A kind of glass fiber ball bundle and preparation method thereof

The technology of glass fiber and ball bundle is applied in the field of glass fiber ball bundle and its preparation, which can solve the problems of human harm, easy generation of dust, entering the respiratory tract and eyes, etc., and achieves the effect of cost saving and application expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The waste printed circuit boards are crushed and sorted to collect non-metallic powder. Take 100g of non-metallic powder and add it to 300mL6mol / L nitric acid solution, heat at 85°C for 20 hours, filter, extract the filtrate with ethylene glycol ether, and wash the solid with ethylene glycol ether to obtain glass fiber powder; combine the ethylene glycol ether extraction Liquid and washing liquid, distill off ethylene glycol ethyl ether with rotary evaporator, obtain recovery epoxy resin.

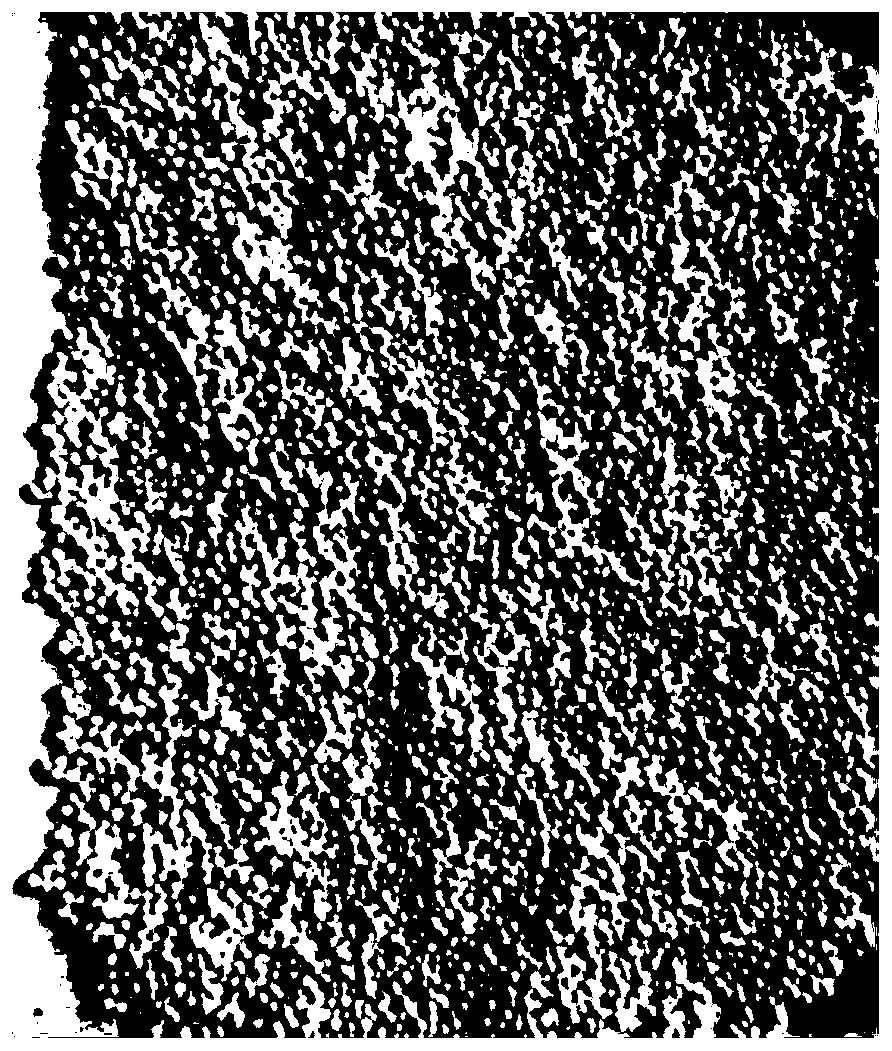

[0032] Take 50g of glass fiber powder, reclaim 1g of epoxy resin, add it to 200mL of 6% (by weight) ethanol solution of diethylenetriamine, heat at 50°C for 7 hours, filter to obtain glass fiber ball bundles, and then glass The fiber ball bundles were added to 150mL of ethanol, heated at 40°C for 5 hours, filtered, and dried to obtain the following: figure 1 Fiberglass bundles shown.

Embodiment 2

[0034] The waste printed circuit boards are crushed and sorted to collect non-metallic powder. Take 130g of non-metallic powder and add it to 910mL of 8mol / L nitric acid and phosphoric acid solution (3:1 by volume), heat at 80°C for 10 hours, filter, extract the filtrate with ethyl acetate, and wash the solid with ethyl acetate to obtain glass fiber powder ; Combine the ethyl acetate extract and the washing solution, and evaporate the ethyl acetate with a rotary evaporator to obtain an epoxy resin recovery.

[0035] Take 50g of glass fiber powder, reclaim 3g of epoxy resin, add it to 230mL of 9% (by weight) propanol solution of hexamethylenediamine, heat at 60°C for 6 hours, filter to obtain glass fiber ball bundles, and then glass The fiber ball bundles were added to 150mL of 4M nitric acid, heated at 50°C for 3 hours, filtered and dried.

Embodiment 3

[0037] The waste printed circuit boards are crushed and sorted to collect non-metallic powder. Take 120g of non-metallic powder and add it to 720mL of 6mol / L nitric acid and sulfuric acid solution (4:1 by volume), heat at 83°C for 12 hours, filter, extract the filtrate with butyl acetate, and wash the solid with butyl acetate to obtain glass fiber powder ; Merge the butyl acetate extract and the washing solution, and evaporate the butyl acetate with a rotary evaporator to obtain an epoxy resin recovery.

[0038] Take 50g of glass fiber powder, reclaim 0.5g of epoxy resin, add it to 200mL of 15% (by weight) methanol solution of ethylenediamine, heat at 60°C for 6 hours, filter to obtain glass fiber ball bundles, and then The fiber ball bundles were added to 150mL of 4M nitric acid and phosphoric acid solution (3:1 by volume), heated at 60°C for 10 hours, filtered and dried.

[0039] In summary, in the present invention, the waste printed circuit board is crushed and sorted and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com