Flexible strain sensor based on carbon nano-tubes and preparation method thereof

A technology of strain sensor and carbon nanotubes, applied in nanotechnology for sensing, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of strain sensor, low detection range, and low resolution and other problems, to achieve the effect of improving sensitivity, improving measurement range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

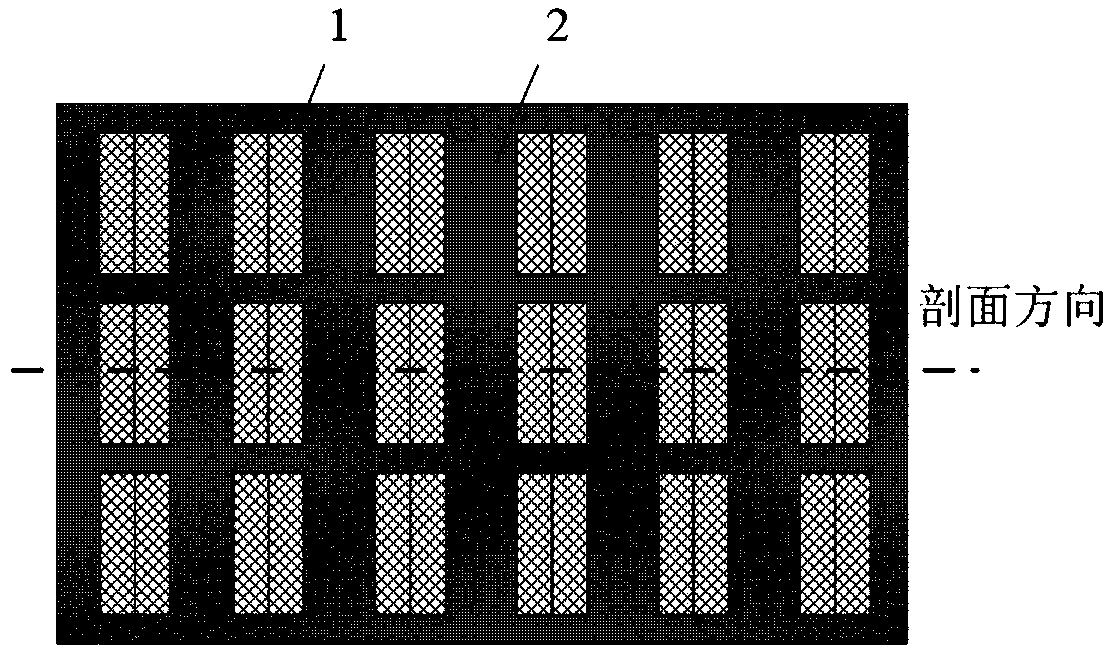

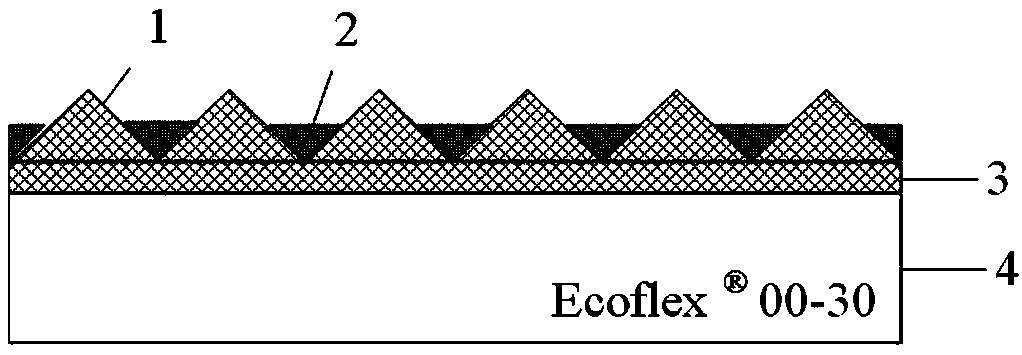

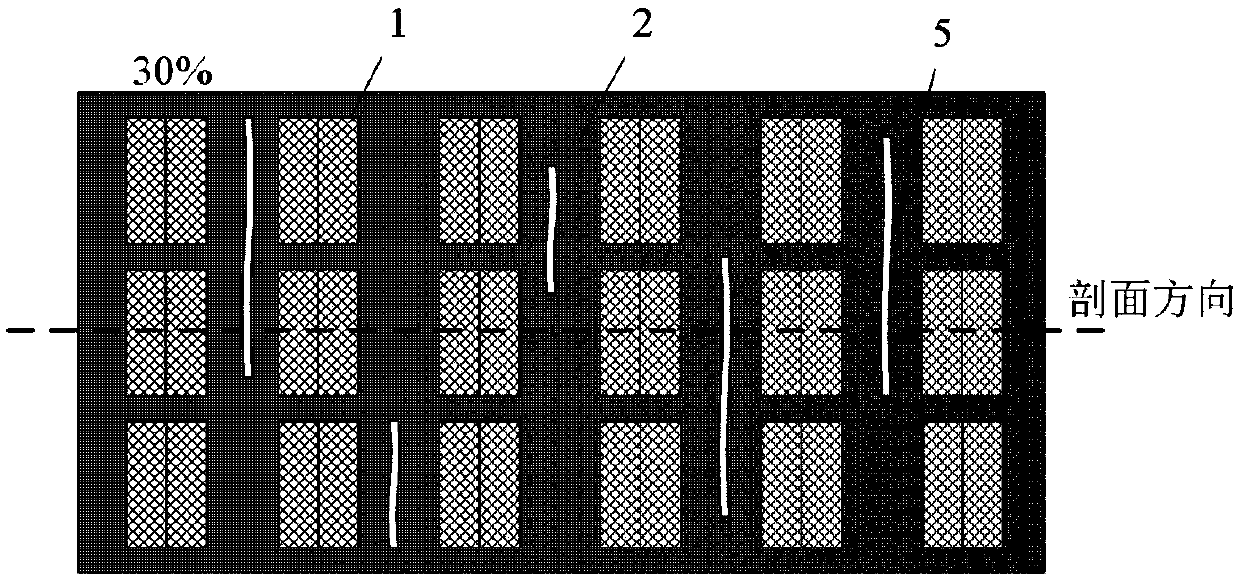

[0024] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a flexible strain sensor based on carbon nanotubes, including an epoxy resin layer 4 , a composite layer 3 and a multi-walled carbon nanotube layer 2 . The composite layer 3 is laid on the upper surface of the epoxy resin layer 4, and the composite layer 3 has protrusions 1 distributed in an array. The multi-walled carbon nanotube layer 2 is laid between the protrusions 1 and connects adjacent protrusions 1 . Wherein the composite layer 3 is made of epoxy resin multi-walled carbon nanotube composite material.

[0025] The protrusion 1 can be in the shape of a triangular prism, a triangular pyramid, a quadrangular pyramid or a hemisphere, etc. The lower parts of adjacent protrusions are connected, and a valley region is formed between the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com