Preparation method of fluororesin composite, fluororesin composite and product produced by molding fluororesin composite

A manufacturing method, fluororesin technology, applied in other household appliances, household components, applications, etc., can solve the problems of expensive special devices, increase production processes, needs, etc., and achieve the effect of excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

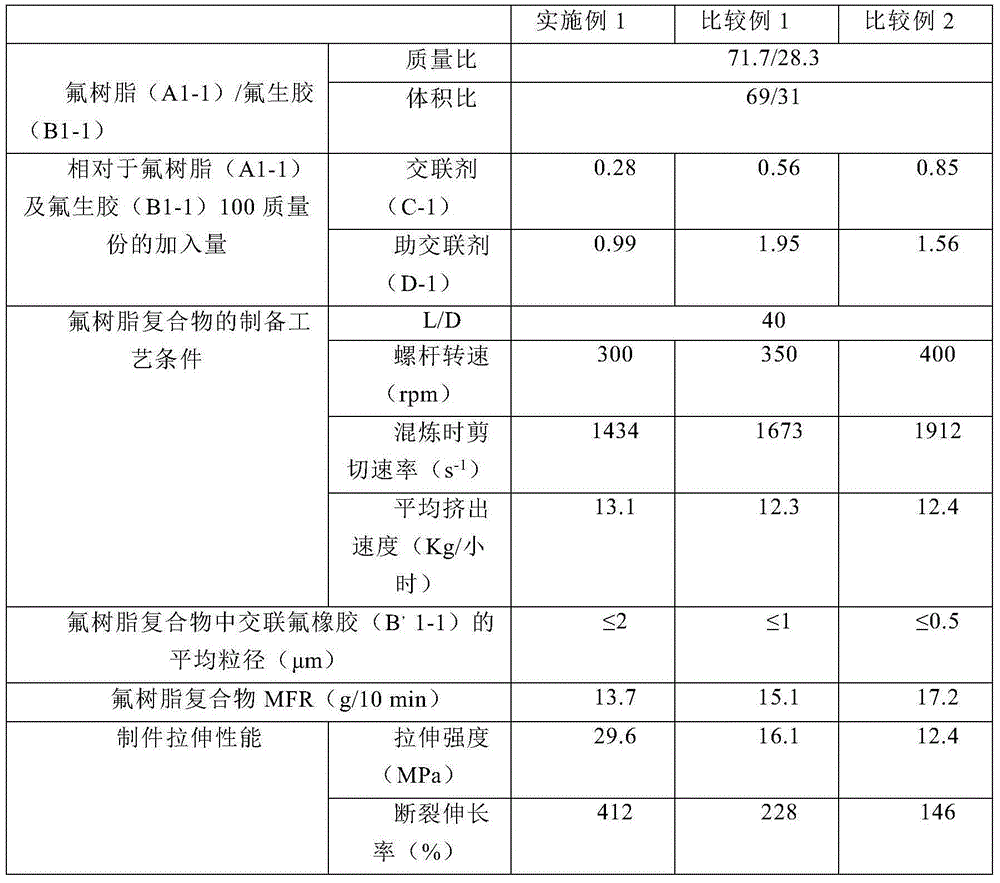

Embodiment 1

[0271] Fluoroplastic (B1-1) 0.85kg, cross-linking agent (C-1) added at 0.99w% according to the mass sum of fluoroplastic (B1-1) and fluororesin (A1-1) described later at 0.28w% The cross-linking aid (D-1) and 8.5 g of the processing accelerator (D-3) were kneaded on a twin-roller until uniform, and a fluororubber rubber sheet was obtained. In order to mix it evenly with the fluororesin, the obtained rubber sheet was cut into 2mm-sized particles on a rubber pelletizer.

[0272] After mixing the aforementioned rubber particles and 2.15kg of fluororesin (A1-1) evenly, add them into a twin-screw extruder (manufactured by Nanjing Jieya Extrusion Equipment Co., Ltd. L / D=40, outer diameter D=35.6mm, length L =1424mm.), according to the screw speed (rpm) represented in Table 1, the shear rate (s) when twin-screw extruder mixing -1 ), the average extrusion amount (kg / h) is melt-kneaded and extruded, and the fluororubber (B1-1) is cross-linked to become a cross-linked fluororubber (B'1...

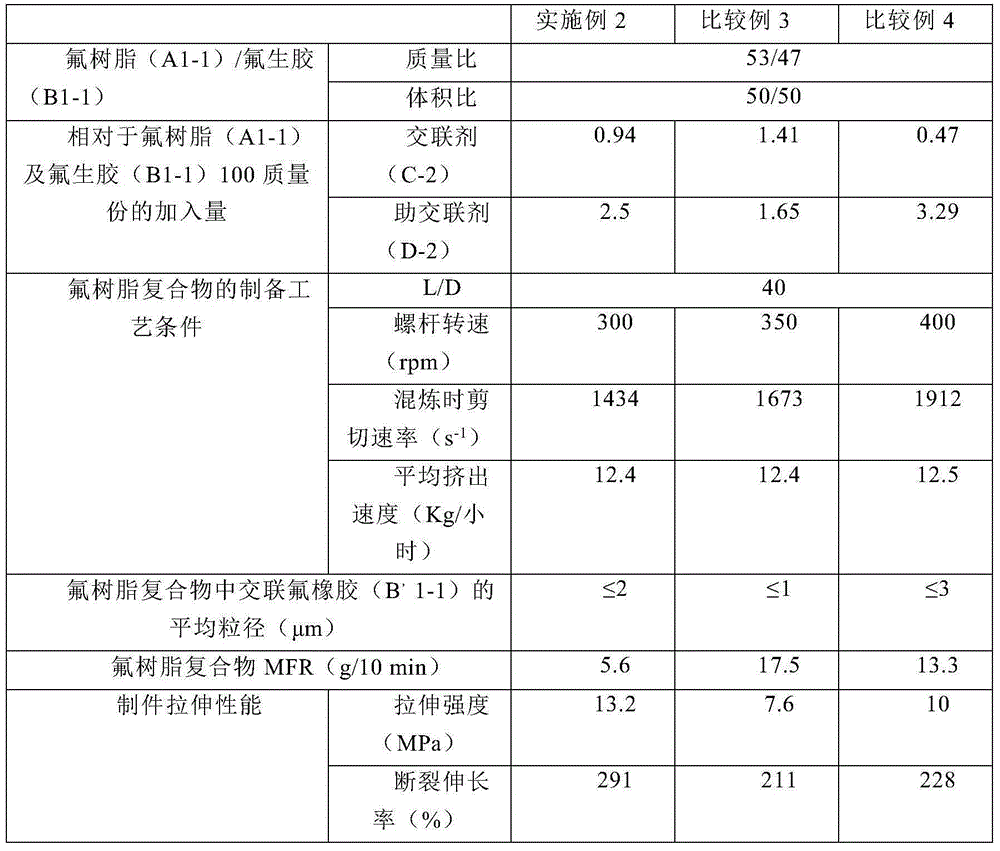

Embodiment 2 and comparative example 3、4

[0281] Use cross-linking agent (C-2) instead of cross-linking agent (C-1); cross-linking aid (D-2) instead of cross-linking aid (D-1), fluororesin (A1-1), fluoroplastic (B1-1), the addition of cross-linking agent (C-2) and cross-linking auxiliary agent (D-2), and shear rate, average extruded volume and all in table 2 when twin-screw extruder mixing Except for the difference, the same fluororesin composite as in Example 1 was prepared.

[0282] The average particle diameter of the crosslinked fluororubber (B'1-1) in the fluororesin composite obtained by embodiment 2 and comparative examples 3 and 4, MFR (g / 10min), the mechanical strength of the product (tensile strength ( MPa), elongation at break (%)) are shown in Table 2.

[0283] Table 2: Fluorine resin compound formula, preparation process and performance comparison

[0284]

[0285] As shown in Table 2, the mixing shear rate of the twin-screw extruder is 1434s -1 The tensile strength of the product obtained in the em...

Embodiment 2

[0286] The addition amount of crosslinking agent (C-2) and crosslinking aid (D-2) of embodiment 2 is close to comparative example 4, has the same trend, and has nothing to do with the addition amount of the two, which shows that twin-screw extrusion The shear rate during extruding mixing is an important reason for the excellent tensile properties of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com