Compound rubber modified styrene series resin composition and preparation method thereof

A styrene resin and rubber modification technology, which is applied in the field of ultrafine powder rubber and cis-butadiene rubber modified styrene resin composition and its preparation field, can solve the problems of particle size control and complex polymerization process, and achieve good The effect of drop impact strength, low hygroscopicity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

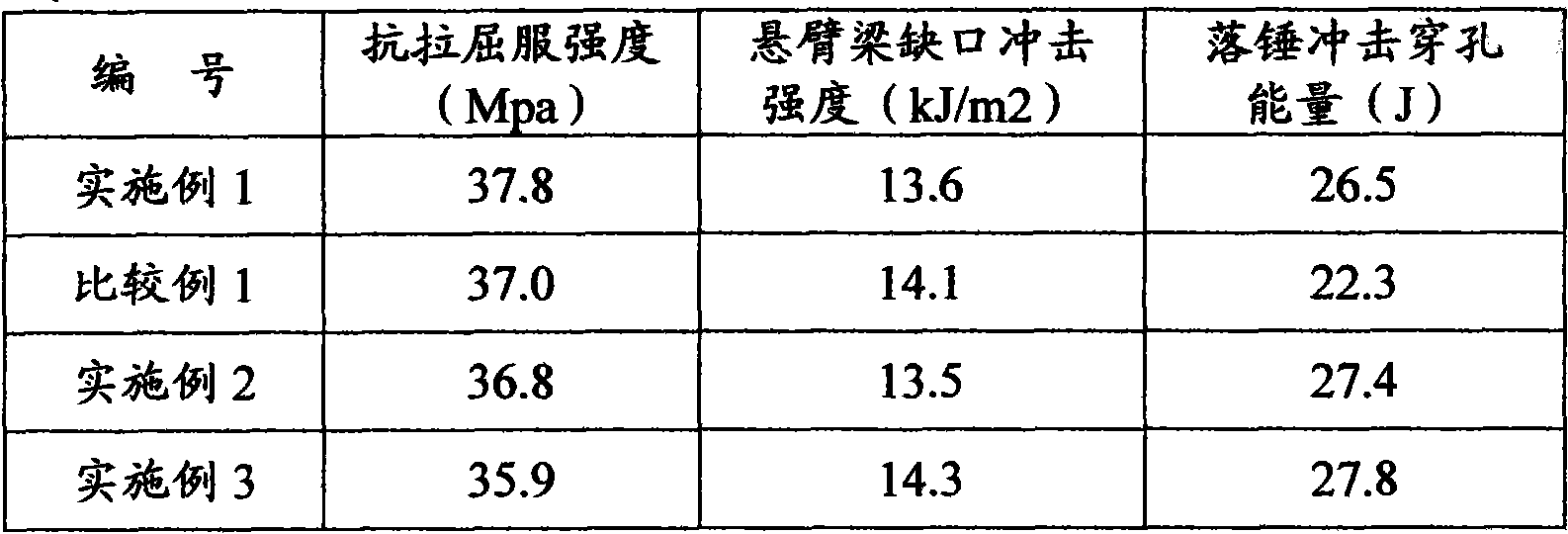

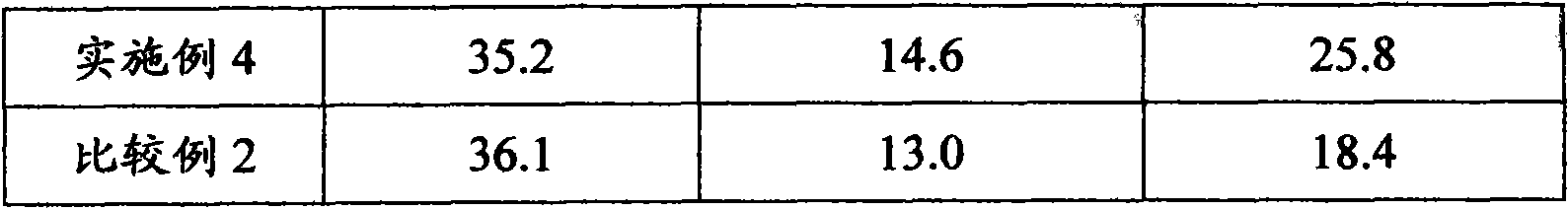

Embodiment 1

[0034] 1. Preparation of styrene-butadiene rubber powder:

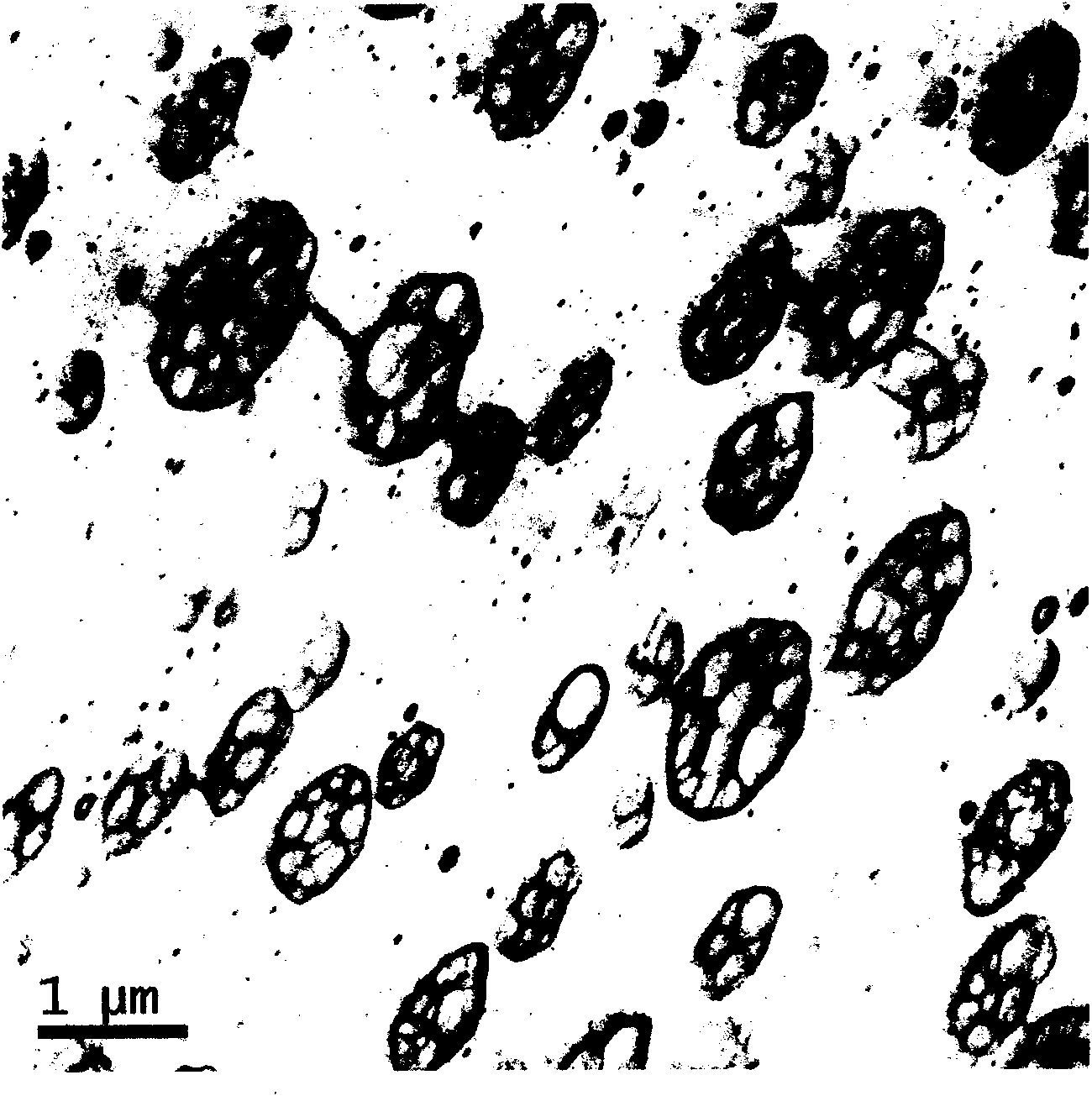

[0035] Commercially available styrene-butadiene latex (produced by Yanshan Petrochemical, brand: XSBRL-54B1) with a solid content of 50wt% was placed in a container, and 75 g of acrylic acid isooctanoic acid was added dropwise under stirring. The cobalt source was irradiated with a dose of 2.5Mrad and a dose rate of 50Gy / min. The irradiated latex is spray-dried by a spray dryer, the inlet temperature of the spray dryer is 140°C to 160°C, and the outlet temperature is 40°C to 60°C, and the dried carboxylated styrene-butadiene rubber powder is collected in a cyclone separator to obtain Free flowing fully vulcanized styrene butadiene rubber powder. The measured average particle diameter of the powdered rubber is about 150nm, the gel content is 92.6%, and the swelling index is 7.6.

[0036] 2. Preparation of polystyrene composition:

[0037] 11.7g of the styrene-butadiene rubber powder obtained above, low-cis polybutad...

Embodiment 2

[0042] Add mineral oil (63#, produced by Yanshan Petrochemical) to the styrene-butadiene rubber powder prepared in Example 1 according to the ratio of mineral oil: powder rubber = 0.2: 1, stir evenly with a mixer, leave it for 24 hours to fully absorb, take the oil-extended After the rubber 14.6g, other conditions are identical with embodiment 1. The physical property analysis of the obtained final composition is listed in Table 1.

Embodiment 3

[0044] Add mineral oil (63#, produced by Yanshan Petrochemical) to the styrene-butadiene rubber powder prepared in Example 1 according to the ratio of mineral oil: powder rubber = 0.5: 1, stir evenly with a mixer, leave it for 24 hours to fully absorb, take the oil-extended After the rubber 17.6g, other conditions are identical with embodiment 1. The physical property analysis of the obtained final composition is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com