Nano TiO2/ZnO-doped composite hydrosol, and preparation method thereof and finishing method of textile

A kind of hydrosol and nanotechnology, applied in the fields of textile technology and chemical technology, can solve the problems of premature aging of fiber materials or adhesives, and can not play a good role in photocatalysis, so as to achieve high cost and energy saving , the effect of low baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

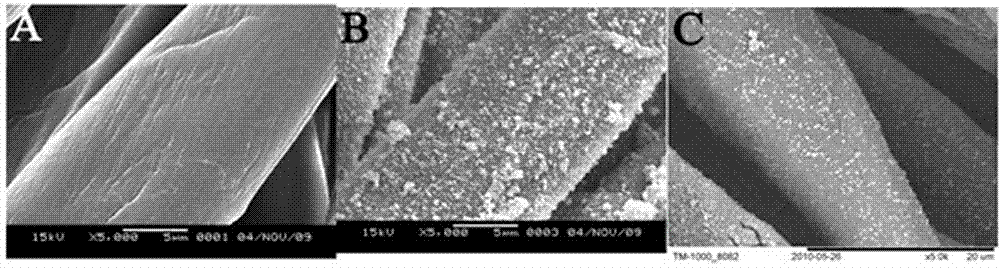

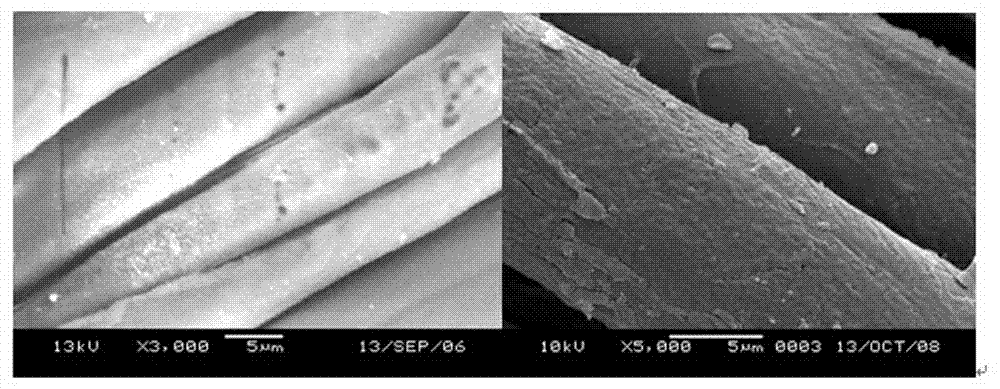

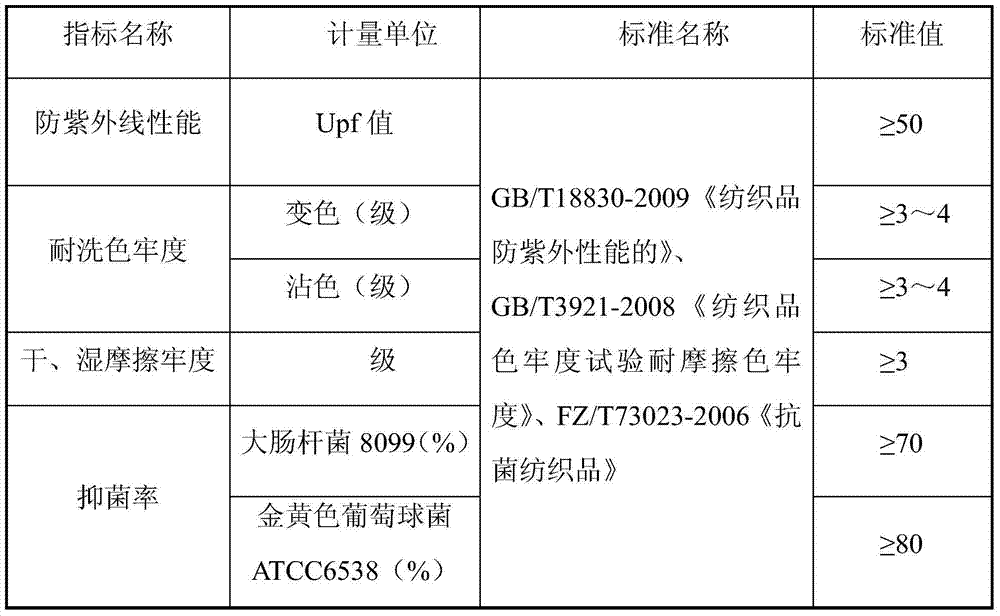

Image

Examples

Embodiment 1

[0054] Embodiment 1: a kind of nanometer TiO 2 / ZnO doped composite hydrosol, including ZnO hydrosol, TiO 2 Hydrosol and 1% Ag by mass percentage + or La 3+ , where TiO 2 The molar ratio of hydrosol to ZnO hydrosol is 1:5. Its preparation method comprises the following steps:

[0055] a Preparation of ZnO hydrosol:

[0056] Take 0.05 mol of zinc acetate dihydrate, under the stirring effect of a magnetic stirrer, the stirring speed is 1000 rpm to 2000 rpm, dissolve it in deionized water at room temperature, then slow down the stirring speed, and the stirring speed is 800 rpm / min~1500rpm, add 0.1mol precipitant to produce white flocculent Zn(OH) 2 Precipitate, increase the stirring speed, the stirring speed is 1500 rpm to 2500 rpm, then add 2mol glacial acetic acid to completely dissolve the precipitate, and then fully stir for 60 minutes to obtain uniform and transparent ZnO hydrosol A;

[0057] b. Preparation of TiO 2 Hydrosol:

[0058] Take 0.01mol of tetra-n-butyl...

Embodiment 2

[0072] Embodiment 2: a kind of nanometer TiO 2 / ZnO doped composite hydrosol, including ZnO hydrosol, TiO 2 Hydrosol and 0.3% Ag by mass percentage + or La 3+ , where TiO 2 The molar ratio of the hydrosol to the ZnO hydrosol substance is 1:0.5. Its preparation method comprises the following steps:

[0073] a Preparation of ZnO hydrosol:

[0074] Take 0.03mol of zinc acetate dihydrate, under the stirring effect of a magnetic stirrer, the stirring speed is 1000 rpm to 2000 rpm, dissolve it in deionized water at room temperature, then slow down the stirring speed, and the stirring speed is 800 rpm / min~1500rpm, add 0.06mol precipitant to produce white flocculent Zn(OH) 2 Precipitate, increase the stirring speed, the stirring speed is 1500 rpm to 2500 rpm, then add 0.06mol glacial acetic acid to completely dissolve the precipitate, and then fully stir for 30 minutes to obtain uniform and transparent ZnO hydrosol A;

[0075] b. Preparation of TiO 2 Hydrosol:

[0076] Take...

Embodiment 3

[0093]Embodiment 3: a kind of nanometer TiO 2 / ZnO-doped composite hydrosols, including TiO 2 Hydrosol Hydrosol and 0.1% Ag by mass percentage + or La 3+ . Its preparation method comprises the following steps:

[0094] b. Preparation of TiO 2 Hydrosol:

[0095] Take 0.03mol of tetra-n-butyl titanate, mix it with 0.09mol of glacial acetic acid evenly, then add 0.02mol of absolute ethanol, stir thoroughly with a glass rod to form a homogeneous solution as the drop solution B, at room temperature and under stirring, The stirring speed is 1000 rpm to 2000 rpm, and the drip solution B is slowly added dropwise to the mixture of deionized water and acetic acid, and stirred for 45 minutes to obtain TiO 2 Hydrosol C;

[0096] d. Preparation of Ag-doped + or La 3+ TiO 2 / ZnO composite hydrosol

[0097] Take silver nitrate or lanthanum acetate as 0.1% by mass percentage, add dropwise to the TiO prepared in step b 2 in the hydrosol, and stirred for 0.5h to obtain the doped Ag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com