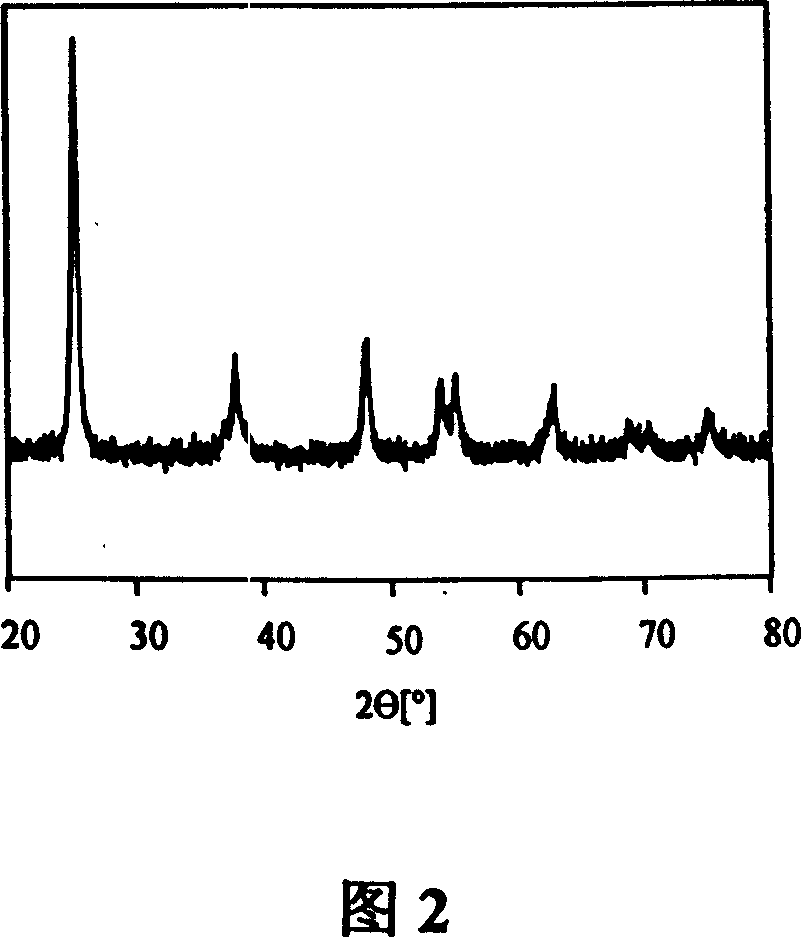

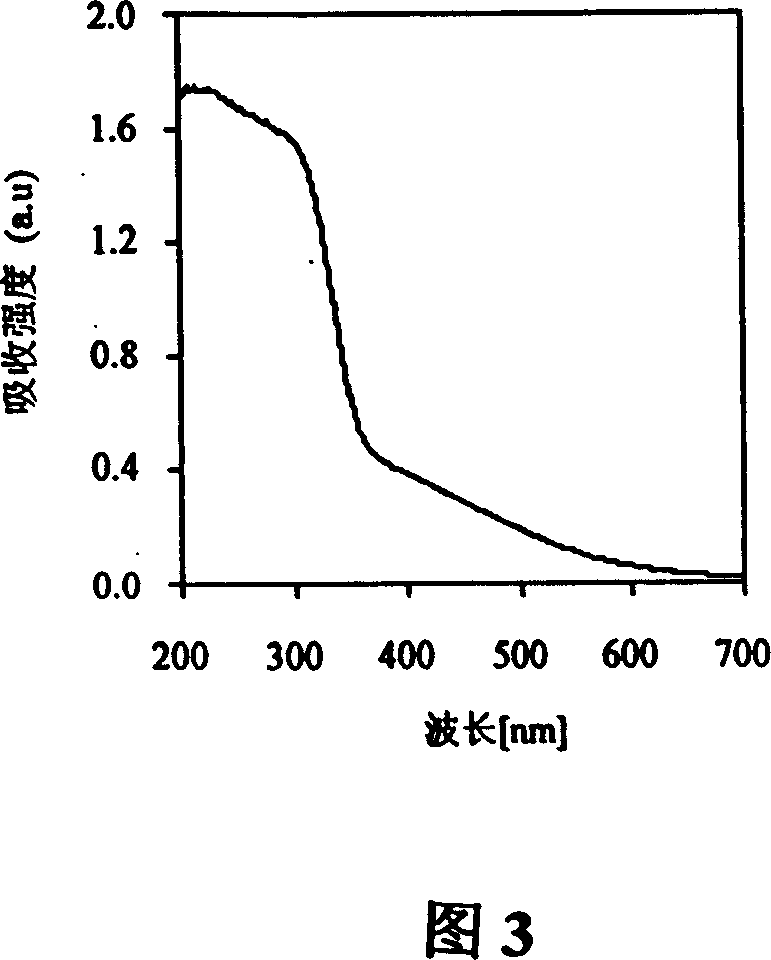

[0045] Example 1: Using the sol-gel method, 60g of butyl titanate with a purity of 99.0%, 3g of diethanolamine and 10g of absolute ethanol were mixed, then added to a three-necked flask, and stirred evenly with a GS122 electronic constant speed stirrer. Mix 20 g of absolute ethanol with 4 g of distilled water, and then slowly drop them into the three-necked flask through a separatory funnel. Butyl titanate forms low molecular weight TiO through hydrolysis and condensation reactions 2 Sol, while heating it to 200° C., and adding 2 g and 8 g each of polyethylene glycol and polyethylene; keep the temperature and evaporate for 3 hours. Then put it into the spinning barrel and spin under pressure at 200 °C, while the temperature of the vacuum oven is kept at 300 °C to obtain continuous porous TiO 2 fiber. Then it is heat-treated at 500° C. for 2 hours, and its crystal form is anatase, and the size of nano particles is 30-50 nm. The fiber length reaches 2m, and the specific surfa...

Embodiment 2

[0046] Example 2: Using the sol-gel method, 60 g of butyl titanate with a purity of 99.0%, 3 g of diethanolamine and 10 g of absolute ethanol were mixed, then added to a three-necked flask, and stirred evenly with a GS122 electronic constant speed stirrer. Mix 20 g of absolute ethanol with 4 g of distilled water, and then slowly drop them into the three-necked flask through a separatory funnel. Butyl titanate forms low molecular weight TiO through hydrolysis and condensation reactions 2 sol, while heating it to 225°C, and adding 3 g and 7 g of polyethylene glycol and polyethylene respectively, keeping the temperature and evaporating for 3 hours. Then put it into the spinning barrel and spin under pressure at 250 °C, while the temperature of the vacuum oven is kept at 300 °C to obtain continuous porous TiO 2 fiber. Then it is heat-treated at 500° C. for 2 hours, and its crystal form is anatase, and the size of nano particles is 30-50 nm. Its length reaches 3.5m and its speci...

Embodiment 3

[0047] Example 3: Using the sol-gel method, 60 g of butyl titanate with a purity of 99.0%, 3 g of diethanolamine and 10 g of absolute ethanol were mixed, then added to a three-necked flask, and stirred evenly with a GS122 electronic constant speed stirrer. Mix 20 g of absolute ethanol with 4 g of distilled water, and then slowly drop them into the three-necked flask through a separatory funnel. Butyl titanate forms low molecular weight TiO through hydrolysis and condensation reactions 2 sol, while heating it to 225°C, and adding 3 g and 7 g of polyethylene glycol and polyethylene respectively, keeping the temperature and evaporating for 3 hours. Then put it into the spinning barrel and spin under pressure at 225 °C, while the temperature of the vacuum oven is kept at 400 °C to obtain continuous porous TiO 2 fiber. Then it is heat-treated at 500° C. for 2 hours, and its crystal form is anatase, and the size of nano particles is 30-50 nm. Fiber length up to 10m, specific surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com