Method for synthesizing Al-Cu alloy in situ by powder metallurgy

A powder metallurgy in-situ, al-cu technology, applied in coating and other directions, can solve problems such as long-term ball milling, and achieve the effect of excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

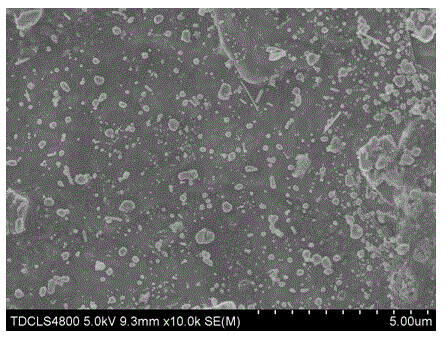

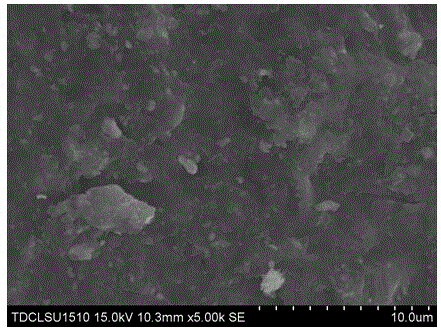

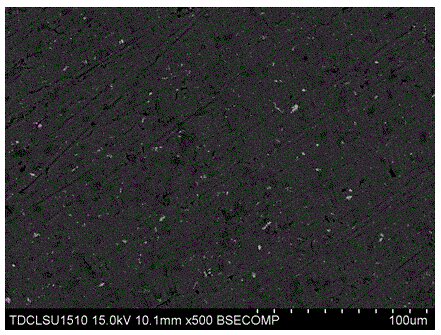

Embodiment 1

[0023] Mix 1.26g of copper acetate monohydrate with 9.6g of aluminum powder, add it to 120ml of absolute ethanol, evaporate to dryness with magnetic stirring at 65°C, and place it in the air for 1 day to obtain a precursor powder. Take 10g of the precursor powder prepared by the above process and place it in the constant temperature zone of the tube furnace, raise the temperature to 300°C under the protection of argon, feed argon at a flow rate of 200ml / min for 1 hour, then turn off the argon, and use 200ml The flow rate of / min was fed with hydrogen for another hour, then the hydrogen was turned off, and the furnace was cooled to room temperature under the protection of argon to obtain Al-Cu powder with a Cu content of 4wt.%. Prepare 3 times in this way. Take 20g of the Al-Cu powder prepared by the above process, add 200g of steel balls, put it into a ball mill tank, vacuumize it, fill it with argon gas, and ball mill it at 400 rpm for 1 hour. The powder obtained by ball mil...

Embodiment 2

[0025] The specific method and steps are the same as in Example 1, except that the ball milling process is omitted. The tensile strength of the obtained material is (260~270) MPa, and the elongation at break is (16.9~17.6)%.

Embodiment 3

[0027] Concrete method and step are with embodiment 1, and difference is: sintering temperature becomes 570 ℃ by 600 ℃. The tensile strength of the prepared material is (262~268) MPa, and the elongation at break is (7.0~8.8)%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com