Environment-friendly BOPP flexible package film and preparation method thereof

A flexible packaging film, an environmentally friendly technology, applied in the field of environmentally friendly BOPP flexible packaging film and its preparation, can solve the problems of endangering the social environment, poor comprehensive performance of the film, environmental pollution, etc., and achieve wide application prospects, good tensile strength, and improved durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

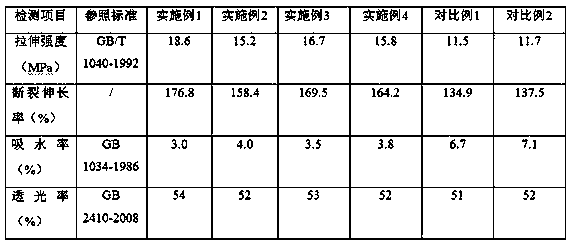

Examples

Embodiment 1

[0019] An environmentally friendly BOPP flexible packaging film, prepared from the following raw materials in parts by weight: 15 parts of polypropylene, 22 parts of polyhydroxyalkanoate, 8 parts of silk fibroin, 9 parts of carboxymethyl cellulose, 6 parts of chitosan, 7 parts of gliadin, 6 parts of polycaprolactone, 4 parts of talc, 7 parts of polylactic acid, 7 parts of epoxy butyl soyate, 5 parts of phytic acid, lauryl dimethyl betaine 4 parts.

[0020] The preparation method of environment-friendly BOPP flexible packaging film of the present invention comprises the following steps:

[0021] (1) Add polypropylene, polyhydroxyalkanoate, silk fibroin, carboxymethyl cellulose, chitosan, and polycaprolactone into the reactor, slowly raise the temperature to 110°C at a speed of 150r / min and continue Stir the reaction for 25 minutes, then lower the temperature to 75°C, add gliadin, talcum powder, polylactic acid, epoxy butyl soyate, phytic acid, dodecyl dimethyl betaine and cont...

Embodiment 2

[0025] An environmentally friendly BOPP flexible packaging film, prepared from the following raw materials in parts by weight: 10 parts of polypropylene, 15 parts of polyhydroxyalkanoate, 5 parts of silk fibroin, 6 parts of carboxymethyl cellulose, 4 parts of chitosan, 4 parts of polycaprolactone, 5 parts of gliadin, 3 parts of talc, 4 parts of polylactic acid, 5 parts of epoxy butyl soyate, 3 parts of phytic acid, lauryl dimethyl betaine 2 servings.

[0026] The preparation method of environment-friendly BOPP flexible packaging film of the present invention comprises the following steps:

[0027] (1) Add polypropylene, polyhydroxyalkanoate, silk fibroin, carboxymethyl cellulose, chitosan, and polycaprolactone into the reactor, slowly raise the temperature to 100°C at a speed of 100r / min and continue Stir the reaction for 15 minutes, then lower the temperature to 70°C, add gliadin, talcum powder, polylactic acid, epoxy butyl soyate, phytic acid, dodecyl dimethyl betaine and c...

Embodiment 3

[0031] An environmentally friendly BOPP flexible packaging film, prepared from the following raw materials in parts by weight: 20 parts of polypropylene, 30 parts of polyhydroxyalkanoate, 10 parts of silk fibroin, 13 parts of carboxymethyl cellulose, 8 parts of chitosan, 8 parts of polycaprolactone, 12 parts of gliadin, 7 parts of talc, 10 parts of polylactic acid, 9 parts of epoxy butyl soyate, 6 parts of phytic acid, lauryl dimethyl betaine 6 servings.

[0032] The preparation method of environment-friendly BOPP flexible packaging film of the present invention comprises the following steps:

[0033] (1) Add polypropylene, polyhydroxyalkanoate, silk fibroin, carboxymethyl cellulose, chitosan, and polycaprolactone into the reactor, slowly raise the temperature to 120°C at a speed of 200r / min and continue Stir the reaction for 35 minutes, then lower the temperature to 80°C, add gliadin, talcum powder, polylactic acid, epoxy butyl soyate, phytic acid, dodecyl dimethyl betaine a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com