Directly-compoundable low-melting-point polyester thin film preparation method for laminated steel

A technology of low-melting point polyester and coated iron, which is applied in the field of polyester film to achieve the effects of non-toxic shedding, high processability, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

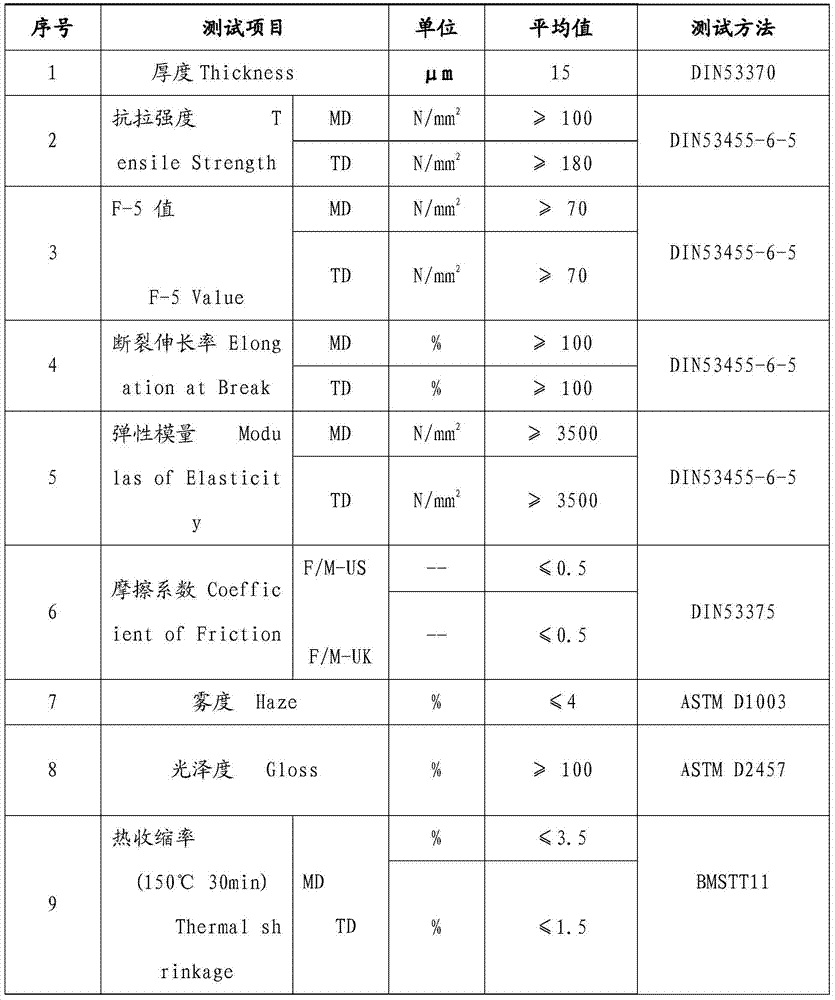

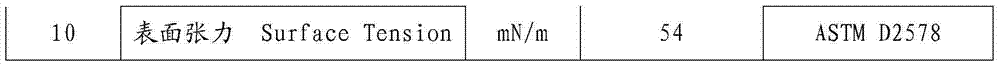

Image

Examples

Embodiment 1

[0029] 1) Core layer polyester chips: 60-80% of the total mass of HS230 is mixed with 40-20% of the total mass of HS230-A, and the polyester chips after mixing are crystallized and dried: in order to avoid the melt extrusion process Medium PET degradation, crystallization and drying of the core polyester chips, the first crystallization temperature is 80-120°C for 12 hours, the second crystallization temperature is 150°C, the drying temperature is 160°C, and the drying time is not less than 6 hours.

[0030] 2) Surface and bottom polyester chips: 60-80% of the total mass of HS230 is mixed with 40-20% of the total mass of HS230-A, and the surface and bottom layer use twin-screw vacuum pumps to remove moisture.

[0031] 3) Melt extrusion: three-layer co-extrusion, in which the main extruder extrudes the core layer material, and the other two are twin-screw auxiliary extruders with vacuum exhaust function, which respectively extrude the surface layer and the bottom layer material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com