Preparation method for graphene-carbon nanofiber composite current collectors

A nano-carbon fiber and graphene technology, applied in capacitors, electrical components, electrolytic capacitors, etc., can solve the problem of low tensile strength of graphene, achieve good tensile strength and improve mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

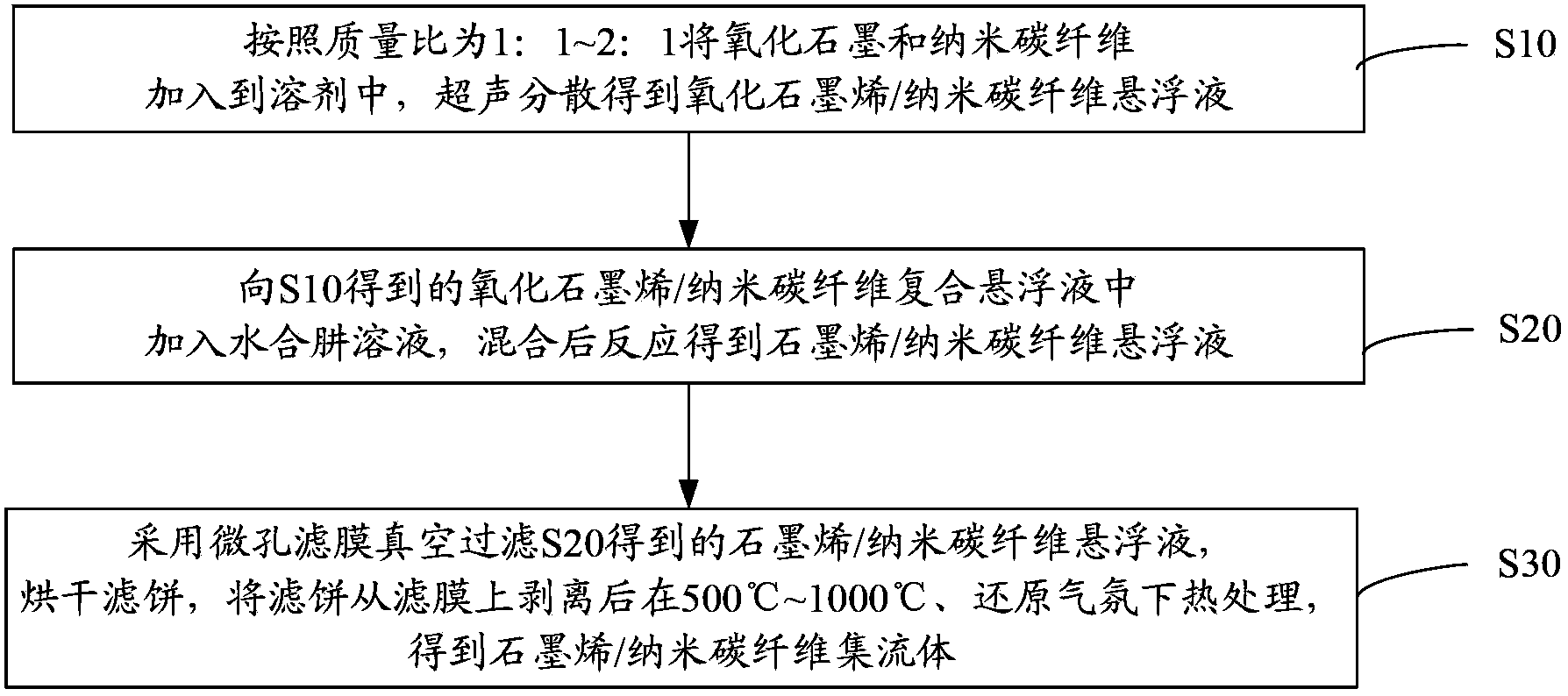

[0024] Such as figure 1 The preparation method of the graphene-carbon nanofiber composite current collector of one embodiment shown, comprises the steps:

[0025] S10. Add graphite oxide and carbon nanofibers into the solvent according to the mass ratio of 1:1 to 2:1, and ultrasonically disperse to obtain a composite suspension of graphene oxide-carbon nanofibers.

[0026] The solvent can be ionized water, ethanol, isopropanol, propanol, N-methylpyrrolidone (NMP) or N,N-dimethylformamide (DMF).

[0027] The time for ultrasonic dispersion can be 1h~2h, subject to obtaining the graphene oxide suspension.

[0028] The total concentration of the obtained graphene oxide-carbon nanofiber composite suspension can be 0.1 mg / ml-5 mg / ml.

[0029] S20, adding a hydrazine hydrate solution to the graphene oxide-carbon nanofiber composite suspension obtained in S10, and reacting after mixing to obtain a graphene-carbon nanofiber composite suspension.

[0030] Hydrazine hydrate generally ...

Embodiment 1

[0042] Graphite oxide and carbon nanofibers were added into deionized water at a ratio of 1:1, and ultrasonically dispersed for 1 h to obtain a graphene oxide-carbon nanofiber composite suspension with a concentration of 0.1 mg / ml.

[0043] Add a hydrazine hydrate solution with a mass fraction of 85% to the obtained graphene oxide-carbon nanofiber composite suspension (the mass ratio of hydrazine hydrate and graphene oxide is 1:10), and react at a temperature of 100°C for 12 hours to obtain graphite ene-carbon nanofiber composite suspension.

[0044] Vacuum filter the graphene-carbon nanofiber composite suspension through a microporous filter membrane to obtain a filter cake, place the filter cake in an oven to dry at 40°C, then peel off the graphene-carbon nanofiber composite film from the filter membrane, and remove the graphite Put the alkene-carbon nanofiber composite film into a tube furnace, pass in argon gas to discharge the air in the furnace, then control the flow rate ...

Embodiment 2

[0046] Graphite oxide and carbon nanofibers were added to ethanol at a ratio of 2:1, and ultrasonically dispersed for 1.5 h to obtain a graphene oxide-carbon nanofiber composite suspension with a concentration of 1 mg / ml.

[0047] Add a hydrazine hydrate solution with a mass fraction of 85% (the mass ratio of hydrazine hydrate and graphene oxide is 4:10) to the obtained graphene oxide-carbon nanofiber composite suspension, and react at a temperature of 90°C for 18 hours to obtain graphite ene-carbon nanofiber composite suspension.

[0048] Vacuum filter the graphene-carbon nanofiber composite suspension through a microporous filter membrane to obtain a filter cake, place the filter cake in an oven to dry at 40°C, then peel off the graphene-carbon nanofiber composite film from the filter membrane, and remove the graphene - Put the nano-carbon fiber composite film into the tube furnace, pass in argon to discharge the air in the furnace, then control the flow of argon to 70ml / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com