High-wear-resistance rubber sealing gasket and preparation method thereof

A technology of rubber gasket and high rubber powder, applied in the field of gasket, can solve the problems of low strength, poor wear resistance, unsatisfactory sealing effect, etc., to achieve excellent sealing performance, improve compatibility, stable storage and transportation characteristics and size The effect of maintaining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

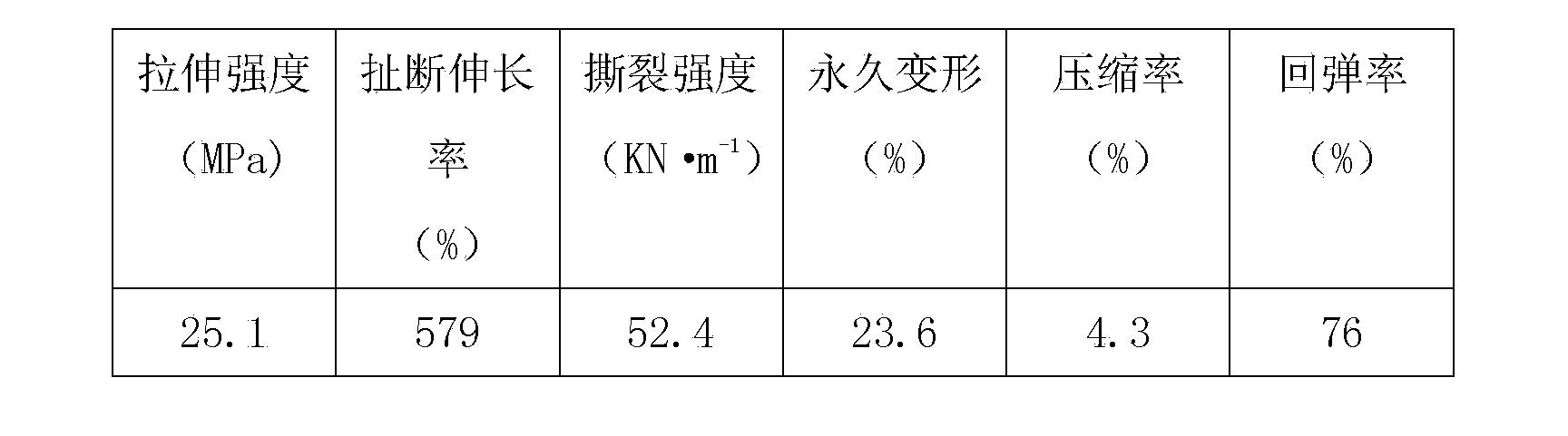

[0015] A high wear-resistant rubber gasket made of raw materials with the following weight (kg): Nitrile rubber (N220S) 60、 Butadiene rubber (BR9000 ) 25, ABS high rubber powder 12 , diisobutyl nylon acid Ester 4, lemon Tributyl citrate 3, tricresyl phosphate 5, isooctyl dithioglycolate di-n-octyl tin 1.5, barium stearate 2, zinc oxide 3, magnesium oxide 2, modified barite powder 12, nano silicon carbide 8 、 High wear-resistant carbon black N330 15, 2-mercaptobenzimidazole 1.5, diperoxycarbamate 2, antioxidant DNP 2, accelerator TMTD 1, accelerator TETD 2.

[0016] The preparation method of the modified barite powder is as follows: crush the barite to below 10 μm, then add tree ash equivalent to 5% of the barite weight, 4% tungsten carbide, 3% zirconium fluoride, 4% % polyisobutene, 5% ferrocene, 4% calcium lignosulfonate, mixed and ground at 55°C for 20 minutes, and then sprayed with isopropyl distearyl oxide equivalent to 3% of barite weight base aluminate and 1.5% an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com