Novel photo-irradiation induced self-repairing precious metal nano composite hydrogel and preparation method thereof

A photothermal-induced, nanocomposite technology, applied in the field of nanomaterials, can solve the problems of no nanocomposite hydrogel bonding, high repair time and repair efficiency, and achieve good anti-notch sensitivity performance, good self-healing performance, good stretchability performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1. Novel photothermally induced self-healing noble metal nanocomposite hydrogel.

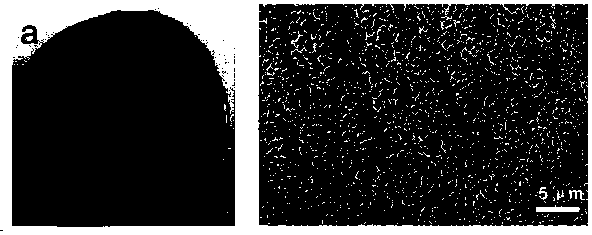

[0031] The novel photothermally induced self-healing noble metal nanocomposite hydrogel of this embodiment uses the dynamic noble metal-sulfur coordination bond as the self-healing main body, and has a uniform network structure, that is, the homogeneous polymerization reaction of monomers occurs during the polymerization process. So that the hydrogel has good stretchability and strength, its mechanical strength can reach MPa level, and its tensile strain can reach more than 20 times; it has good anti-notch sensitivity performance, that is, there is a gap on the surface of the hydrogel Or cracks, it still has good tensile properties, showing unique anti-notch sensitivity; it uses the dynamic coordination bonds between noble metals and sulfur and the good photothermal properties of noble metals, and shows good performance under the stimulation of 808 nm infrared laser self-healing p...

Embodiment 2

[0032] Example 2. Preparation of noble metal nanomaterial dispersion.

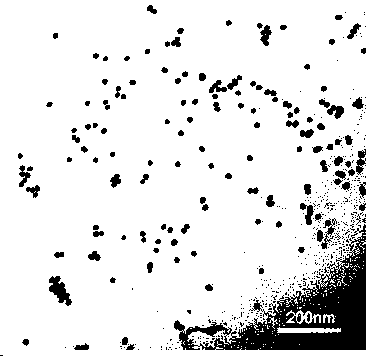

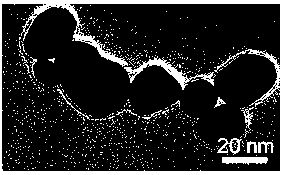

[0033] There are three trial forms of noble metal nanomaterial dispersions: zero-dimensional noble metal nanoparticle morphology dispersion, one-dimensional noble metal nanowire morphology dispersion or two-dimensional noble metal nanosheet morphology dispersion.

[0034] (1) Preparation of noble metal nanoparticle dispersion: Prepare solution 1: 0.3 mmol / L chloroauric acid aqueous solution and solution 2: 40 mmol / L trisodium citrate aqueous solution respectively, then take 50 mL of solution 1 and heat to boiling, then take 1 mL Solution 2 was added to solution 1 to keep boiling for 5 minutes, and after natural cooling, it was centrifuged and washed with distilled water and alcohol for 3 times to obtain the precious metal nanoparticle dispersion;

[0035] (2) Preparation of noble metal nanowire dispersion: Take 0.1 g of chloroauric acid and 10 mL of oleylamine in 1 mL of n-hexane and mix them uniformly in 1 ...

Embodiment 3

[0037] Embodiment 3. Modification of noble metal nanomaterials.

[0038] Weigh 0.02% of the total mass of the noble metal nanomaterial dispersion (using the particle shape dispersion) as a functional modifier and add it to the noble metal nanomaterial dispersion, fully stir and ultrasonically mix for 20 minutes to obtain surface functionalized noble metal nanomaterials; Among them, the functional modifier adopts water-soluble thiolate organic small molecules, and the small molecular structure contains polymerizable carbon-carbon double bonds, such as allyl thiol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com