A method for semi-free molding of translucent yag luminescent thin ceramics

A translucent and ceramic technology, applied in the direction of lasers, semiconductor devices, phonon exciters, etc., can solve the problem of ceramic luminous efficiency, unsatisfactory transmittance, easy to form powdery shape, and difficult to control product shape and other problems, to achieve the effect of large market promotion and application prospects, good product appearance, simple and feasible production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of translucent YAG spherical luminous ceramics

[0027] Preparation of the adhesive: Mix 1000g of styrene-acrylic emulsion and 800g of vinyl emulsion, and stir evenly to obtain the product.

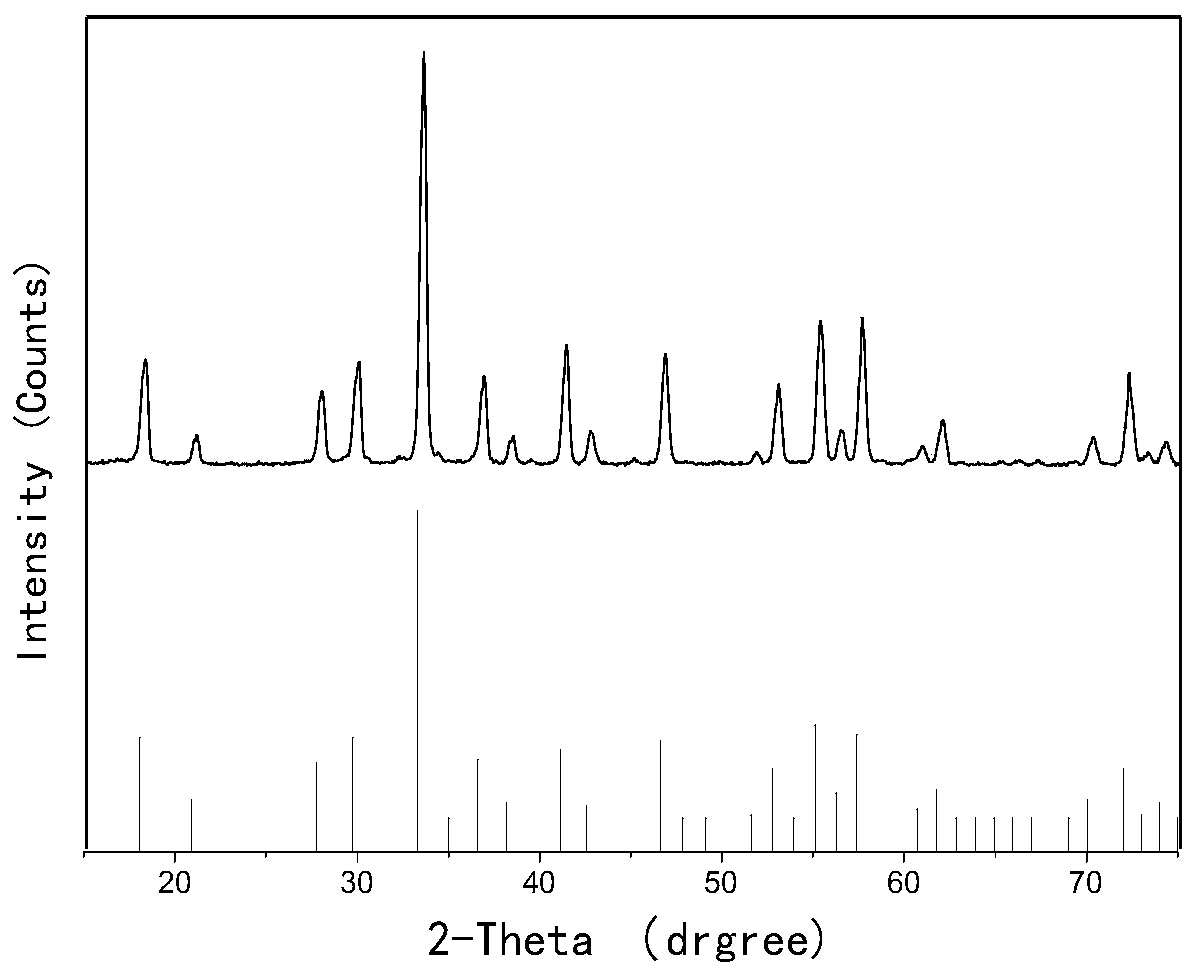

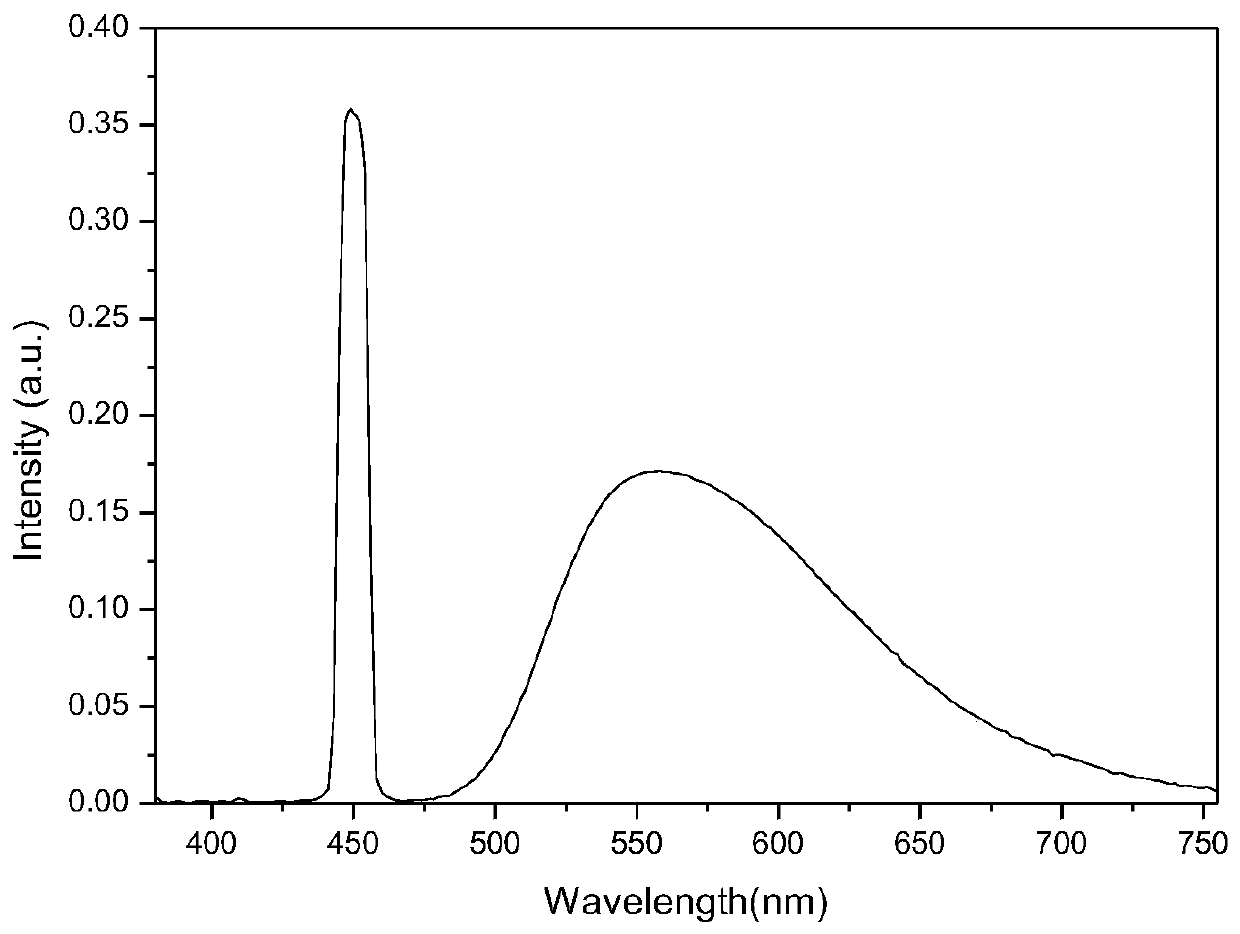

[0028] Preparation of YAG phosphor: take yttrium oxide Y 2 o 3 , alumina Al 2 o 3 , CeO 2 Feed materials at a molar ratio of 3:5:0.06, grind and mix evenly, and then use a high-temperature solid-phase method to sinter in a reducing atmosphere at 1600°C to obtain YAG phosphors. The reducing atmosphere is a volume ratio of H 2 :N 2 =10:90;

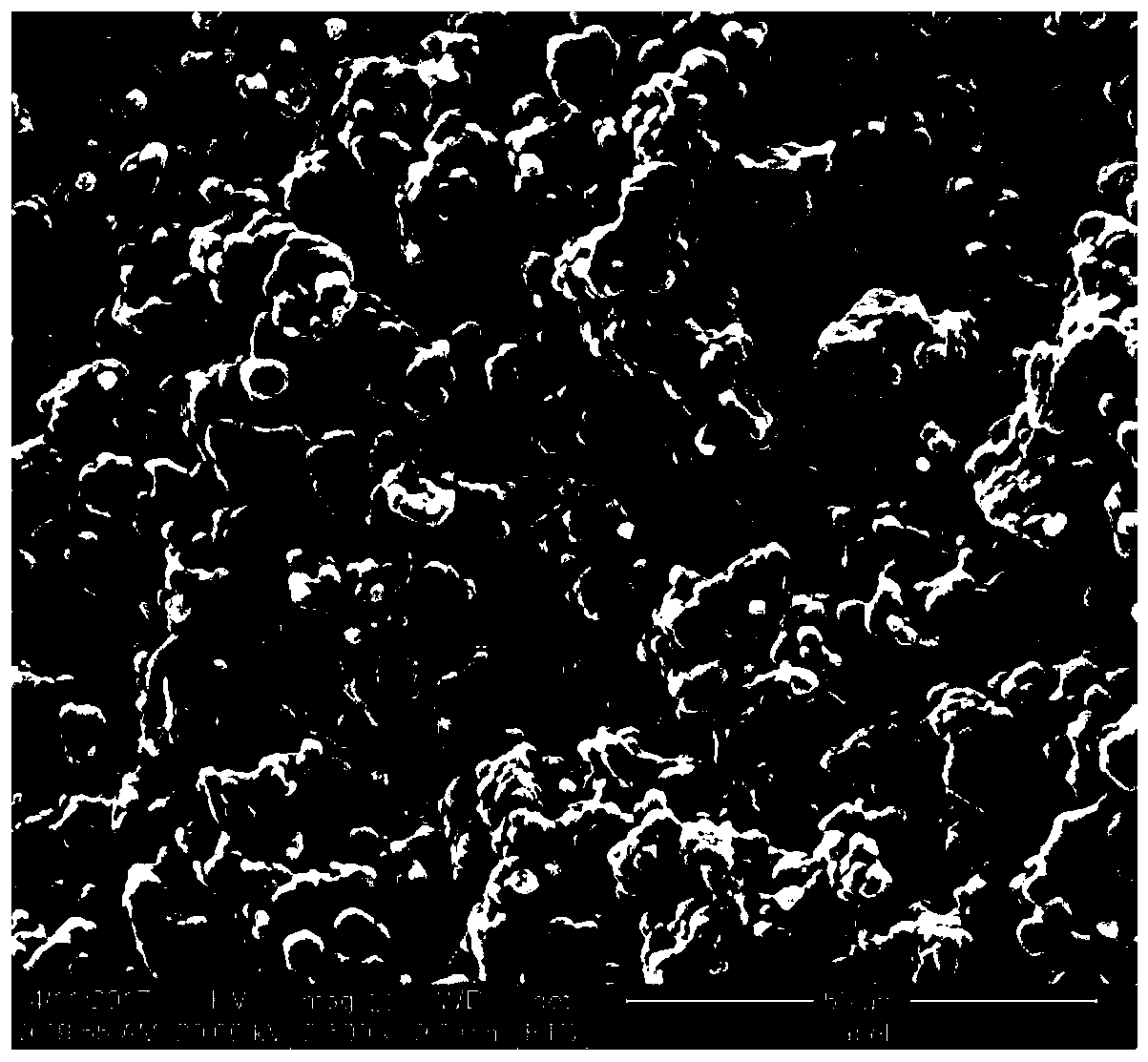

[0029]Preparation of the bisque: Take the YAG phosphor prepared in the above steps, add the binder to grind and mix evenly at a temperature of 20°C, put it in a vacuum box for degassing, set the vacuum degree to -0.008Mpa, and vacuum for 3 minutes , take it out, cast it on a spherical plastic mold whose surface is covered with a thin layer of wax oil in advance, and then place it in a vacuum box for degassing, air-dr...

Embodiment 2

[0031] Example 2: Preparation of translucent YAG spherical luminous ceramics

[0032] Preparation of the adhesive: Mix 1000g of styrene-acrylic emulsion and 1200g of vinyl emulsion, stir evenly, and obtain the product.

[0033] Preparation of YAG phosphor: take yttrium oxide Y 2 o 3 , alumina Al 2 o 3 , CeO 2 Feed materials at a molar ratio of 3:5:0.06, grind and mix evenly, and then use a high-temperature solid-phase method to sinter in a reducing atmosphere at 1600°C to obtain YAG phosphors. The reducing atmosphere is a volume ratio of H 2 :N 2 =10:90;

[0034] Preparation of the bisque: Take the YAG phosphor prepared in the above steps, add the binder and grind it evenly at a temperature of 25°C, put it in a vacuum box for degassing, set the vacuum degree to -0.01Mpa, and vacuum for 5 minutes , take it out, cast it on a spherical plastic mold whose surface is covered with a thin layer of wax oil in advance, and then place it in a vacuum box for degassing, air-drying,...

Embodiment 3

[0036] Example 3: Preparation of translucent YAG spherical luminous ceramics

[0037] Preparation of the adhesive: Take 1000g of styrene-acrylic emulsion and 1000g of vinyl emulsion, mix them, and stir them evenly.

[0038] Preparation of YAG phosphor: take yttrium oxide Y 2 o 3 , alumina Al 2 o 3 , CeO 2 Feed materials at a molar ratio of 3:5:0.06, grind and mix evenly, and then use a high-temperature solid-phase method to sinter in a reducing atmosphere at 1600°C to obtain YAG phosphors. The reducing atmosphere is a volume ratio of H 2 :N 2 =10:90;

[0039] Preparation of the bisque: Take the YAG phosphor prepared in the above steps, add the binder to grind and mix evenly at a temperature of 23°C, put it in a vacuum box for degassing, set the vacuum degree to -0.006Mpa, and vacuum for 5 minutes , take it out, cast it on a spherical plastic mold whose surface is covered with a thin layer of wax oil in advance, and then place it in a vacuum box for degassing, air-drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ll | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com