Ultrasonic preparation method of rapeseed protein microcapsule and application of rapeseed protein microcapsule as functional food

A technology of microcapsules and rapeseeds, applied in the fields of application, food ingredients, food science, etc., can solve the problems of low encapsulation efficiency of bioactive components, and achieve long sustained release time, good biocompatibility, and high encapsulation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

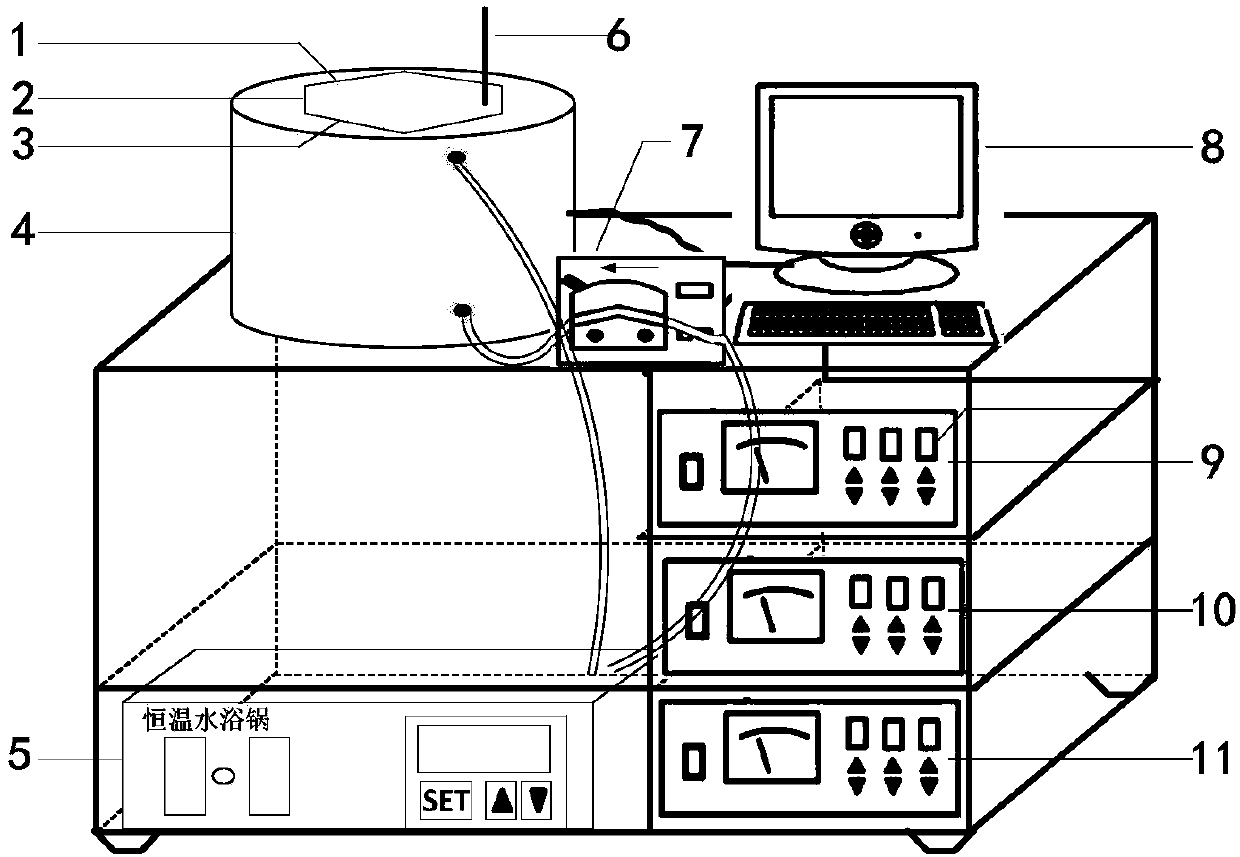

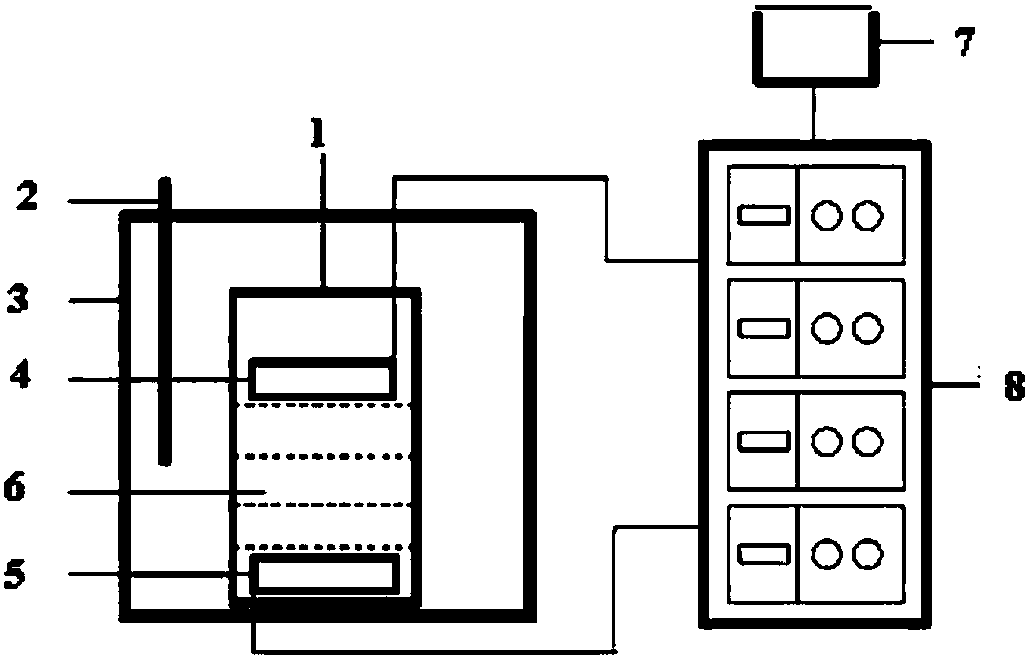

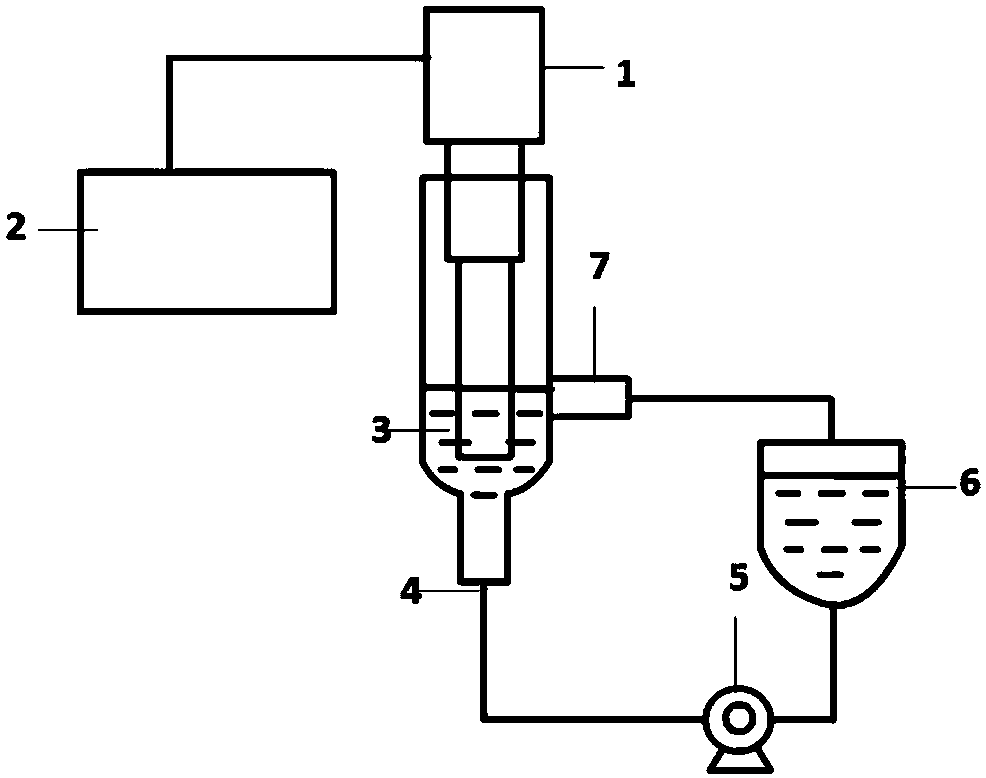

Method used

Image

Examples

Embodiment 1-4

[0054] Embodiment 1-4 (do not add ultrasonic)

[0055] (1) Dissolving rapeseed active protein in distilled water, adjusting pH=12 while magnetically stirring until the protein is completely dissolved; obtaining a solution of rapeseed active protein with a concentration of (10-25) mg / mL;

[0056] (2) The lutein ethanol solution with a concentration of (10-20) mg / mL is quickly injected into the rapeseed active protein solution prepared in step (1), so that the mass ratio of rapeseed active protein and curcumin is shown in Table 1; Adjust the pH=10 of the solution system;

[0057] (3) After standing still for 1 hour, a curcumin-loaded rapeseed active protein microcapsule solution is obtained, which is spray-dried or freeze-dried to obtain curcumin-loaded rapeseed active protein microcapsules.

[0058] (4) Determination of Lutein Encapsulation Rate and Loading Rate

[0059] Take the rapeseed active protein-chitosan composite nanoparticle solution loaded with curcumin, centrifuge...

Embodiment 5-8

[0066] Embodiment 5-8 (add dual-frequency sweeping ultrasonic treatment)

[0067] (1) Dissolving rapeseed active protein in distilled water, adjusting pH=12 while magnetically stirring until the protein is completely dissolved; obtaining a solution with a concentration of rapeseed active protein of 20 mg / mL;

[0068] (2) Rapidly inject the ethanol solution of lutein with a concentration of (10-20) mg / mL into the rapeseed active protein solution prepared in step (1), so that the mass ratio of rapeseed active protein and curcumin is 10:1 ; Adjust the pH=10 of the solution system;

[0069] (3) Under room temperature, the mixed solution obtained in step (2) is subjected to dual-frequency sweep ultrasonic treatment. During the dual-frequency sweep ultrasonic treatment, the distance between the upper and lower plates is fixed to be 10cm, the frequency sweep period is 300s, and the intermittent ratio is 1:1.2 (ultrasonic wave 10s, Intermittent 12s), the power of each vibrating plate...

Embodiment 9-10

[0075] Embodiment 9-10 (add countercurrent ultrasonic treatment)

[0076] (1) Dissolving rapeseed active protein in distilled water, adjusting pH=12 while magnetically stirring until the protein is completely dissolved; obtaining a solution with a concentration of rapeseed active protein of 20 mg / mL;

[0077] (2) Rapidly inject the ethanol solution of lutein with a concentration of (10-20) mg / mL into the rapeseed active protein solution prepared in step (1), so that the mass ratio of rapeseed active protein and curcumin is 10:1 ; Adjust the pH=10 of the solution system;

[0078] (3) Under room temperature, the mixed solution obtained in step (2) is subjected to countercurrent ultrasonic treatment, and the specific ultrasonic parameters are pulse width 1-5s, pulse interval 1-5s, ultrasonic power density 50-80W / L; ultrasonic frequency 20kHz, feed liquid Pass the ultrasound probe in a countercurrent cycle.

[0079] (4) After the ultrasonication, stand still for 1 hour to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com