Polyester elastomer and preparation method thereof

A technology of polyester elastomer and esterification reaction, applied in the field of polyester elastomer and its preparation, can solve problems such as high glass transition temperature, and achieve the effects of good resilience, low glass transition temperature and excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

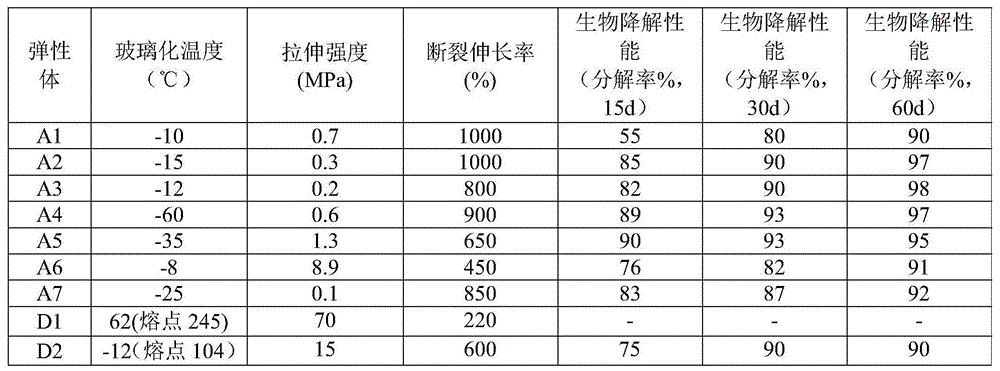

Examples

preparation example Construction

[0014] The preparation method of polyester elastomer provided by the invention comprises: under the condition of esterification reaction and / or transesterification reaction, make the mixture that contains dibasic carboxylic acid (ester) and dibasic alcohol react; Under polycondensation reaction condition, In the presence of a polycondensation catalyst, the product after the esterification reaction and / or transesterification reaction is subjected to a polycondensation reaction; wherein, the dicarboxylic acid (ester) contains succinic acid (ester), isophthalic acid (ester) and For terephthalic acid (ester), the dihydric alcohol contains ethylene glycol.

[0015] In the present invention, said dibasic carboxylic acid (ester) means dibasic carboxylic acid and / or dibasic carboxylic acid ester, similarly, said succinic acid (ester) means succinic acid and / or succinic acid ester , the isophthalic acid (ester) means isophthalic acid and / or isophthalic acid ester, and the terephthalic ...

Embodiment 1

[0053] Add 16.6g (0.1mol) of isophthalic acid, 166g (1.0mol) of terephthalic acid, 93g (1.5mol) of ethylene glycol, 13g (0.11mol) of succinic acid and ethylene glycol in a batch reactor Diol antimony (based on the weight of the above-mentioned dicarboxylic acid (ester), the consumption is 0.01% by weight), after esterification and transesterification at 220~250°C and a pressure of 0.25MPa for 1 hour, the reaction kettle The pressure is released to normal pressure, after adding trimethyl phosphate (based on the weight of the product after esterification and transesterification, the consumption is 0.1% by weight), gradually reduce the pressure and heat up, at 200 ℃, the pressure is under the condition of 30kPa Polycondensate for 0.5 hour, then continue to heat up and depressurize. After 45 minutes, the vacuum of the reactor reaches 1500Pa, and the reaction temperature is maintained at 250-260°C. After another 110 minutes of polymerization, the polymerization reaction is terminate...

Embodiment 2

[0055] Add 16.6g (0.1mol) of isophthalic acid, 62.0g (1.0mol) of ethylene glycol, 106g (0.9mol) of succinic acid and magnesium acetate (with the weight of the above-mentioned dibasic carboxylic acid) in the batch reactor As a benchmark, the amount used is 0.1% by weight), replaced with nitrogen three times, and the esterification was completed after 10 hours of transesterification under normal pressure at 160-240°C. Then add phosphoric acid (based on the weight of the product after the esterification and transesterification reaction, the consumption is 0.5% by weight), ethylene glycol antimony (based on the weight of the above-mentioned dicarboxylic acid (ester), the consumption is 0.03% by weight ) and stir evenly, gradually depressurize and heat up, and polycondense for 4 hours at 220 ° C and a pressure of 10 kPa. Then, continue to heat up and decompress. After 15 minutes, the vacuum of the reactor reaches 90 Pa, and the reaction temperature is maintained at 250 ~ 260 °C, af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com