Corn fiber gel-protein emulsifier and preparation method thereof

A corn fiber glue and protein technology, which is used in vegetable protein processing, food ingredients as emulsifiers, food preparation, etc., can solve the problems of unstable emulsification properties of corn fiber glue, and achieve simple processing, improved emulsification properties, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

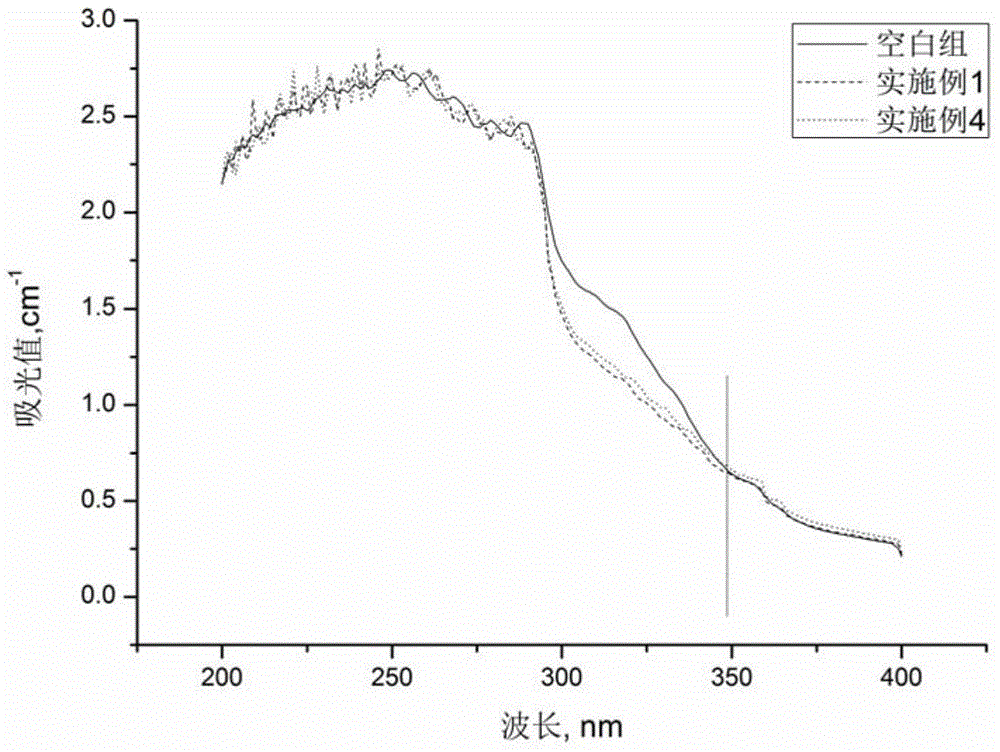

[0042] The preparation principle of the emulsifier in the present invention is as follows: in the enzymatic reaction system, corn fiber gum and protein form intermolecular copolymers to increase the protein content of the corn fiber gum and improve the emulsification of the corn fiber latex.

[0043] The preparation method of emulsifying agent of the present invention, concrete steps are as follows:

[0044] a) Prepare buffer: select buffer as the solution of the reaction system, the pH value is between 6.0 and 7.0, and the buffer is preferably phosphate buffer;

[0045] b) Preparation of corn fiber gum solution: when the corn fiber gum is prepared into a solution, select the prepared buffer solution in step a as a solvent, prepare a clear solution according to the mass fraction of the corn fiber gum between 0.125% and 5.0%, and stir at the same time until fully dissolved;

[0046] c) Preparation of protein solution: When preparing protein into a solution, select the buffer p...

Embodiment 1

[0053] The emulsifier of Example 1 has a composition: the ratio of corn fiber gum to protein is 1:4 (by mass ratio). Concrete preparation process is as follows:

[0054] a) Prepare phosphate buffered saline: prepare phosphate buffered saline (PBS) with pH 6.0;

[0055] b) Preparation of corn fiber glue solution: its mass fraction is 0.125%, and the phosphate buffer solution prepared in step a is selected as a solvent to prepare a clear solution, and stirred until fully dissolved at the same time, and the stirring time is 2 hours;

[0056] c) Preparation of bovine serum albumin solution: its mass fraction is 2.0%, and the phosphate buffer solution prepared in step a is selected as a solvent to prepare a clear solution, and stirred until fully dissolved at the same time, and the stirring time is 4 hours;

[0057] d) Preparation of H 2 o 2 And horseradish peroxidase solution: get 20 μ L of 30% (mass fraction) H 2 o 2 , diluted to 10 mL of 0.06% (mass fraction) H with the pre...

Embodiment 2

[0063] The emulsifier of Example 2 has a composition: the ratio of corn fiber gum to protein is 1:1 (by mass ratio). Concrete preparation process is as follows:

[0064] a) Prepare phosphate buffered saline: prepare phosphate buffered saline (PBS) with pH 6.0;

[0065] b) Preparation of corn fiber glue solution: its mass fraction is 0.5%, and the phosphate buffer solution prepared in step a is selected as a solvent to prepare a clear solution, and stirred until fully dissolved at the same time, and the stirring time is 2 hours;

[0066] c) Preparation of bovine serum albumin solution: its mass fraction is 2.0%, and the phosphate buffer solution prepared in step a is selected as a solvent to prepare a clear solution, and stirred until fully dissolved at the same time, and the stirring time is 4 hours;

[0067] d) Preparation of H 2 o 2 And horseradish peroxidase solution: get 20 μ L of 30% (mass fraction) H 2 o 2 , diluted to 10 mL of 0.06% (mass fraction) H with the prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com