Drum type cullet cleaning system

A cleaning system and drum-type technology, applied in the field of drum-type broken glass cleaning system, can solve the problems of waste of resources, easy adhesion of materials in the drum, low cleaning efficiency, etc., so as to reduce the use of materials, avoid adhesion and accumulation, and prolong the promotion effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

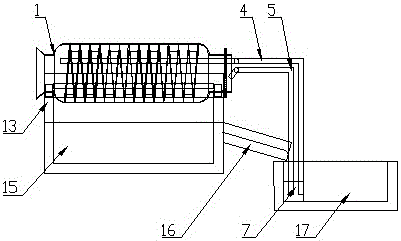

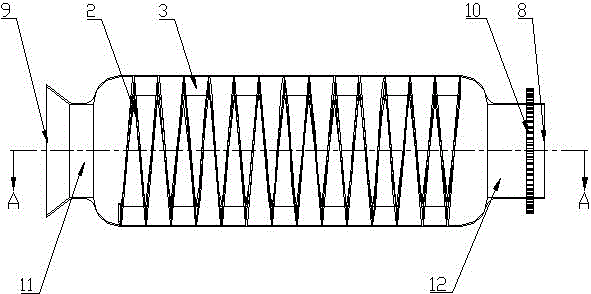

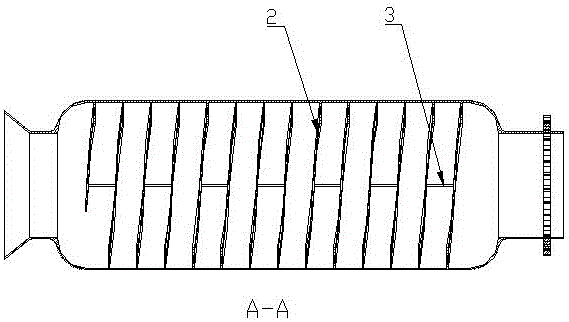

[0018] Such as Figure 1 to Figure 7 As shown, the drum-type cullet cleaning system of the present invention includes a drum 1, an internal screw propulsion device 2, a material lifting plate 3, a high-pressure circulating water spray pipe I4, a high-pressure circulating water spray pipe II5, several spray ports 6, and a water pump 7. Material inlet 8, material outlet 9, ring gear 10, ring track Ⅰ11, ring track Ⅱ12, roller support 13, roller 14, water collection tank 15, diversion tank 16, sedimentation overflow pool 17, sedimentation overflow Impurity area 18 of flow pool, clear water area 19 of sedimentation overflow pool.

[0019] The drum 1 is a cylindrical structure with a certain thickness and open ends. The drum 1 is placed horizontally and the inner wall of the drum 1 is welded with an inner screw propulsion device 2, and a material lifting plate 3 is arranged on the inner screw propulsion device 2. The drum 1 1 is a cylindrical sieve with small holes on the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com