Exposed welding leg of chip packaging body and processing method of exposed welding leg

A technology of chip packaging and processing methods, which is applied in the manufacture of semiconductor devices, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of not being able to observe solder piles, tin out observations are not obvious, and connections are not in conformity, etc., so as to facilitate observation , to avoid oxidation, to avoid the effect of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The directional terms mentioned in the present invention, such as: up, down, left, right, front, rear, inside, outside, front, back, side, etc., are only the directions with reference to the accompanying drawings, and the following implementations are described with reference to the accompanying drawings. The manners and the directional terms used are exemplary and are only used to explain the present invention and should not be construed as limiting the present invention. In addition, various specific process and material examples are provided herein, and those of ordinary skill in the art will recognize the application of other processes and / or the use of other materials.

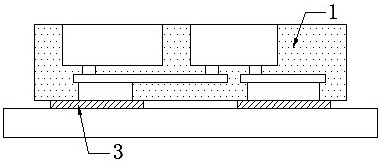

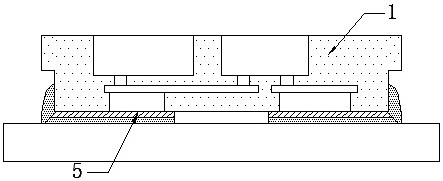

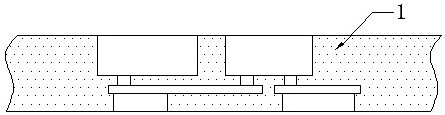

[0030] In order to better understand the purpose, structure and function of the present invention, the following is in conjunction with the appendix Figure 1-8 , a chip package body exposed solder fillet and its processing method proposed by the present invention will be further described in detai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com