Rubber composite material, composite board prepared from material and board technique

A composite material and composite sheet technology, which is applied in the field of rubber composite materials to achieve the effects of reducing pollution, good elasticity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

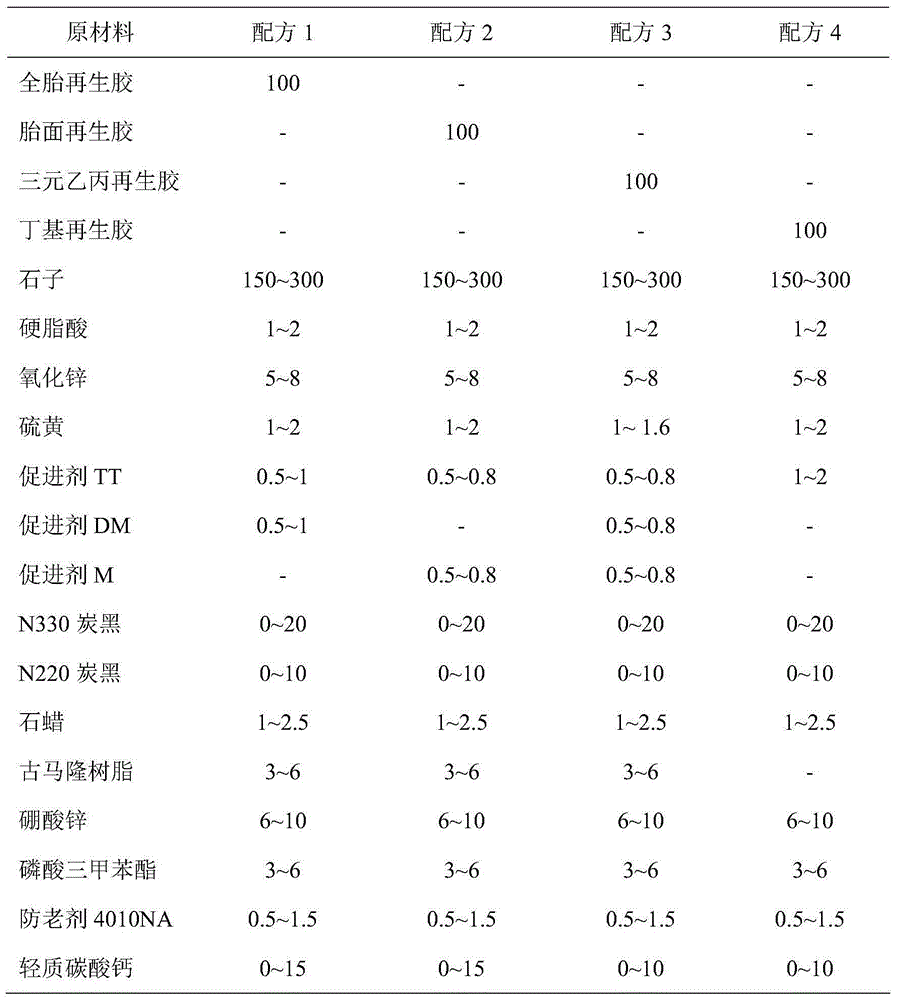

[0029] According to the rubber composite material embodiment provided by the invention, this rubber composite material contains following materials and parts by weight:

[0030] 100 parts of reclaimed rubber;

[0031] 150-300 parts of stones;

[0032] Rubber compounding agent 18.5-85 parts.

[0033] The reclaimed rubber is any one of whole tire reclaimed rubber, tread reclaimed rubber, EPDM reclaimed rubber or butyl reclaimed rubber. The rubber compounding agent is stearic acid, zinc oxide, sulfur, accelerator TT, accelerator DM, accelerator M, N330 carbon black, N220 carbon black, paraffin, coumarone resin, zinc borate, tricresyl phosphate, Combination of at least 11 kinds of antioxidant 4010NA and light calcium carbonate. The stone is any one or combination of basalt, andesite and limestone. The diameter of the stone particles is 6-20 mm. This embodiment is preferably 10mm. The main raw materials of the present invention are reclaimed rubber and stones, which are low i...

Embodiment 2

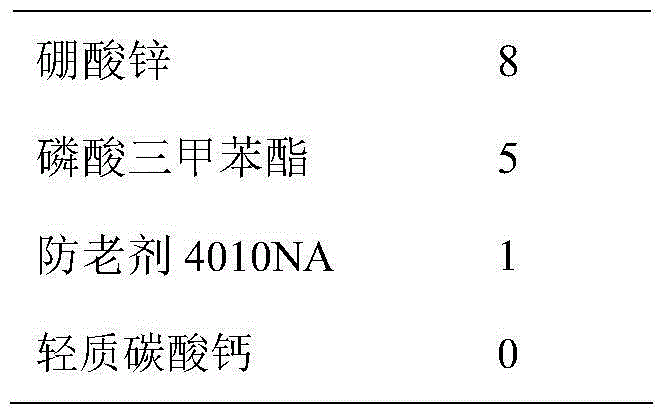

[0039] This embodiment is roughly the same as the above-mentioned embodiment one, and the difference is that the rubber composite material described in this implementation contains the following substances and parts by weight:

[0040]

Embodiment 3

[0042] This embodiment is roughly the same as the above-mentioned embodiment one, and the difference is that the rubber composite material described in this implementation contains the following substances and parts by weight:

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com