Water film on inner wall of paper tableware and preparation method thereof

A tableware and paper technology, used in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of strange smell and poor processing technology, and achieve the effect of improving antibacterial properties, enhancing sensory quality and excellent plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation method of water-repellent film on the inner wall of paper tableware (such as paper cups, paper plates, paper plates, etc.)

[0035] A method for preparing a water barrier film on the inner wall of paper tableware (such as paper cups, paper plates, paper plates, etc.), comprising the following steps:

[0036] 1. Membrane solution preparation: Take potassium sorbate, emulsifier monoglyceride, polyethylene glycol PEG-400 and stearic acid in water and stir evenly, and the weight percentages are respectively 0.05% potassium sorbate and 0.1% monoglyceride , 0.6% polyethylene glycol PEG-400 and 0.26% stearic acid aqueous solution, with Na 2 CO 3 Adjust the pH value of the lye to pH=10, then add the modified product of konjac glucomannan esterification, xanthan gum and carrageenan, and the weight percentages of the added raw materials and water are respectively the modified product of esterification of konjac glucomannan 1%, xanthan gum 1% and carrageen...

Embodiment 2

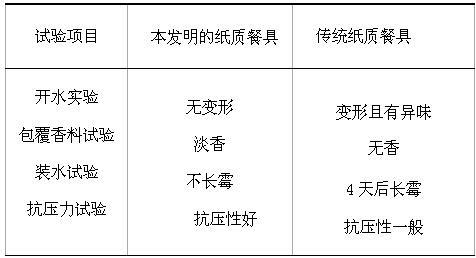

[0043] Embodiment two: performance comparison of paper tableware

[0044] Various tests were done with the paper tableware and traditional paper tableware prepared in Example 1. The results of observation and record comparison experiments are shown in Table 1.

[0045] Table 1 paper tableware of the present invention and the contrast of traditional paper tableware

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com