Biodegradable antibacterial plastic

An antibacterial plastic, biodegradable technology, applied in the field of antibacterial plastic, to achieve good antibacterial effect, good tensile properties, and good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

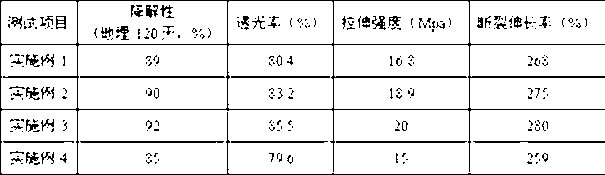

Examples

Embodiment 1

[0010] 60 parts of polyethersulfone resin

[0011] Modified resin 10 parts

[0012] Starch 20 parts

[0013] Silane coupling agent 1 part

[0014] 1 part antiseptic

[0015] Compatibilizer 5 parts

[0016] 1 part glycerin

[0017] Degradation Accelerator 2 parts

[0018] Carbon black 1 part

[0019] Montan wax 0.1 parts

[0020] The raw materials are weighed according to the above parts by weight, placed in a disperser and mixed uniformly to obtain a mixed material, and then the obtained mixed material is extruded and granulated by a granulator to obtain a biodegradable antibacterial plastic.

Embodiment 2

[0022] 65 parts of polyethersulfone resin

[0023] Modified resin 15 parts

[0024] Starch 25 parts

[0025] Silane coupling agent 2 parts

[0026] Antibacterial agent 3 parts

[0027] Compatibilizer 5 parts

[0028] 1 part glycerin

[0029] Degradation Accelerator 3 parts

[0030] Carbon black 1 part

[0031] 0.2 parts of montan wax

[0032] The raw materials are weighed according to the above parts by weight, placed in a disperser and mixed uniformly to obtain a mixed material, and then the obtained mixed material is extruded and granulated by a granulator to obtain a biodegradable antibacterial plastic.

Embodiment 3

[0034] 68 parts of polyethersulfone resin

[0035] Modified resin 18 parts

[0036] Starch 30 parts

[0037] Silane coupling agent 2 parts

[0038] Antibacterial agent 4 parts

[0039] Compatibilizer 8 parts

[0040] 2 parts glycerin

[0041] Degradation Accelerator 3 parts

[0042] 2 parts carbon black

[0043] 0.4 parts of montan wax

[0044] The raw materials are weighed according to the above parts by weight, placed in a disperser and mixed uniformly to obtain a mixed material, and then the obtained mixed material is extruded and granulated by a granulator to obtain a biodegradable antibacterial plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com