Flame-retardant smoke-suppressing thermoplastic polyurethane antistatic composite material and preparation method thereof

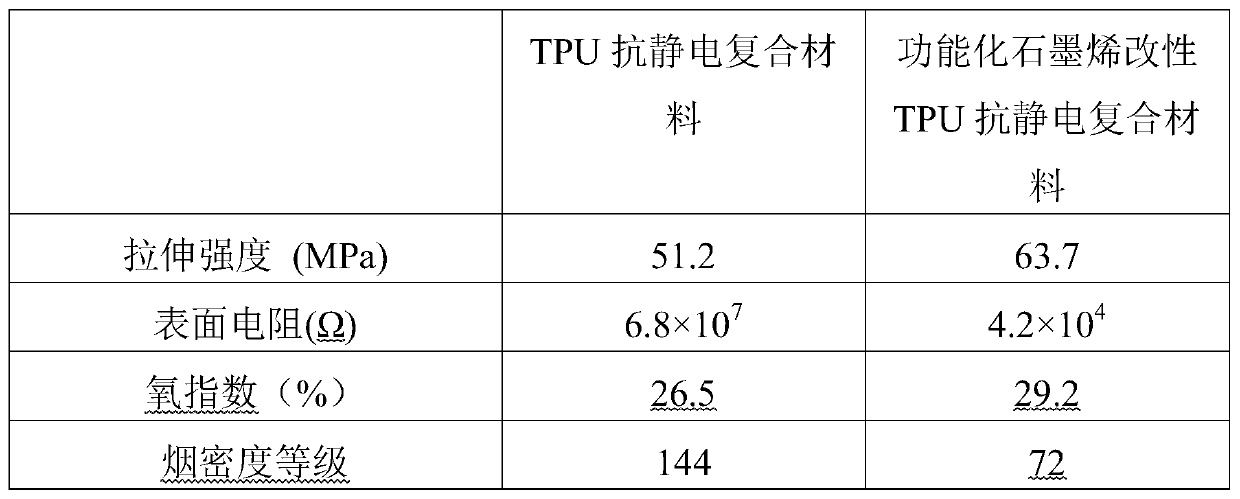

A plastic polyurethane and composite material technology, which is applied in the field of flame-retardant and smoke-suppressing thermoplastic polyurethane antistatic composite materials and its preparation, can solve the problems of low technical content and single function of antistatic materials, so as to improve mechanical properties and reduce secondary pollution , Improve the effect of smoke suppression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

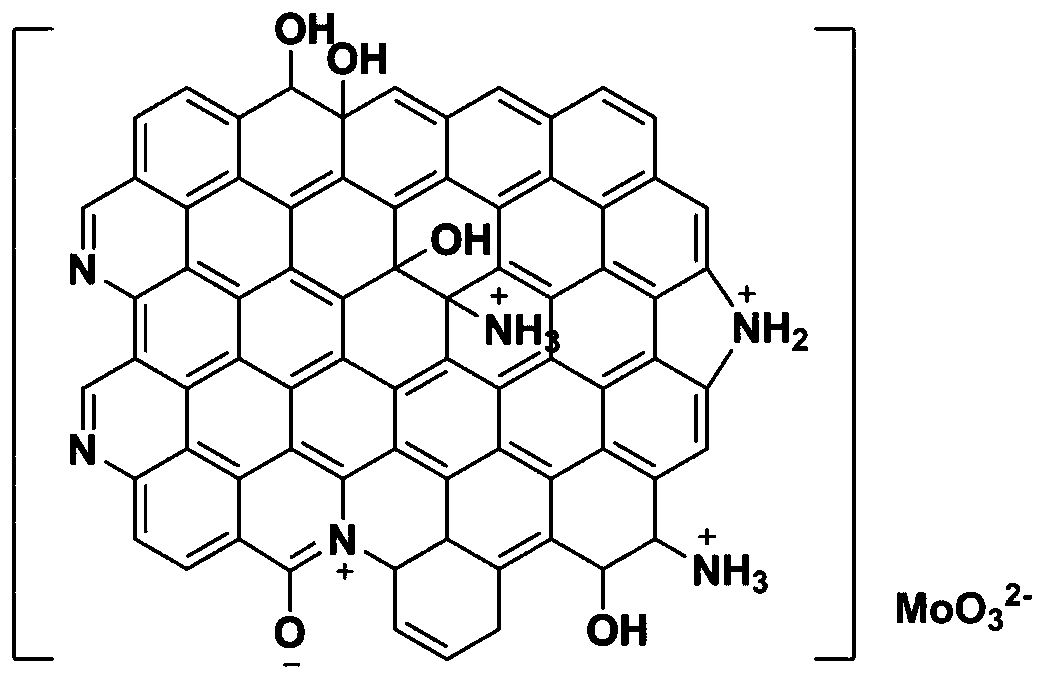

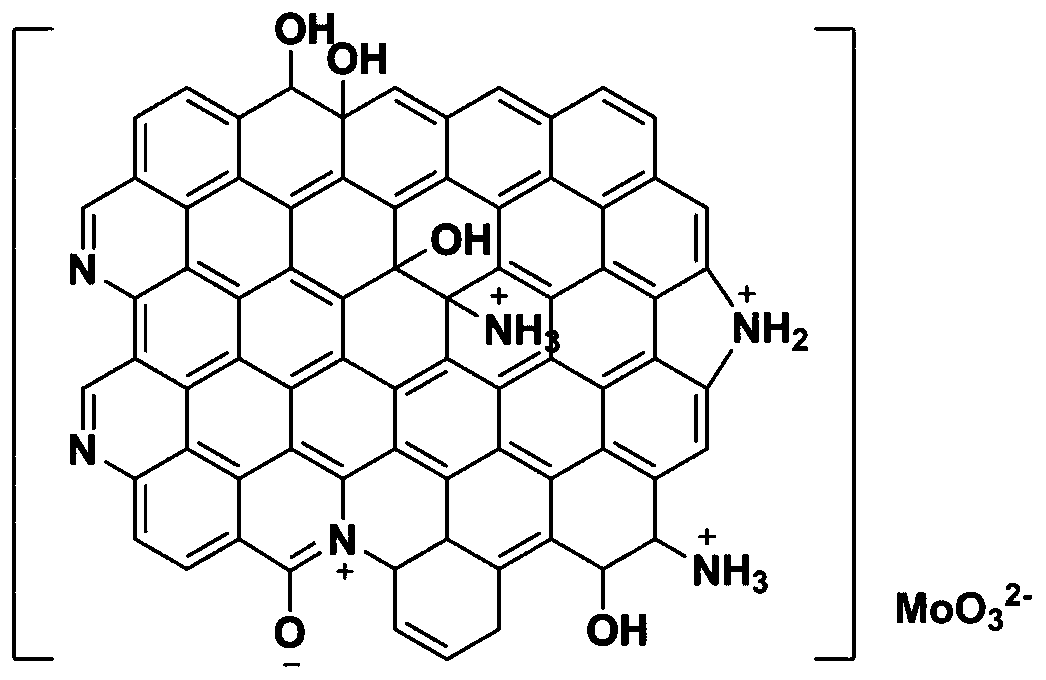

[0028] Preparation of functionalized graphene:

[0029] (1) Nitriding of graphene oxide (GO)

[0030] Add 0.5g GO to 100g DMF and sonicate at room temperature for 40 minutes, add 5g ethylenediamine and mix well, then transfer to a polytetrafluoroethylene-lined autoclave, seal and store in an oven, and heat to 120°C for 9 hours; Suction filtration was performed after the reaction, and the precipitate was washed three times with methanol, and then vacuum-filtered and dried to obtain the product graphene nitride (N-GO).

[0031] (2) Molybdate ionization modification

[0032] Add 0.5g N-GO powder to 500mL deionized water and ultrasonically disperse at room temperature for 3 hours to obtain a suspension, add 0.25g ammonium octamolybdate to the above suspension, and stir the reaction at room temperature for 5 hours, and extract the product Filter, and wash 3 times with deionized water to remove excess reagent, and obtain the product functionalized graphene.

Embodiment 2

[0034] Preparation of functionalized graphene:

[0035] (1) Nitriding of graphene oxide (GO)

[0036] Add 3g GO to 100g DMF, sonicate at room temperature for 40 minutes, add 60g p-phenylenediamine and mix evenly, then transfer to a polytetrafluoroethylene-lined autoclave, seal and store in an oven, and heat to 220°C for 3 hours; Suction filtration was performed after the reaction, and the precipitate was washed three times with methanol, and then vacuum-filtered and dried to obtain the product graphene nitride (N-GO).

[0037] (2) Molybdate ionization modification

[0038] Add 2g of N-GO powder to 100mL of deionized water and ultrasonically disperse at room temperature for 3 hours to obtain a suspension, add 4g of calcium molybdate to the above suspension, and stir the reaction at room temperature for 5 hours, filter the product with suction, and use Wash with deionized water 3 times to remove excess reagents to obtain the product functionalized graphene.

Embodiment 3

[0040] Preparation of functionalized graphene:

[0041](1) Nitriding of graphene oxide (GO)

[0042] Add 1.5g GO to 100g DMF, ultrasonicate for 40 minutes at room temperature, add 35g p-o-phenylenediamine, mix evenly, transfer to a polytetrafluoroethylene-lined autoclave, store in an oven sealed, and heat to 180°C for reaction 5 hour; Suction filtration is carried out after reaction finishes, precipitate is washed 3 times with methanol, then vacuum filtration is dried, obtains product graphene nitride (N-GO).

[0043] (2) Molybdate ionization modification

[0044] Add 1.5g of N-GO powder to 300mL of deionized water and ultrasonically disperse at room temperature for 3 hours to obtain a suspension, add 2.5g of zinc molybdate to the above suspension, and stir the reaction at room temperature for 5 hours, then filter the product with suction , and washed 3 times with deionized water to remove excess reagents to obtain the product functionalized graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com