Alloy material with high comprehensive performance and preparation method thereof

A technology of comprehensive properties and alloy materials, applied in metal material coating technology, metal processing equipment, coatings, etc., to achieve the effect of improving plasticity and mechanical properties, excellent comprehensive properties, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

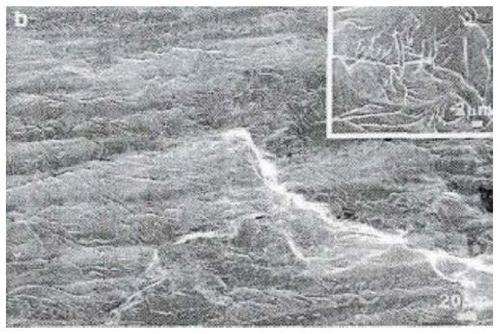

Image

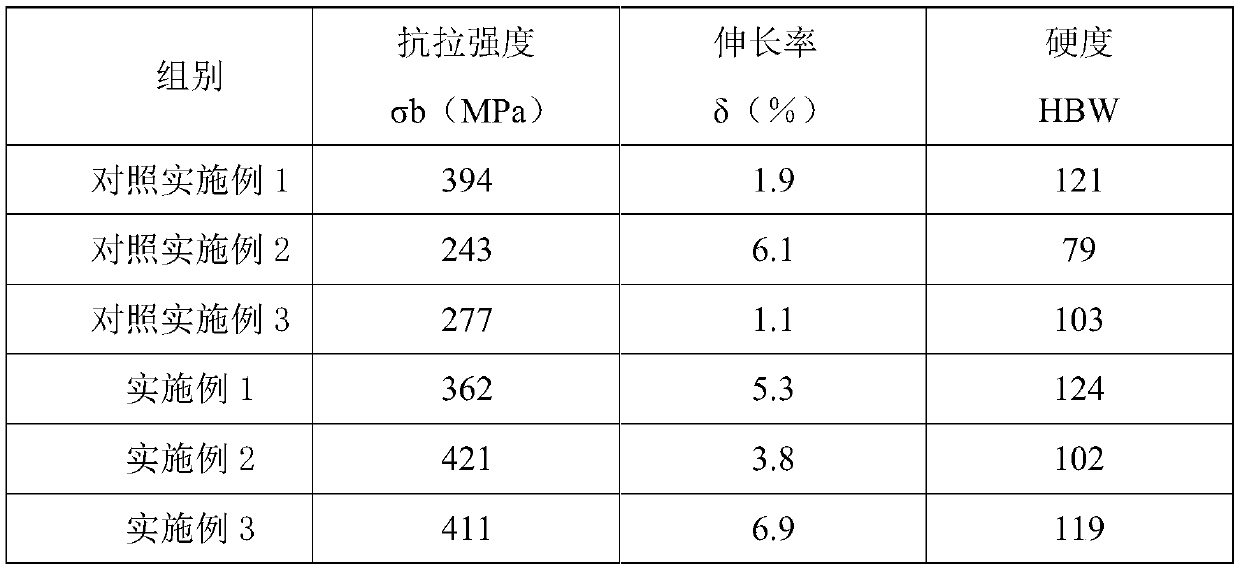

Examples

Embodiment 1

[0035] Embodiment 1: prepare the alloy material of high comprehensive performance as follows:

[0036] 1. Preparation of raw materials:

[0037] Fe, Cu, Au, Pd, Ho, Al all use pure substances as raw materials for preparation, and the purity is greater than 99.9%; Sr is prepared in the form of aluminum-strontium alloy, wherein the weight percentage of Sr is 10%, and the rest is aluminum; Ni The form of aluminum-nickel alloy is used as the raw material for preparation, wherein the weight percentage of Ni is 15%, and the rest is aluminum; Si, Mg, and Zn are prepared in the form of aluminum-magnesium-zinc alloy, and the content of Si is 30wt%; Zn The content is 20wt%; the content of Mg is 2.0wt%, and the rest is aluminum.

[0038] Au, Pd, Ho, and Fe pure material raw materials are in the form of powder, with an average particle size of 100 mesh; the aluminum-magnesium-zinc alloy and copper raw materials are alloy ingots, and the aluminum-nickel alloy and aluminum-strontium alloy ...

Embodiment 2

[0048] Embodiment 2: prepare the alloy material of high comprehensive performance as follows:

[0049] 1. Preparation of raw materials:

[0050] Fe, Cu, Au, Pd, Ho, Al all use pure substances as raw materials for preparation, and the purity is greater than 99.9%; Sr is prepared in the form of aluminum-strontium alloy, wherein the weight percentage of Sr is 10%, and the rest is aluminum; Ni The form of aluminum-nickel alloy is used as the preparation raw material, wherein the weight percentage of Ni is 15%, and the rest is aluminum; Si, Mg, and Zn are prepared in the form of aluminum-magnesium-zinc alloy, and the content of Si is 24wt%; Zn The content is 4wt%; the content of Mg is 1.6wt%, and the rest is aluminum.

[0051] Au, Pd, Ho, and Fe pure material raw materials are in the form of powder, with an average particle size of 200 mesh; the aluminum-magnesium-zinc alloy and copper raw materials are alloy ingots, and the aluminum-nickel alloy and aluminum-strontium alloy are a...

Embodiment 3

[0061] Embodiment 3: prepare the alloy material of high comprehensive performance as follows:

[0062] 1. Preparation of raw materials:

[0063] Fe, Cu, Au, Pd, Ho, Al all use pure substances as raw materials for preparation, and the purity is greater than 99.9%; Sr is prepared in the form of aluminum-strontium alloy, wherein the weight percentage of Sr is 10%, and the rest is aluminum; Ni The form of aluminum-nickel alloy is used as the preparation raw material, wherein the weight percentage of Ni is 15%, and the rest is aluminum; Si, Mg, and Zn are prepared in the form of aluminum-magnesium-zinc alloy, wherein the content of Si is 27wt%; The content is 12wt%; the content of Mg is 1.8wt%, and the rest is aluminum.

[0064] Au, Pd, Ho, and Fe pure material raw materials are in the form of powder, with an average particle size of 150 mesh; the aluminum-magnesium-zinc alloy and copper raw materials are alloy ingots, and the aluminum-nickel alloy and aluminum-strontium alloy are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com