Side-entry light guide plate, and preparation and application thereof

A light guide plate and side-entry technology, which is applied in the field of side-entry light guide plate and its preparation and application, can solve the problem of poor transmittance luminance of the light-emitting surface, light refraction of the light guide plate, low reflection uniformity, and influence on the quality control of liquid crystal display and other issues, to achieve the effect of improving light reflection and refraction, good collection effect, and excellent internal reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

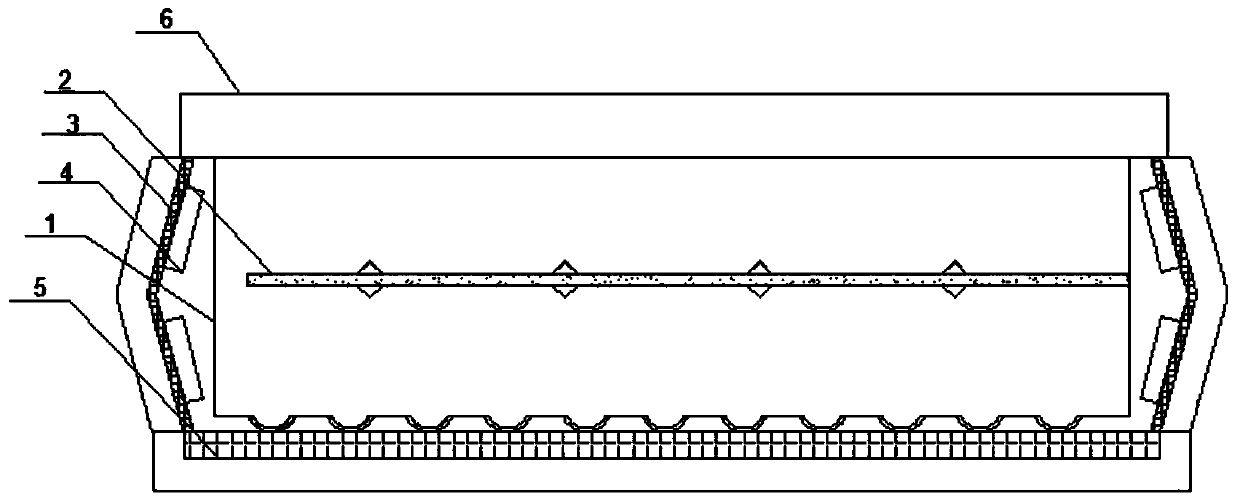

[0030] A side-entry light guide plate. There is a light-transmitting plate inside the light-guide plate. One side of the light-transmitting plate is fixedly connected to the inner wall of the light-transmitting plate (molded integrally during injection). Eight reflective strips are arranged symmetrically on the top and bottom of the light-transmitting plate. There are 4 upper and lower ones. There are several strip grooves on the bottom surface of the light guide plate, and several dots are distributed on the upper and lower surfaces of the light-transmitting plate ( figure 1 ).

[0031] Among them, the light guide plate and the light-transmitting plate are formed by injection molding, the light-guiding plate is made of PMMA material, the light-transmitting plate is made of PC material, and the light transmittance of the light-transmitting plate is 94.7%. The longitudinal section of the bar-shaped groove is set in a "U" shape, and the bar-shaped groove is also densely covered ...

Embodiment 2

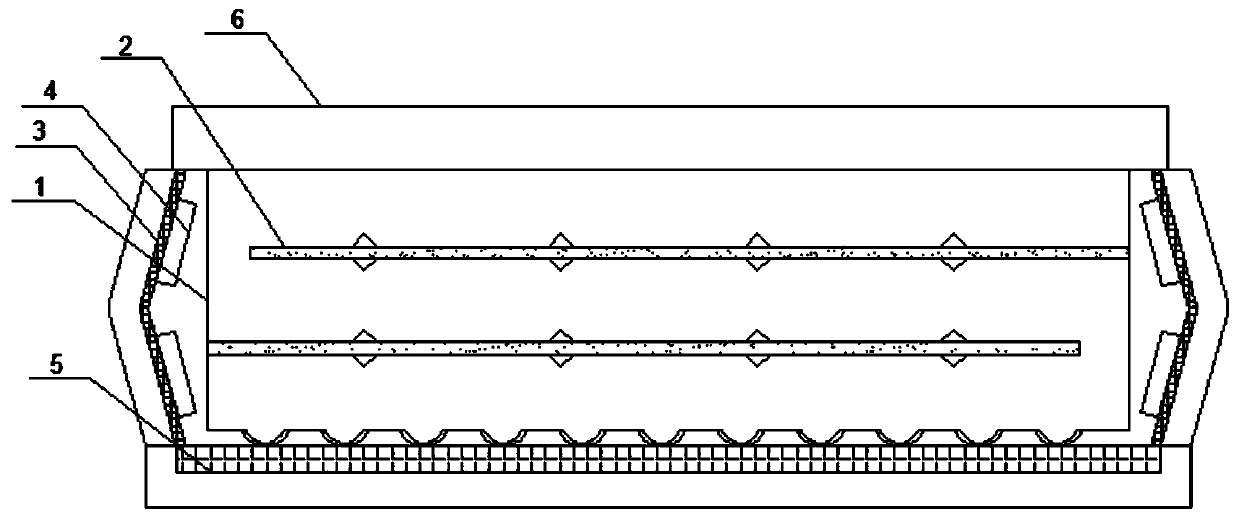

[0034] A side-entry light guide plate. There are two light-transmitting plates inside the light-guide plate. One side of the light-transmitting plate is fixedly connected to the inner wall of the light-transmitting plate (integrated molding during injection). Each light-transmitting plate is symmetrically equipped with eight light-reflecting plates. Strips, 4 upper and lower sides, a number of bar-shaped grooves are provided on the bottom surface of the light guide plate, and a number of dots are distributed on the upper and lower surfaces of the light-transmitting plate ( figure 2 ).

[0035] Among them, the light guide plate and the light-transmitting plate are formed by injection molding, the light-guiding plate is made of PMMA material, the light-transmitting plate is made of PC material, and the light transmittance of the light-transmitting plate is 94.3%. The longitudinal section of the bar-shaped groove is set in a "U" shape, and the bar-shaped groove is also densely c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com