Coal chemical industry pyrolysis and gasification system

A technology of pyrolysis gasification and coal chemical industry, which is applied in the field of coal chemical industry to achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

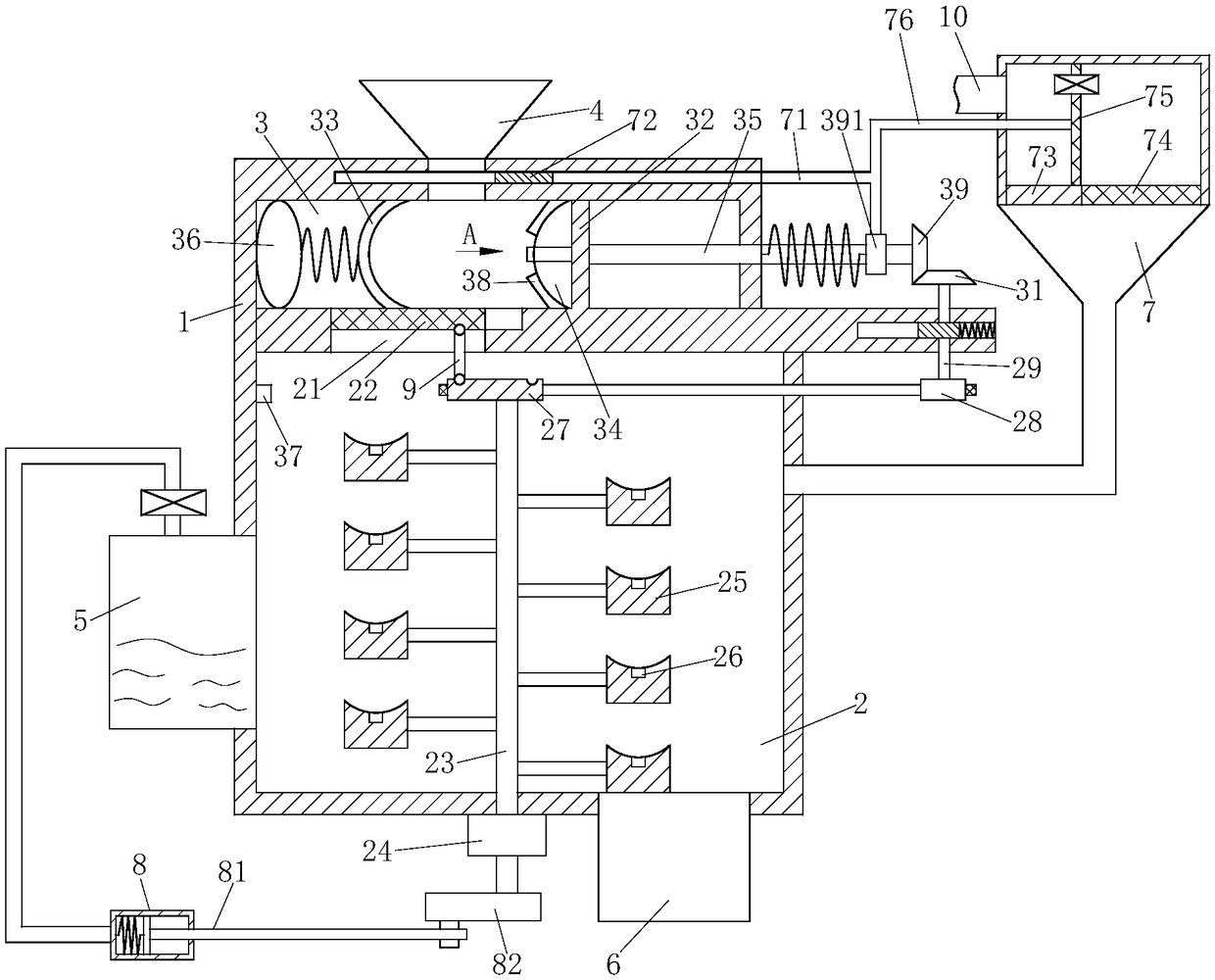

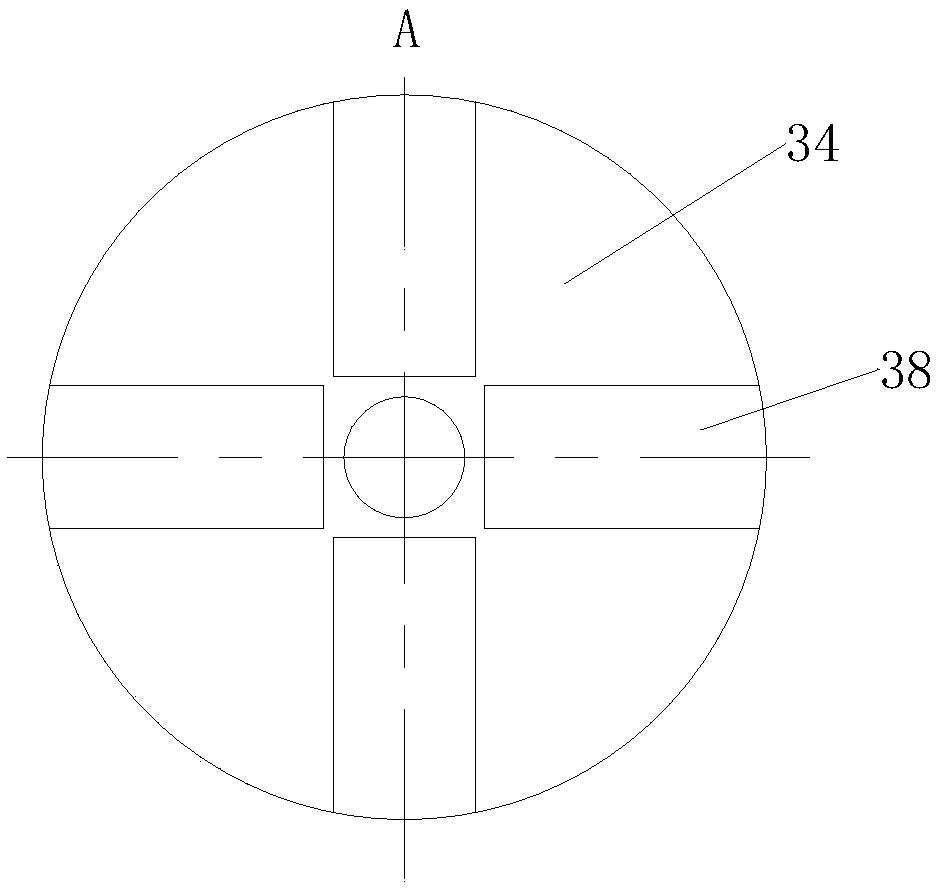

[0022] As an embodiment of the present invention, a mounting block 391 is slidably mounted on one end of the first connecting rod 35, and the mounting block 391 is connected to the side wall of the grinding chamber 3 by a spring; the mounting block 391 is connected to the second connecting rod. One end of the rod 71 is fixedly connected, and the other end of the second connecting rod 71 is hinged to a sealing plate 72, and the sealing plate 72 can be slidably installed under the feed pipe. During work, the open feed pipe 4 will make the coal block enter too much, thereby affecting the grinding effect of the grinding device 32; when the No. 1 connecting rod 35 moves, it will squeeze the mounting block 391, thereby compressing the spring, and by moving the mounting block 391 It is connected with the sealing plate 72 through the No. 2 connecting rod 71. When the mounting block 391 is pressed to one side by the No. 1 connecting rod 35, it can drive the sealing plate 72 to slide in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com