Anti-corrosion repairing method for flange on ocean oil platform

A technology for offshore oil and flanges, which is applied in the direction of pipeline anticorrosion/rust protection, damage protection, pipes/pipe joints/fittings, etc. In order to achieve the effect of strong plasticity, good anti-corrosion effect and avoid falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiment of the present invention provides a method for anti-corrosion repairing of flanges on offshore oil platforms, which solves the problem of anti-corrosion repair methods in the prior art, which have higher requirements for flange surface treatment and poor anti-corrosion performance. The technical problem that the flange surface is not firmly bonded or fit tightly, and water vapor is easy to penetrate.

[0040] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

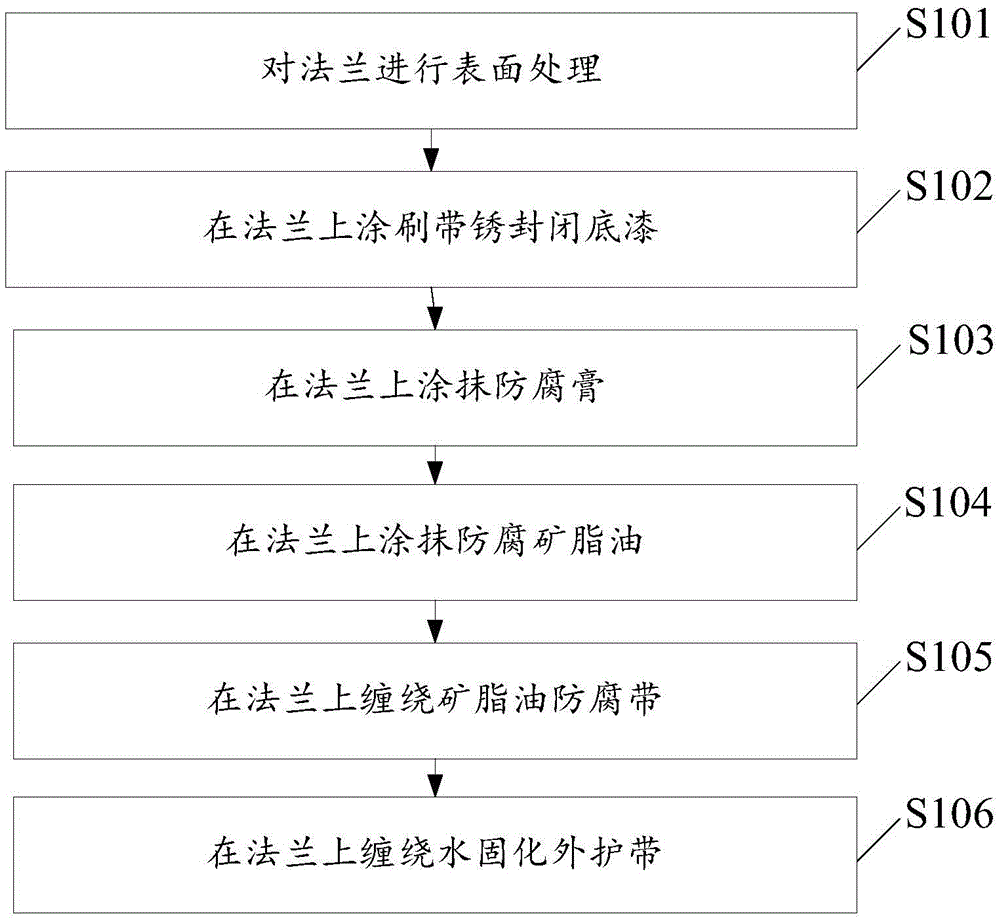

[0041] A method for anti-corrosion repairing of flanges on offshore oil platforms, comprising: surface treatment of the flanges; coating of rusty sealing primers on the flanges; coating of anti-corrosion paste on the flanges; Anti-corrosion petrolatum oil; wrap petrolatum oil anti-corrosion tape on flange; wrap water-cured outer protective tape on flange.

[0042] In order to better understand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com