High-performance freezing-resistant and flame-retardant chloroprene rubber covering material

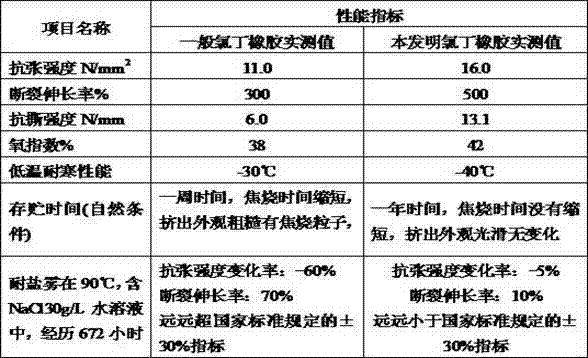

A neoprene sheath and neoprene technology, applied in the direction of rubber insulators, organic insulators, conductors, etc., can solve the problems of poor cold resistance, decreased fluidity, low cold temperature, etc., to improve the flame retardant level and scope of application, Improved tensile strength and good tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high-performance cold-resistant flame-retardant neoprene sheathing material, which is made up of the following raw materials in parts by weight (kg):

[0032] Neoprene CR3221 100

[0034] Magnesium oxide 3

[0035] Accelerator TMTD 0.75

[0036] Accelerator DM 0.8

[0037] Accelerator NA-22 0.70

[0038] stearic acid 2

[0039] Microcrystalline Paraffin 4.5

[0040] Antiaging agent ODA-40 3

[0042] Tricresyl Phosphate 15

[0043] 5000 mesh talcum powder 15

[0044] N550 carbon black 35

[0045] Dioctyl sebacate 25

[0046] Bis(dioctyloxypyrophosphate)ethylene titanate 0.9

[0047] N, N'-m-phenylene bismaleimide 2

[0048] Modified sepiolite 3

[0049] The preparation method of described modified sepiolite is: add sepiolite to soak in (1.2) g / L potassium permanganate solution, 10% sodium hydroxide solution, remove impurities, then filter and wash to be neutral, calcined 450°C, 1 hour, grind into powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com