High-impact-resistance PVC (polyvinyl chloride) sheath material for cables and preparation method thereof

A polyvinyl chloride sheath, high-impact technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of sheath rupture, poor toughness, poor impact resistance, etc., to prolong service life, improve toughness, and good softness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

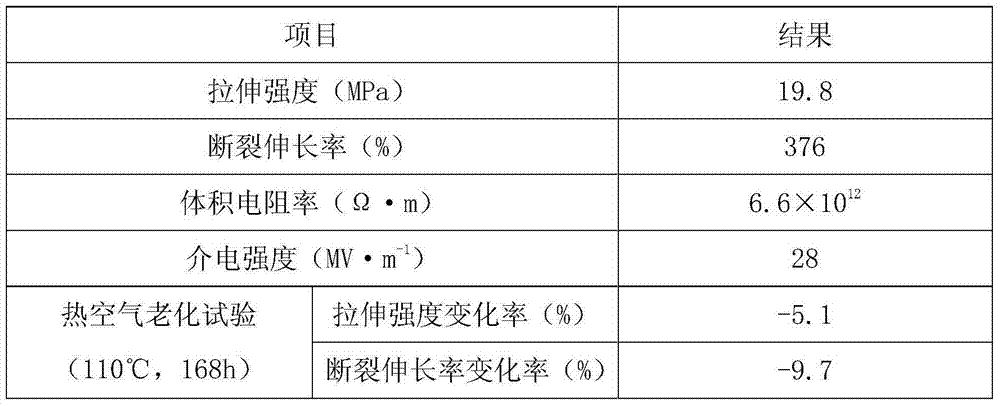

Examples

Embodiment Construction

[0010] A high-impact polyvinyl chloride sheath material for cables, which is made of the following raw materials (kg): SG-5 type PVC resin 100, MABS resin 15, BOVC resin 10, di-n-octyltin dilaurate 3, hard Calcium fatty acid 1, zinc stearate 2, oxidized polyethylene wax 4, barium sulfate 15, carbon black N22025, white oil 5, bis(dioctyloxypyrophosphate) ethylene titanate 1.5, epoxy hard Butyl fatty acid 6, triphenyl phosphite 8, tricresyl phosphate 6, asbestos powder 10, calcium sulfate whisker 5, composite filler 4;

[0011] The preparation method of the composite filler is as follows: a. Take bentonite, barite, and monazite in a weight ratio of 4:3:2, then add 2% coal powder and 1% activated carbon by weight of bentonite, and mix them uniformly at 560 ° C. Calcined for 3 hours, cooled to room temperature, crushed to a particle size below 15 μm, then added water to make a slurry with a concentration of 50%, added hydrochloric acid solution with a concentration of 10% to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com