Automotive rubber material, preparation method and application thereof

A technology for rubber materials and vehicles, applied in the field of rubber materials for vehicles and their preparation, can solve the problems of shortened service life, poor flexural fatigue resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

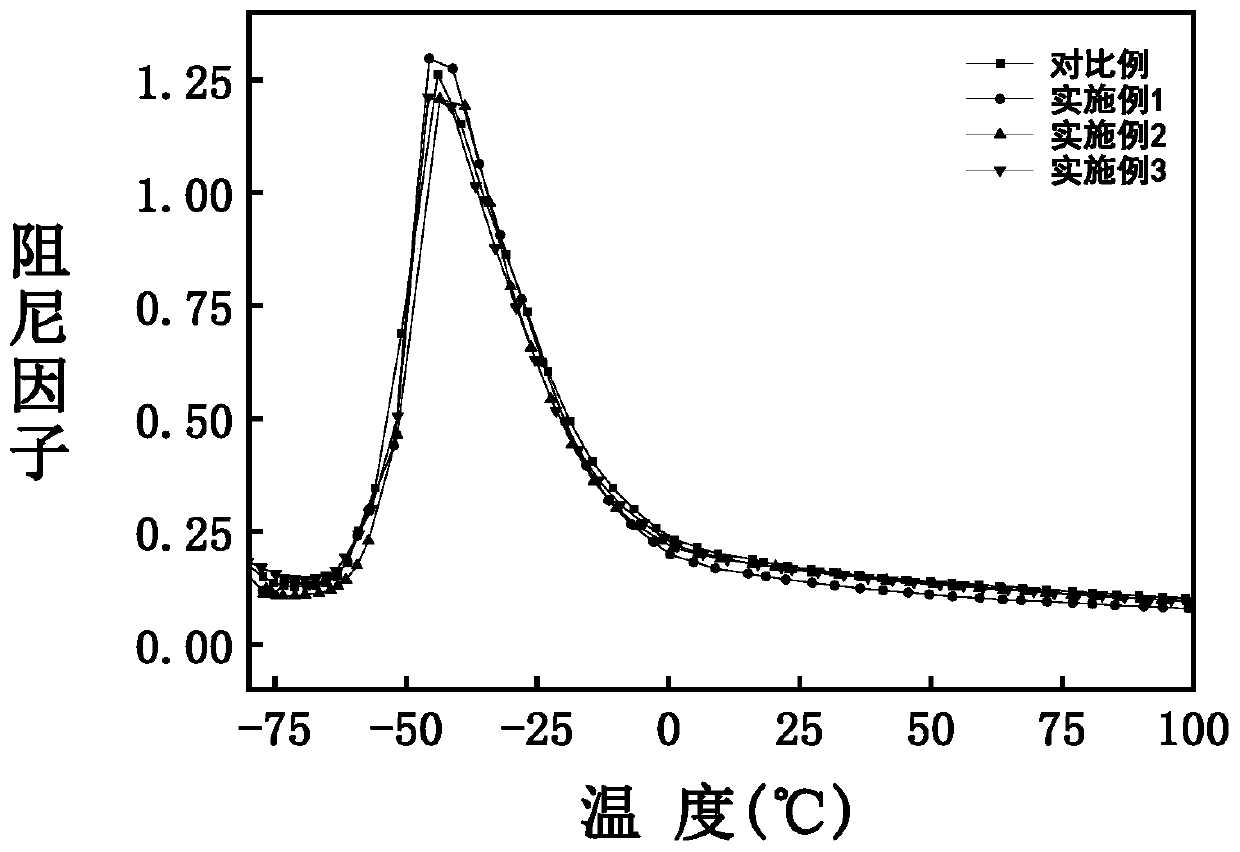

Examples

Embodiment 1

[0038] A rubber material for the hinged compression layer of an automobile torsion beam, the rubber material is prepared from the following raw materials in terms of parts by mass:

[0039]

[0040] The preparation method step of producing this rubber material is as follows:

[0041] 1) Preparation of natural rubber masterbatch:

[0042] Put 70 parts of natural rubber (national standard 10#) into the internal mixer, after mixing for 1 minute, add carbon black N339 (5 parts) and carbon black N550 (5 parts), mix for 1 minute, add white carbon black 233 (3 parts) and coupling agent SI-69 (0.7 parts), after mixing for 0.5 minutes, lift the top plug to clean, continue to mix for 1 minute after cleaning, and then discharge the glue, not exceeding 150 °C.

[0043] 2) Preparation of Eucommia rubber masterbatch

[0044] Put Eucommia rubber (5 parts) into the internal mixer, after mixing for 1 minute, add carbon black N339 (5 parts) and carbon black N550 (5 parts), mix for 1 mi...

Embodiment 2

[0057] A rubber material for vehicles, which is prepared from the following raw materials according to the parts by mass:

[0058]

[0059]

[0060] The preparation method step of producing this rubber material is as follows:

[0061] 1) Preparation of natural rubber masterbatch:

[0062] Put 85 parts of natural rubber (national standard 20#) into the internal mixer, after mixing for 1 minute, add carbon black N339 (25 parts), mix for 1 minute, add white carbon black 233 (8 parts) and coupling agent SI- 69 (0.8 parts), after mixing for 0.5 minutes, lift the top bolt to clean, continue to mix for 1 minute after cleaning, and then discharge the glue, not exceeding 150°C.

[0063] 2) Preparation of Eucommia rubber masterbatch

[0064] Put Eucommia rubber (15 parts) into the internal mixer, after mixing for 1 minute, add carbon black N339 (5 parts), mix for 1 minute, add white carbon black 233 (2 parts) and coupling agent SI-69 (0.2 parts), after mixing for 0.5 minutes,...

Embodiment 3

[0075] A rubber material for vehicles, which is prepared from the following raw materials according to the parts by mass:

[0076]

[0077] The preparation method step of producing this rubber material is as follows:

[0078] 1) Preparation of natural rubber masterbatch: put 90 parts of natural rubber (national standard 10#) into the internal mixer, mix for 1 minute, add carbon black N339 (25 parts) and carbon black N550 (4 parts), and mix for 1 minute , add white carbon black 233 (6 parts) and coupling agent SI-69 (0.8 parts), after mixing for 0.5 minutes, lift the top plug to clean, continue mixing for 1 minute after cleaning, and then remove the glue, not exceeding 150 ° C.

[0079] 2) Preparation of Eucommia rubber masterbatch

[0080] Put 25 parts of eucommia rubber into the internal mixer, after mixing for 1 minute, add carbon black N339 (5 parts) and carbon black N550 (1 part), mix for 1 minute, add white carbon black 233 (2 parts) and coupling Agent SI-69 (0.2 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com