Alkaline anion-exchange composite membrane with high mechanical properties, and preparation and application thereof

A technology of basic anion and mechanical properties, which is applied in the field of basic anion exchange composite membranes, can solve the problems of complex preparation process, decline, and decline of membrane performance, and achieve the effect of simple preparation method, good film-forming property and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

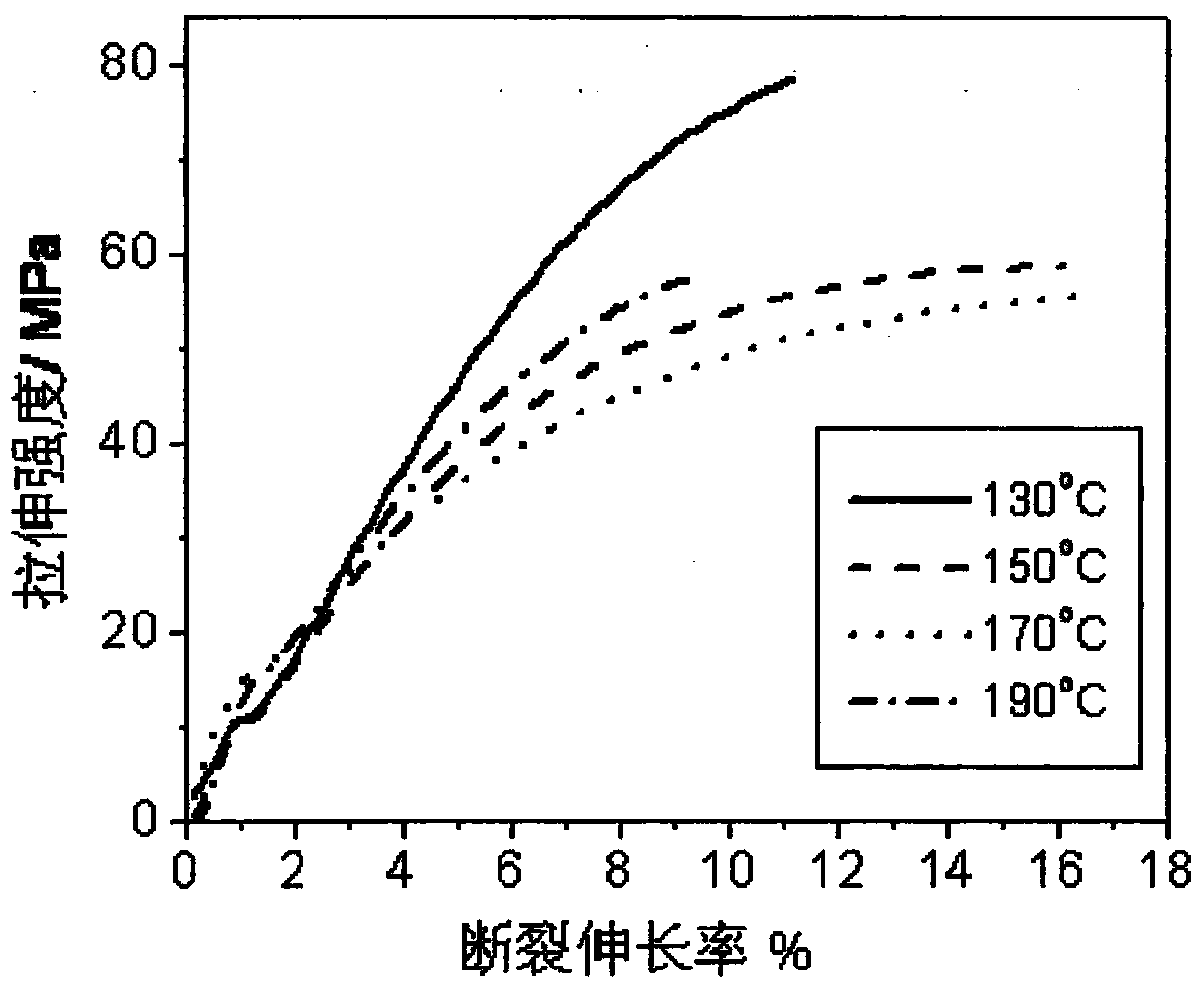

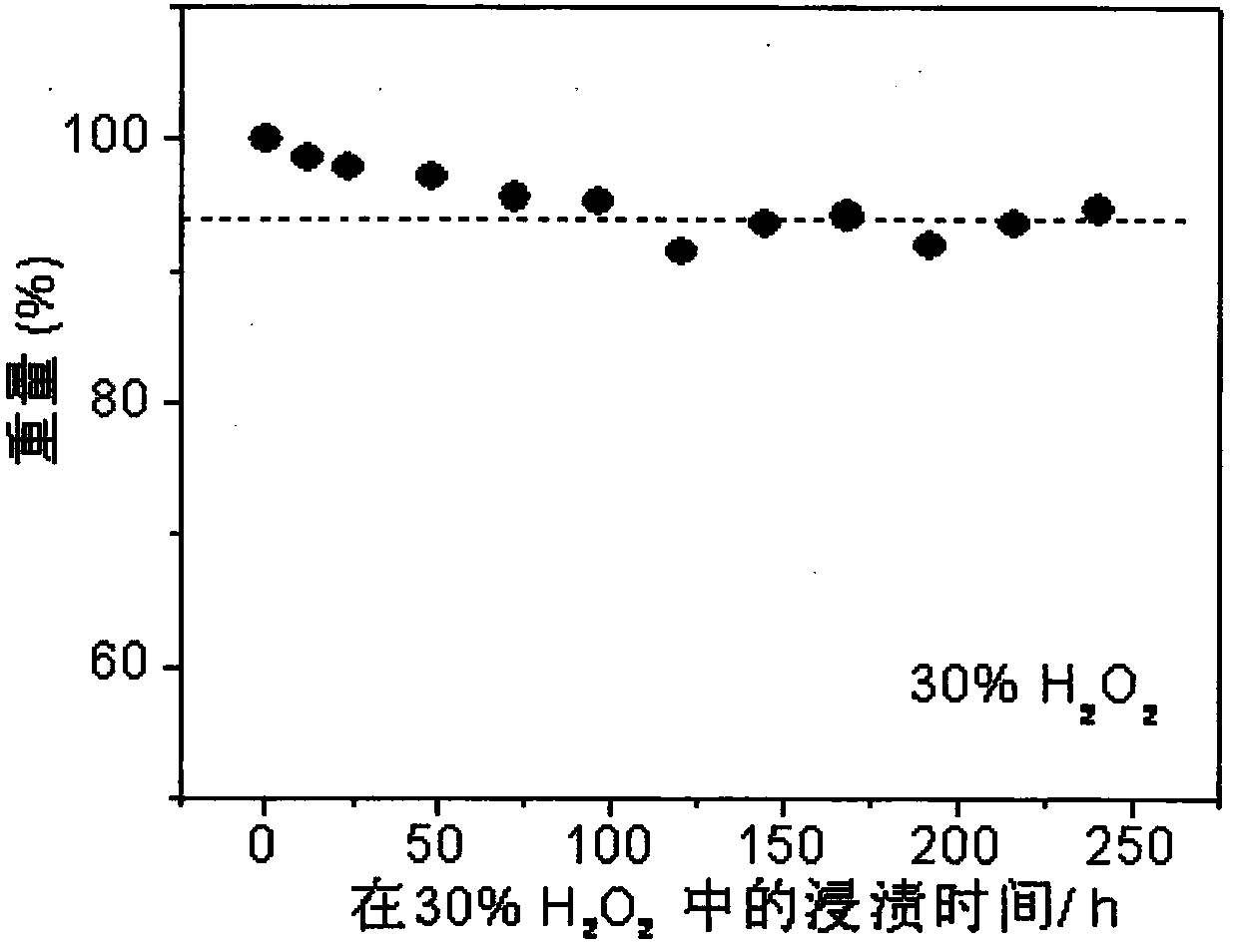

[0029] 30g of oxygen-containing water-soluble PVA powder (molecular weight: 89000-98000) was dissolved in 300ml of deionized water, heated and stirred at 90°C to a transparent and uniform solution to prepare a 10% PVA stock solution. Press PVA and FC370 mass ratio = 1:1, the above PVA aqueous solution and FC370 (molecular weight: about 400,000) solution is mixed, after stirring into a uniform transparent solution, the mixed solution is cast into a plastic disc, and naturally dried to form a film. The film was naturally peeled off and placed in an oven at 130°C for physical cross-linking for 1 hour, and then immersed in 15mL 10% glutaraldehyde (GA, 25wt%) acetone (≥99.5wt%) solution containing a small amount of HCl at room temperature After carrying out the chemical cross-linking reaction for 1 hour, the membrane was taken out and immersed in deionized water to wash thoroughly. The PVA prepared by the above method / The FC370 membrane was immersed in 2M KOH solution for ion ex...

Embodiment 2

[0032] 30 g of PVA powder (molecular weight: 89000-98000) was dissolved in 300 ml of deionized water, and heated and stirred at 90° C. to a transparent and uniform solution to prepare a 10% PVA stock solution. Press PVA and FC370 mass ratio = 1:1, the above PVA aqueous solution and FC370 (molecular weight: about 400,000) solution is mixed, after stirring into a uniform transparent solution, the mixed solution is cast into a plastic disc, and naturally dried to form a film. The membrane was naturally peeled off and placed in an oven at 150°C for physical cross-linking for 1 hour, and then immersed in 15mL 10% glutaraldehyde (GA, 25wt%) acetone (≥99.5wt%) solution containing a small amount of HCl at room temperature After carrying out the chemical cross-linking reaction for 1 hour, the membrane was taken out and immersed in deionized water to wash thoroughly. The PVA prepared by the above method / The FC370 membrane was immersed in 2M KOH solution for ion exchange for 24 hours ...

Embodiment 3

[0035] 30 g of PVA powder (molecular weight: 89000-98000) was dissolved in 300 ml of deionized water, and heated and stirred at 90° C. to a transparent and uniform solution to prepare a 10% PVA stock solution. Press PVA and FC370 mass ratio = 1:1, the above PVA aqueous solution and FC370 (molecular weight: about 400,000) solution is mixed, after stirring into a uniform transparent solution, the mixed solution is cast into a plastic disc, and naturally dried to form a film. The film was peeled off and placed in an oven at 170℃ for physical cross-linking for 1 hour, and then the film was immersed in 15mL 10% glutaraldehyde (GA, 25wt%) acetone (≥99.5wt%) solution containing a small amount of HCl at room temperature After the chemical cross-linking reaction was carried out for 1 hour, the membrane was taken out and immersed in deionized water for full washing. The PVA prepared by the above method / The FC370 membrane was immersed in 2M KOH solution for ion exchange for 24 hours a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com