Composition as well as preparation method and application thereof to force-induced discoloration material field

A composition and raw material technology, applied in the field of mechanochromic materials, the composition and its preparation field, can solve the problems of insensitive discoloration, poor responsiveness to stress, etc., and achieve excellent tensile performance indicators, good tensile strength, The effect of obvious color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

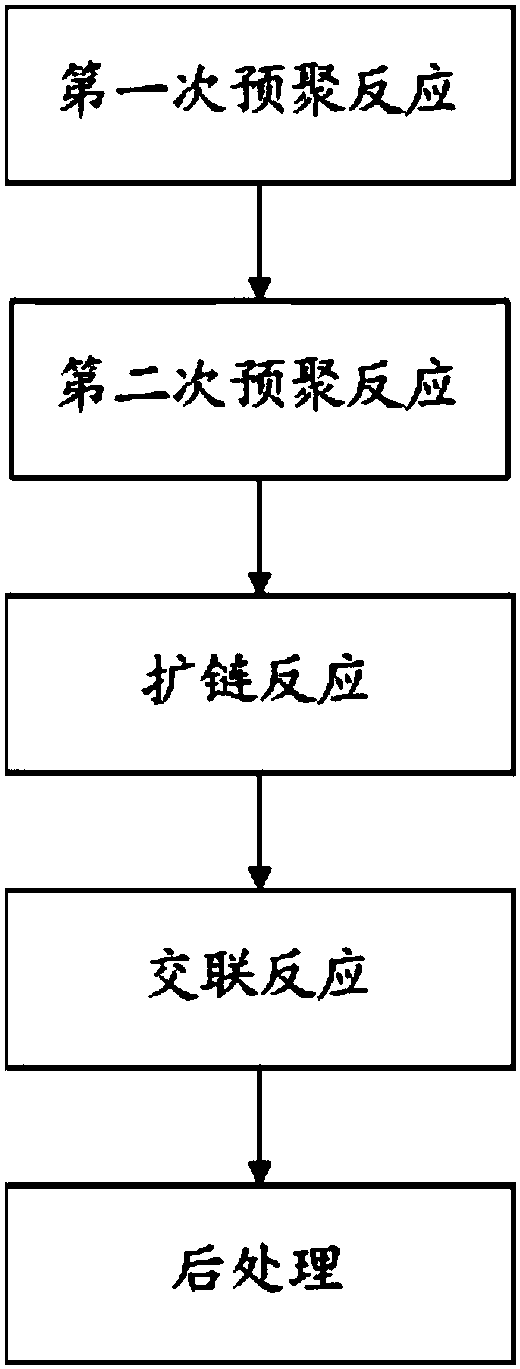

Method used

Image

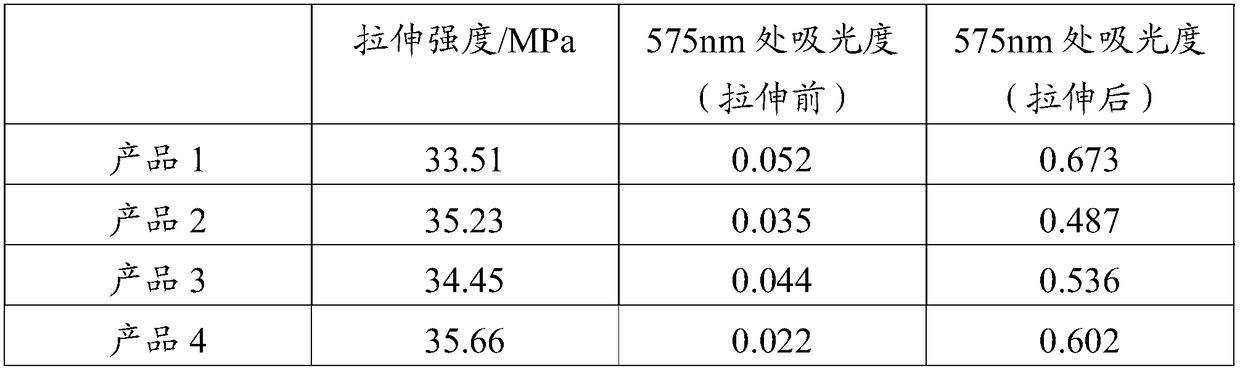

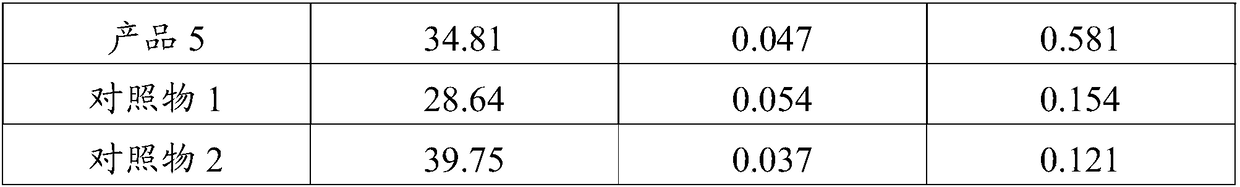

Examples

Embodiment 1

[0040] The first prepolymerization reaction: Mix 0.01mol dihydroxyspiropyran 1, 0.32mol diisocyanate 1a and 0.03mol organic amine catalyst 1a, heat in 40ml dry tetrahydrofuran solution at 60°C for 2.5h, and get First product 1. Among them, the dihydroxy spiropyran 1 is the R group is -CH 3 The spiropyran, the diisocyanate 1a is toluene diisocyanate, and the organic amine catalyst 1a is 1,4-diazabicyclo[2.2.2]octane.

[0041] The second prepolymerization reaction: Add 1 mol of polyol 1 to the system that produces the first product 1 while removing tetrahydrofuran, then add 0.006 mol of organic amine catalyst 1b and 2.5 mol of diisocyanate 1b in sequence, and heat at 70°C for 4 hours , the second product 1 was obtained after the reaction. Wherein, the polyol 1 is polycaprolactone diol, the organic amine catalyst 1b is triethylamine, and the diisocyanate 1b is hexamethylene diisocyanate.

[0042] Chain extension reaction: add 1.1 mol of chain extender 1 to the system that prod...

Embodiment 2

[0047] The first prepolymerization reaction: mix 0.005mol of dihydroxyspiropyran 2, 0.21mol of diisocyanate 2a and 0.024mol of organic amine catalyst 2a, heat in 40ml of dry tetrahydrofuran solution at 50°C for 0.5h, and obtain First product 2. Among them, the dihydroxy spiropyran 2 is the R group is -C 2 h 5 The spiropyran, the diisocyanate 2a is p-phenylene diisocyanate, and the organic amine catalyst 2a is bis(dimethylaminoethyl) ether.

[0048] The second prepolymerization reaction: Add 1 mol of polyol 2 to the system that produces the first product 2 while removing tetrahydrofuran, then add 0.007 mol of organic amine catalyst 2b and 3.2 mol of diisocyanate 2b in sequence, and heat at 80°C for 2 hours , the second product 2 was obtained after the reaction. Wherein, the polyol 2 is polybutylene adipate diol, the organic amine catalyst 2 is bis(dimethylaminoethyl) ether, and the diisocyanate 2b is isophorone diisocyanate.

[0049] Chain extension reaction: add 1.65 mol o...

Embodiment 3

[0054] The first prepolymerization reaction: Mix 0.008mol of dihydroxyspiropyran 3, 0.34mol of diisocyanate 3a and 0.035mol of organic amine catalyst 3a, heat in 40ml of dry tetrahydrofuran solution at 75°C for 2 hours, and obtain the first A product3. Among them, the dihydroxy spiropyran 3 is a spiropyran whose R group is a phenyl group, the diisocyanate 3a is diphenylmethane diisocyanate, and the organic amine catalyst 3a is N,N-dimethylcyclohexylamine.

[0055] The second prepolymerization reaction: Add 1 mol of polyol 3 to the system that produces the first product 3 while removing tetrahydrofuran, then add 0.005 mol of organic amine catalyst 3b and 4.3 mol of diisocyanate 3b in sequence, and heat at 100°C for 3 hours , the second product 3 was obtained after the reaction. Among them, the polyol 3 is polyethylene adipate diol, the organic amine catalyst 3b is N,N,N',N'-tetramethylalkylene diamine, and the diisocyanate 3b is dicyclohexylmethane diisocyanate.

[0056] Cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com