Patents

Literature

97results about How to "Small step" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Physical simulations on a graphics processor

ActiveUS20080021679A1Fast frame rateAvoid small stepComputation using non-denominational number representationDesign optimisation/simulationGraphicsComputational science

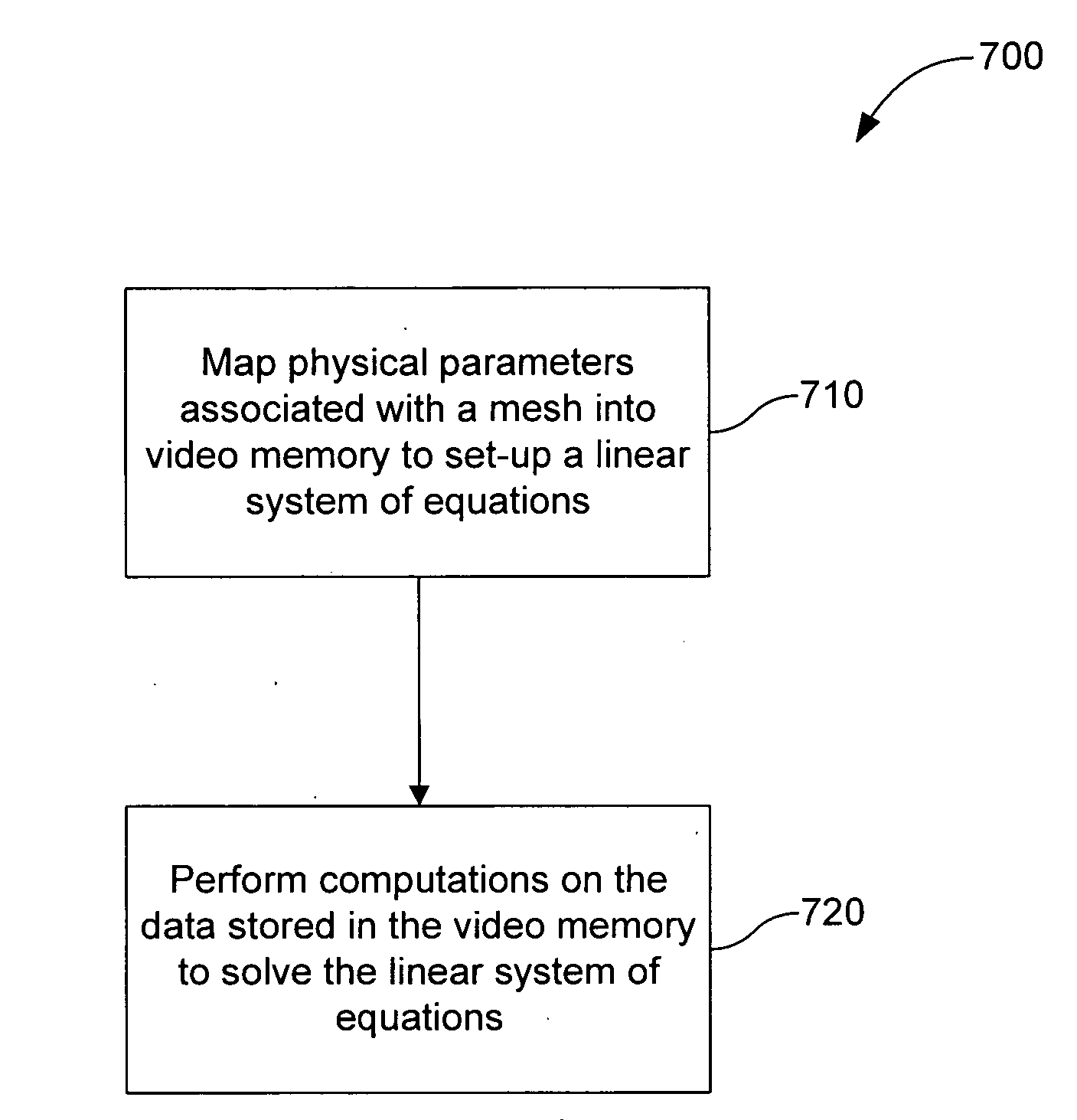

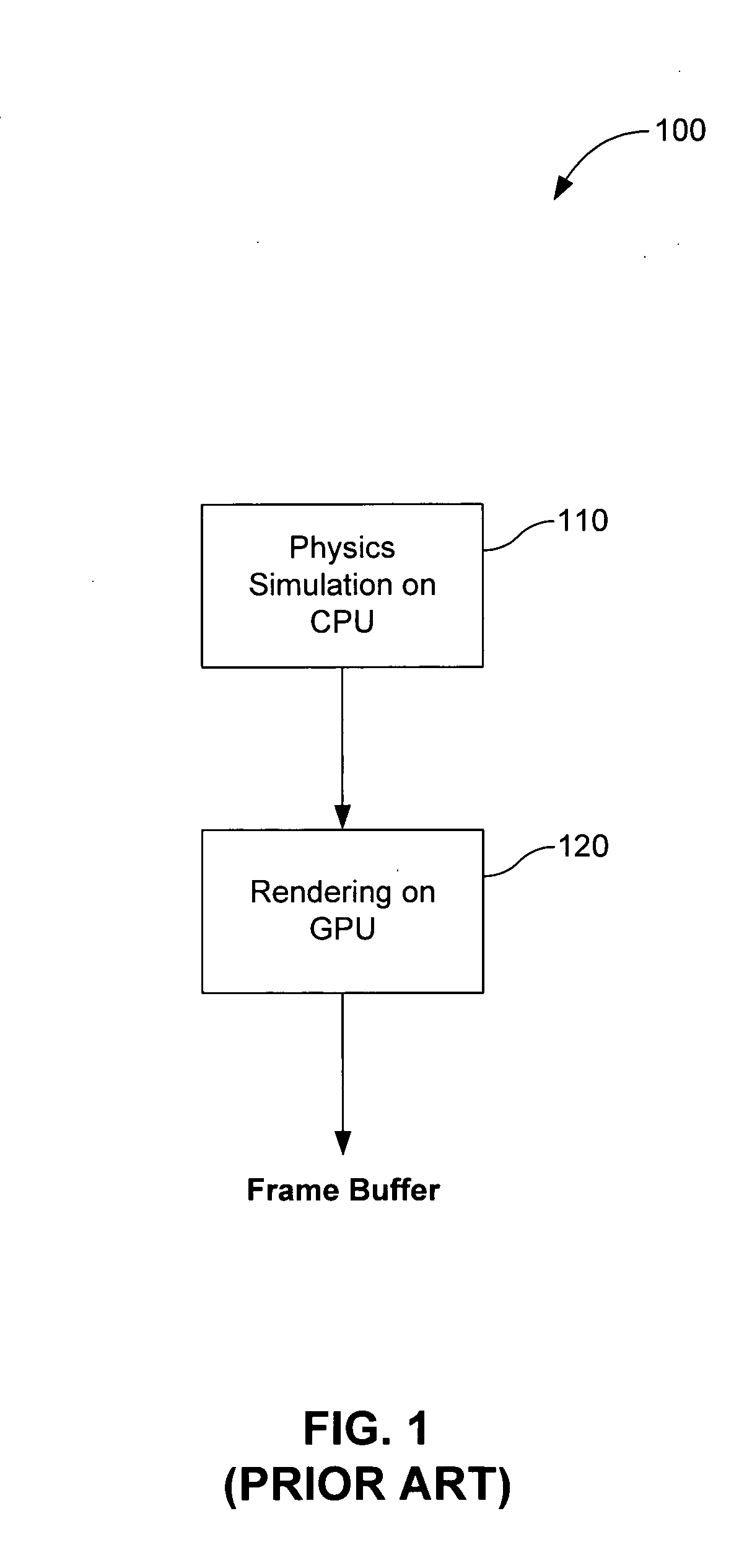

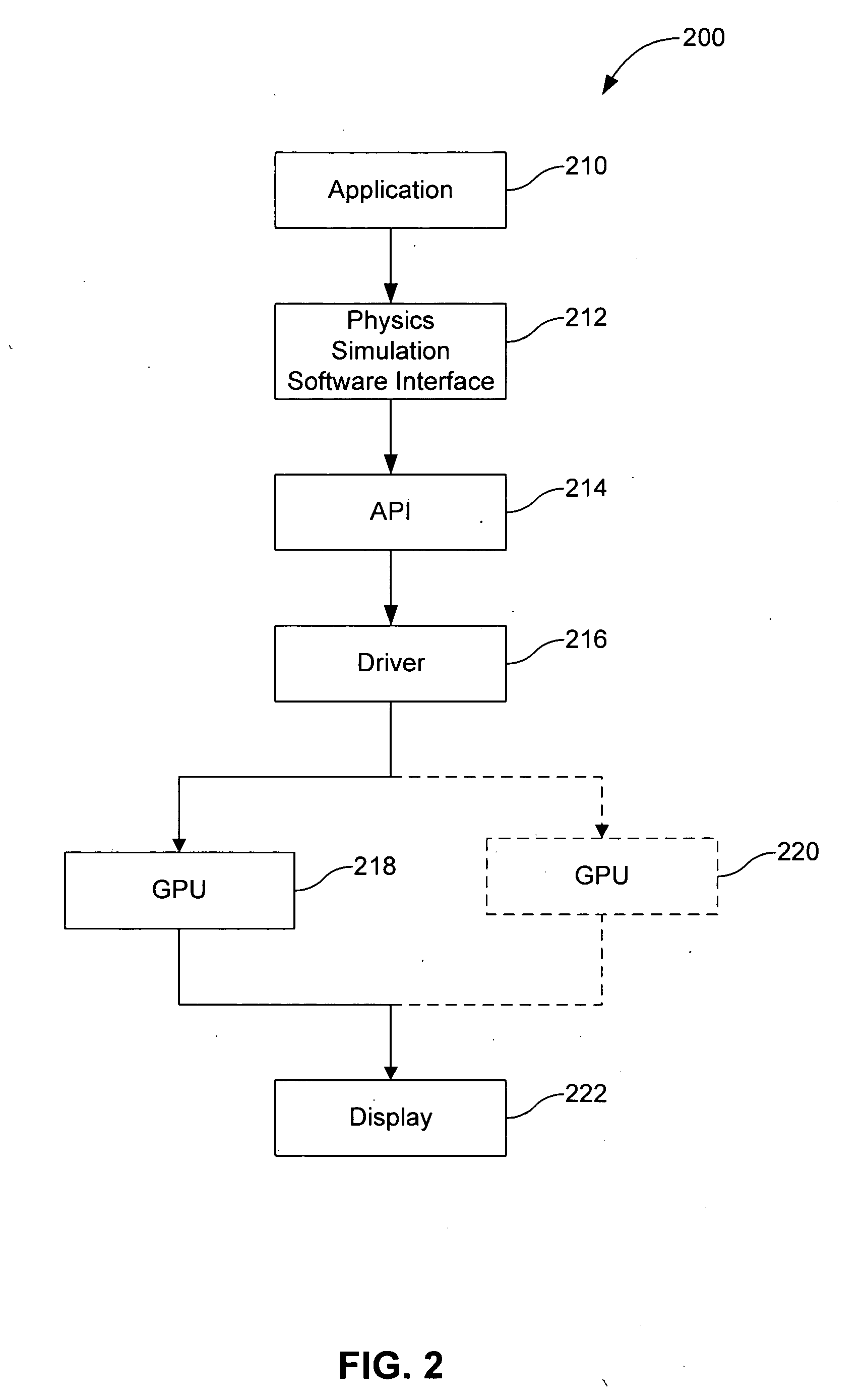

The present invention is directed to a method, computer program product, and system for performing physics simulations on at least one graphics processor unit (GPU). The method includes the following steps. First, data representing physical attributes associated with at least one mesh are mapped into a plurality of memory arrays to set up of a linear system of equations that governs motion of the at least one mesh depicted in a scene. Then, computations are performed on the data in the plurality of memory arrays using at least one pixel processor to solve the linear system of equations for an instant of time, wherein modified data representing the solution to the linear system of equations for the instant of time are stored in the plurality of memory arrays.

Owner:ATI TECH INC

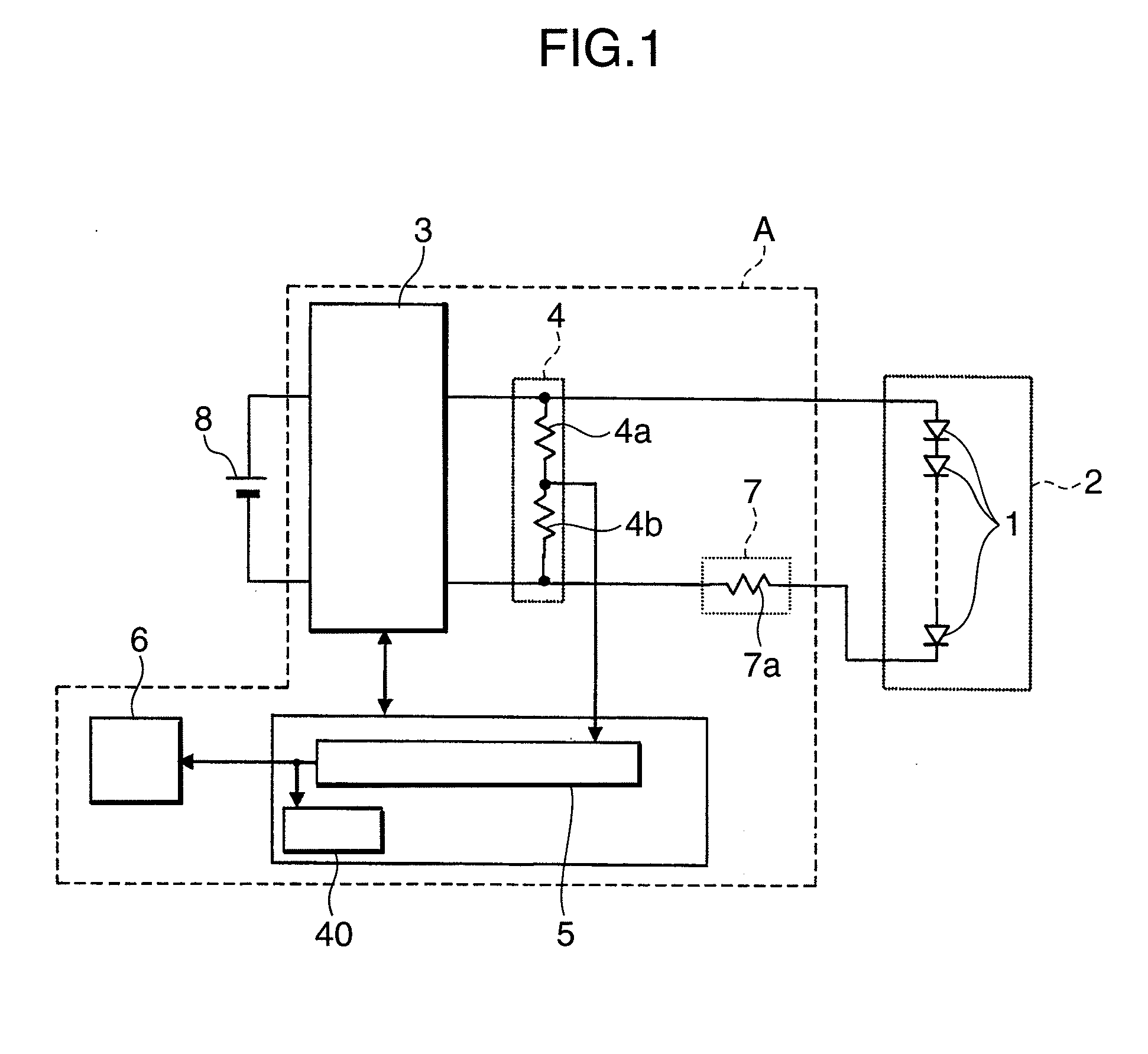

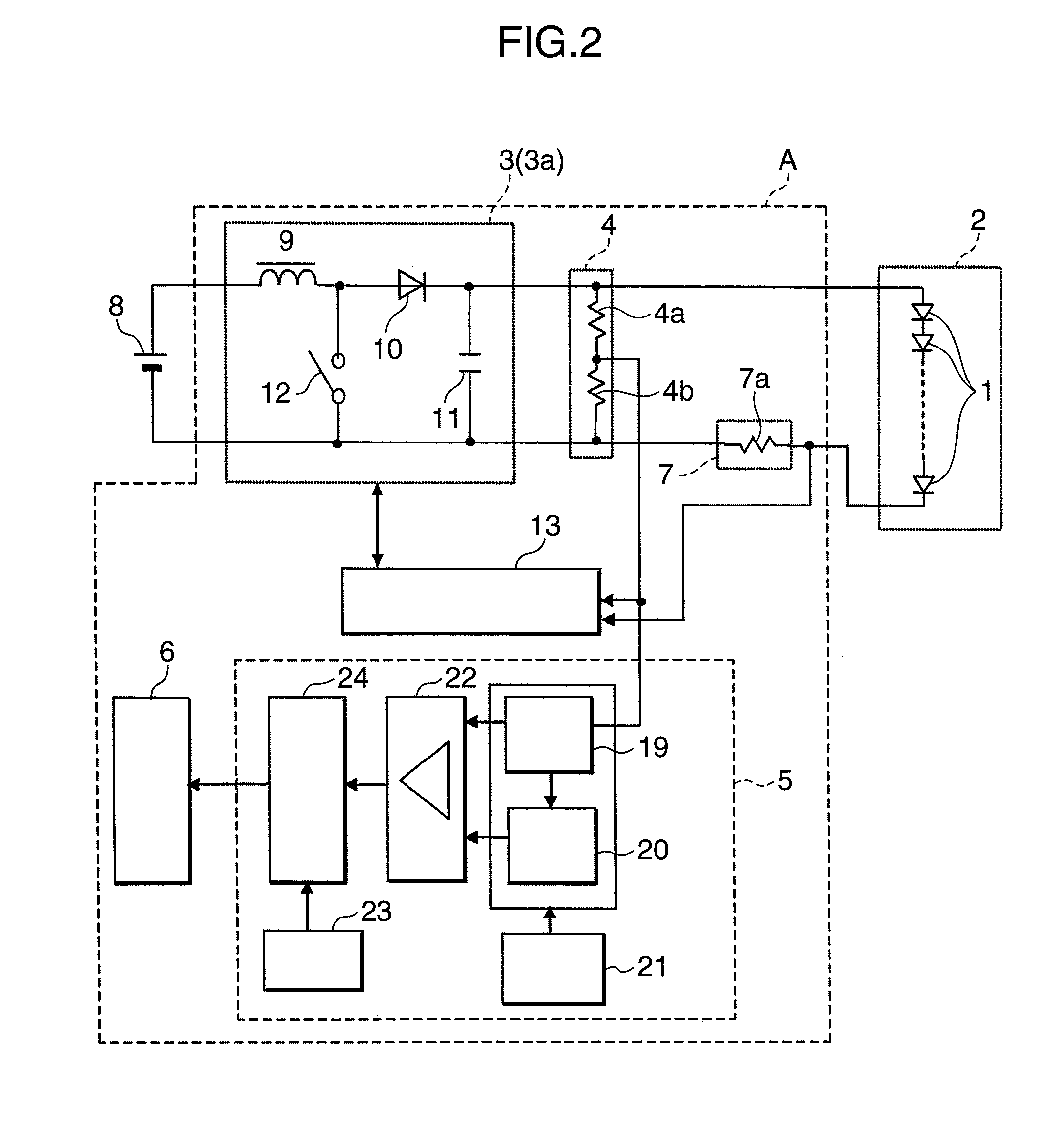

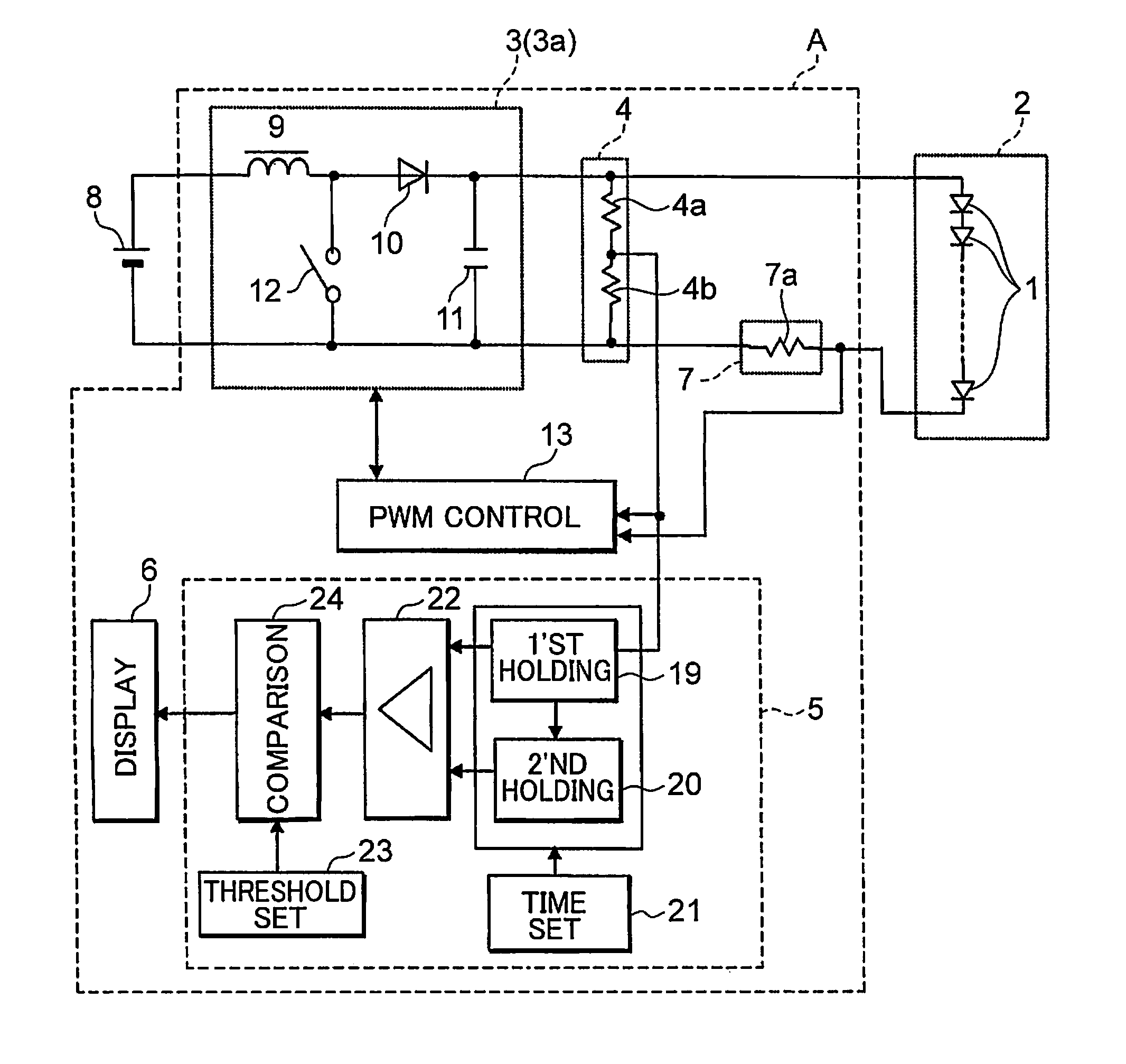

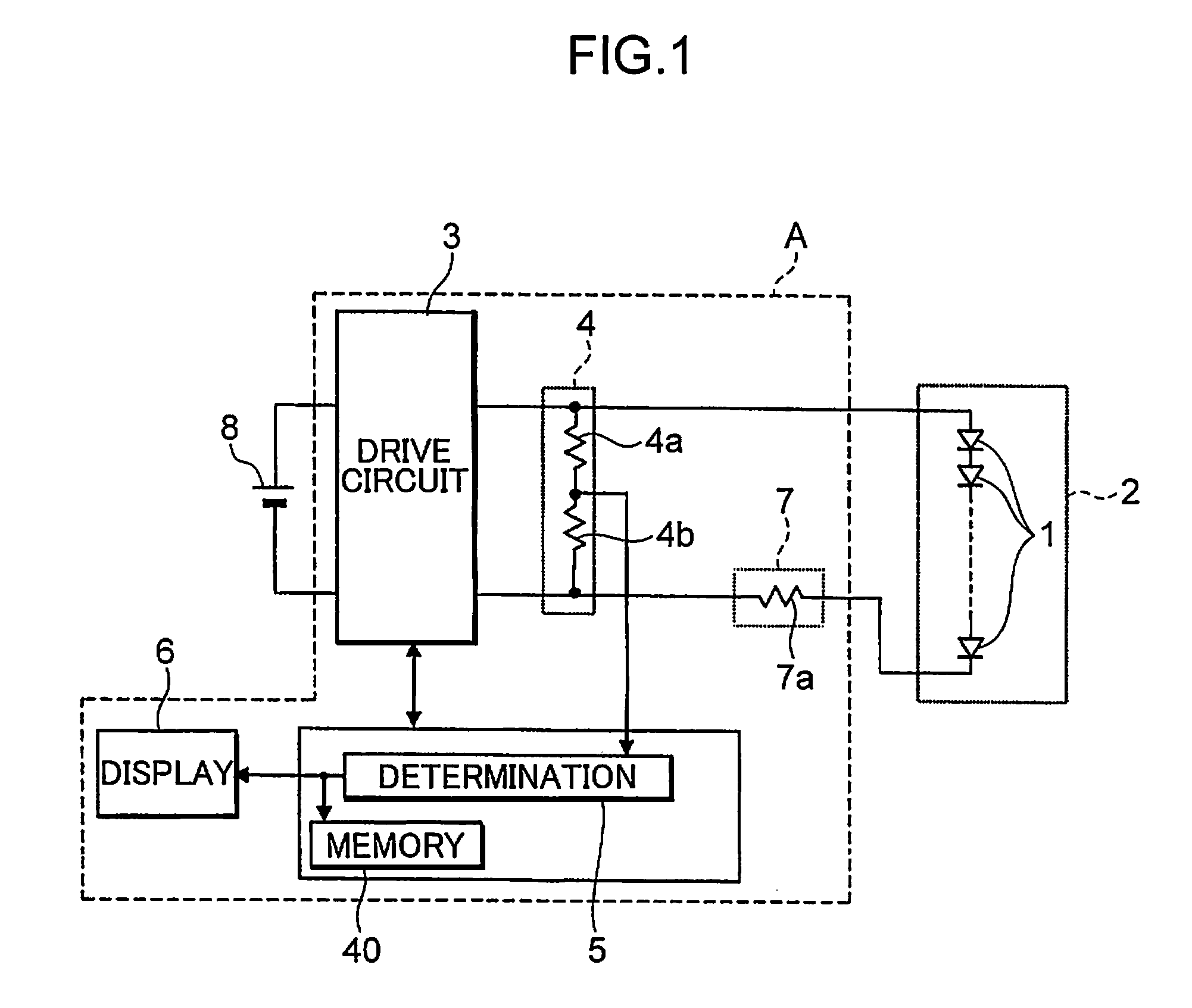

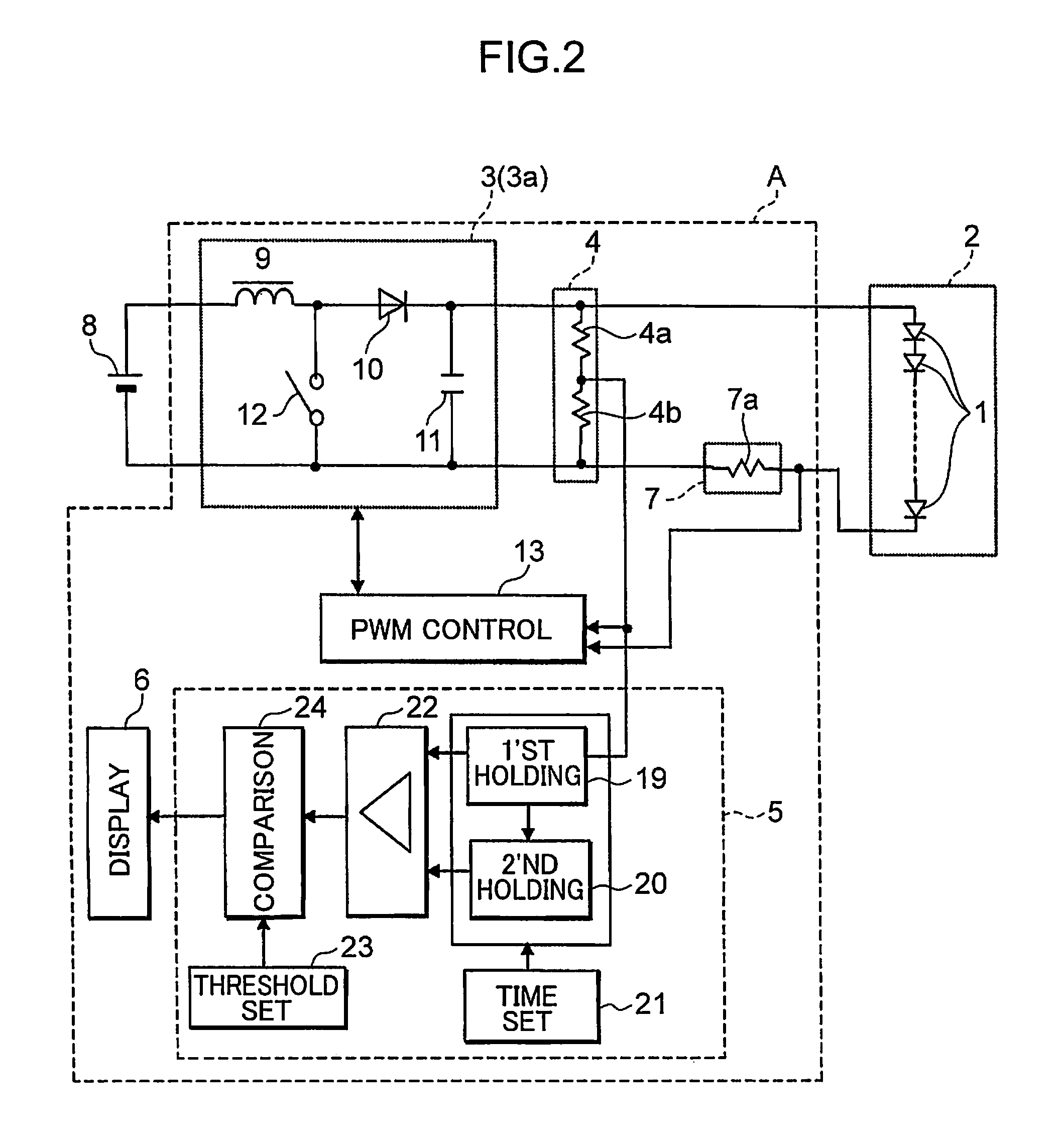

Light emitting diode drive device, illumination device, in-vehicle cabin illumination device, and vehicle illumination device

ActiveUS20100225235A1Simple circuit configurationManufactured with small manufacturing stepDischarge tube incandescent screensElectric discharge tubesIn vehicleVoltage drop

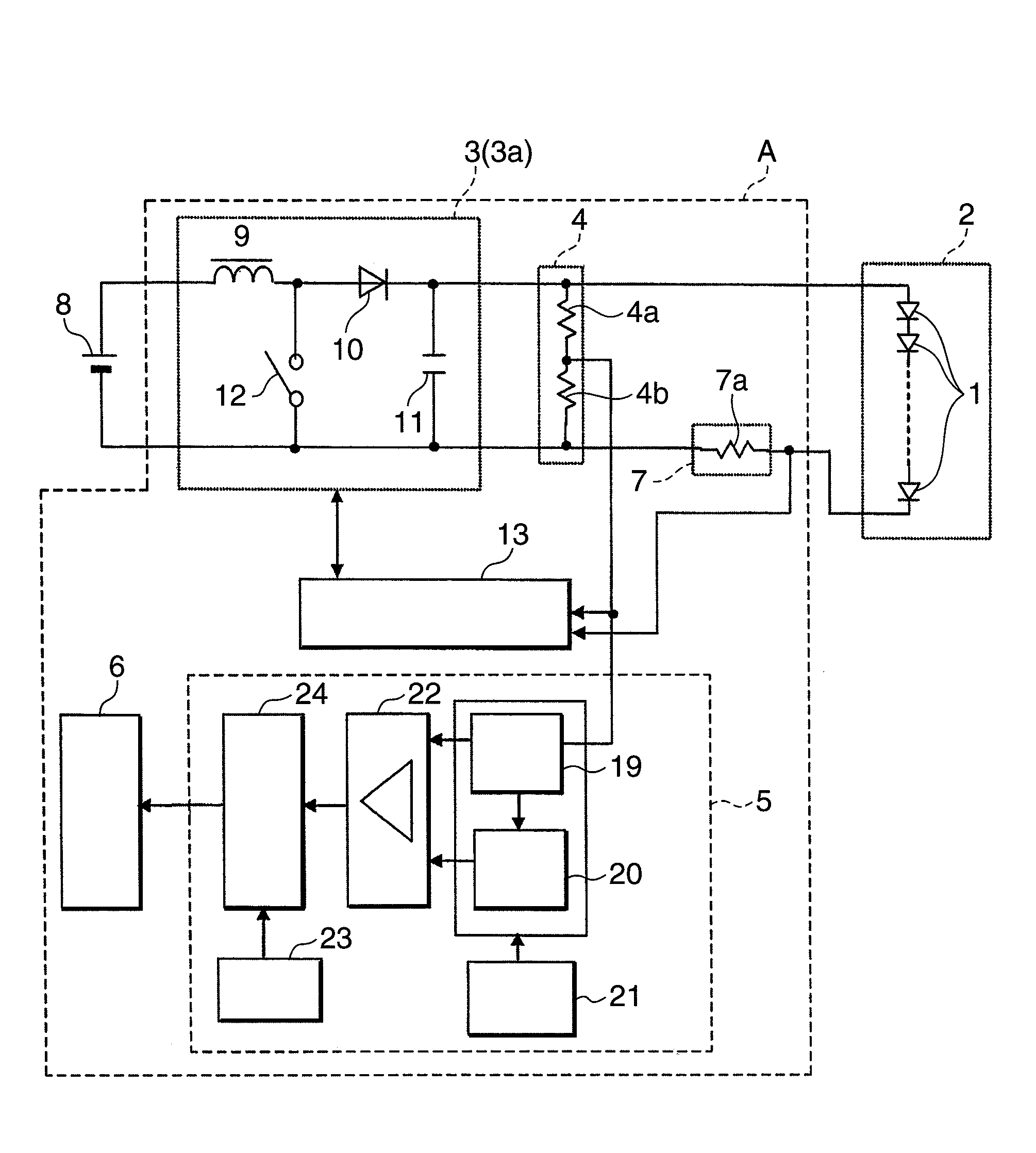

A light emitting diode drive device includes a drive circuit section that applies a direct-current voltage to a light source including a plurality of light emitting diodes connected in series to allow the light source to light up, a voltage detection circuit section that detects a voltage across the light source, and a malfunction determination circuit section that determines that the light emitting diode is short-circuited when the voltage detection circuit section detects a voltage drop and a potential between the voltage before being dropped and the voltage after being dropped is equal to or more than a predetermined threshold value. Thus, it is possible to detect a fact that a light emitting diode, which lights up, is short-circuited or is not short-circuited, with a simple circuit configuration.

Owner:PANASONIC CORP

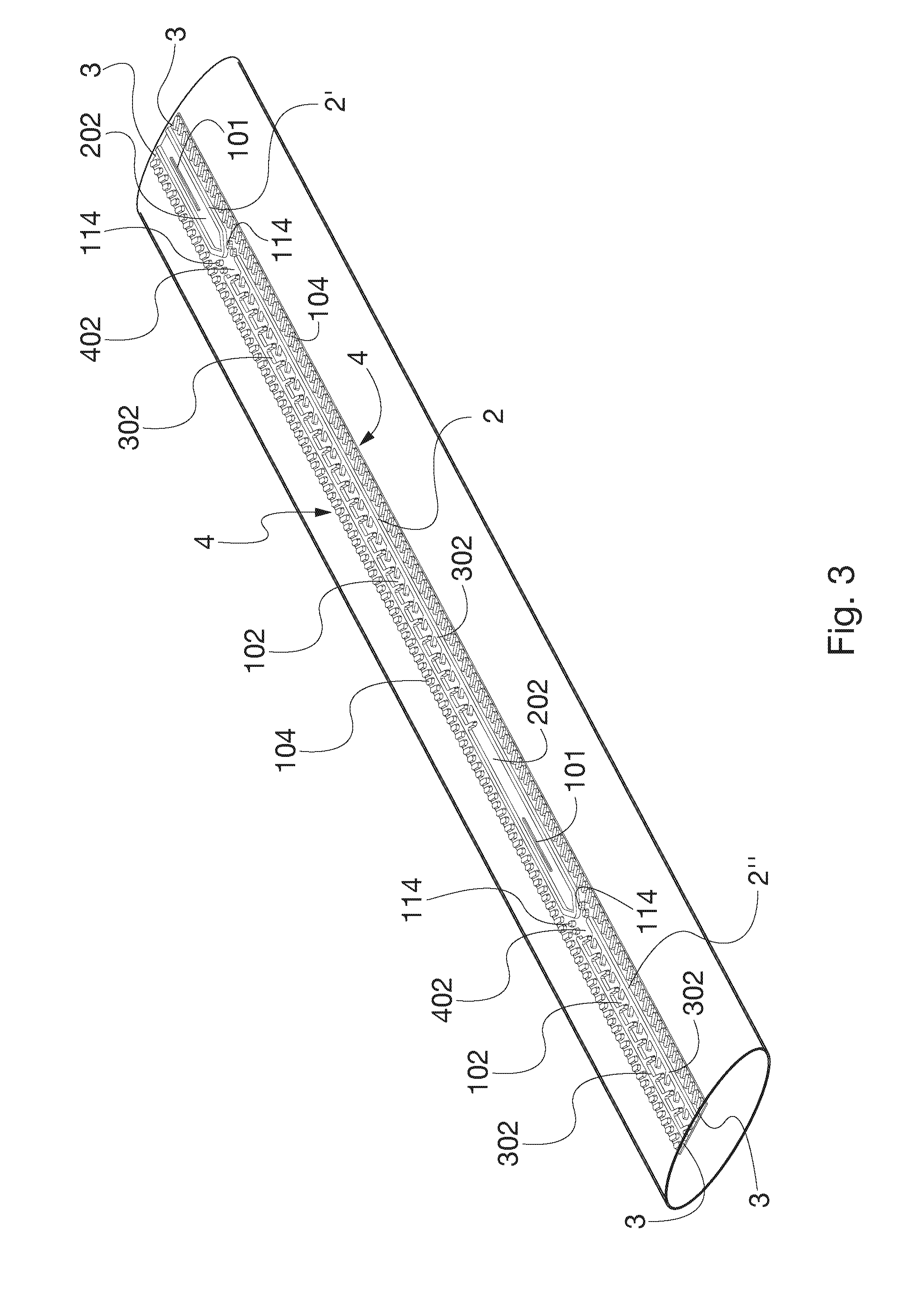

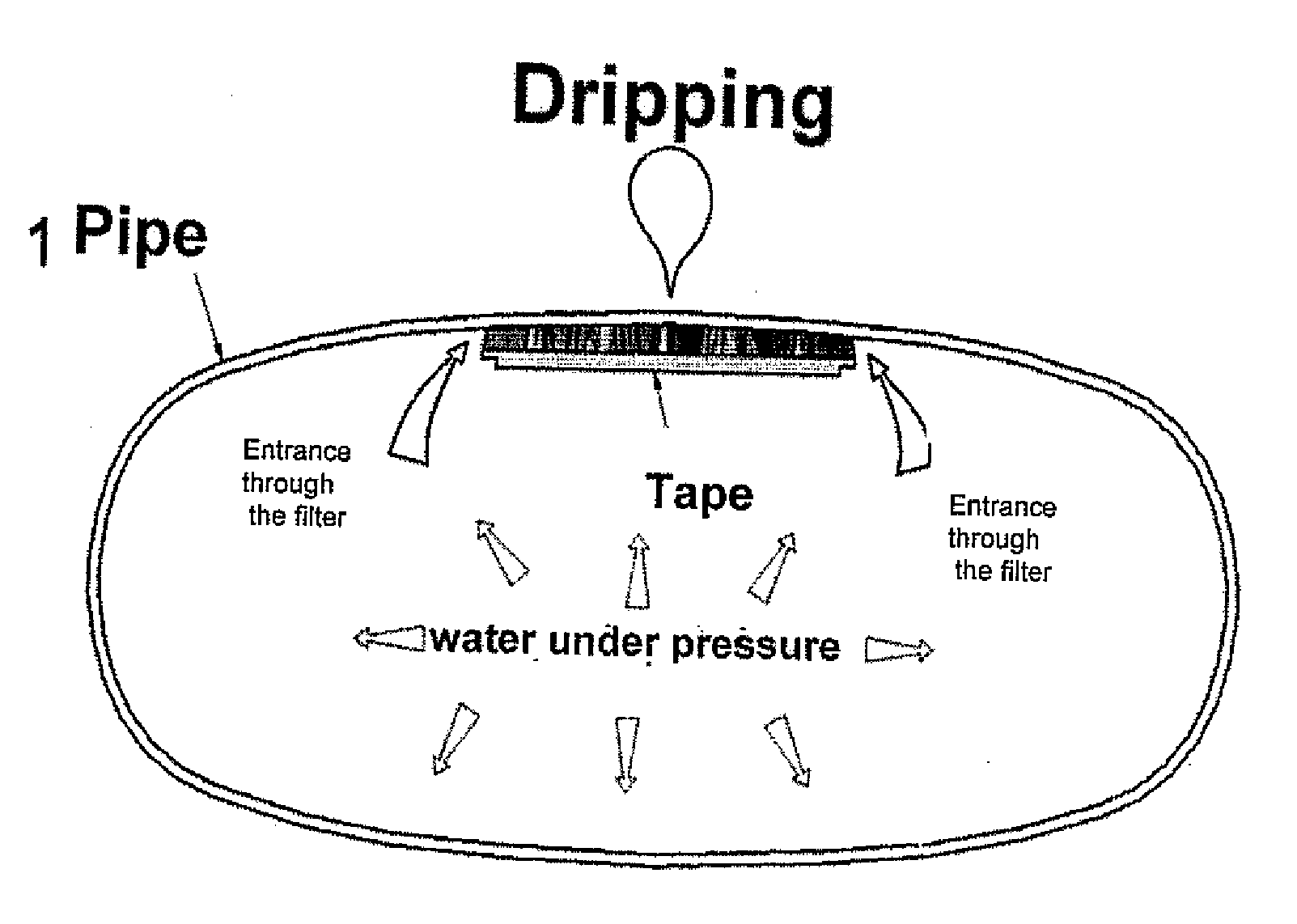

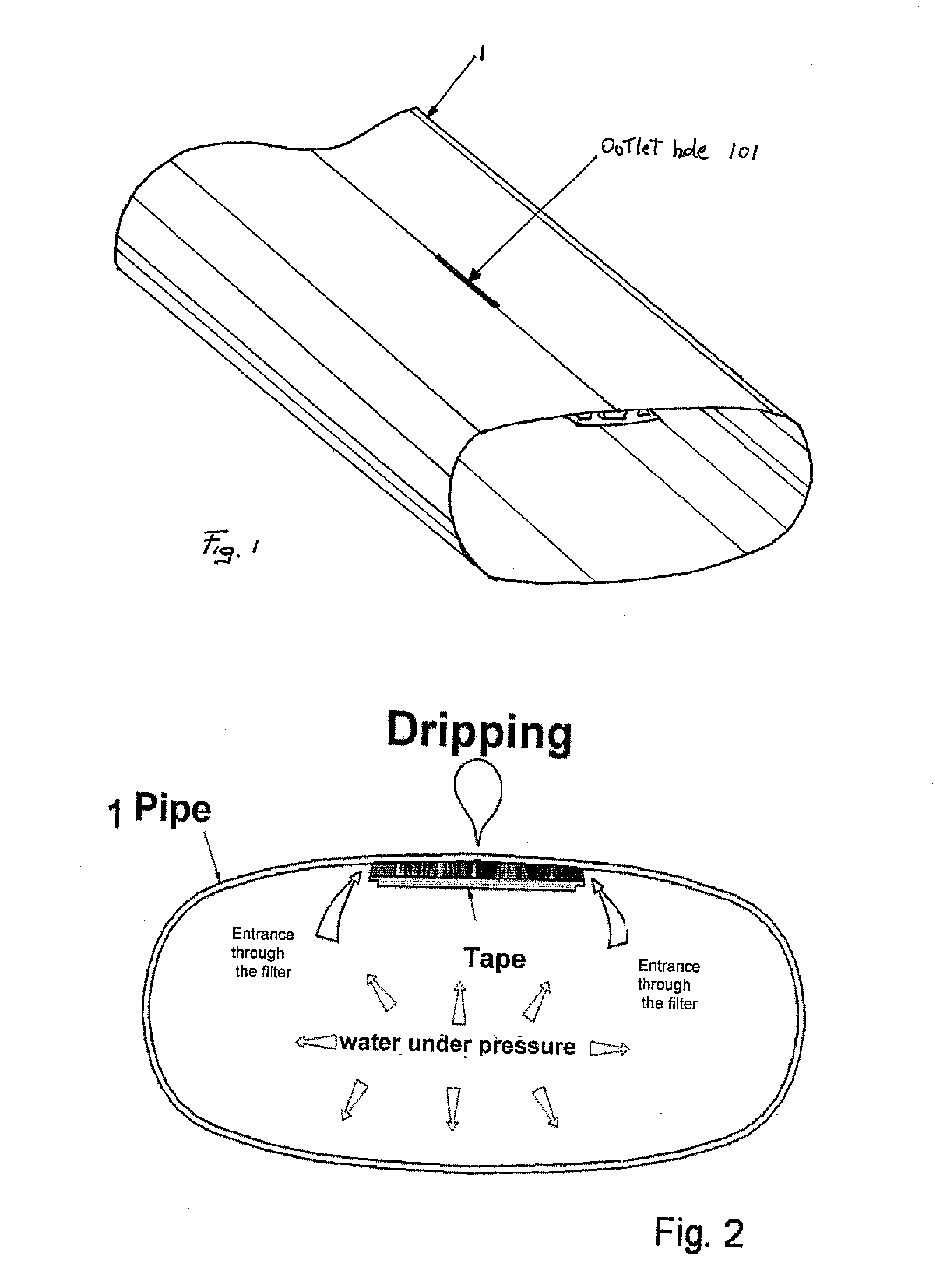

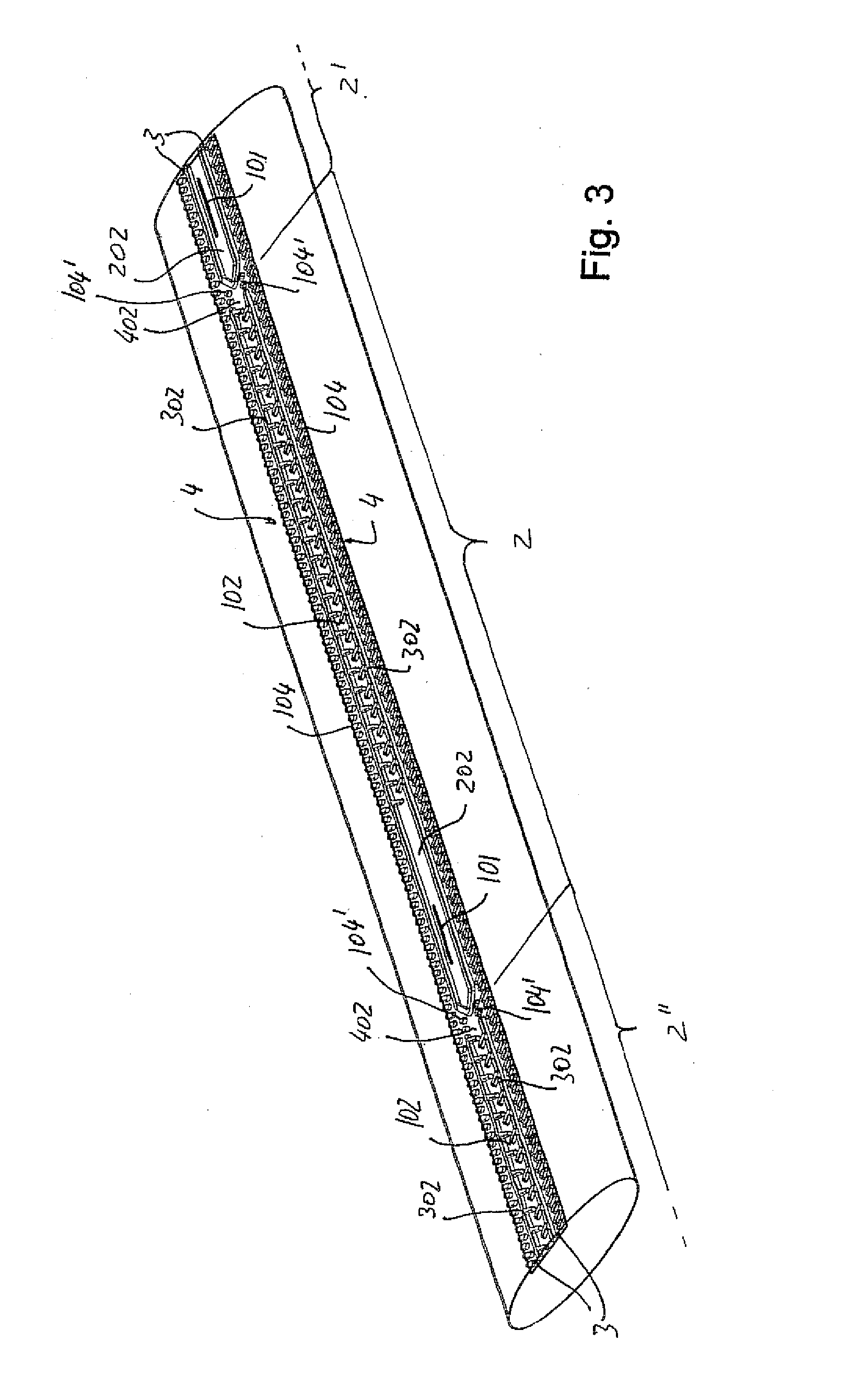

Irrigation pipe

ActiveUS8002496B2High selectivityMissed some of actionConstructionsSoil drainageEngineeringIrrigation

Irrigation pipe including a pipe having at least a longitudinal row of delivery holes arranged at predetermined distances and communicating with a dripping unit provided inside the pipe, and further having an inlet communicating with the inside of the pipe and an outlet communicating with at least one delivery hole. The inlets or outlets of some or all of the dripping units communicate with the inner space of the pipe or with some or all of the delivery holes through an inlet collecting channel or an outlet collecting channel or segments thereof.

Owner:SIPLAST SA

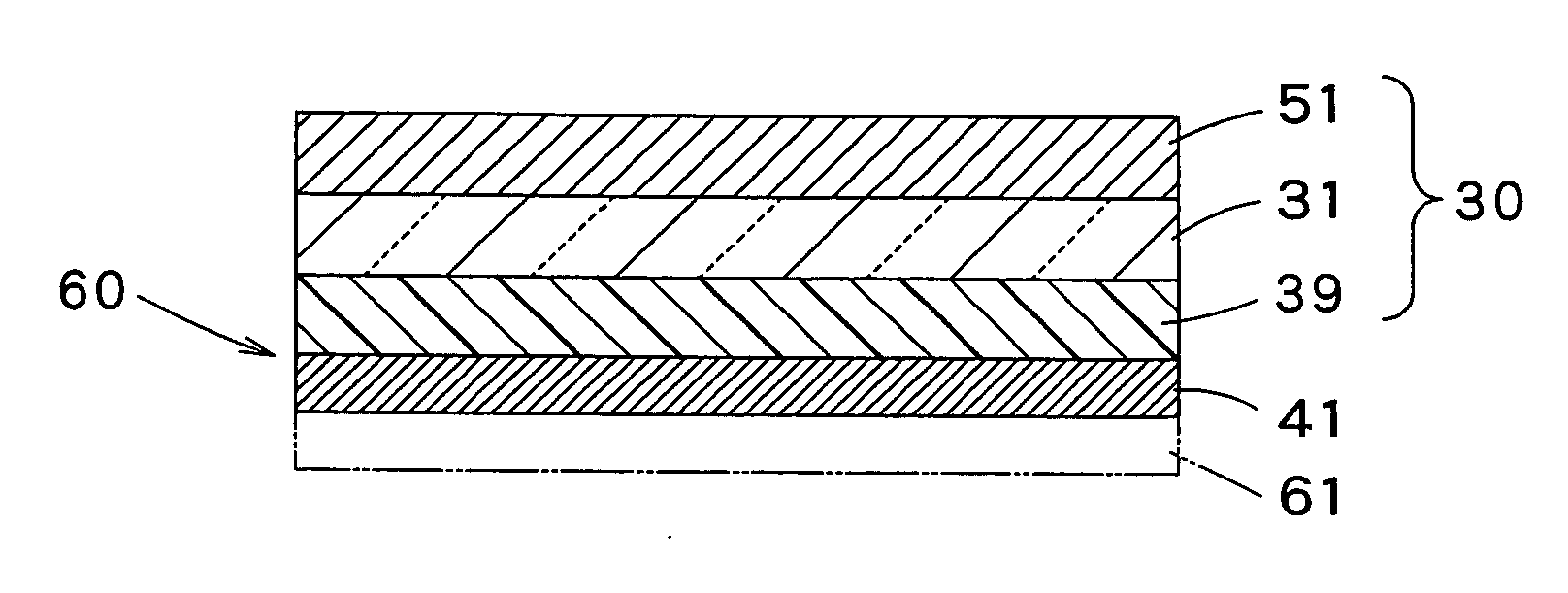

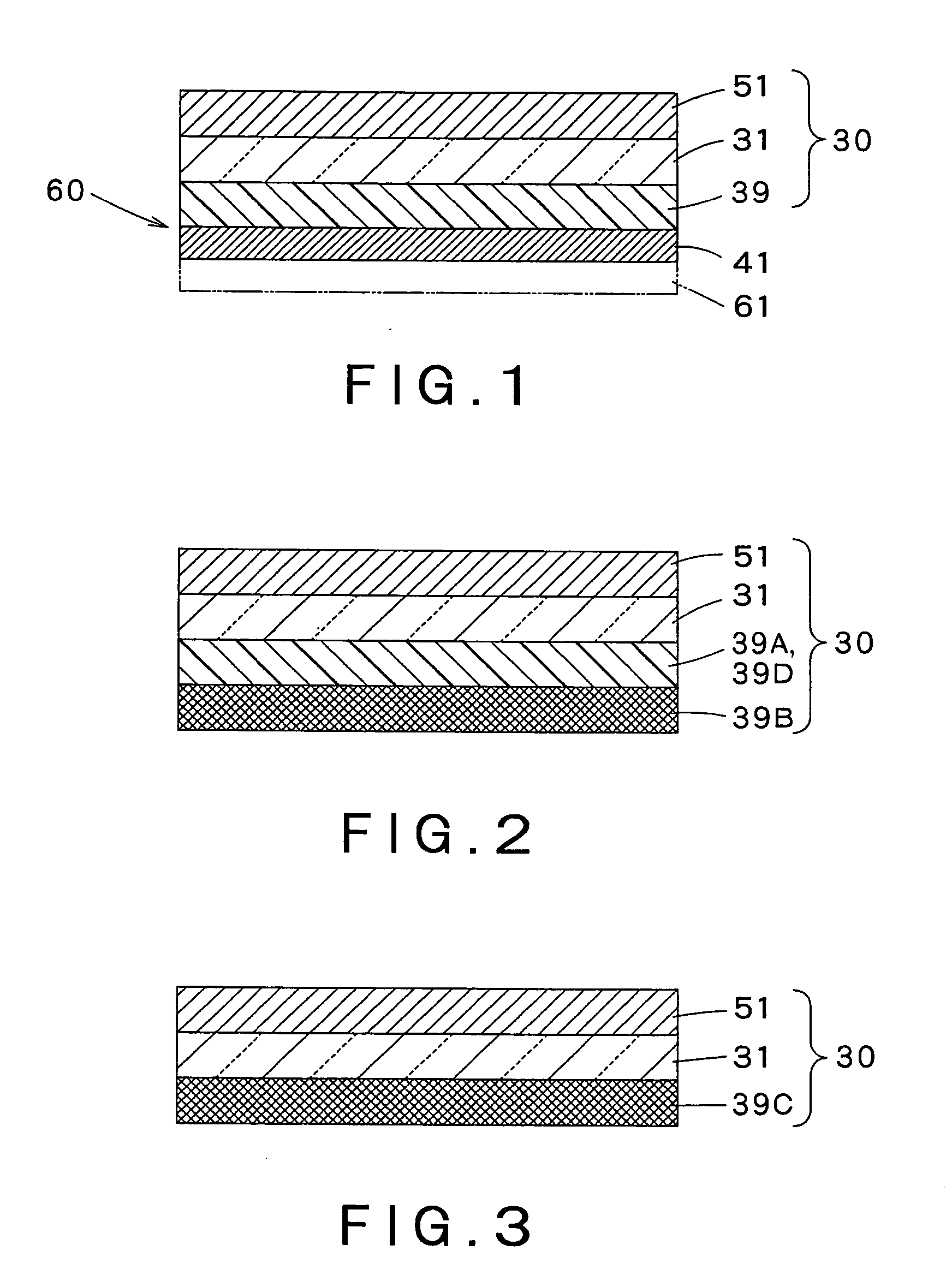

Antireflection film for plasma display

InactiveUS20060286381A1Decrease number of stepSmall stepOptical filtersSynthetic resin layered productsPressure sensitiveColor tone

An anti-reflection layer 51 is provided on one surface of a transparent substrate film 31. A specific-wavelength-light shielding layer 39 containing a coloring agent for color tone correction capable of absorbing light with specific wavelengths originating from the emission spectrum of an insert gas of a PDP, and / or a near infrared rays absorbing agent, is provided on the other surface of the transparent substrate film 31. Further, a pressure-sensitive adhesive layer 41 is optionally provided on the specific-wavelength-light shielding layer 39.

Owner:DAI NIPPON PRINTING CO LTD

Irrigation pipe

ActiveUS20090314377A1Reduce clogReduce pressureConstructionsWatering devicesInterior spaceEngineering

Irrigation pipe including a pipe having at least a longitudinal row of delivery holes arranged at predetermined distances and communicating with a dripping unit provided inside the pipe, and further having an inlet communicating with the inside of the pipe and an outlet communicating with at least one delivery hole. The inlets or outlets of some or all of the dripping units communicate with the inner space of the pipe or with some or all of the delivery holes through an inlet collecting channel or an outlet collecting channel or segments thereof.

Owner:SIPLAST SA

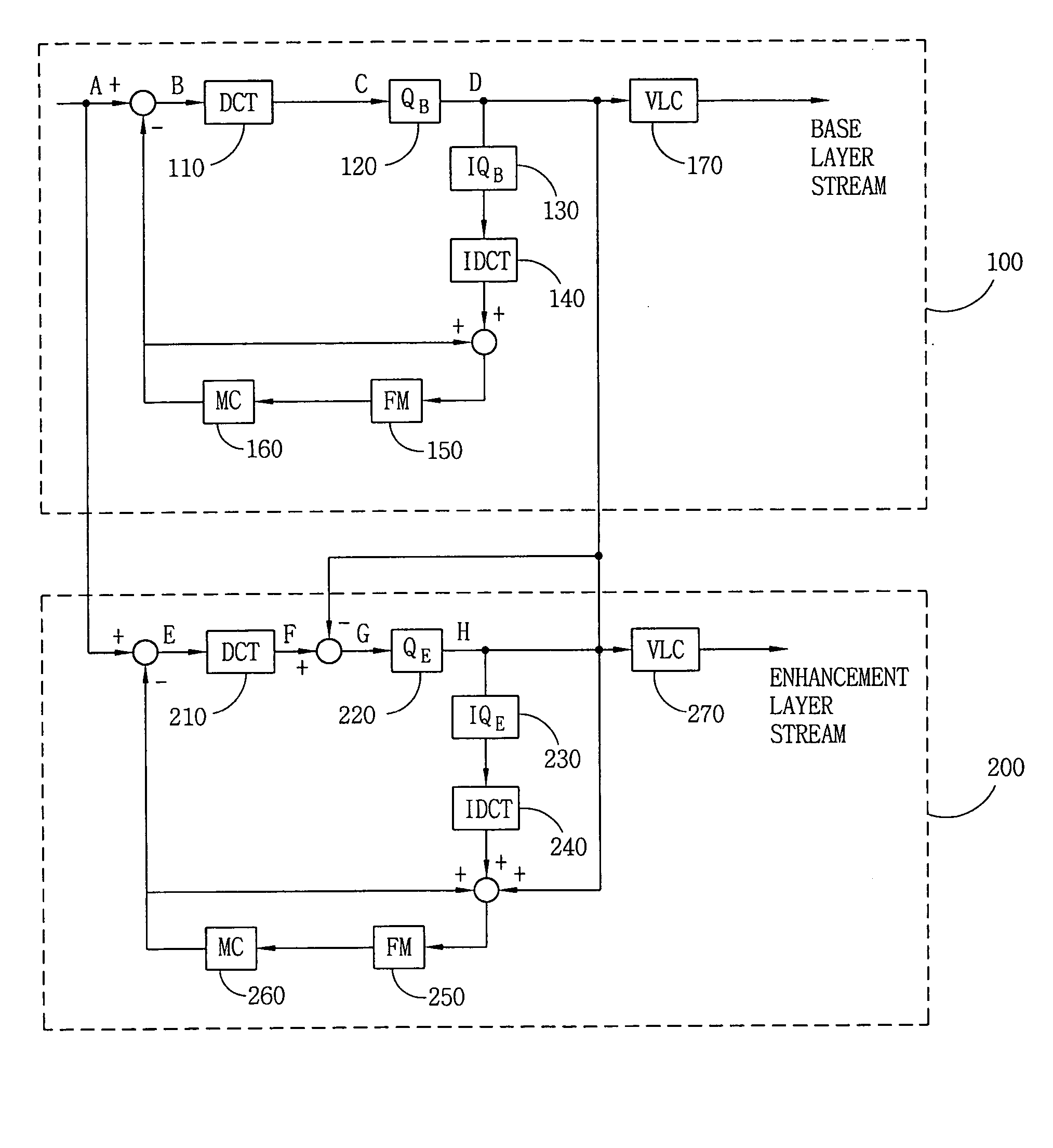

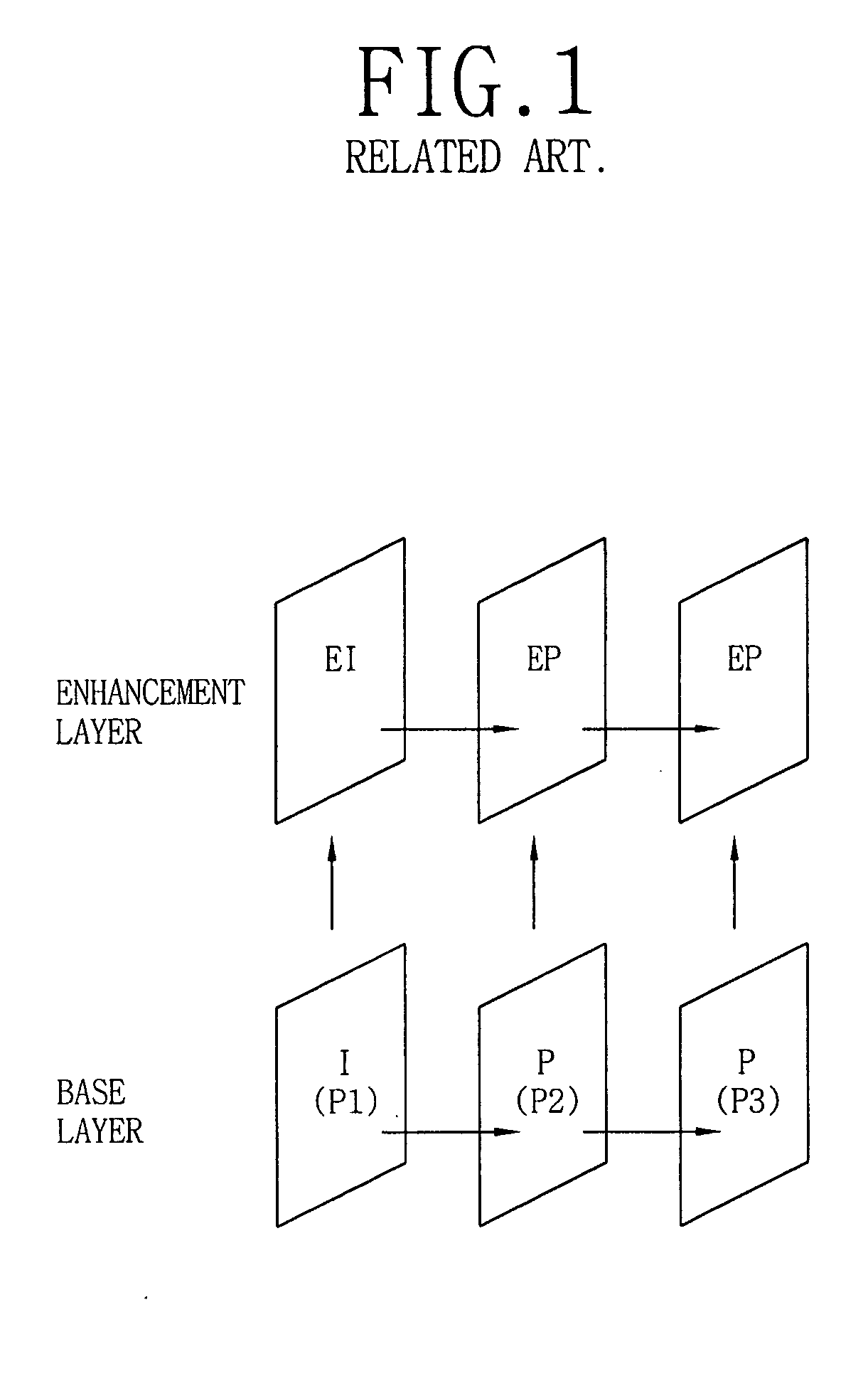

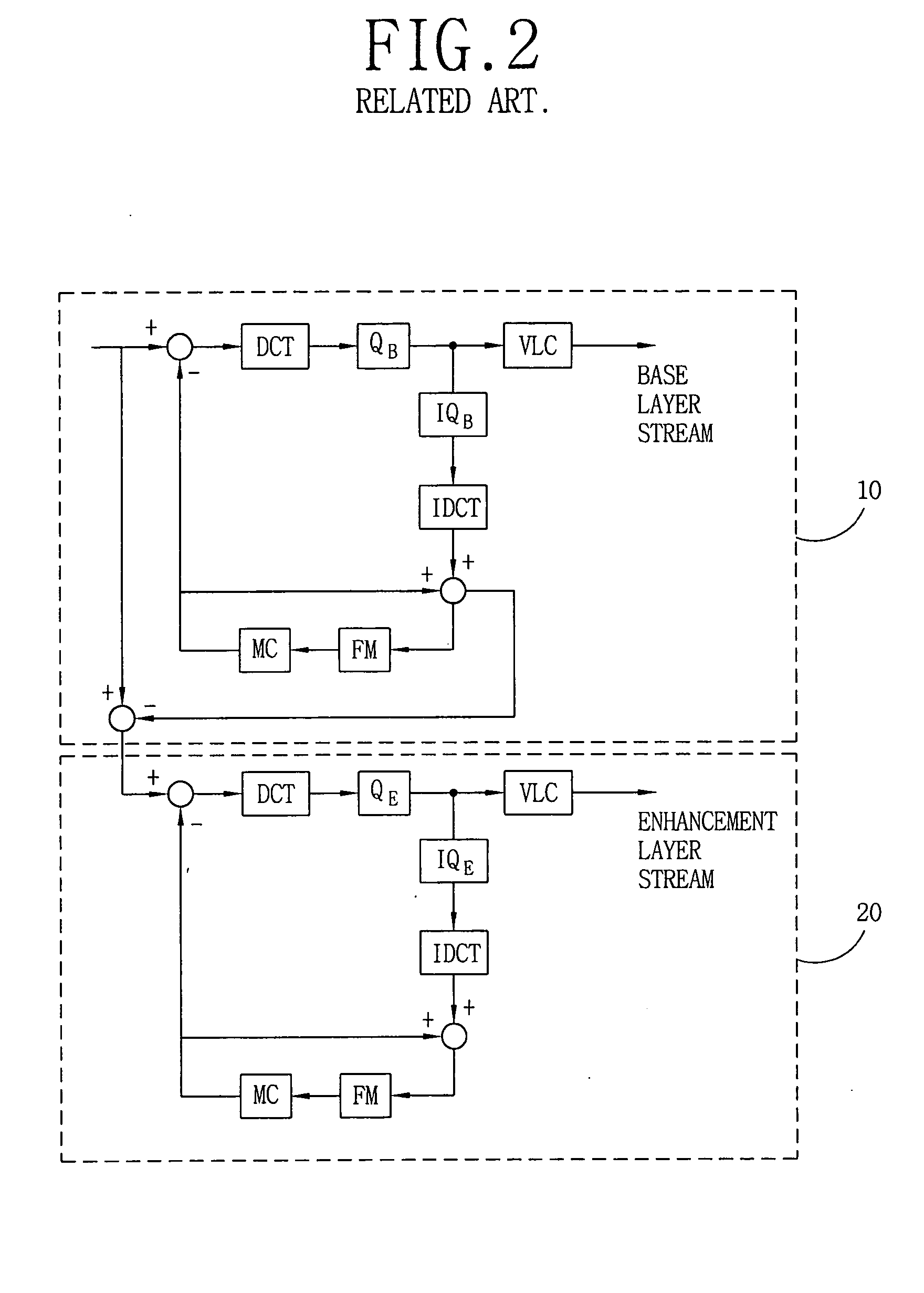

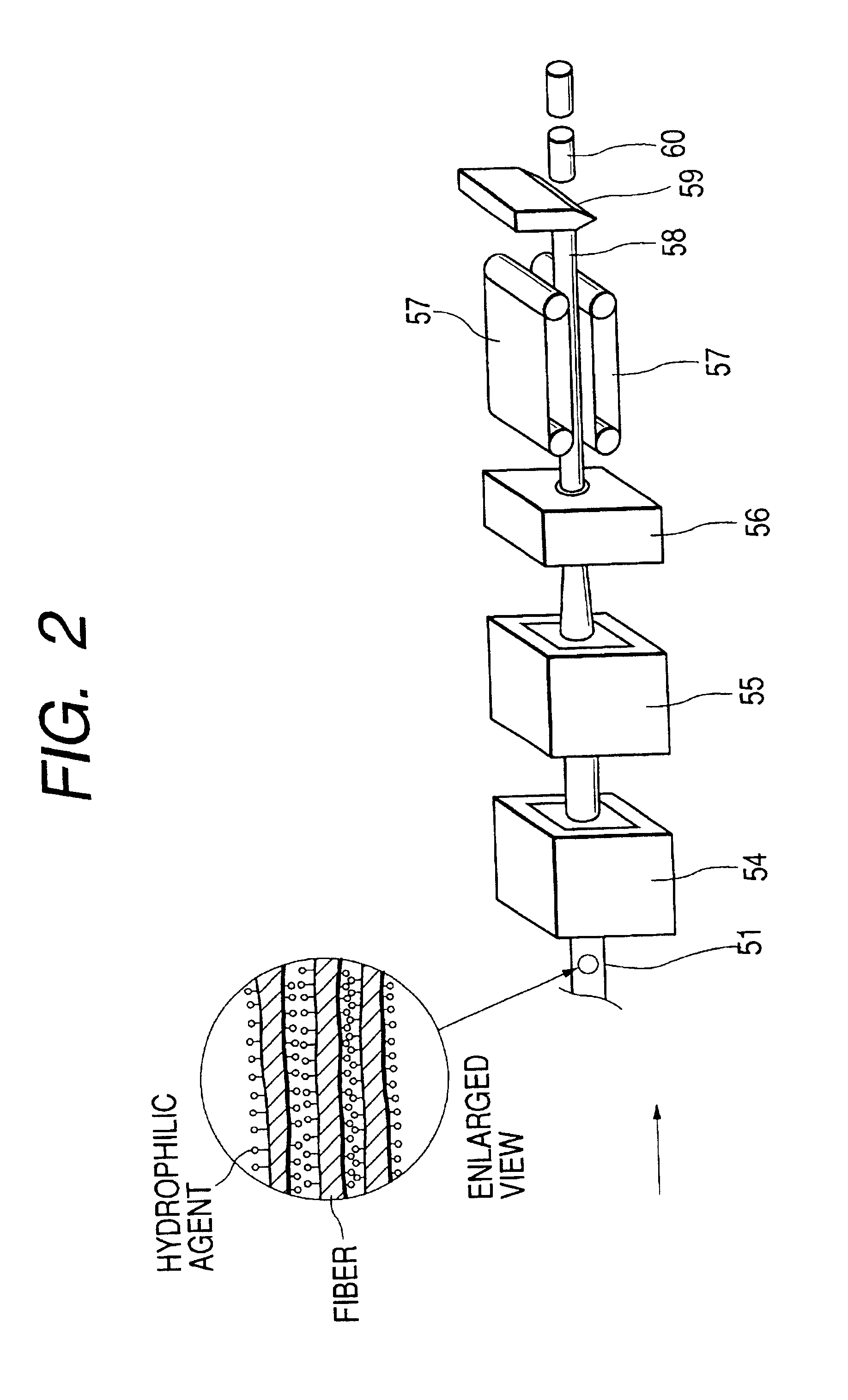

Apparatus and method for processing video for implementing signal to noise ratio scalability

InactiveUS20050111543A1Small stepColor television with pulse code modulationPulse modulation television signal transmissionSignal-to-noise ratio (imaging)First quantization

A system and method for providing video processing and implementing signal-to-noise ratio scalability is provided. The apparatus comprises a first coder and a second coder. The first coder codes inputted image data utilizing a first quantization step for outputting quantized discrete cosine transform coefficients of the first coder. A second coder codes inputted image data utilizing a second quantization step for generating a difference between discrete cosine transform coefficients from the second coder and the quantized discrete cosine transform coefficients of the first coder.

Owner:LG ELECTRONICS INC

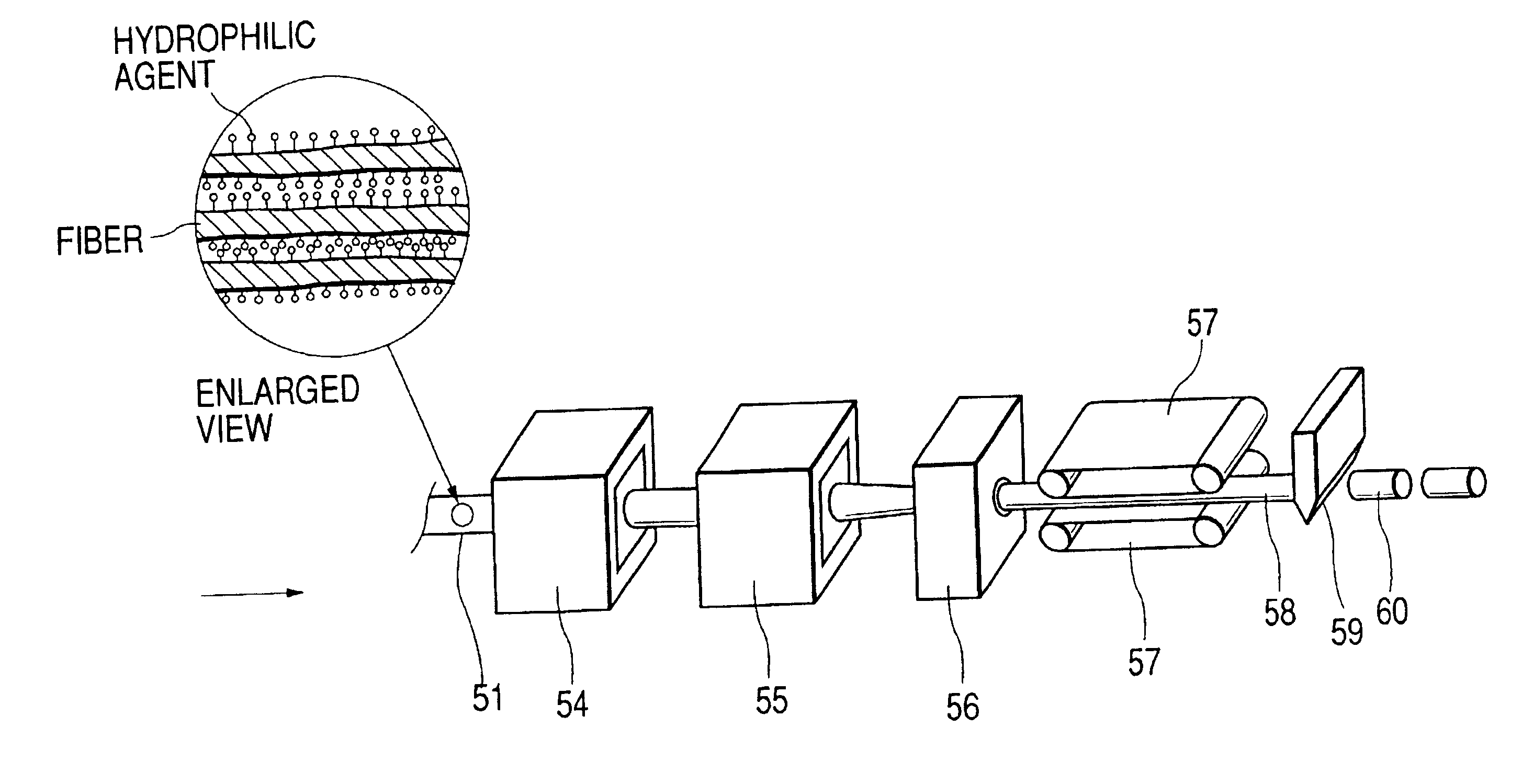

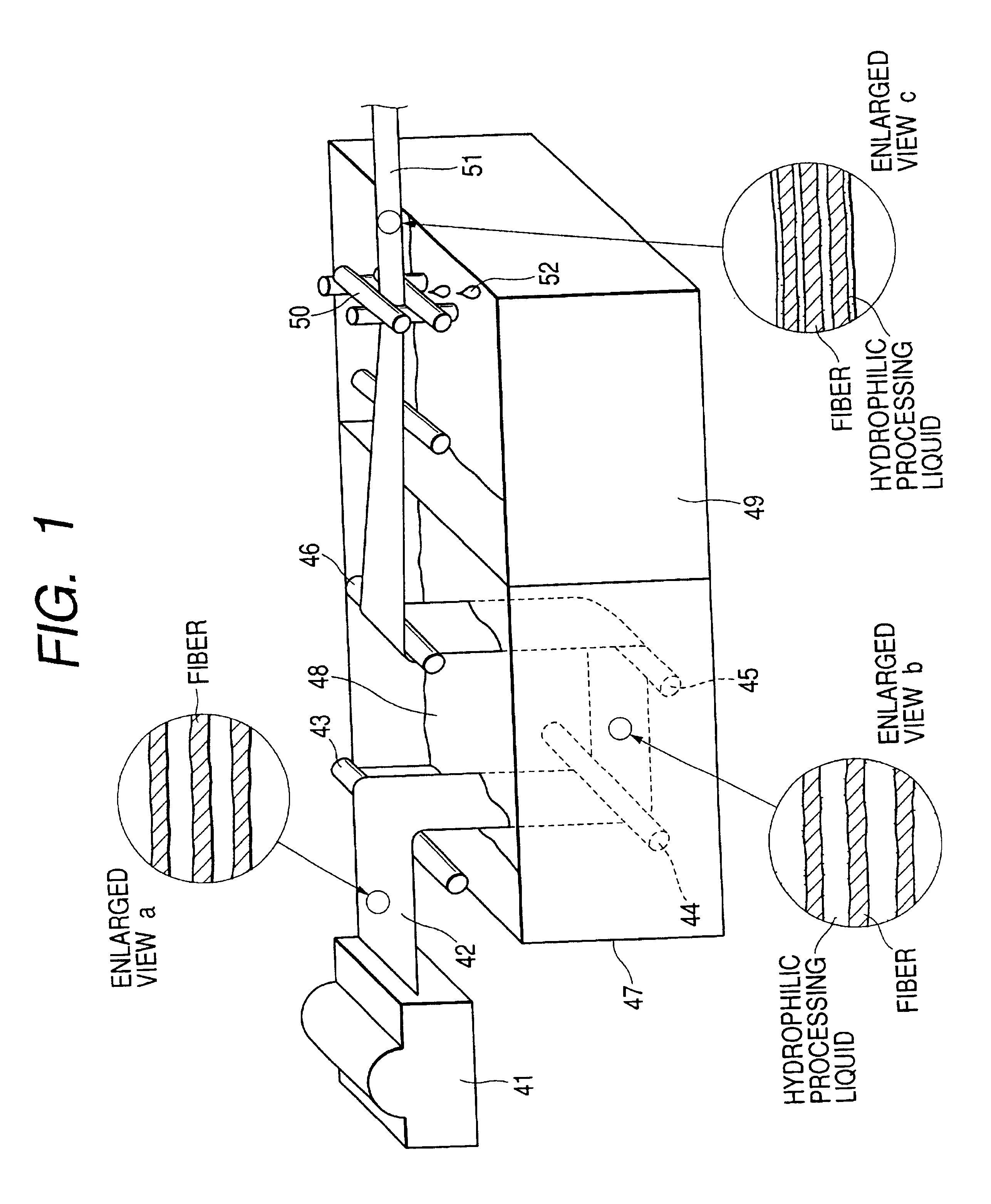

Method for manufacturing fiber aggregate, fiber aggregate, and liquid container using such fiber aggregate

InactiveUS6863762B2Enhancing uniform propertySmall stepMechanical working/deformationWood working apparatusSurface layerSingle fiber

A method for manufacturing a fiber aggregate formed by fiber having reforming surface comprises the steps of providing a fiber surface having thermoplastic resin at least on the surface layer thereof with a hydrophilic processing liquid containing polymer having a first portion with more hydrophilic group than the surface, and a second portion having interfacial energy different from that of the hydrophilic group, and interfacial energy substantially equal to the surface energy of the fiber; orientating the second portion toward the fiber surface, while orientating polymer to the side different from the surface of the first group; and forming a fiber absorber by heating the fiber having the reformed surface in the step of orientating polymer to thermally bond the contact points of fibers themselves. With this method of manufacture, it becomes possible to enhance the uniform property of the fiber aggregate still more, which is formed subsequent to making the property of such fiber aggregate uniform per unit of single fiber or small aggregate existing in any one of stages before the formation thereof.

Owner:CANON KK

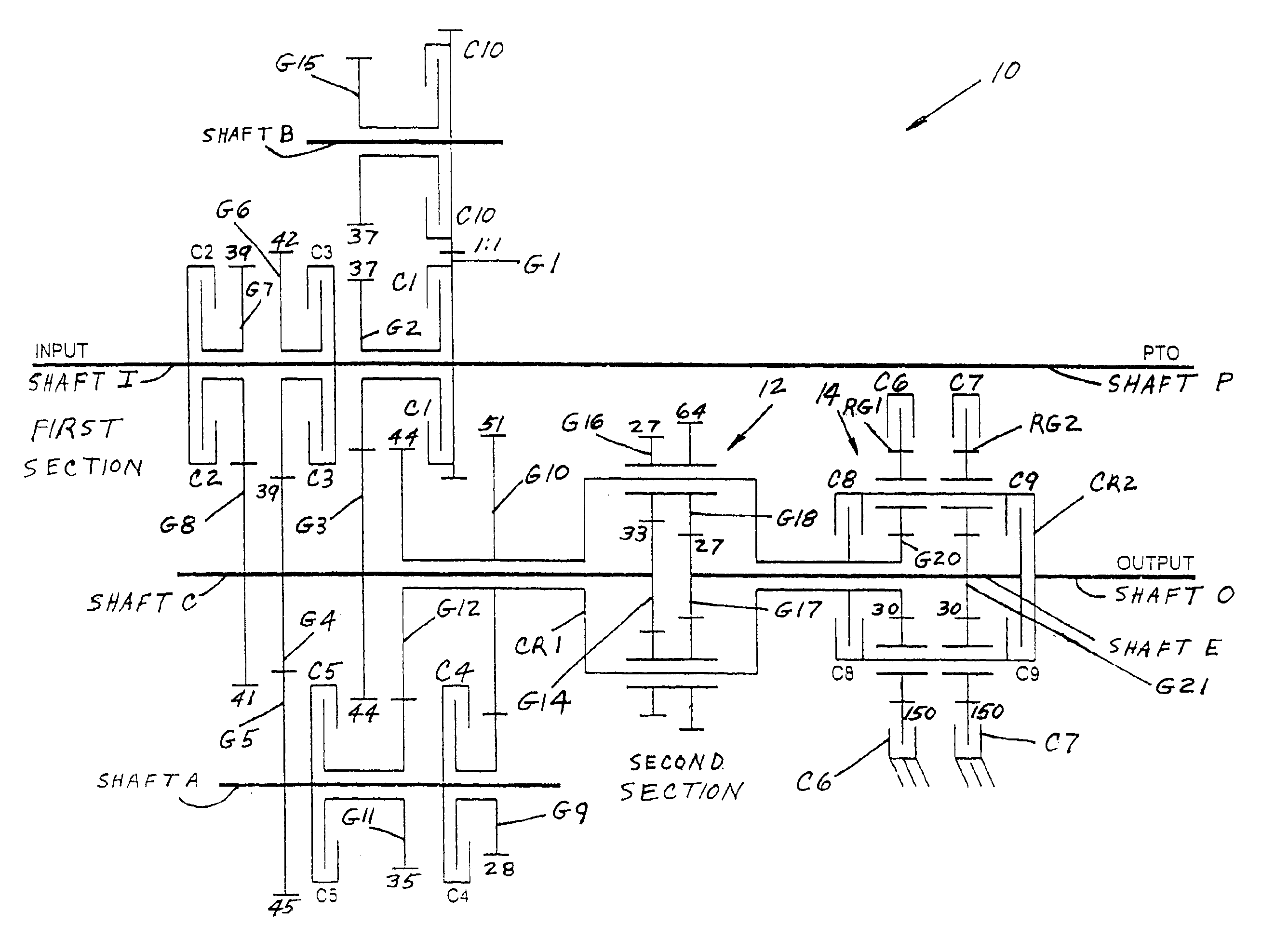

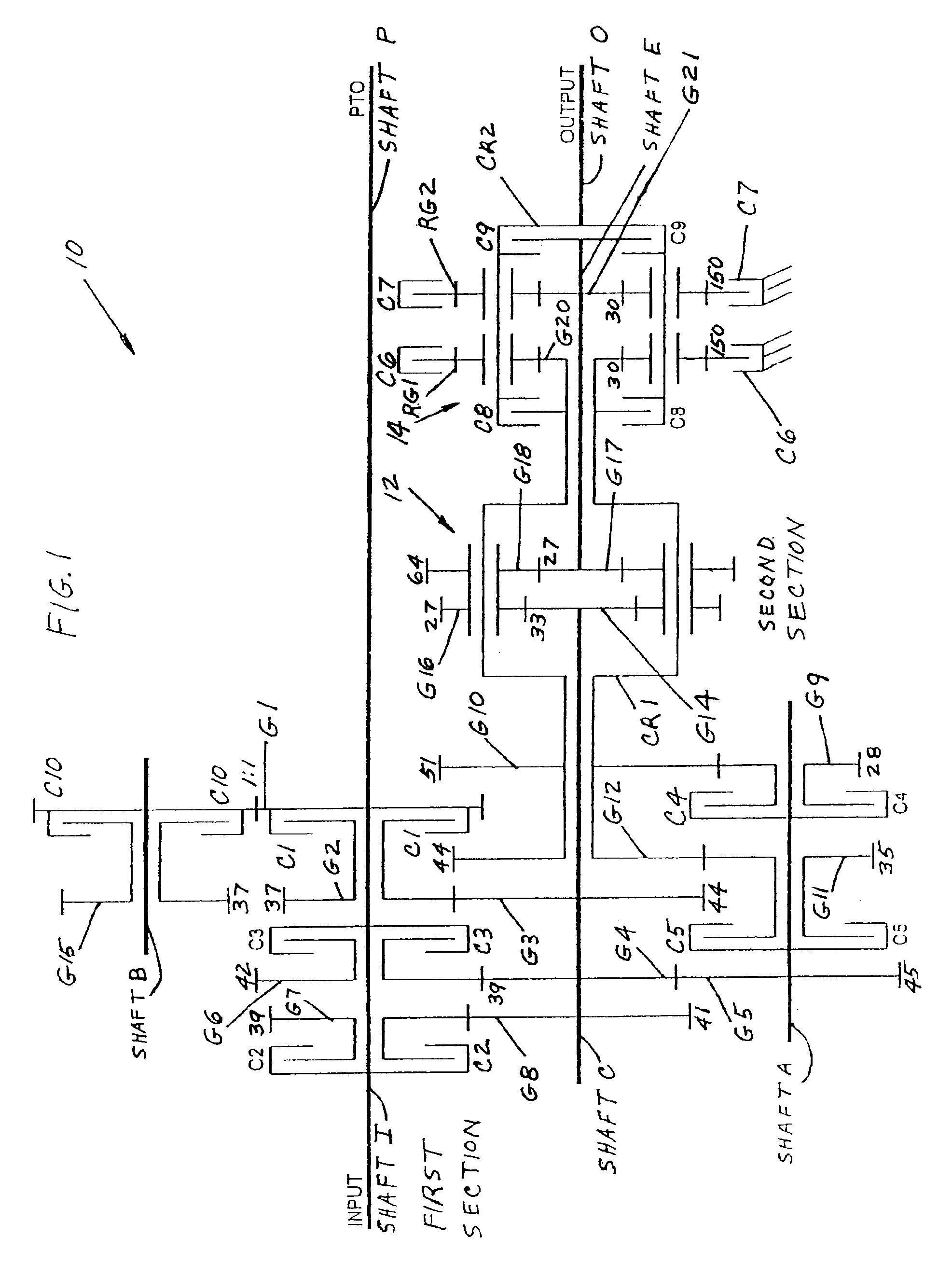

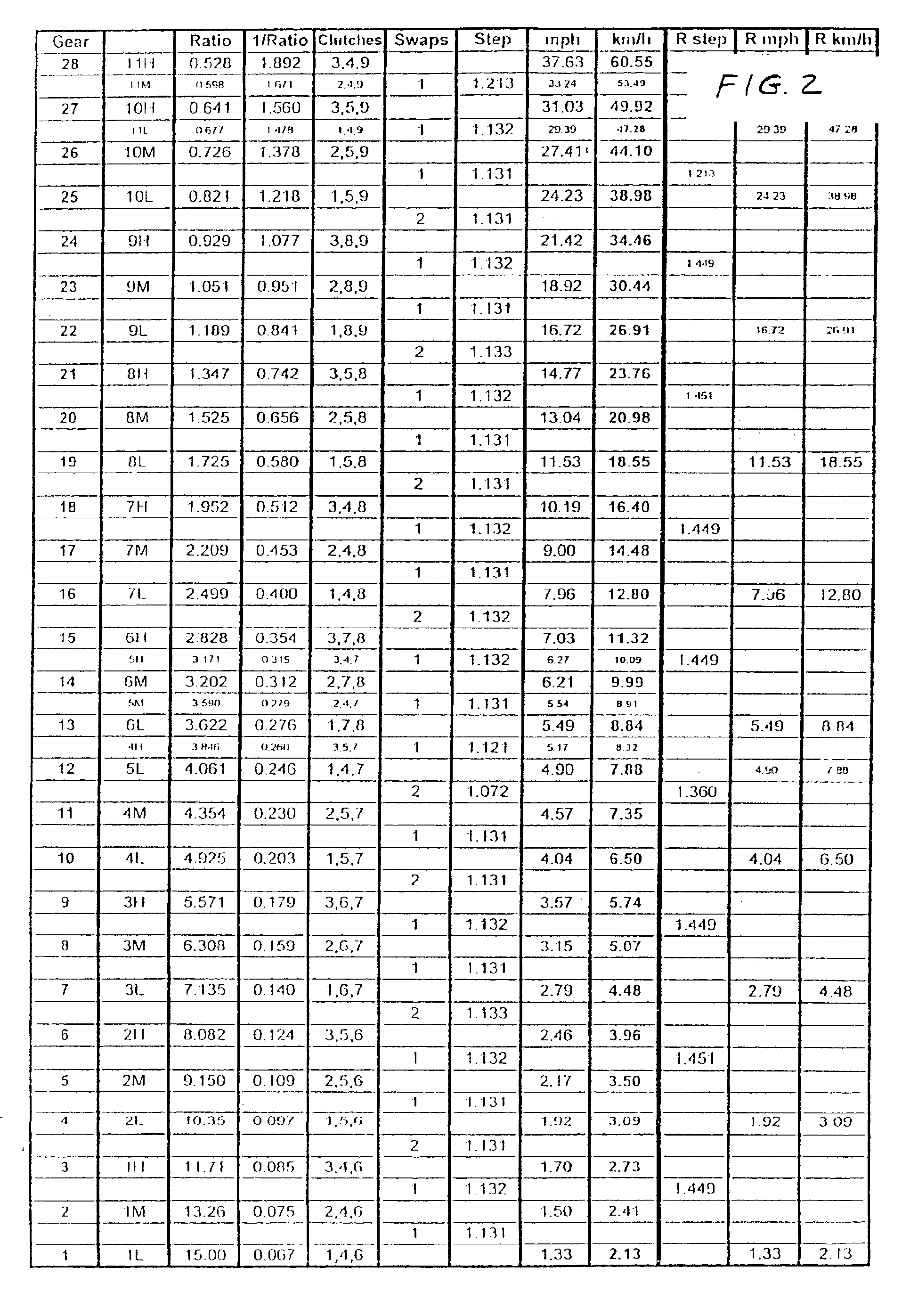

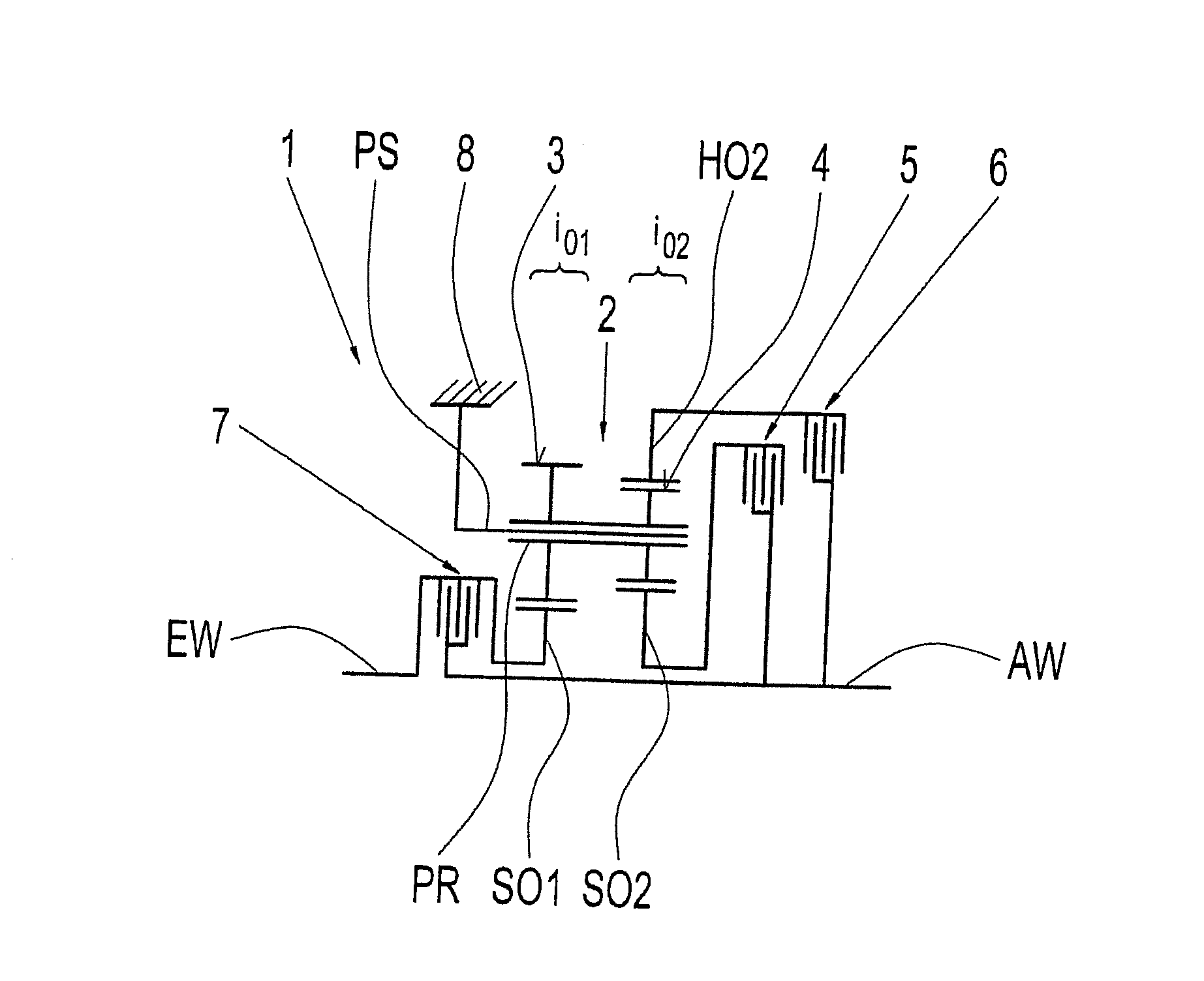

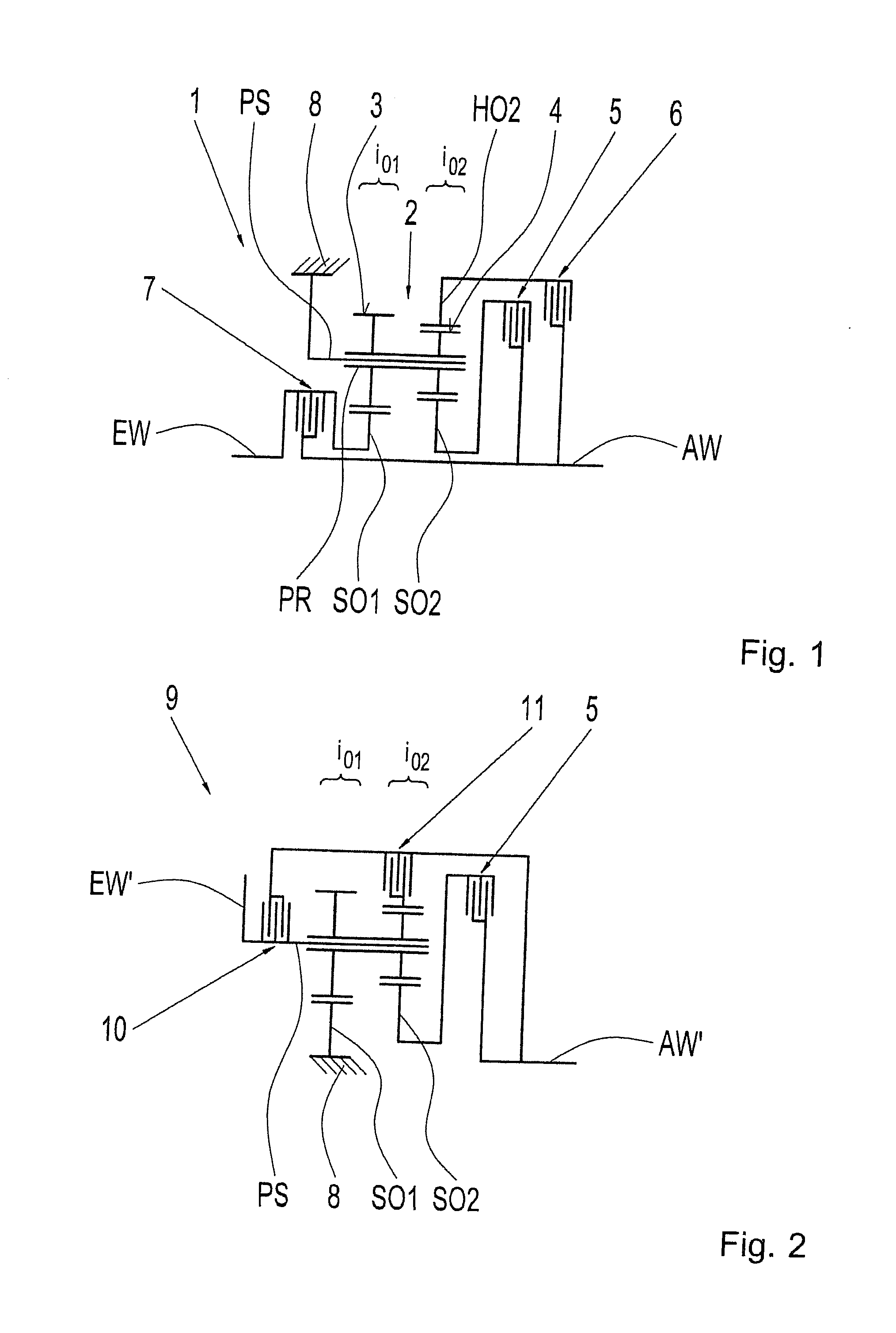

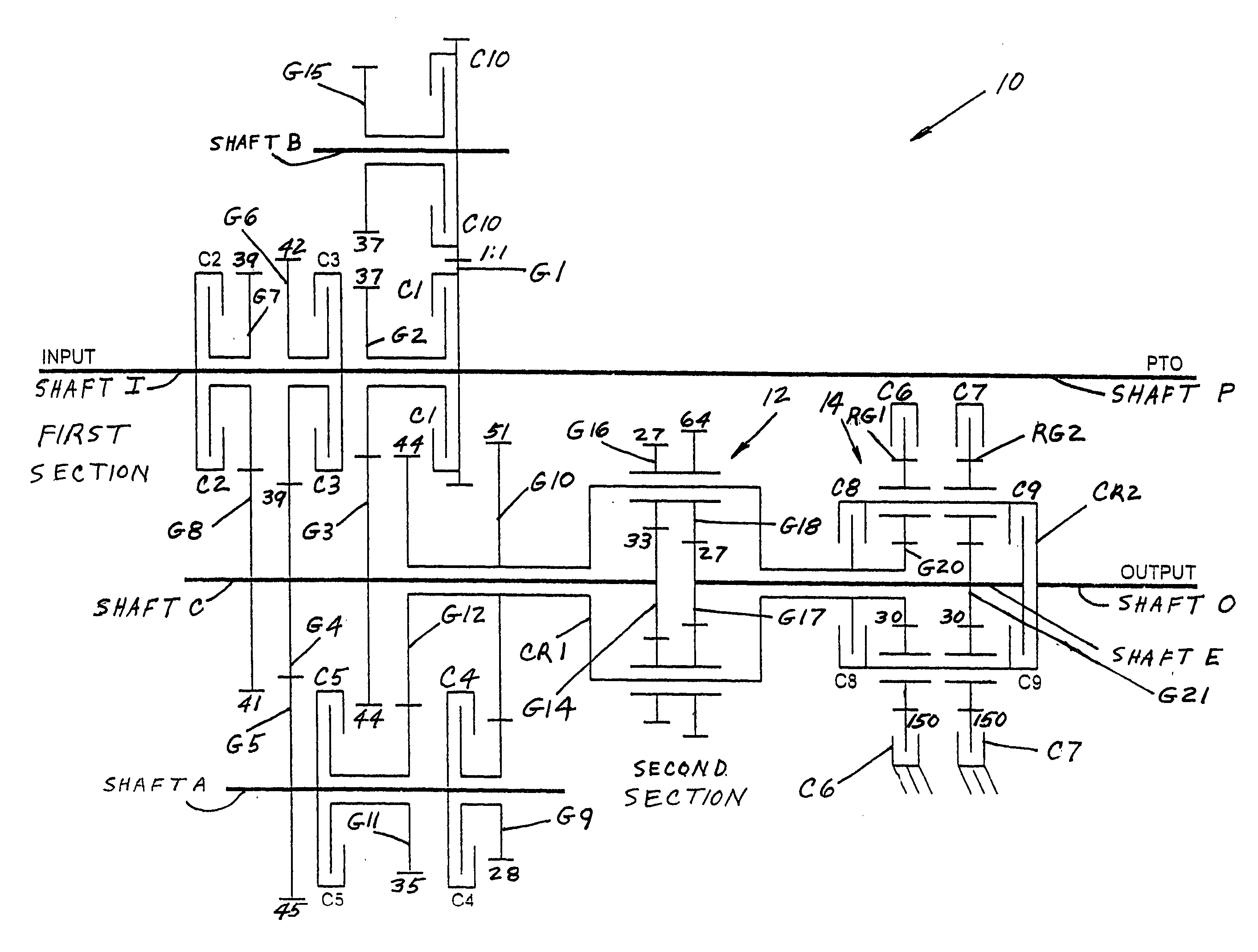

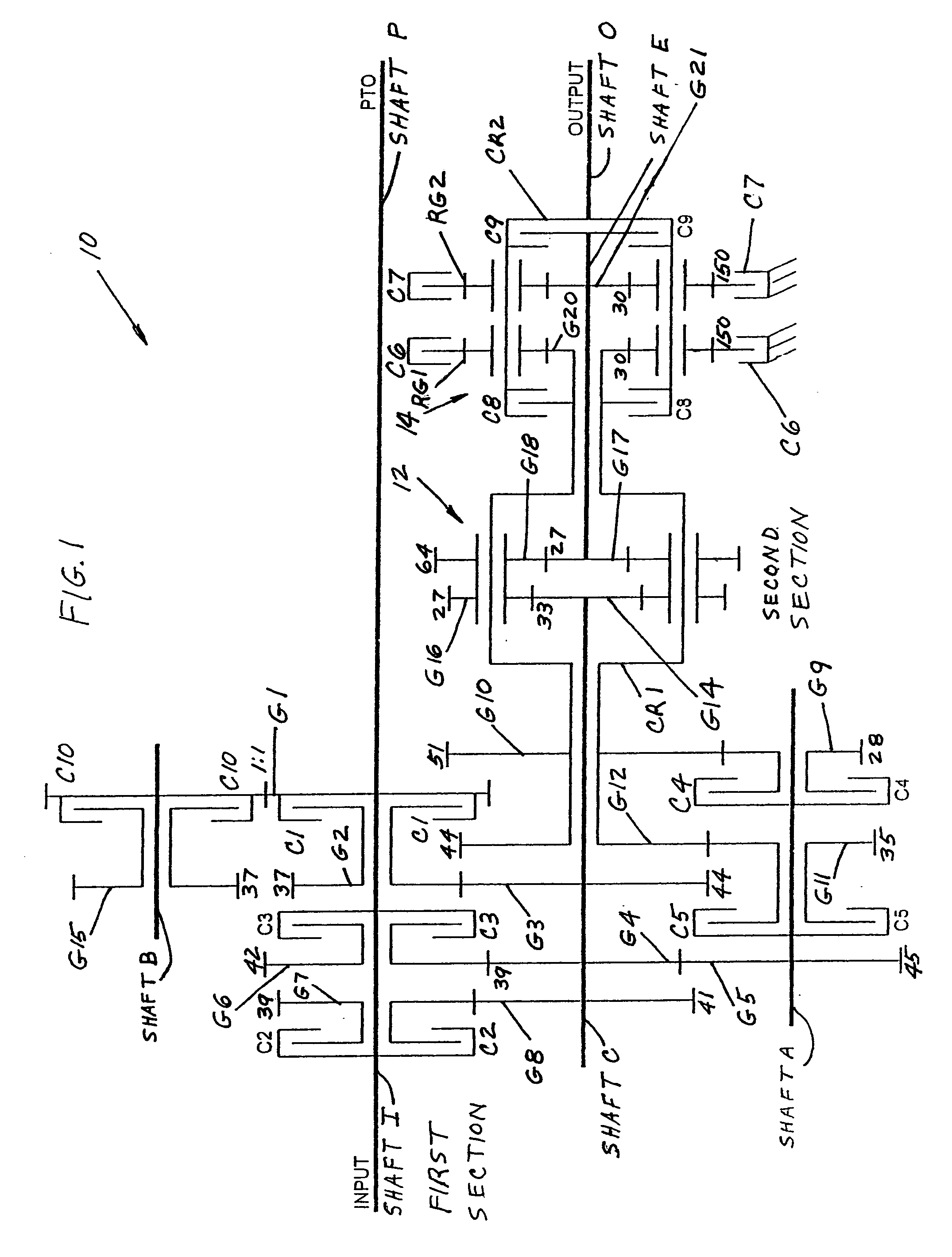

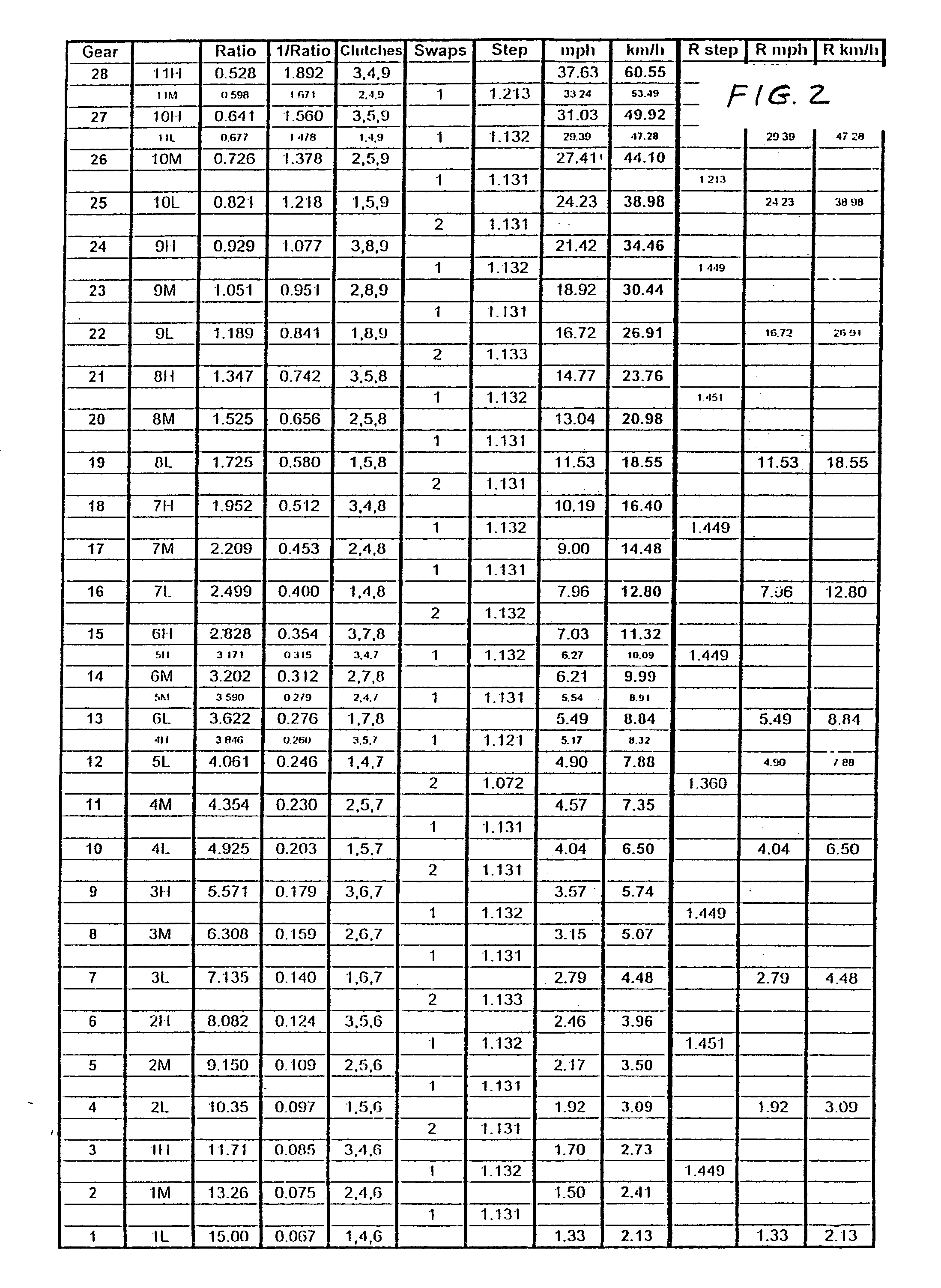

Smoothly shifting multispeed transmission

ActiveUS6845682B1Elimination of difficult shiftSmall ratio stepToothed gearingsTransmission elementsGear wheelEngineering

The apparatus is a 28 speed, two section, transmission that requires only a single clutch swap for most changeovers between adjacent ratios. It uses a first section with three close ratio forward speeds and one reverse along with a second section that is an 11 speed, wide ratio, transmission. The two transmission sections are arranged in series resulting at least 28 usable forward speeds. The second section includes an intermediate planetary gear set without a ring gear and an output planetary gear set that is a conventional simple planetary gear set with a two sun gears, two planes of planetary gears on a single carrier, and two ring gears.

Owner:BLUE LEAF I P +1

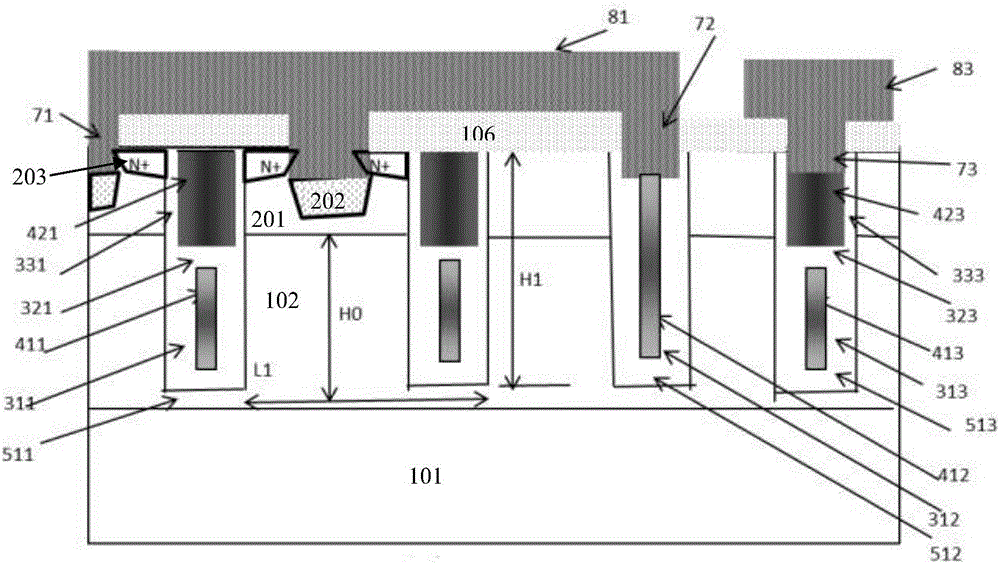

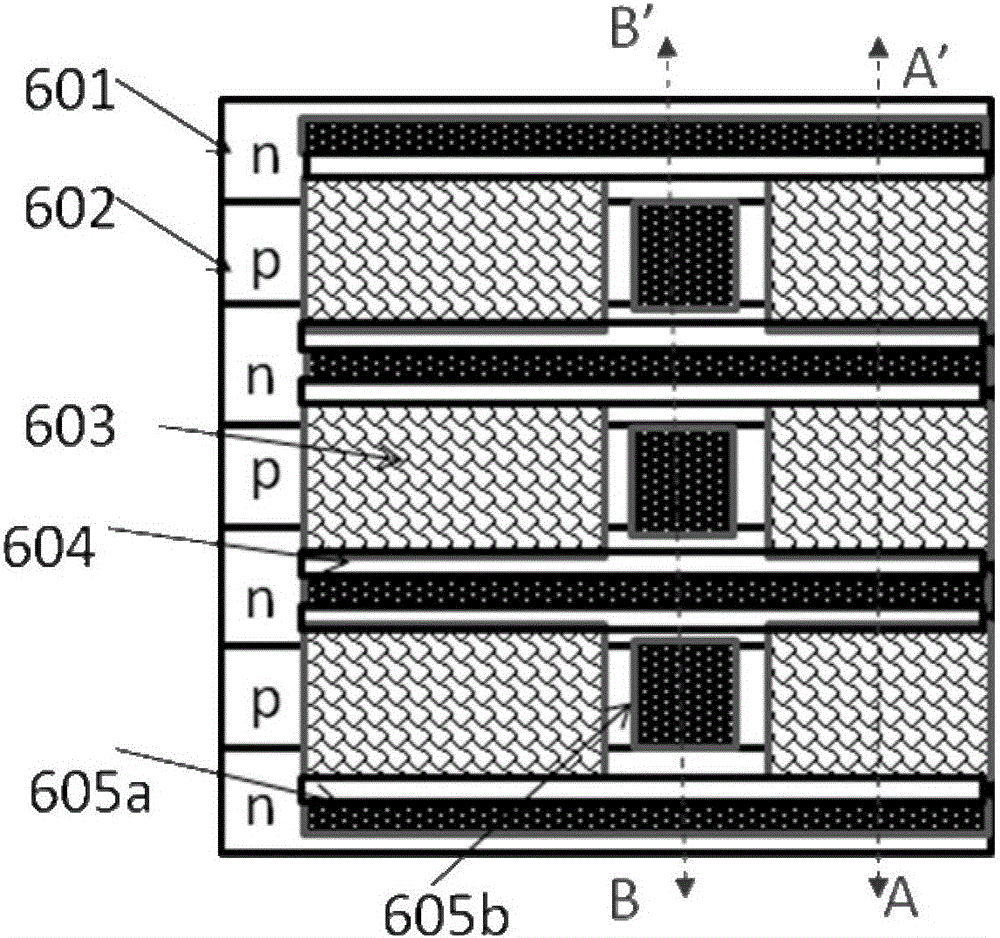

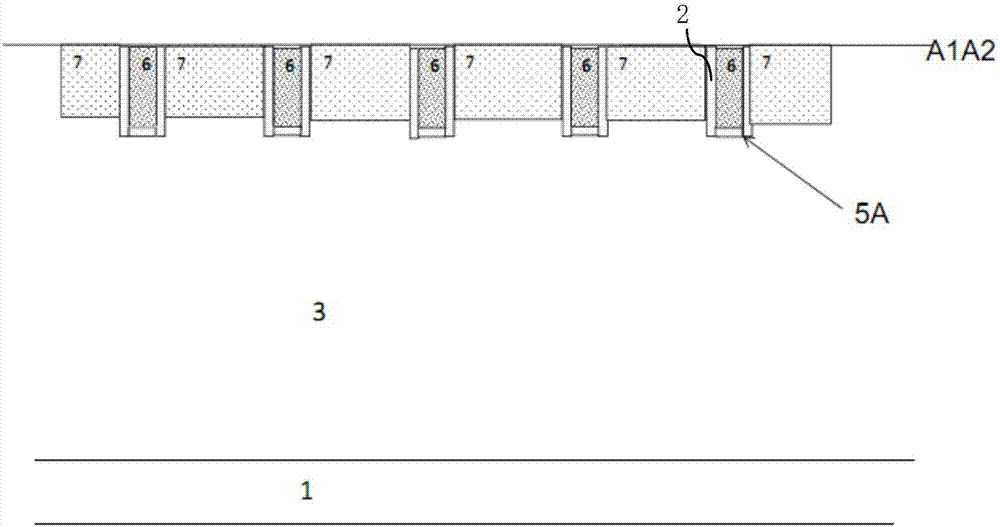

Shield grid trench MOSFET device and manufacturing method thereof

ActiveCN105702739AIncrease the doping concentrationLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetEngineering

The invention discloses a shield grid trench MOSFET device.In grid electrode structures of primitive cells, shield electrodes are formed after epitaxial layers filling trenches are etched back, and trench grids are formed at the tops of the shield electrodes; the shield electrodes and adjacent drift regions make direct contact, carrier balance is achieved, the shield electrodes of the primitive cells and the drift regions form alternately-arranged structures in the transverse direction, and the shield electrodes carry out transverse exhausting on the adjacent drift regions in reverse bias of the device.The invention further discloses a manufacturing method of the shield grid trench MOSFET device.According to the shield grid trench MOSFET device and the manufacturing method, it is unnecessary to arrange dielectric films at the bottoms of the shield electrodes, stepping of device units can be reduced, the specific on-resistance of the device can be reduced, manufacturing difficulty can be lowered, and the uniformity of device performance can be improved.

Owner:SHENZHEN SANRISE TECH CO LTD

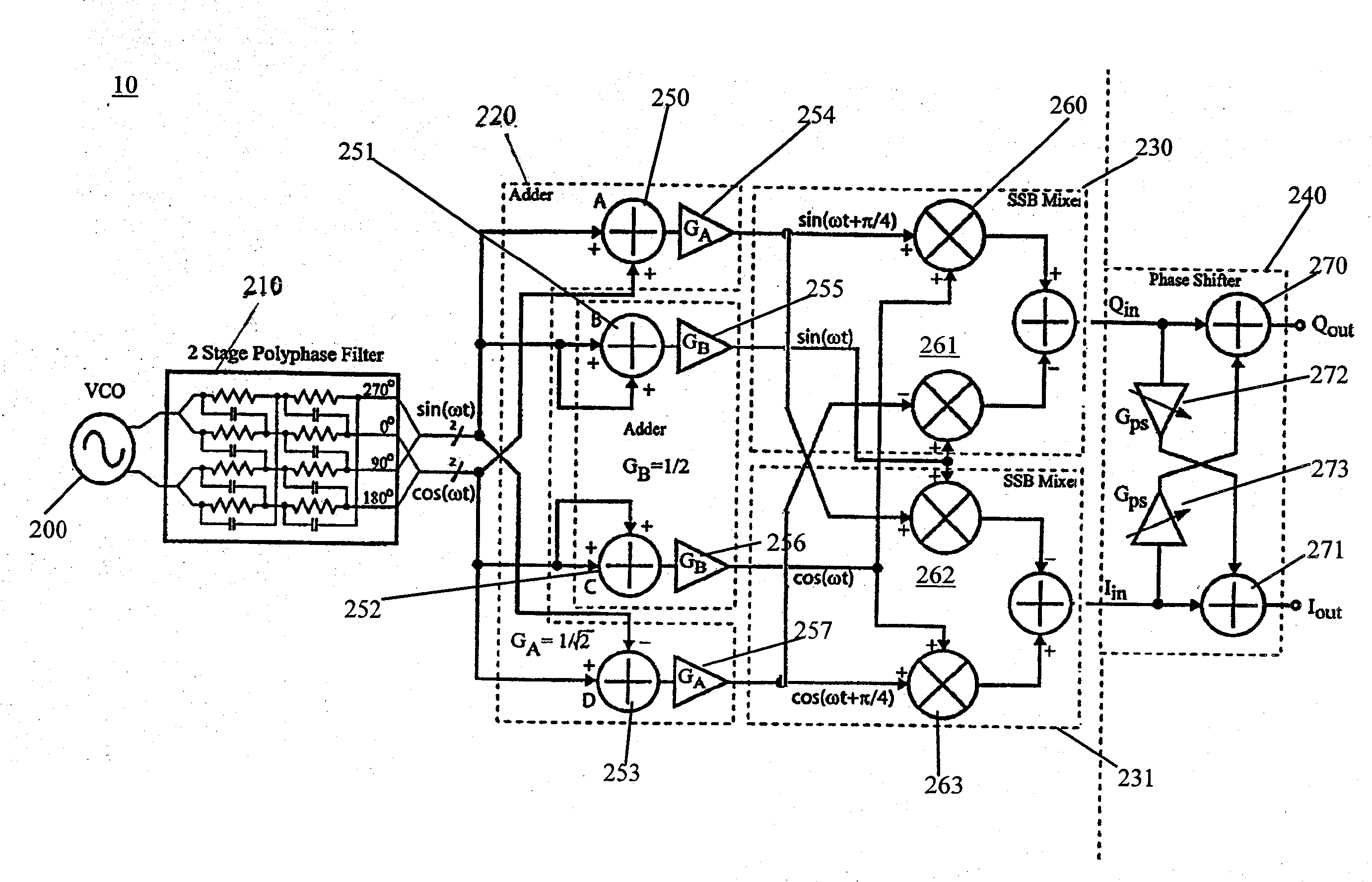

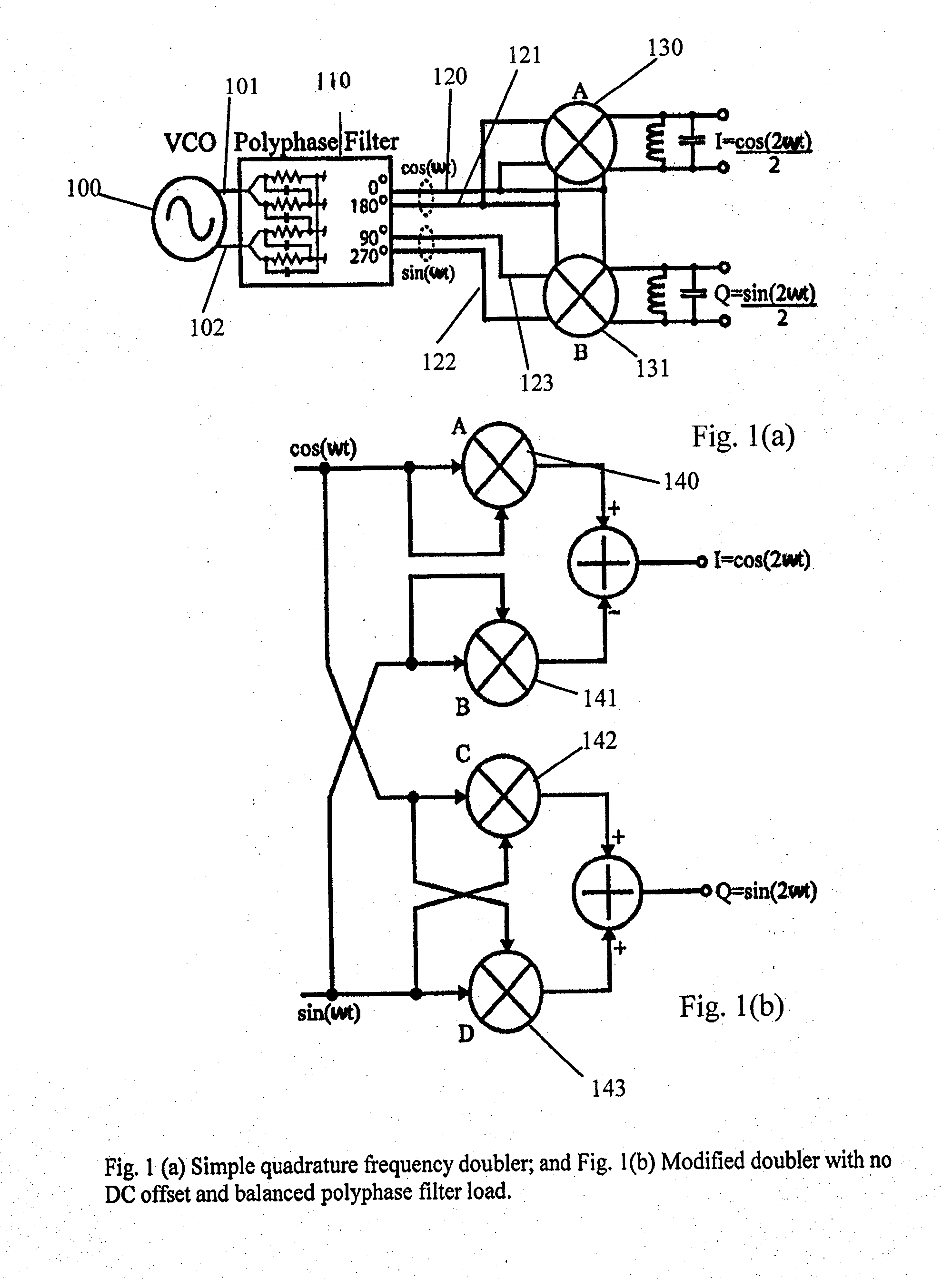

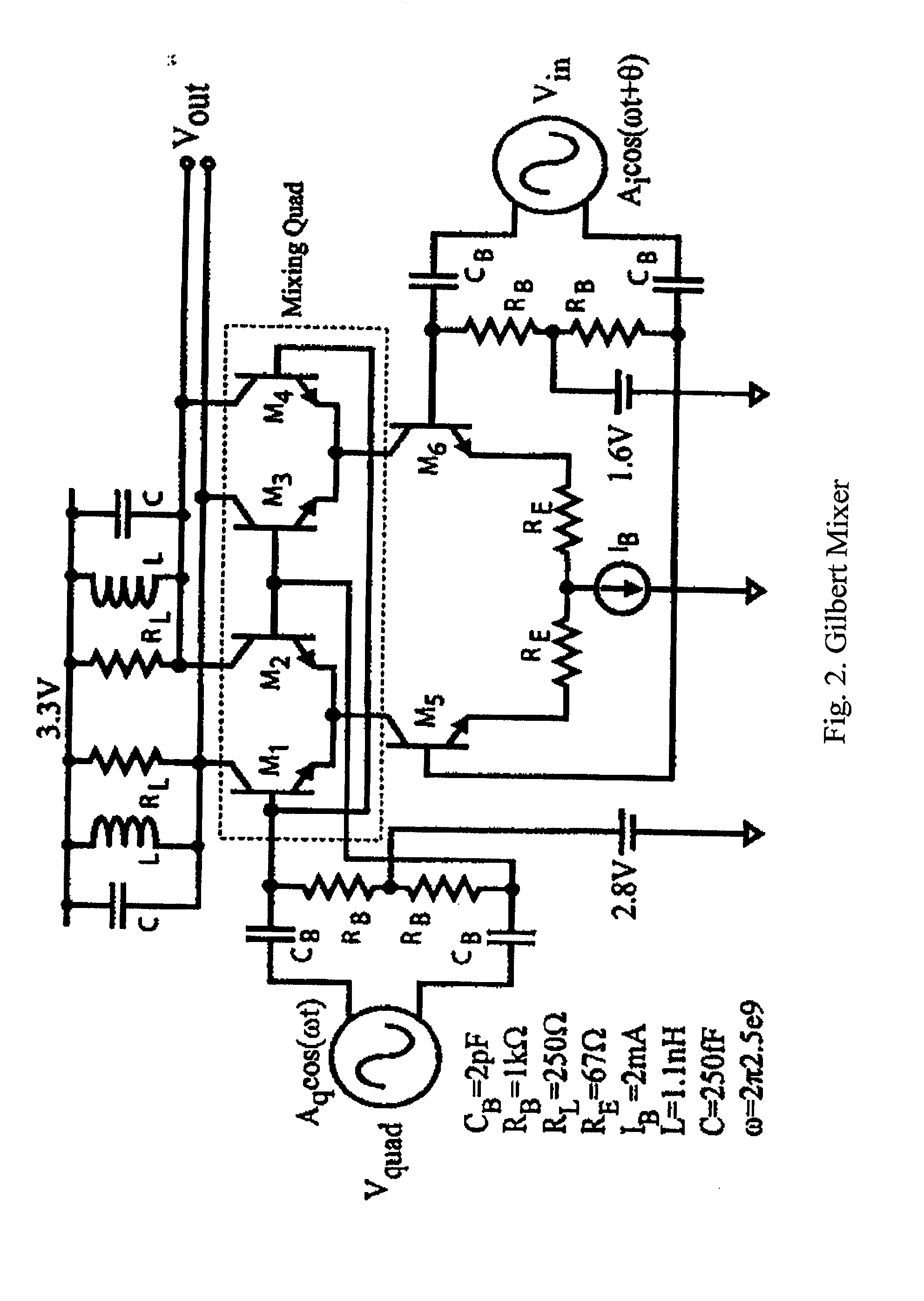

Quadrature frequency doubler with adjustable phase offset

ActiveUS20080030244A1Achievable sideband rejectionSmall stepAngle modulationFrequency-modulated carrier systemsPhase shiftedFrequency mixer

The present invention provides an improved frequency doubling circuit, with adjustable phase offset. Briefly, rather than using the traditional equations cos (2ωt)=cos 2(ωt)−sin 2(ωt) and sin(2ωt)=2 sin(ωt)cos(ωt), the quadrature output signals are generated utilizing mixers, each having two input signals, separated in phase by the same offset. This minimizes the effects of the non-linearities introduced by the mixer, which therefore reduces amplitude mismatch between the quadrature signals. Also, the phase offset of the quadrature output signals can be tuned and calibrated using a phase shifting circuit. This phase shifting circuit realizes a tuning range of approximately 5° in programmable steps. This combination of circuits can be used to minimize the amplitude mismatch and phase errors, thereby reducing the amplitude of and interference caused by transmission of the image frequency to the receivers input.

Owner:EDGEWATER WIRELESS SYST

Method for calibrating three-dimensional micro-touch force sensor

InactiveCN101561334ASmall stepHigh precisionForce/torque/work measurement apparatus calibration/testingMathematical modelClassical mechanics

The invention relates to a method for calibrating a three-dimensional micro-touch force sensor, which comprises the following steps: adopting the bending deformation principle of a cantilever beam to acquire a micro-force signal required by calibrating the three-dimensional micro-touch force sensor; measuring the elastic coefficient of the cantilever beam; based on the cantilever beam of the known elastic coefficient, establishing a calibrating system of the three-dimensional micro-touch force sensor, and measuring input-output property coefficients of the calibrating system by applying acting force of different intensity to the sensor; measuring the measuring bar displacement property of the three-dimensional micro-touch force sensor; according to the measured elastic coefficient of the cantilever beam, the input-output property coefficients of the calibrating system and the measuring bar displacement property coefficient of the sensor, establishing a mathematical model to acquire the input-output property coefficients of the sensor; and according to a zero output voltage value of the sensor and the input-output property coefficients of the sensor, establishing an input-output property equation of the sensor so as to finish the calibration of the three-dimensional micro-touch force sensor. The method can realize the calibration of the output property of the three-dimensional micro-touch force sensor, and has the advantages of high and reliable precision and good repeatability.

Owner:TIANJIN UNIV

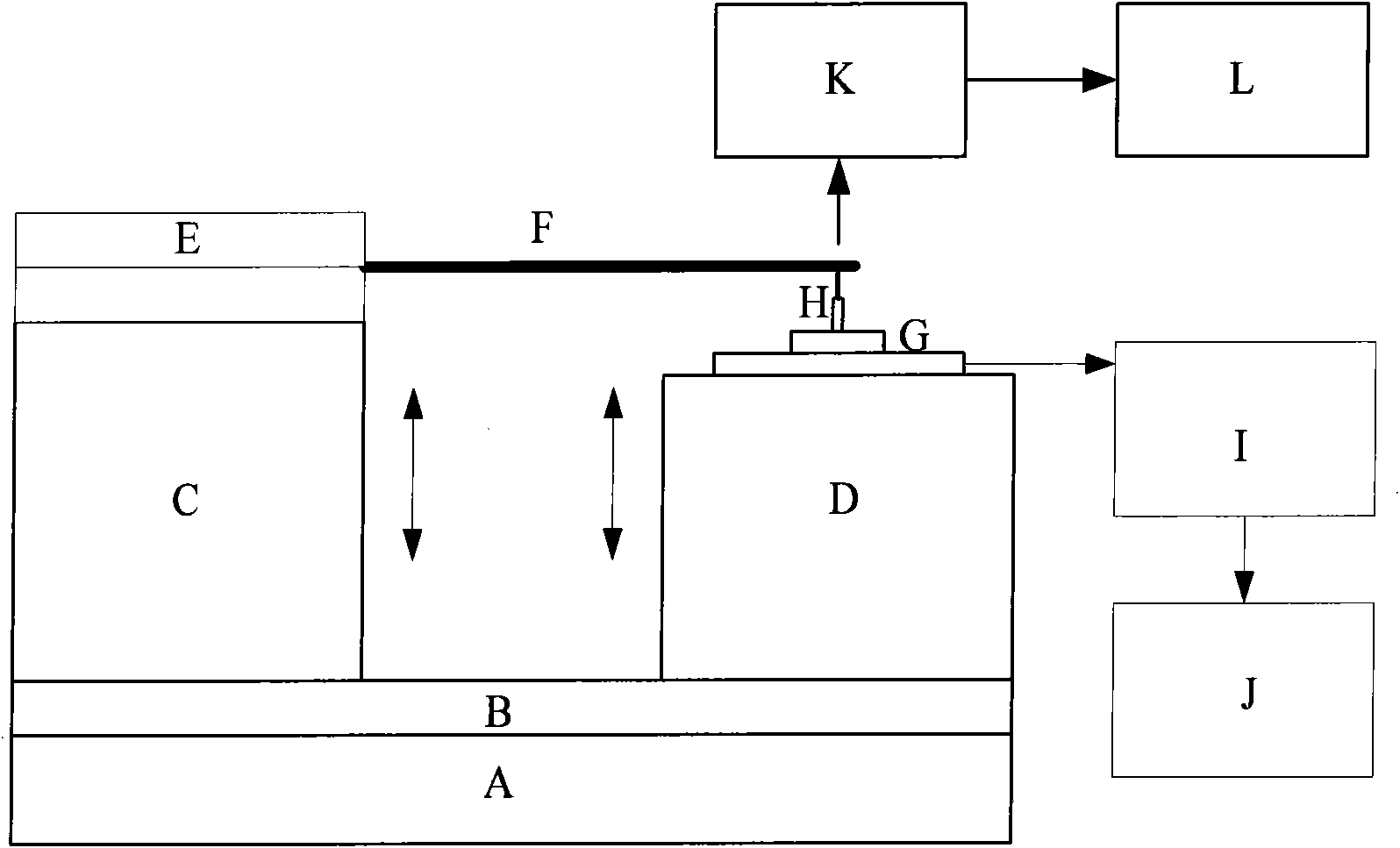

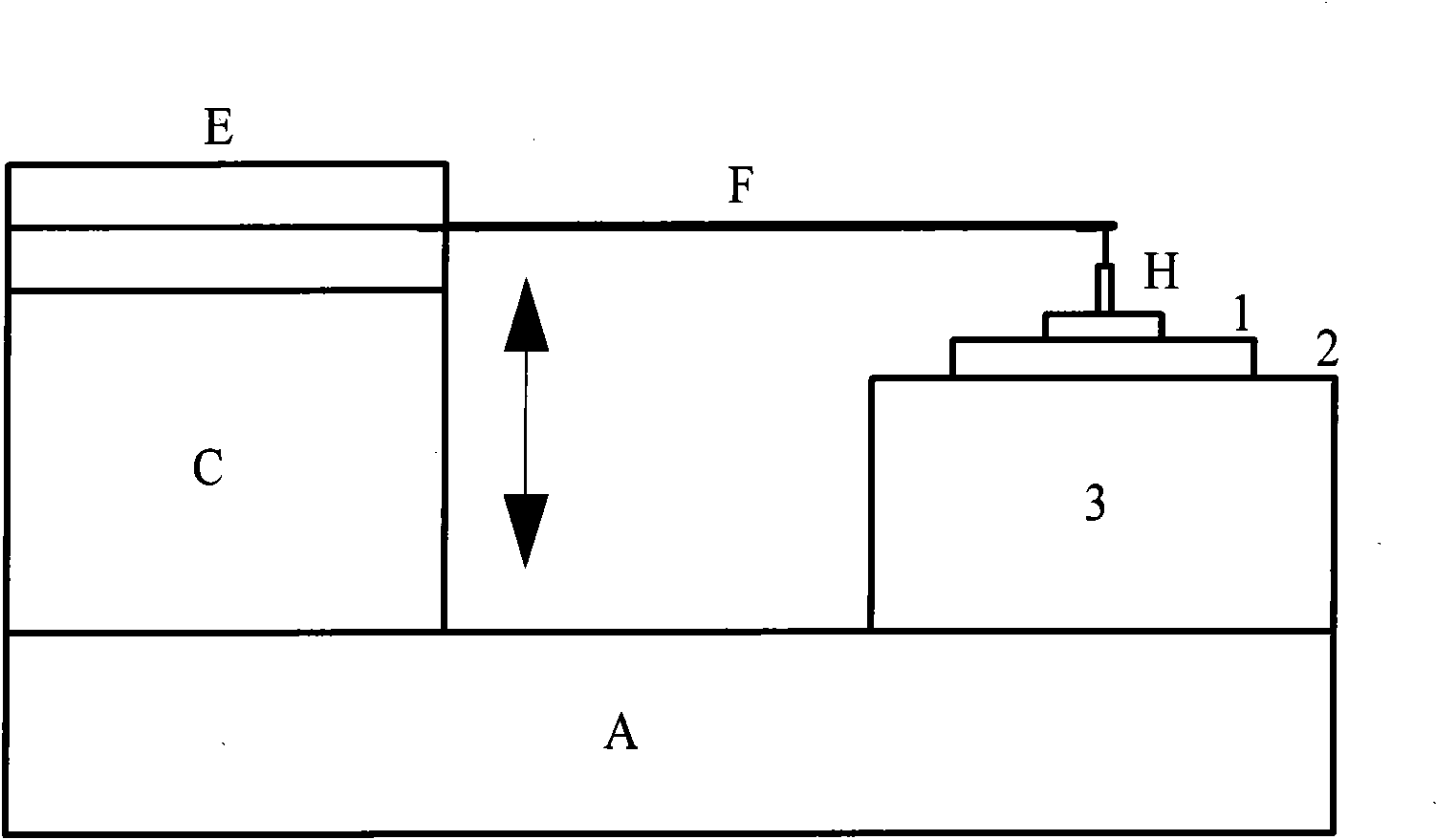

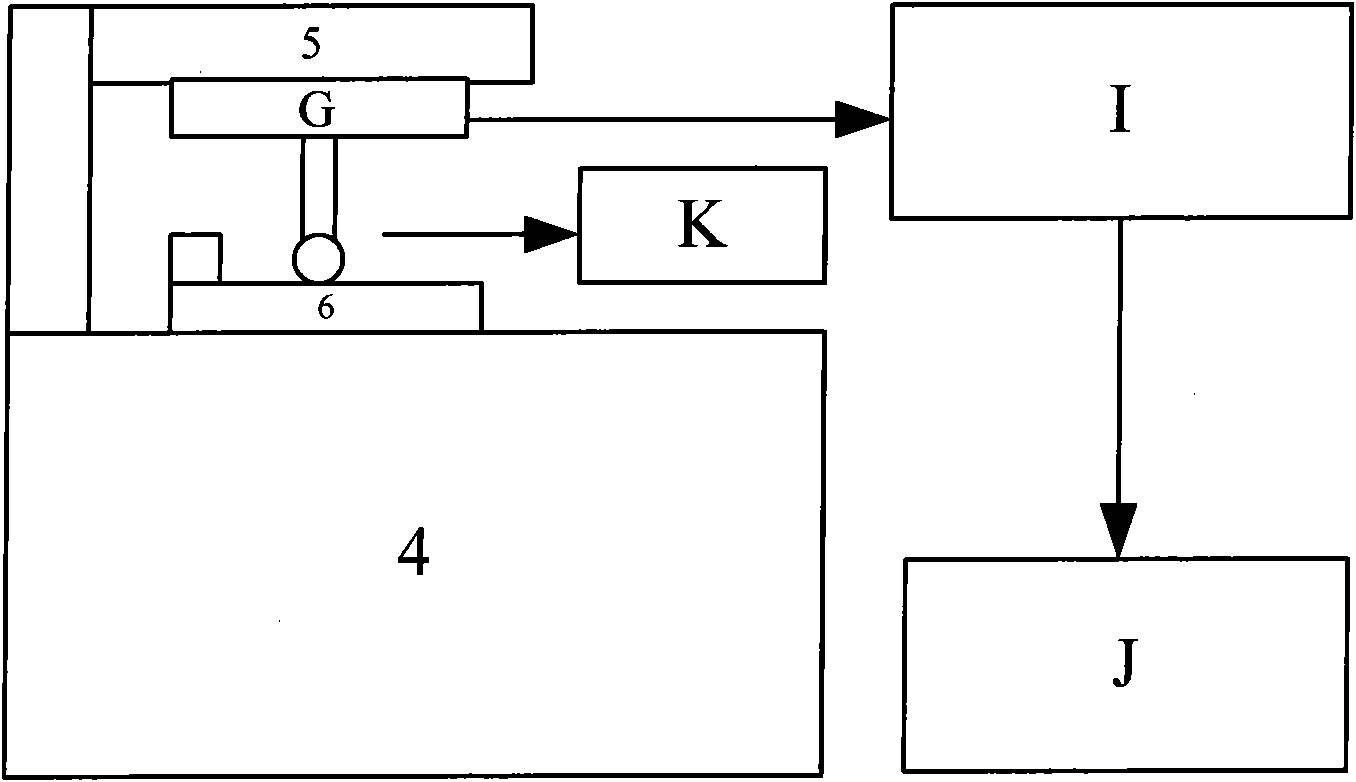

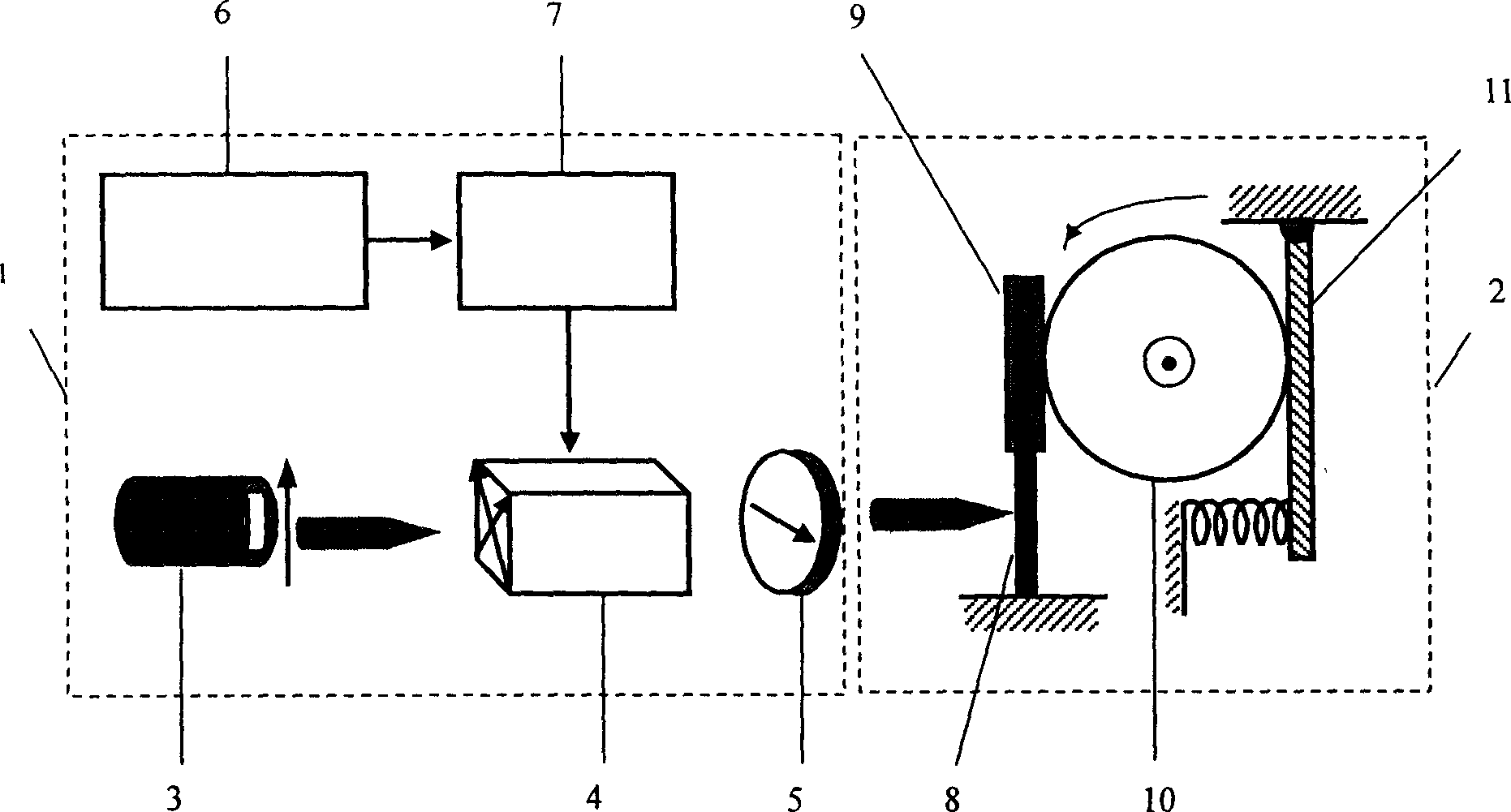

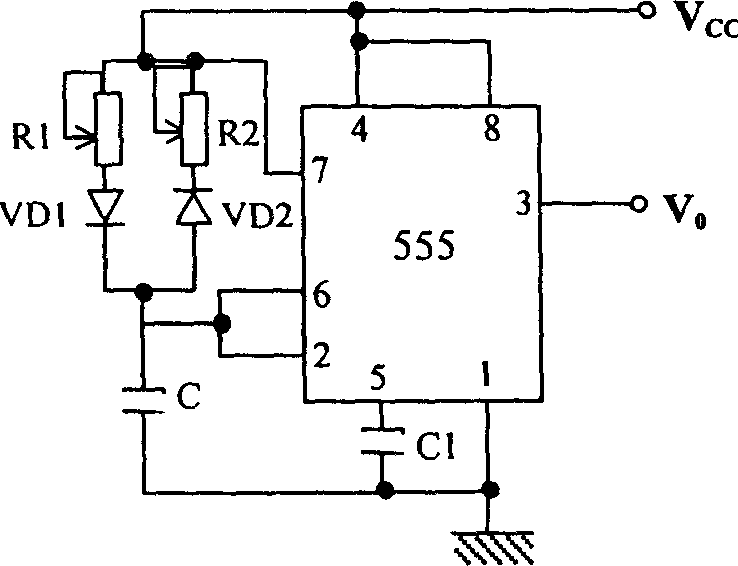

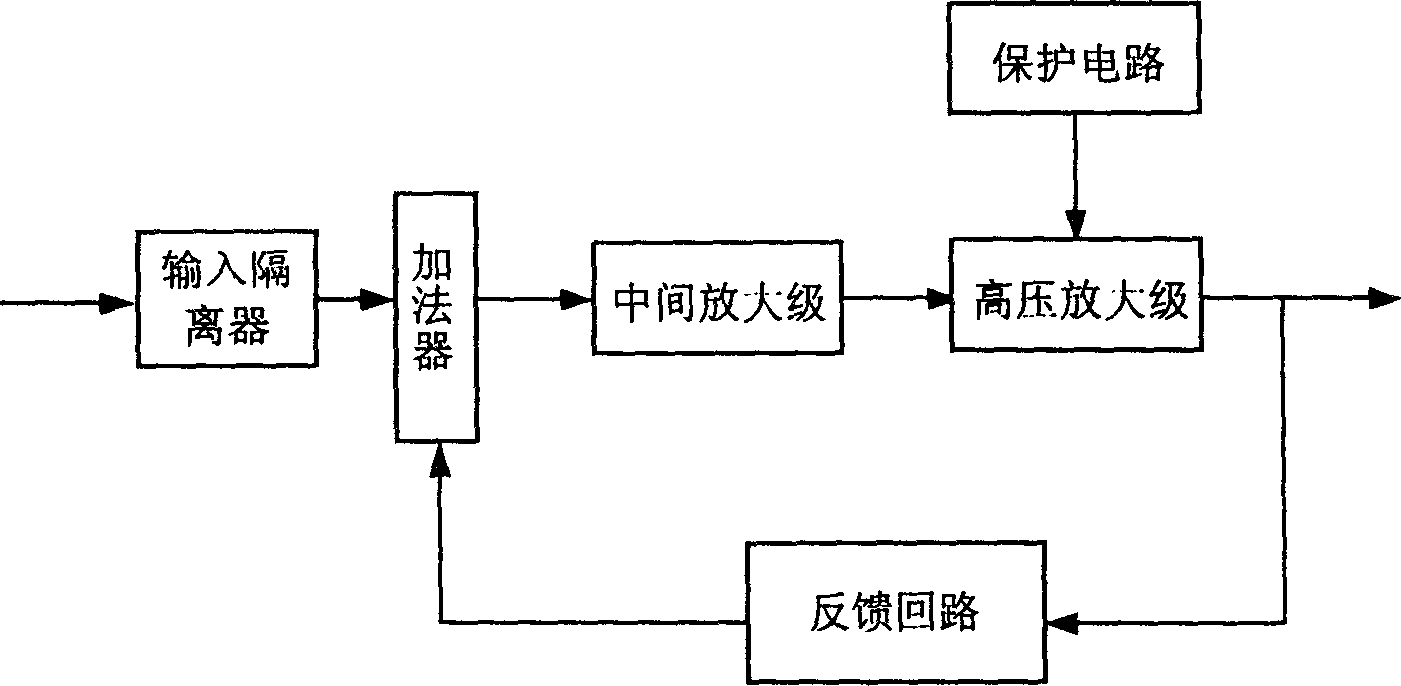

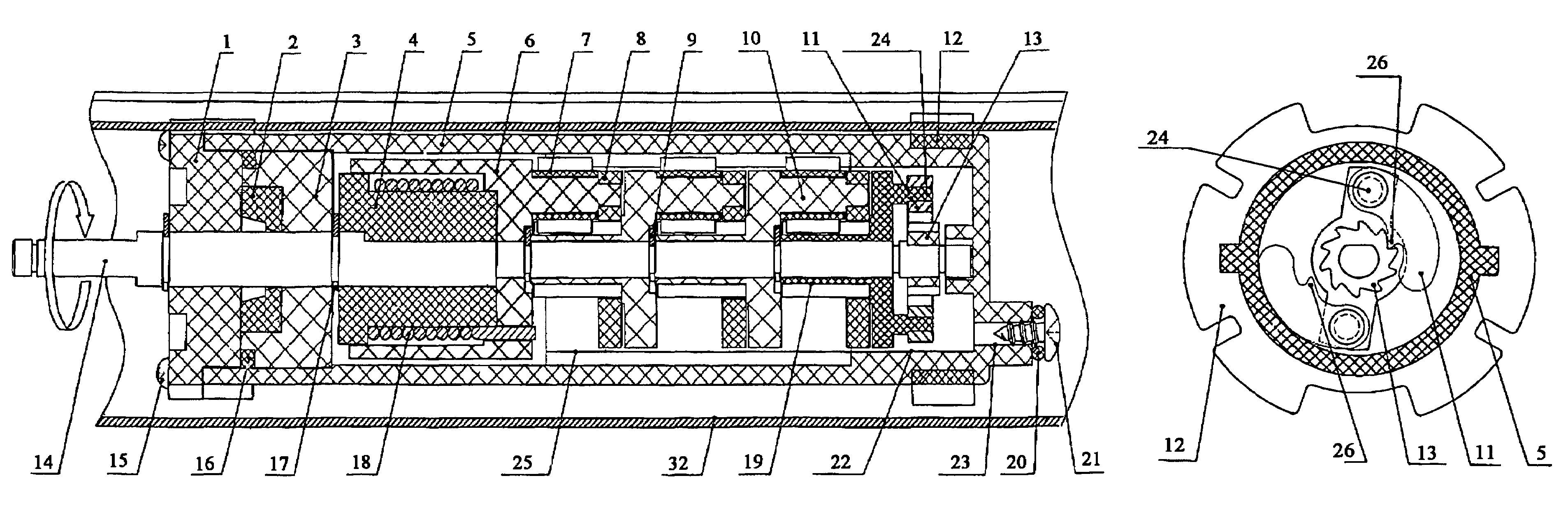

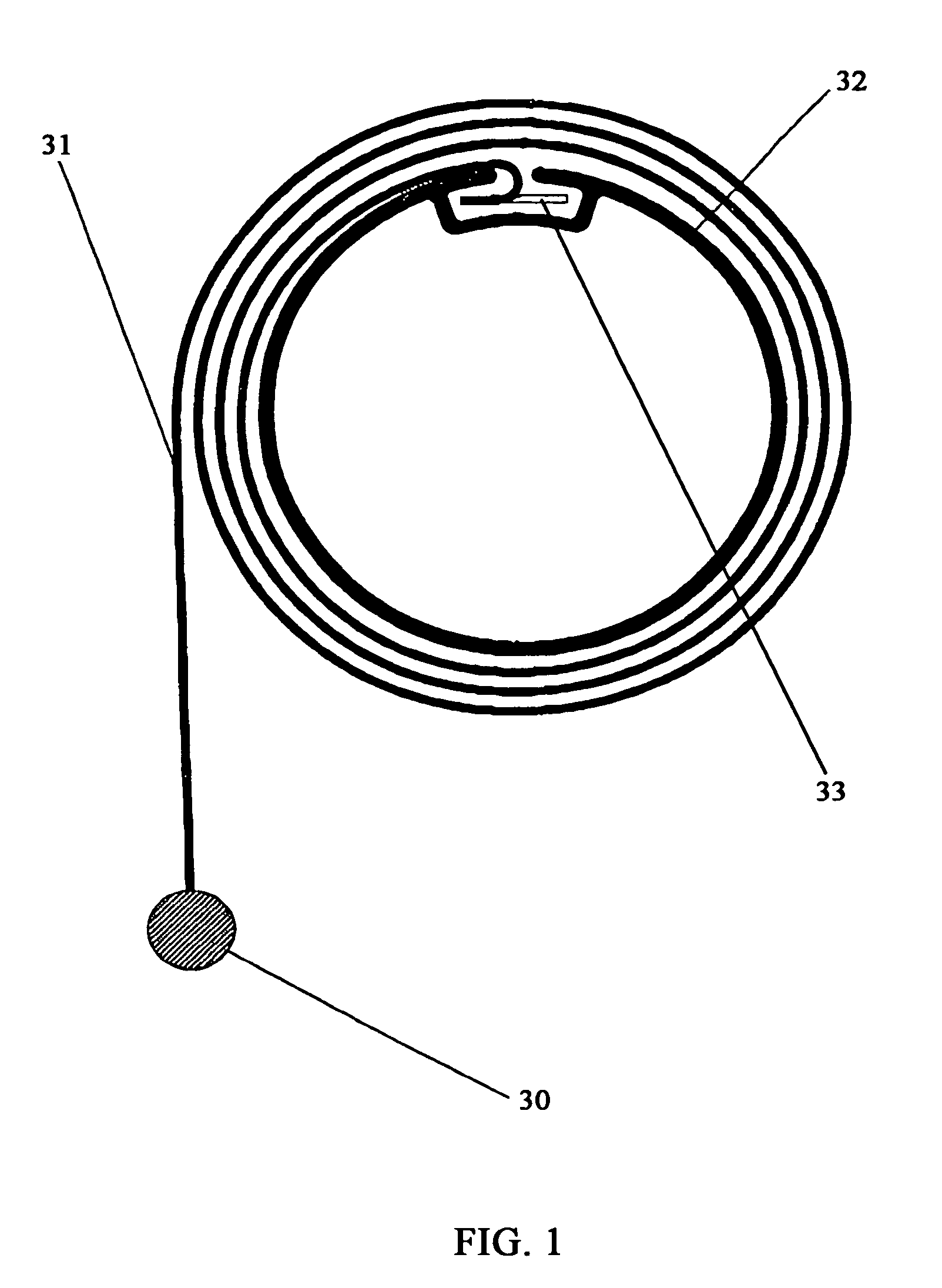

Photo thermal driving micro motor

The mocro motor includes a system of pulsed light source and a rotation system. The system of pulsed light source possesses laser, electrooptic crystal, polarization disk. The electrooptic crystal is controlled by pulsed signal generation module and amplification loop. The rotation system possesses an expanding arm, friction plate, coaxial rotor, and a piece of compression spring. One end of the expanding arm is fixed, and the other end is pasted to the friction plate. One end of the piece of compression spring is fixed, and the other end is connected to a spring. The rotor is connected to the piece of compression spring, and the friction plate. Advantages are: small output step pitch, high speed, driven by laser directly, no read wire required, microminiature, possible to be placed in enclosure space (such as vacuum cavity), and remote controllable.

Owner:ZHEJIANG UNIV

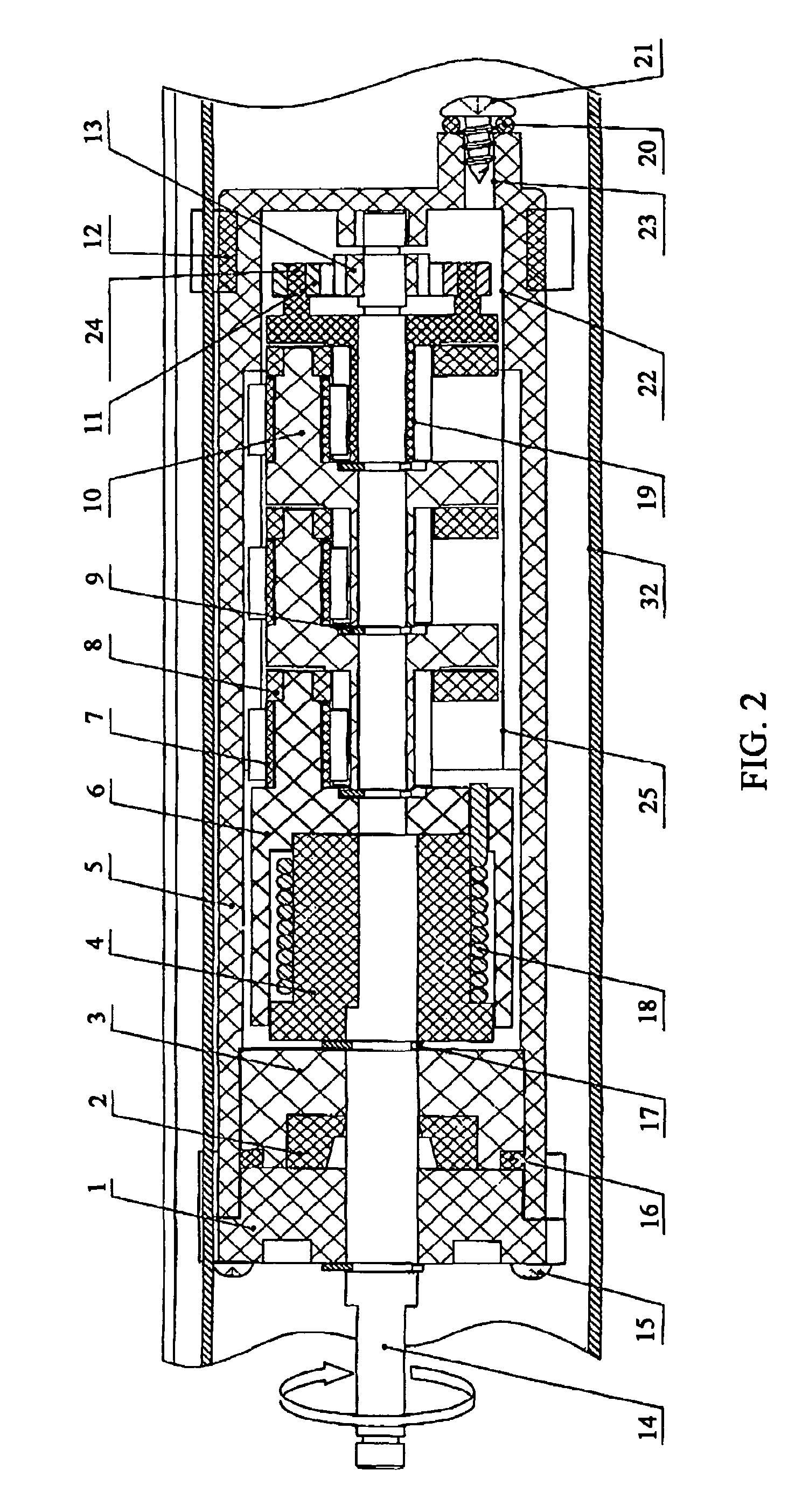

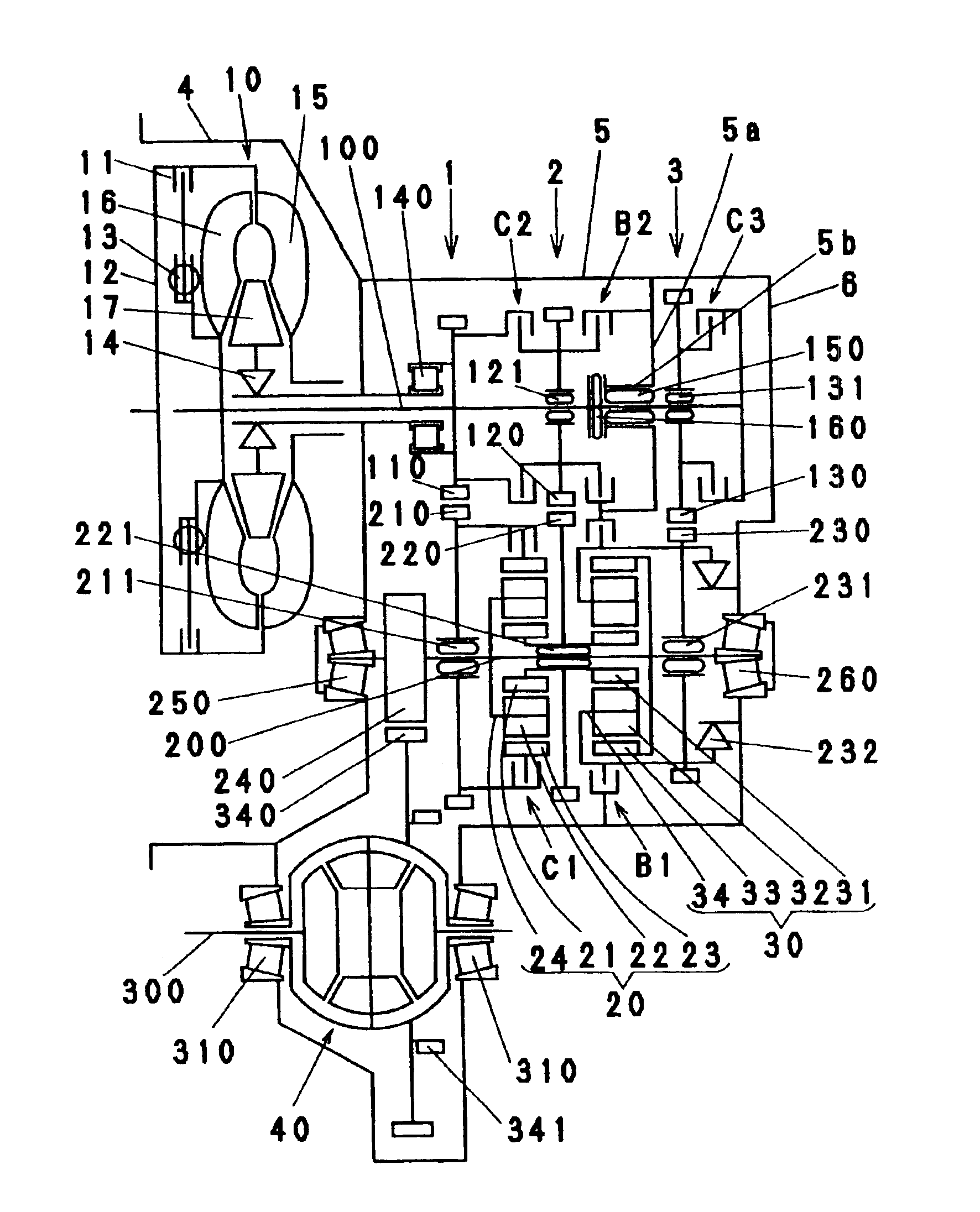

Decelerating and locking mechanism for a projection screen and the manually operated projection screen using the mechanism

The present invention provides a manually operated projection screen having a decelerating and locking mechanism which intergrates a decelerating mechanism and a locking mechanism as a whole. The decelerating and locking mechanism for a projection screen includes a braking and locking device having a centrifugal brake shoe, a brake drum interacting with the centrifugal brake shoe to perform decelerating function, and a ratchet interacting with the centrifugal brake shoe to perform locking function. The decelerating and locking mechanism includes at least three sets of planetary gear, the transmission ratio of the planetary gear is 1:32 or above. The decelerating and locking mechanism and the projection screen using the same is compact and easy to assemble. The projection screen can be freely positioned or locked at any moment and is free of crease.

Owner:GUANGZHOU GRANDVIEW CRYSTAL SCREEN CO LTD

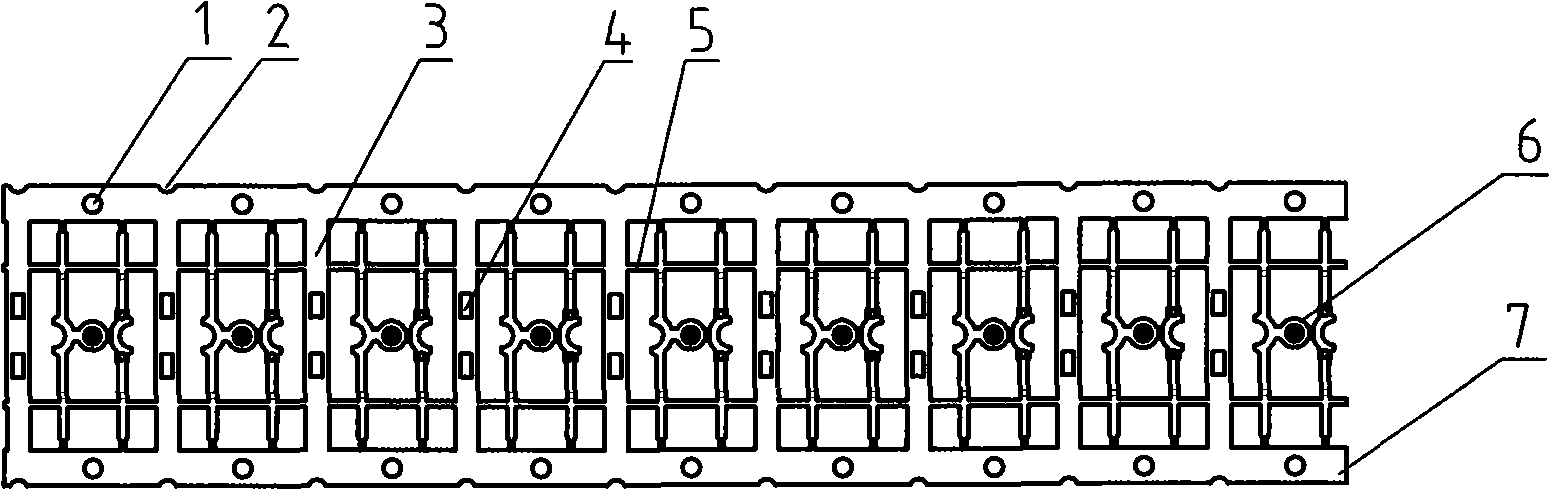

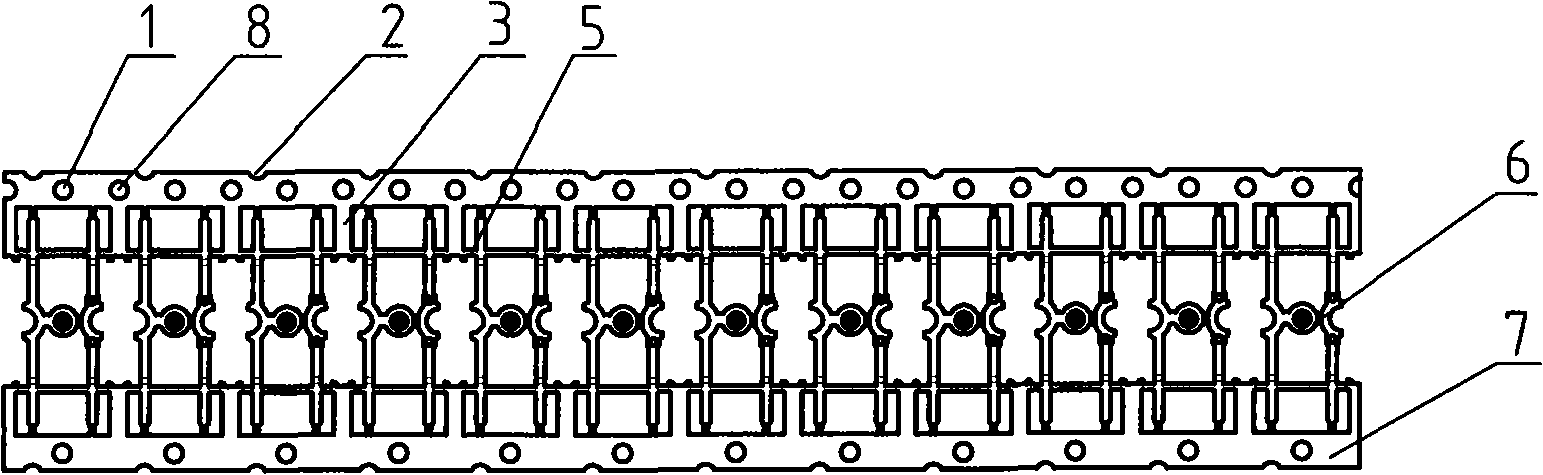

Power type LED lead frame piece and process technique thereof

InactiveCN101294694AImprove rigidityIncrease profitPoint-like light sourceLighting support devicesLead frameEnergy consumption

The invention discloses a power type LED lead frame sheet and belongs to the middle piece in the LED lead frame processing technique. The invention further relates to the processing technology of the power type LED lead frame sheet. The power type LED lead frame sheet includes a lead frame, a frame and a bracing member, wherein a fabrication hole is formed on the frame corresponding to the lead frame longitudinal midline, a fabrication nick is disposed on the outer side thereof, a transverse bracing member is arranged between the bracing member and a pin of the lead frame, the step pitch ranges from 9.5mm to 9.6mm, the width of the bracing member ranges from 1.45mm to 1.55mm, the bracing member is arranged between the frame and the transverse bracing member on the corresponding side, and the length of the transverse bracing member ranges from 1.05mm to 1.30mm. The invention provides the power type LED lead frame sheet with less structural waste, low energy consumption in processing and high production efficiency.

Owner:济南晶恒精密电子有限公司

Gear unit for a compound transmission

InactiveUS20150211608A1Small stepToothed gearingsTransmission elementsReduction driveTransmission ratio

A gear unit for a compound transmission has a planetary stage that couples an input and an output shaft for different transmission ratios. The planetary stage includes a sun gear, a ring gear and planet gears rotatably supported at a planet carrier. The planet gears have a region with two different toothings arranged axially offset with respect to an axis of rotation of the planetary stage. A meshing engagement with a first sun gear and / or a first ring gear is produced via the first toothing. The planet gears mesh at the second toothing with a second sun gear and / or a second ring gear, and one component of the planetary stage is connected to the input shaft to be fixed with respect to rotation and one component is fixed at a housing, while the rest of the components can be coupled with the output shaft, respectively.

Owner:ZF FRIEDRICHSHAFEN AG

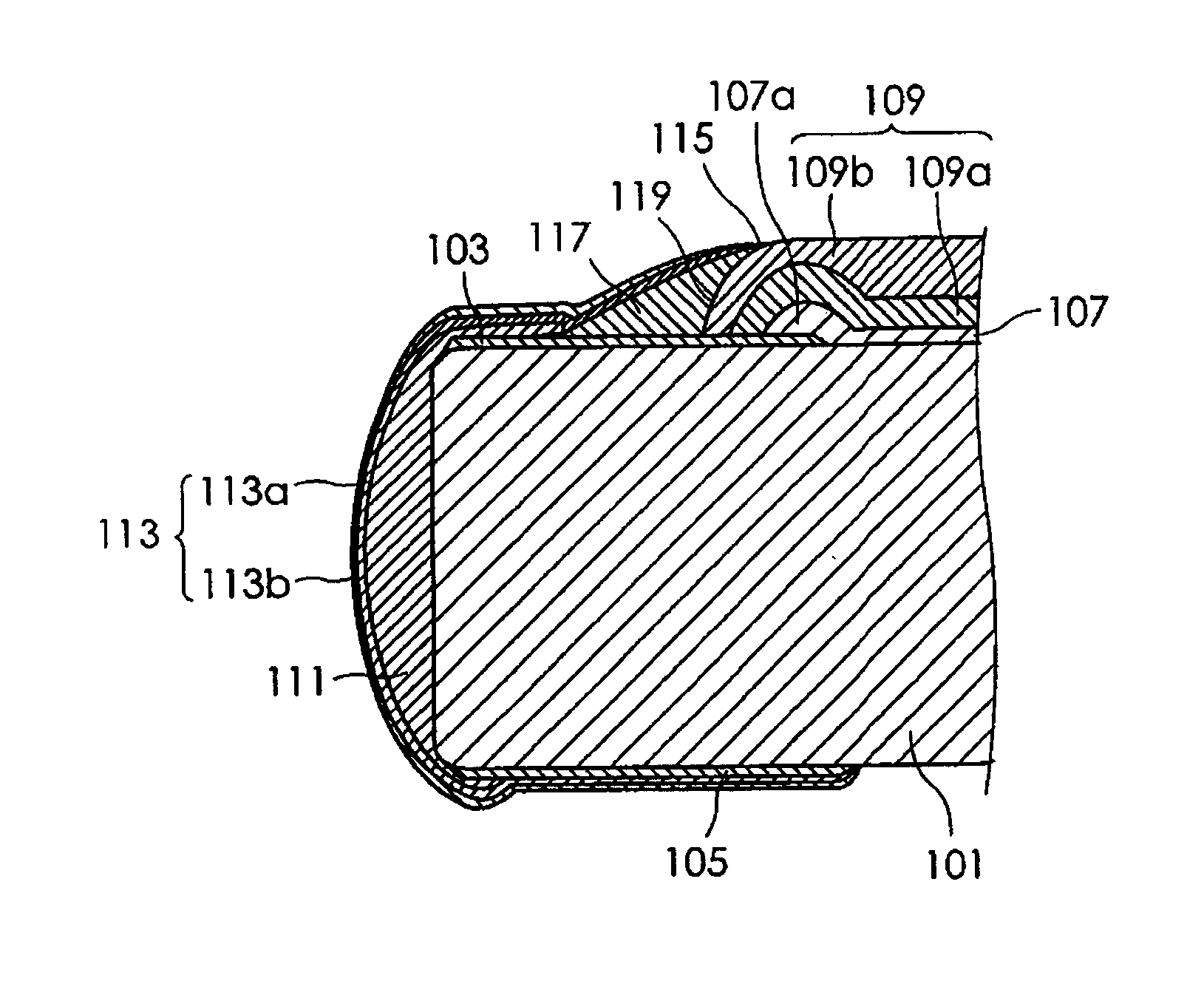

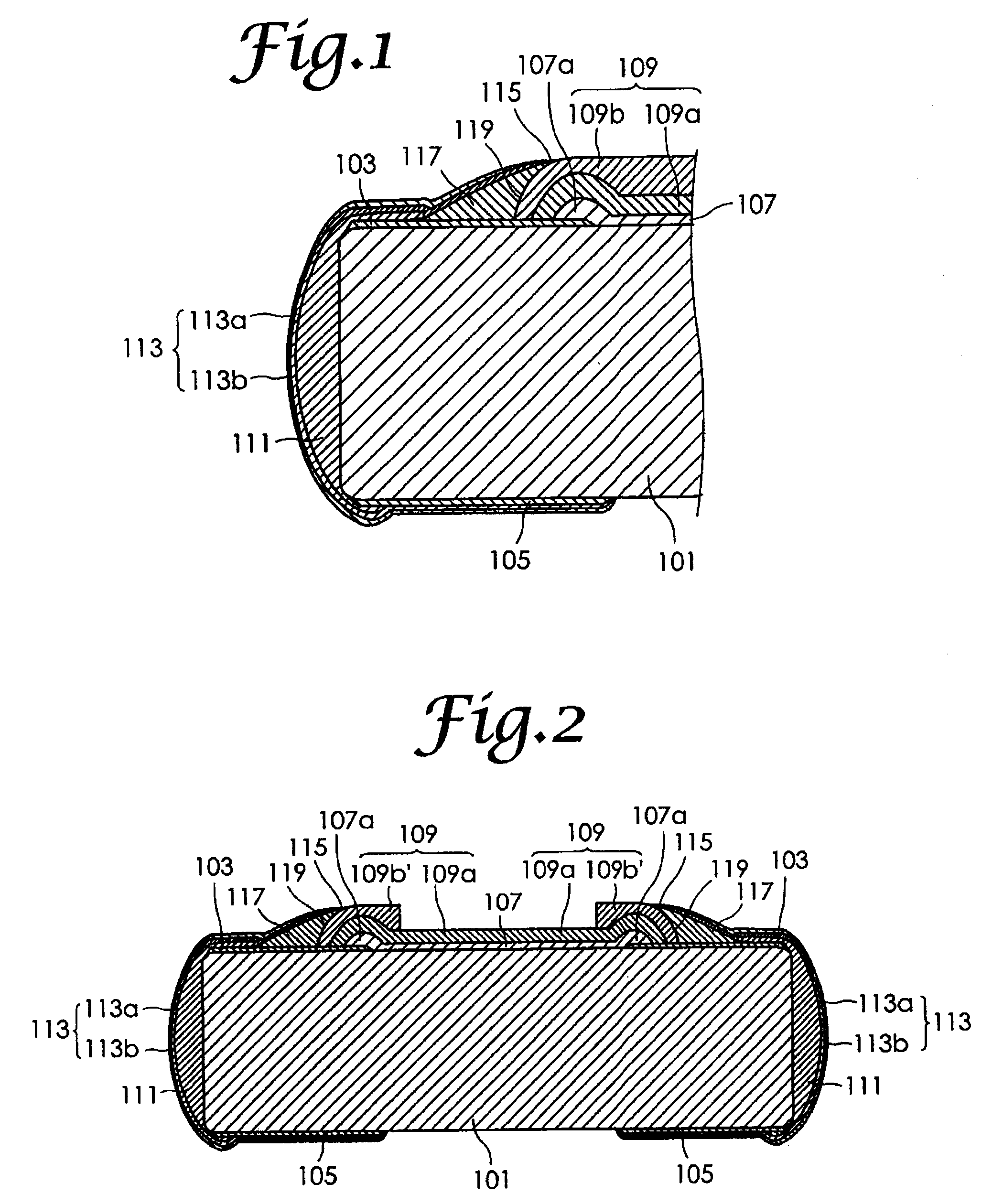

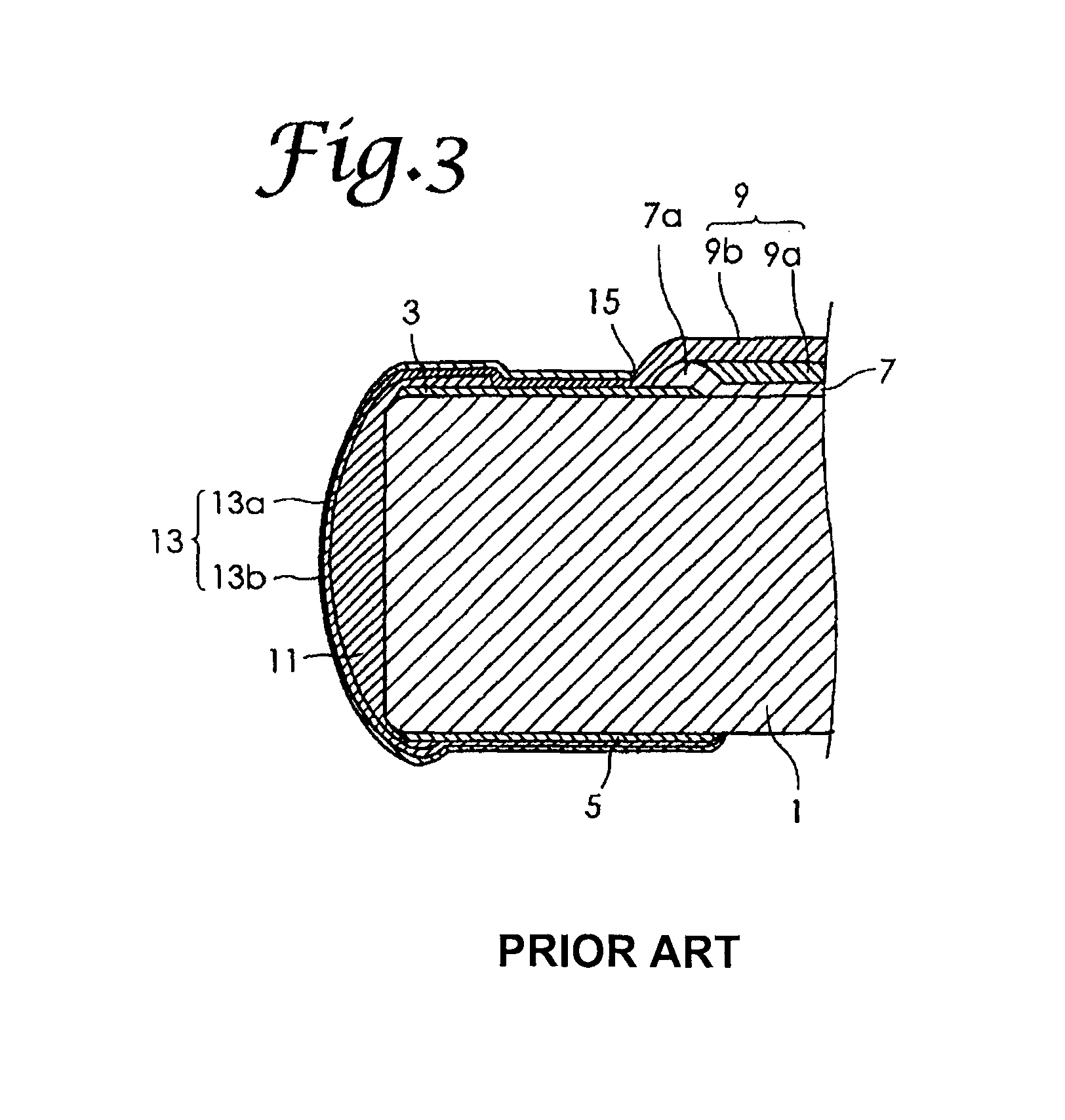

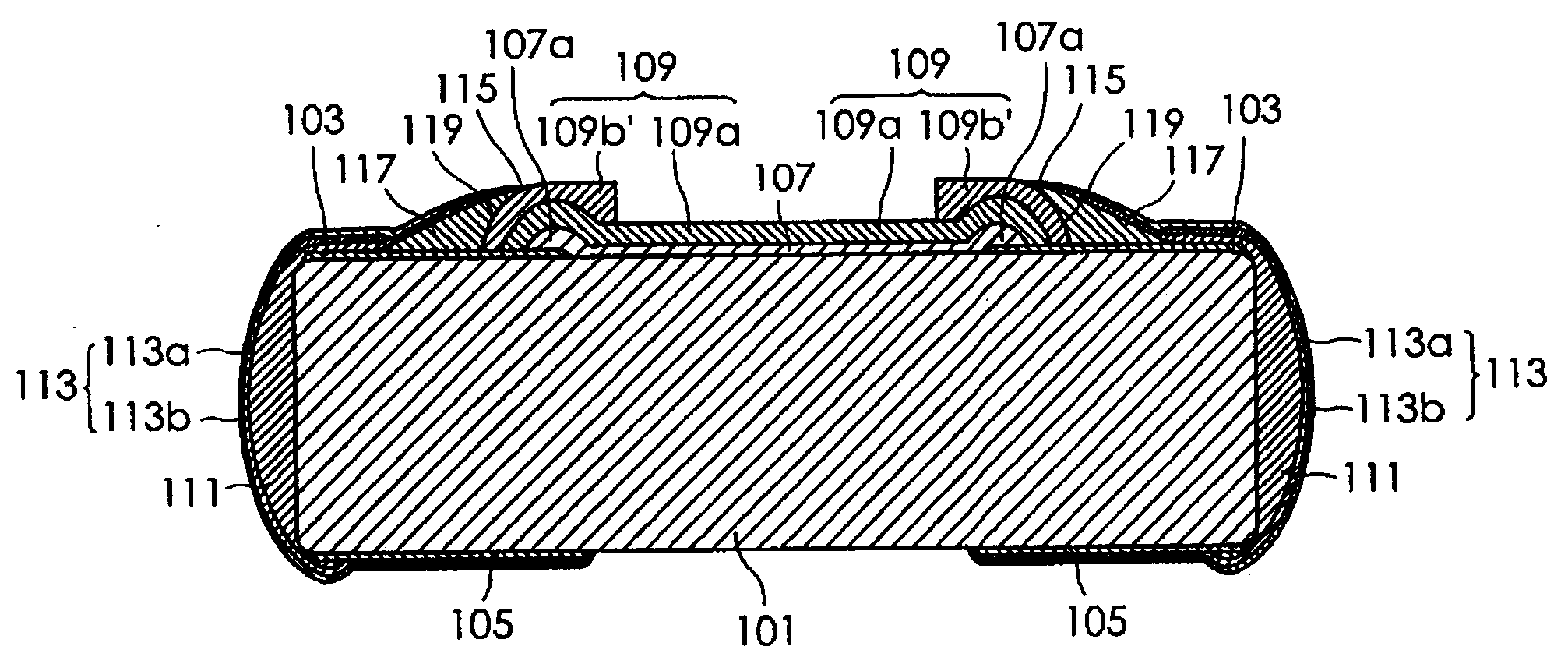

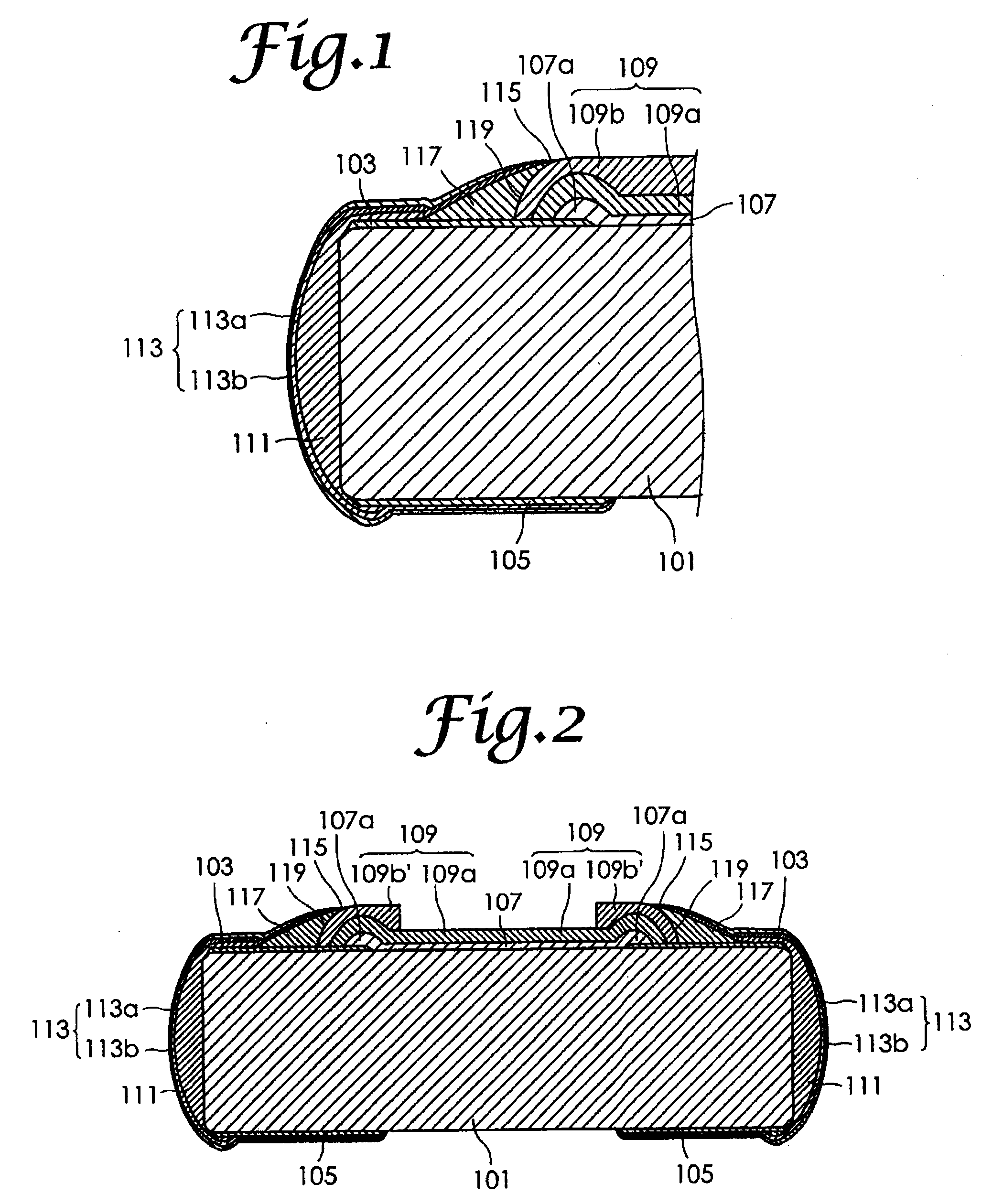

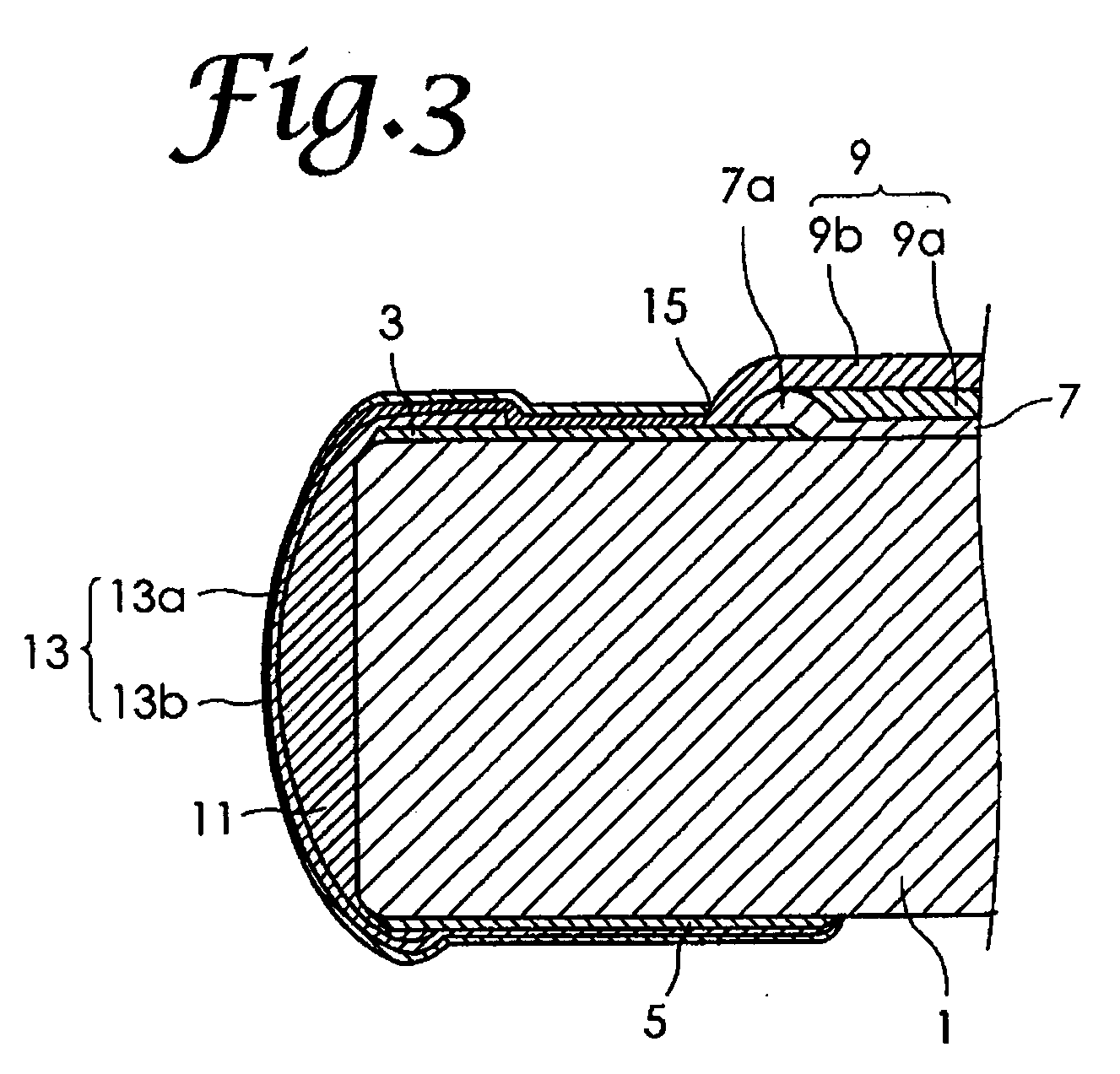

Terminal structure of chiplike electric component

InactiveUS7825769B2Avoid enteringGuaranteed to workResistor chip manufactureFixed capacitor dielectricEpoxyOptoelectronics

Owner:HOKURIKU ELECTRIC INDS

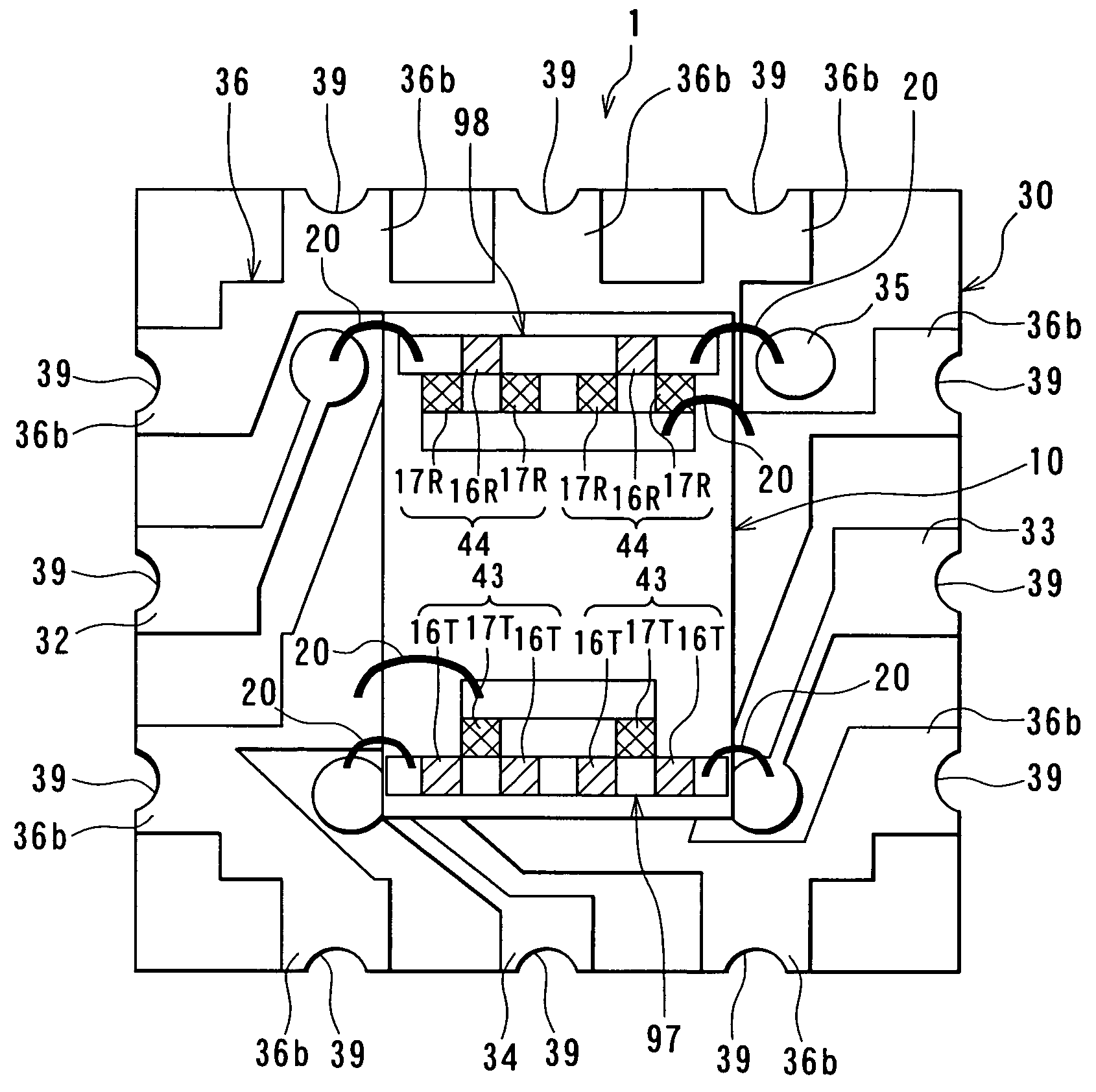

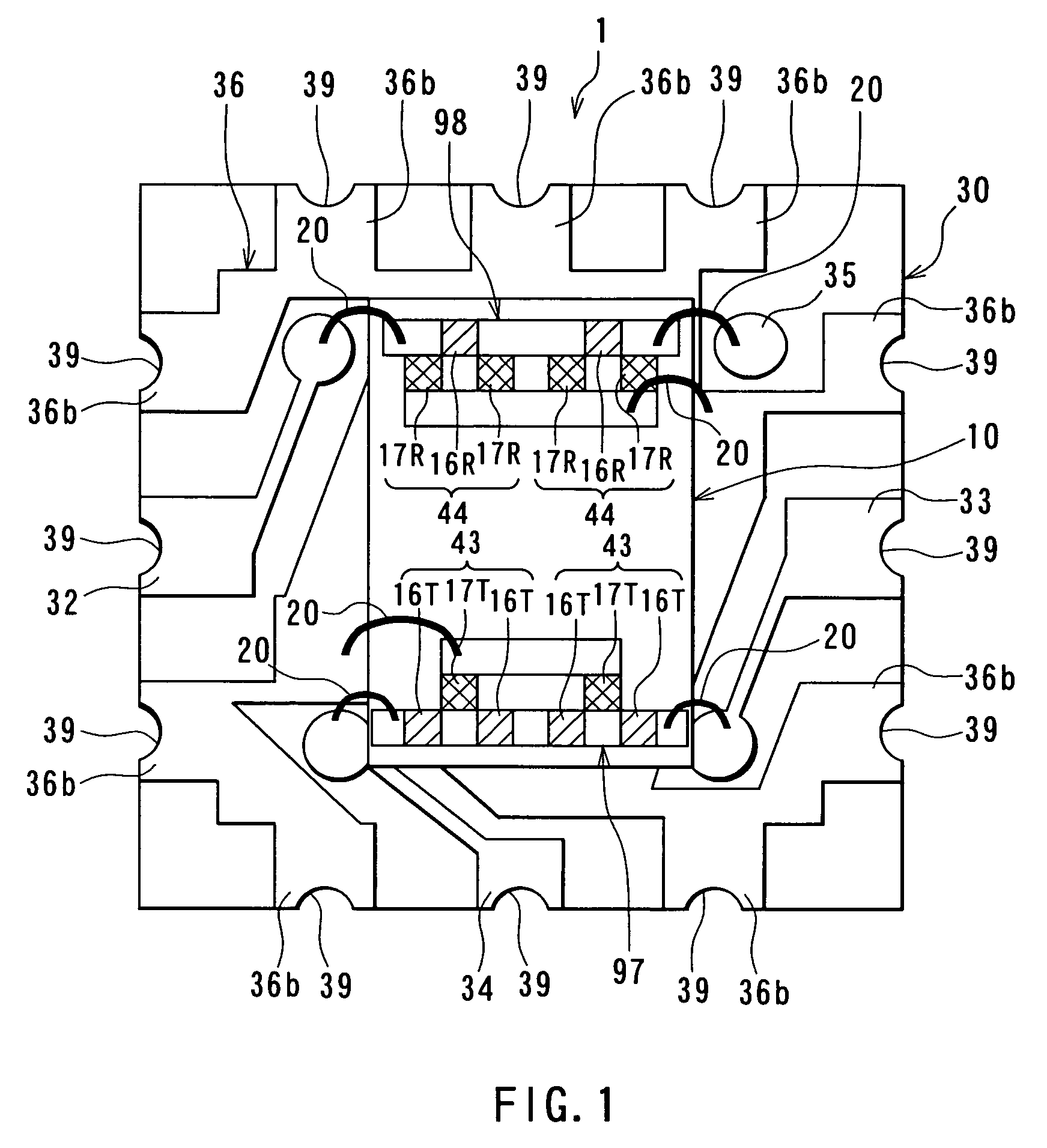

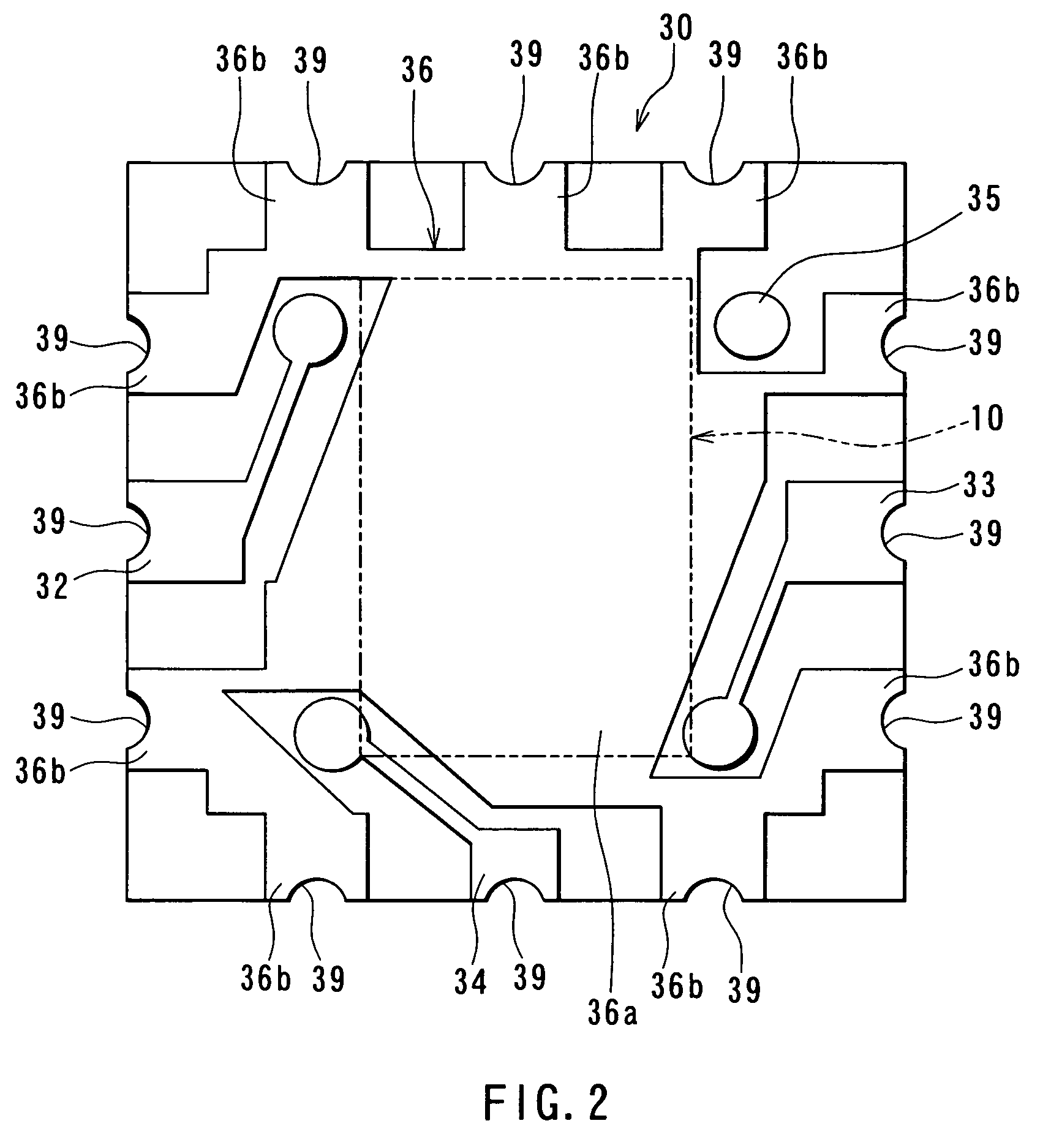

Duplexer and method of manufacturing same

InactiveUS7078984B2Small stepFew stepsPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPhysicsPiezoelectric resonators

A duplexer (1) comprises a chip (10) including a transmission filter (97) for passing a transmission signal therethrough and interrupting a reception signal and a reception filter (98) for passing a reception signal therethrough and interrupting a transmission signal. Each of the transmission filter (97) and the reception filter (98) includes thin-film piezoelectric resonators (16 and 17) each of which has a piezoelectric thin film that exhibits a piezoelectric property and two excitation electrodes that are disposed on both surfaces of the piezoelectric thin film and apply an excitation voltage to the piezoelectric thin film. All of the thin-film piezoelectric resonators (16 and 17) that the transmission filter (97) and the reception filter (98) include are disposed on a single base.

Owner:SNAPTRACK

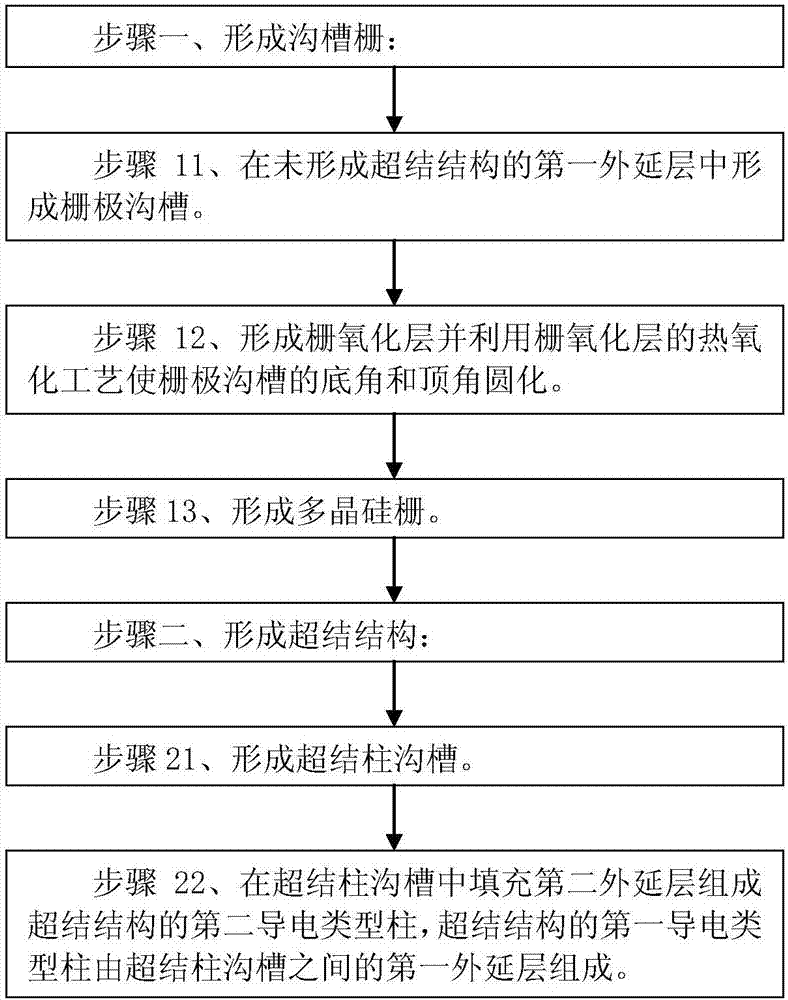

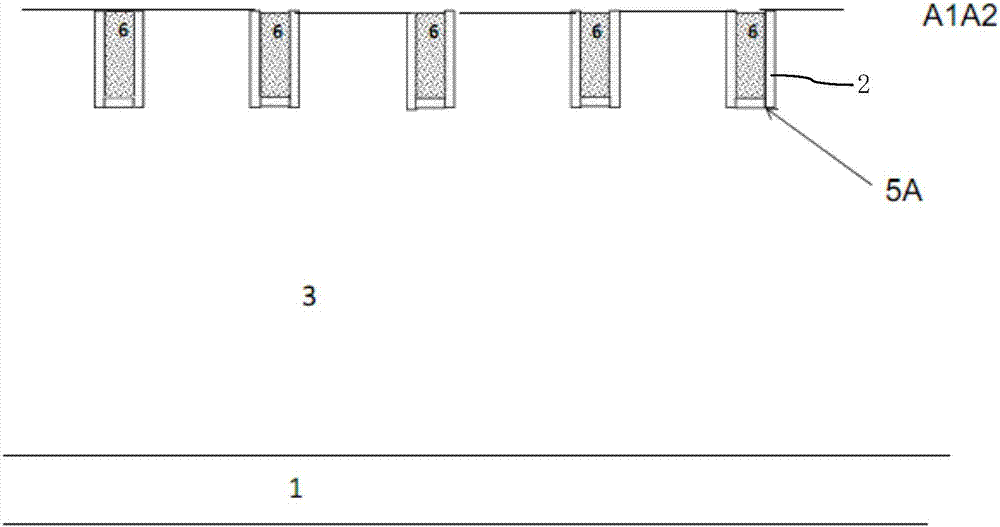

Manufacturing method of trench-gate superjunction device

InactiveCN107994076AReduce leakageImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringPolycrystalline silicon

The invention discloses a manufacturing method of a trench-gate superjunction device. The manufacturing method comprises the steps of 1, forming a trench gate, wherein the step 1 comprises the steps of 11, forming a gate groove in a first epitaxial layer in which a superjunction structure is not formed; 12, forming a gate oxide layer, and rounding a bottom angle and a top angle of the gate grooveby a thermal oxidization process of the gate oxide layer; and 13, forming a poly-silicon gate; and 2, forming the superjunction structure, wherein the step 2 comprises the steps of 21, forming a superjunction post groove; and 22, filling a second epitaxial layer in the superjunction post groove to form a second conductive type of post of the superjunction structure, wherein the first conductive type of post of the superjunction structure comprises the first epitaxial layer between the superjunction grooves. By the manufacturing method, the electric leakage of the device can be reduced, the reliability of the device is improved, and meanwhile, the specific conduction resistance of the device also can be reduced.

Owner:SHENZHEN SANRISE TECH CO LTD

Terminal structure of chiplike electric component

InactiveUS20090231086A1Avoid enteringPrevent electromigrationResistor chip manufactureFixed capacitor dielectricEpoxyOptoelectronics

A terminal structure of a chip-like electric component capable of blocking entry of electromigration-causing factors through an insulating resin layer in the vicinity of the peak of a raised portion of an electrical element forming layer is obtained. A metal-glaze-based front electrode 103 containing silver is provided on a surface of an insulating ceramic substrate 101. A resistor layer 107 electrically connected to the front electrode 103 is provided on the substrate surface. A glass layer 109a is provided to completely cover a surface of the resistor layer 107 as well as a surface of an end portion of the resistor layer 107 and also to partially cover the front electrode 103. An insulating resin layer 109b is provided to cover a surface of the glass layer 109a as well as a surface of at least an end portion of the glass layer 109a and to partially cover the front electrode 103. A conductive layer 117 made of a resin-based conductive paint is provided to extend over the surface of the front electrode 103 and an portion of the insulating resin layer 109b in the vicinity of the peak of raised end portion of the insulating resin layer 109b. The resin-based conductive paint is made by kneading particulate conductive silver powder and scale-like conductive silver powder into an epoxy-based insulating resin paint.

Owner:HOKURIKU ELECTRIC INDS

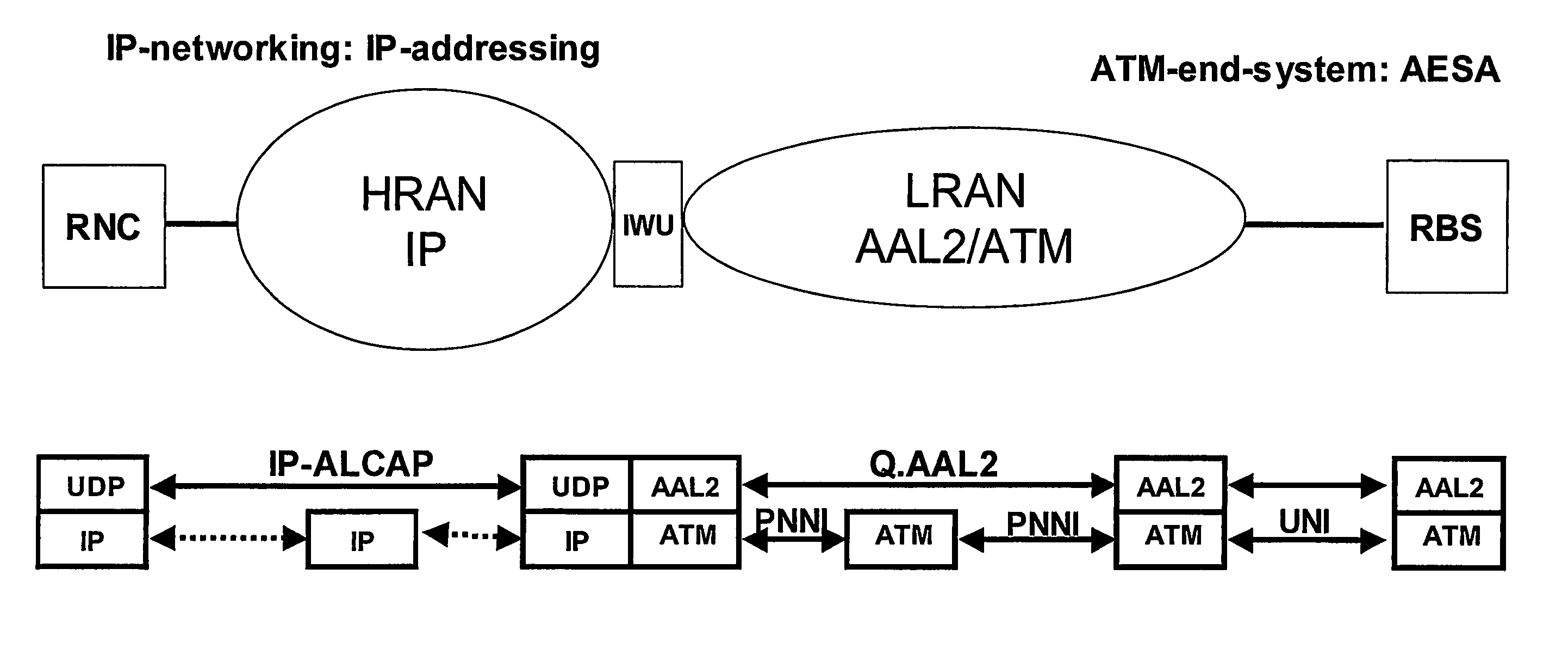

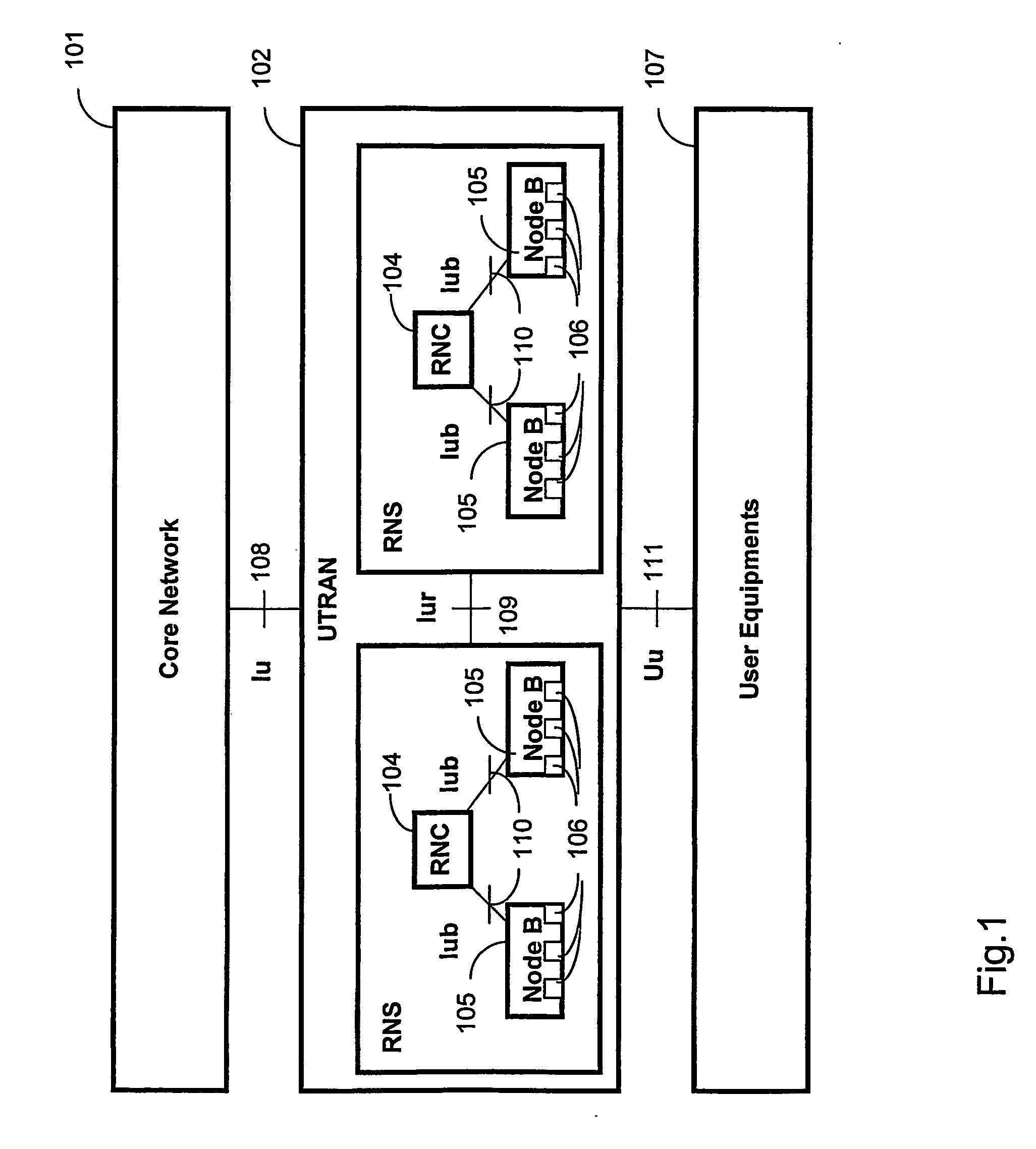

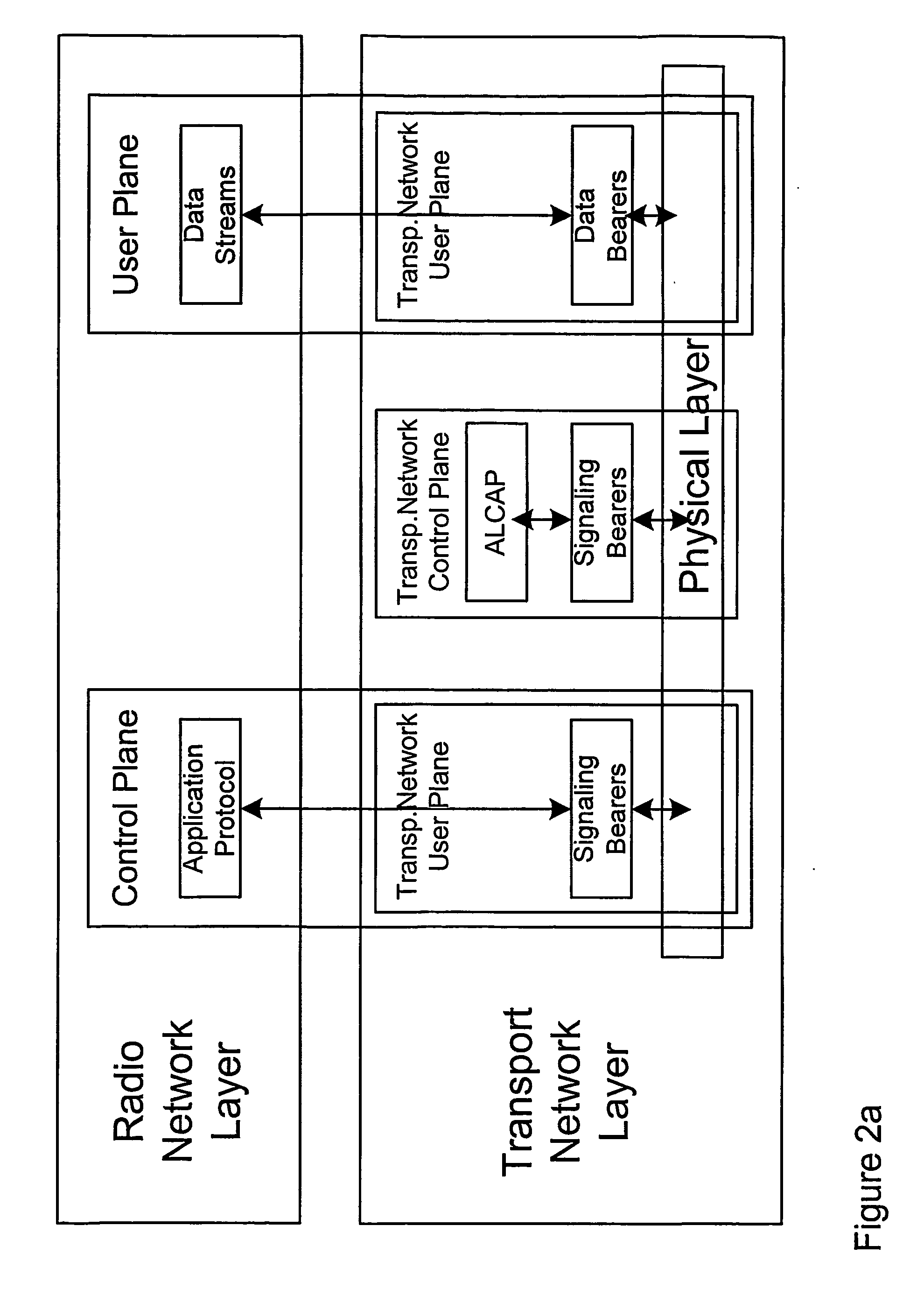

Method and an arrangement for transport layer control signalling in utran supporting both atm and ip transport technologies

InactiveUS20070058553A1Reduces required signallingReduce stepsError preventionTransmission systemsTransport layerControl signal

The present invention relates to a method and an arrangement for controlling the user plane of a UMTS Terrestrial Radio Access Network, UTRAN, comprising a first edge node connected via a Transport Network Layer to a second edge node, by using Transport Network Layer, TNL, signalling. A radio link is set up by using the Node B Application Part between the first and second edge nodes of the UTRAN, RSVP-TE based TNL signalling messages are transmitted between said first and second edge nodes for each TNL flow, and each TNL flow is identified by using RSVP-TE messages, wherein the object SESSION and SENDER_TEMPLATE comprises an IP based 5-tuple flow information, which is adapted to be used as a TNL flow identity.

Owner:TELEFON AB LM ERICSSON (PUBL)

Powdered chocolate

InactiveUS20180035688A1Production cost be reduceEasily produceFatty acid esterificationFatty-oils/fats/waxes solidificationChemistryChemical composition

Provided is a powdered chocolate containing a fat and / or oil composition in a powder form wherein the fat and / or oil composition contains: 65 to 99% by mass of a XXX triglyceride having fatty acid residues X, each with x carbon atoms, at positions 1 to 3; and 35 to 1% by mass of one or more types of X2Y triglycerides each having a fatty acid residue Y with y carbon atoms in place of one of the fatty acid residues X of the XXX triglyceride, provided that a total triglyceride content is 100% by mass, where x number of carbon atoms is an integer selected from 8 to 20, and y number of carbon atoms is each independently an integer selected from x+2 to x+12 and satisfying y≦22.

Owner:THE NISSHIN OILLIO GRP LTD

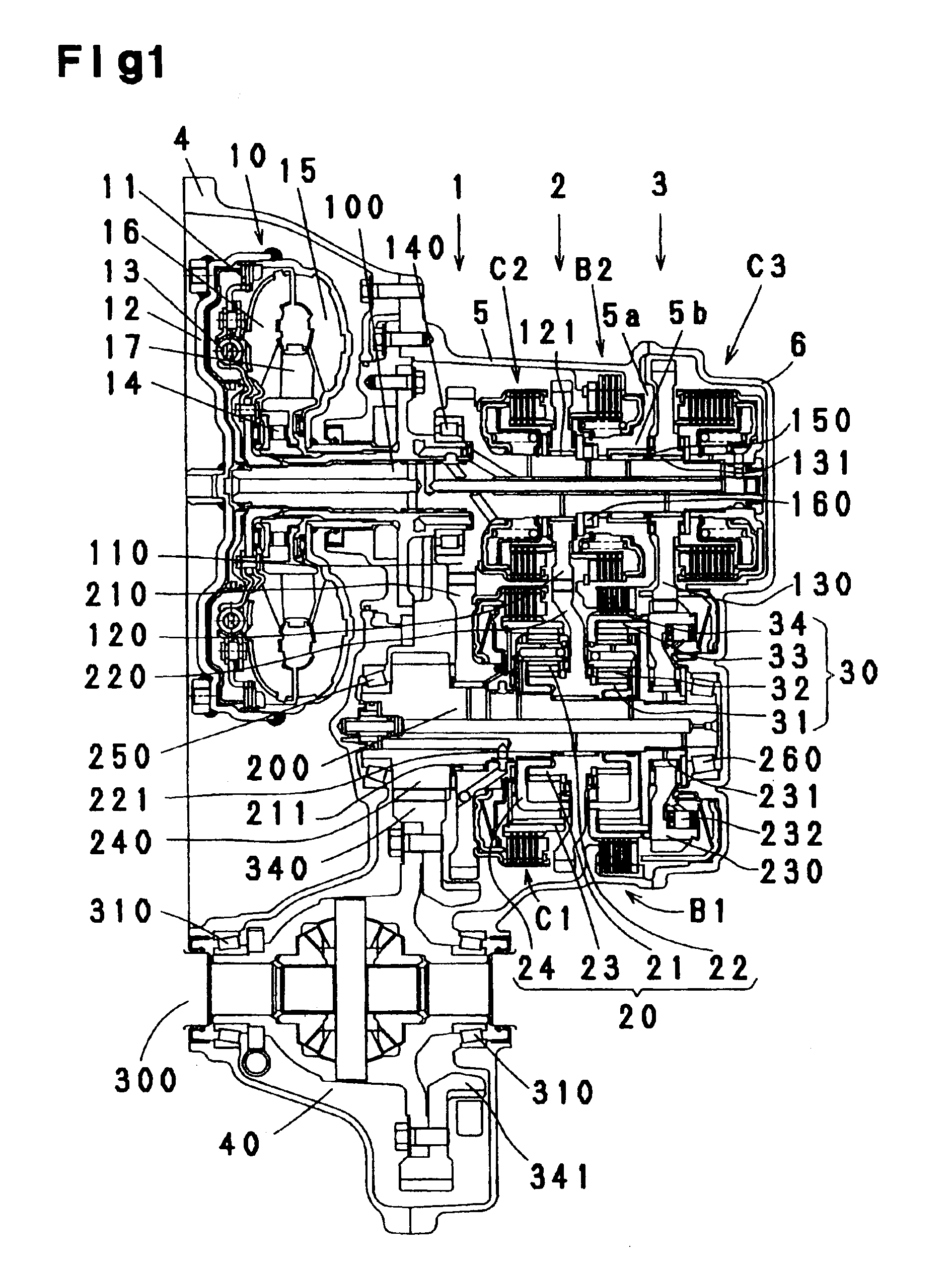

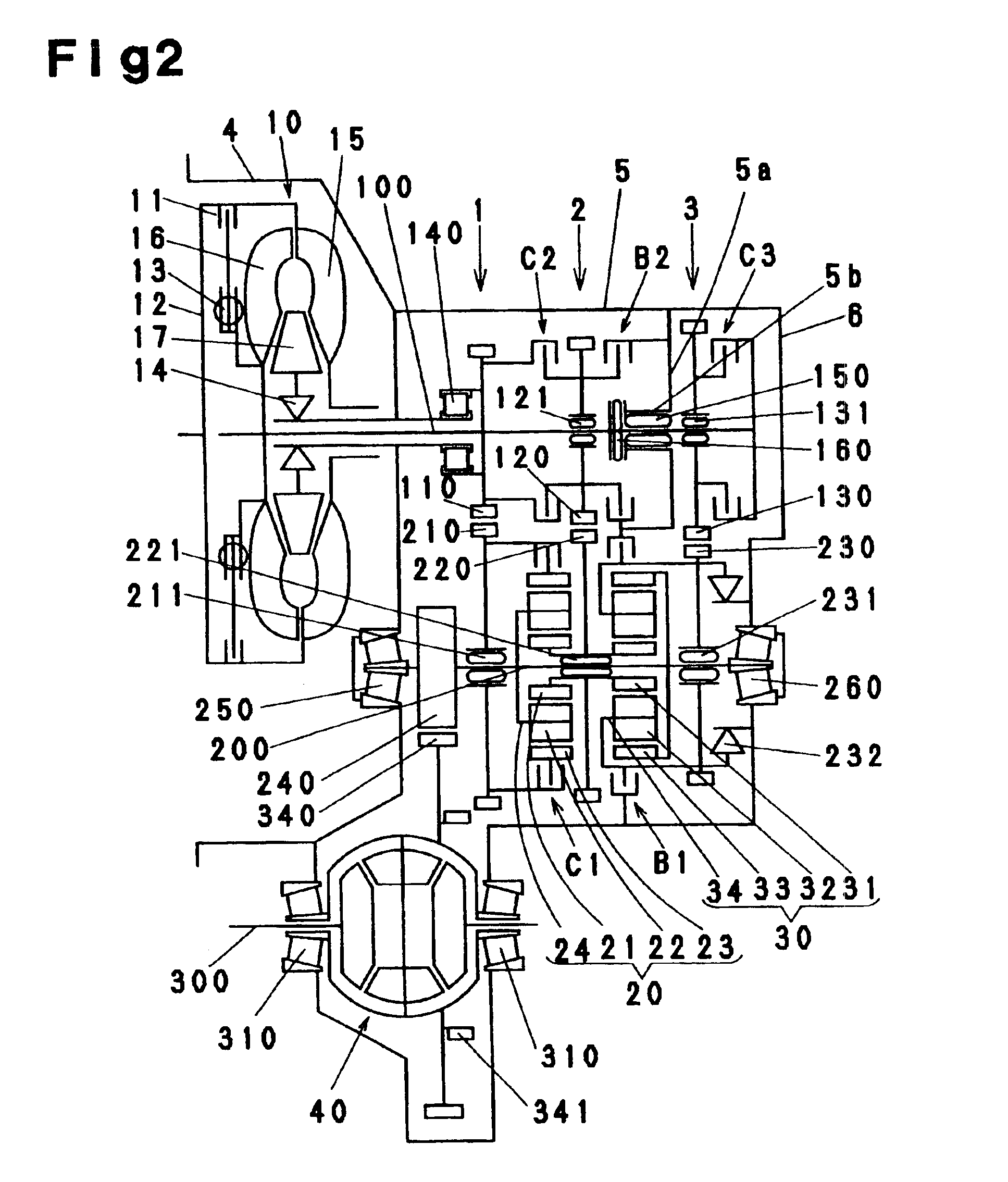

Automatic speed change apparatus

InactiveUS6916268B2Shorten the lengthImprove efficiencyToothed gearingsTransmission elementsGear wheelEngineering

An automatic speed change apparatus including an input shaft, an intermediate shaft and an output shaft arranged in parallel. The input shaft is coupled to the intermediate shaft by counter gear sets providing first, second and third drive paths. The input shaft is provided with clutches for engaging or disengaging the second and third drive paths and with a brake. The intermediate shaft is provided with a clutch, a brake and a one-way clutch for engaging, disengaging or braking the first and third drive path and with planetary gear sets. The first drive path is coupled to a ring gear, the second drive path is coupled to sun gears, and the third drive path is coupled to a planetary carrier. A planetary carrier and a ring gear are connected to the intermediate shaft, and the intermediate shaft is coupled to the output shaft by a fourth counter gear set.

Owner:OHKUBO MASAHIRO

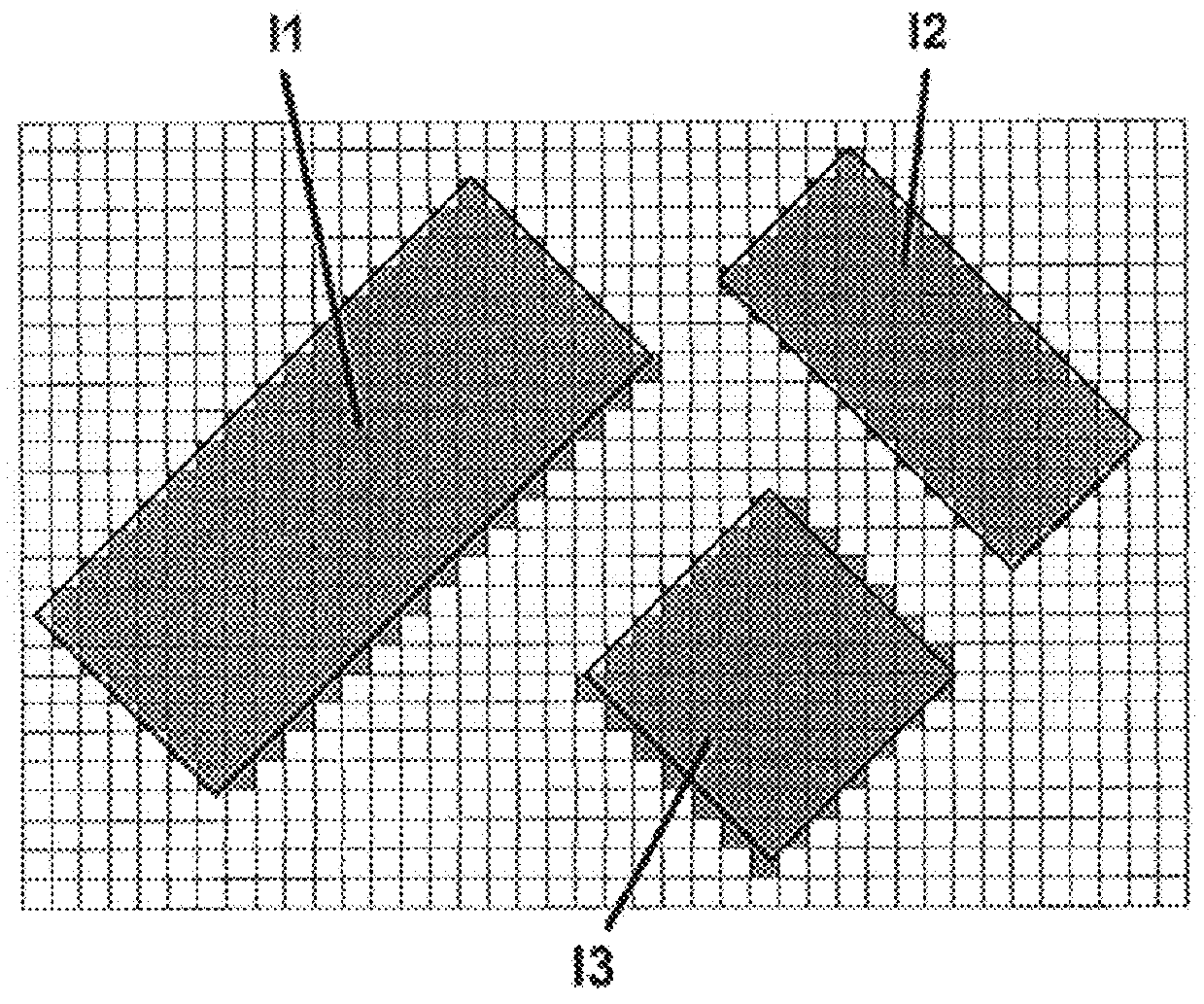

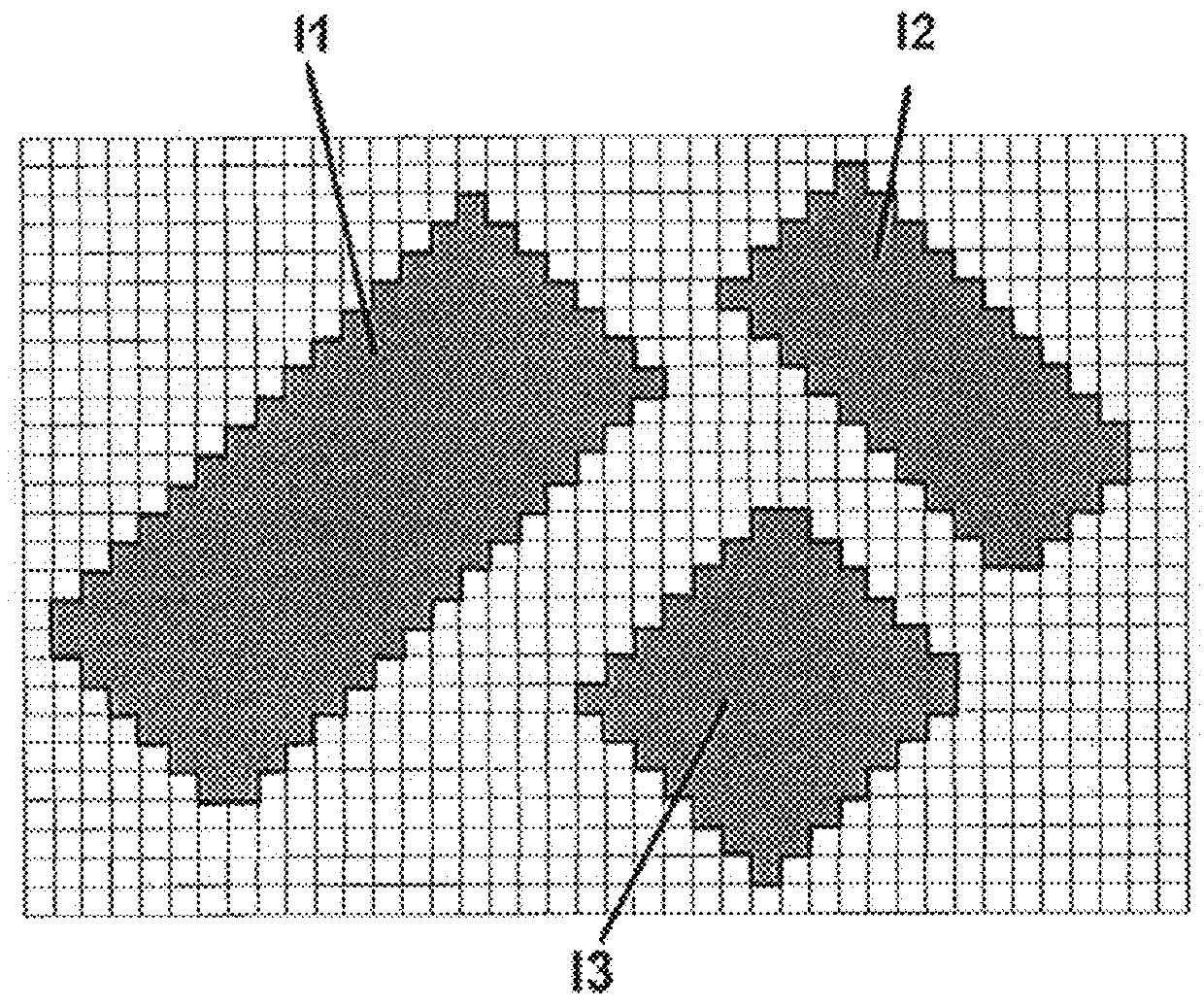

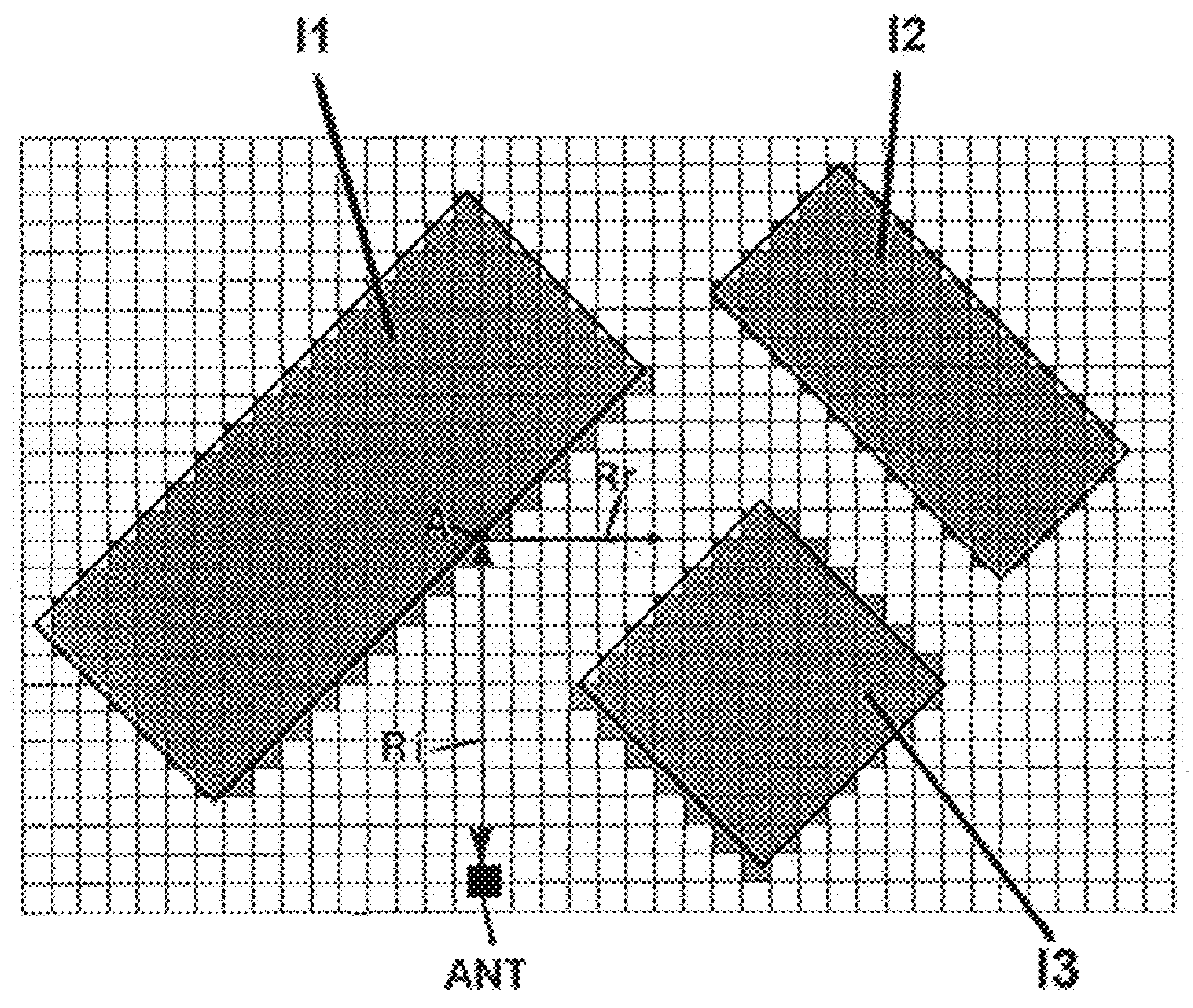

Method for predicting the radio field level and/or the duration of propagation of cellular telephone networks using high-resolution terrain databases

A method of predicting the level of radio field and / or the duration of radio propagation of a mobile telephone network for the coverage of a cell using the ray tracing technique and utilizing geographical databases, wherein the database directly utilized is a matrix base composed of pixels, each pixel carrying at least an information item specific to the type of ground cover and an information item specific to the height of the ground cover, a vectorization processing is applied to the matrix base to linearize the contours of obstacles encountered while rays are fictitiously traced, the rays according to the obstacles encountered being either reflected or diffracted and scattered, whilst the global attenuation and / or propagation duration is calculated, the vectorization processing of the contours of obstacles being applied to matrix bases to linearize the contours of obstacles encountered by forming straight lines whose positions and various angles are known accurately.

Owner:GOOGLE LLC

Smoothly shifting multispeed transmission

InactiveUS20050032603A1Difficult to eliminateSmall stepToothed gearingsTransmission elementsGear wheelEngineering

The apparatus is a 28 speed, two section, transmission that requires only a single clutch swap for most changeovers between adjacent ratios. It uses a first section with three close ratio forward speeds and one reverse along with a second section that is an 11 speed, wide ratio, transmission. The two transmission sections are arranged in series resulting at least 28 usable forward speeds. The second section includes an intermediate planetary gear set without a ring gear and an output planetary gear set that is a conventional simple planetary gear set with a two sun gears, two planes of planetary gears on a single carrier, and two ring gears.

Owner:BLUE LEAF I P INC +1

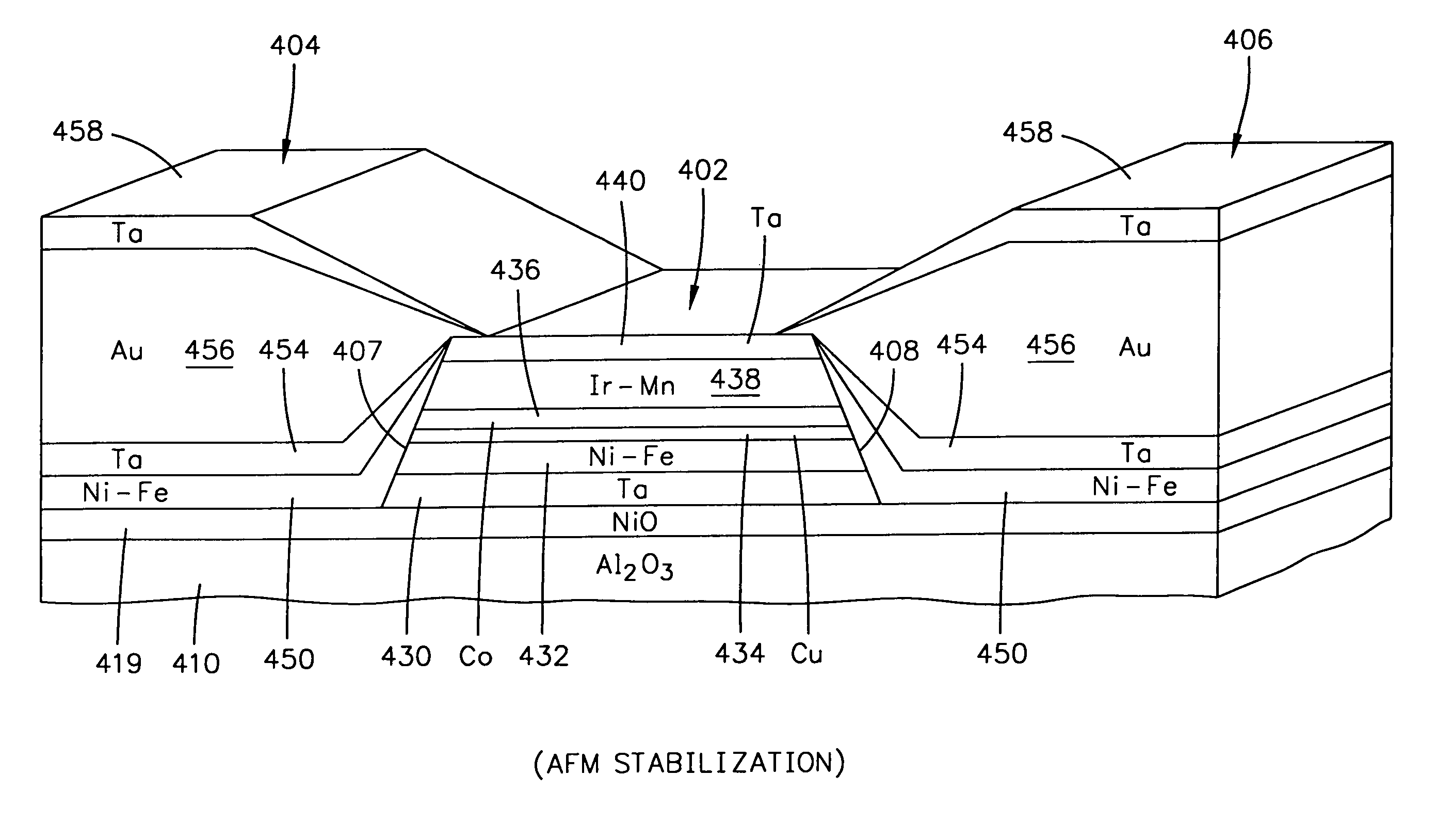

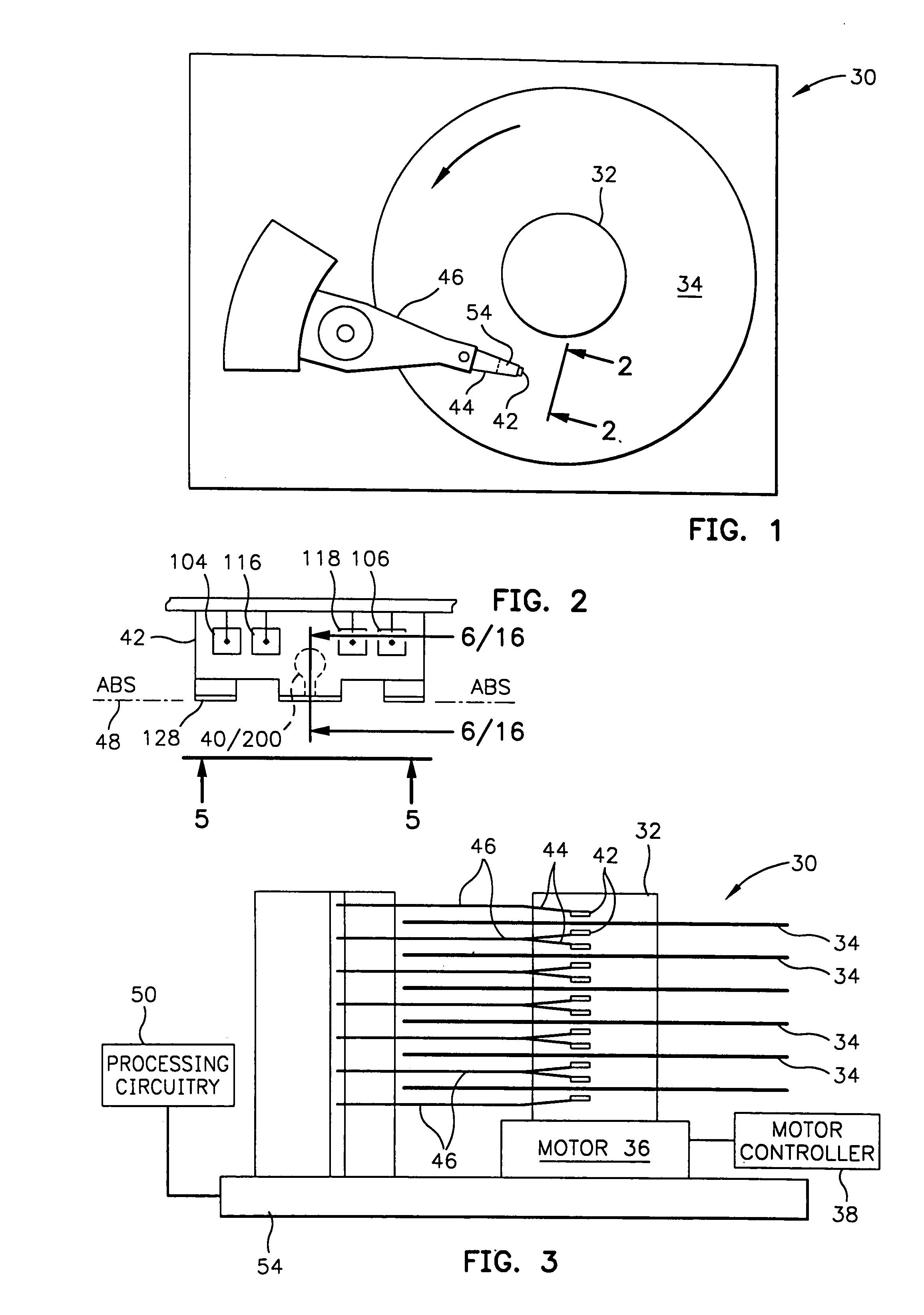

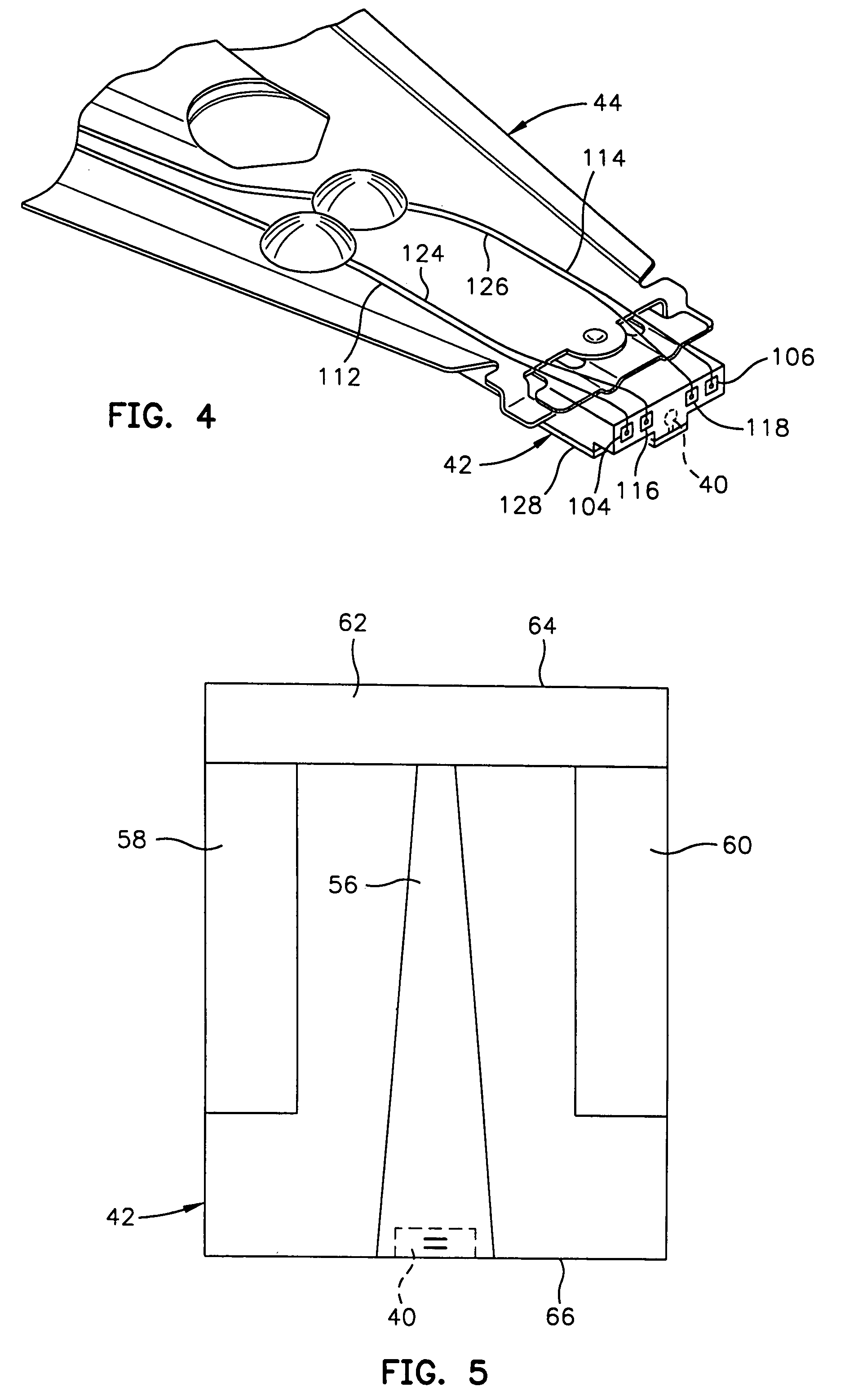

Method of making a merged magnetic read head and write head

InactiveUS7020951B2High sensitivitySmall stepElectrical transducersNanomagnetismElectrostatic couplingEngineering

An antiferromagnetic stabilization scheme is employed in a magnetic head for magnetically stabilizing a free layer of a spin valve. This is accomplished by utilizing an antiferromagnetic oxide film below a spin valve sensor in a read region and first and second lead layers in end regions and a ferromagnetic film in each of the lead layers that exchange couples to the antiferromagnetic oxide film in the end regions. The ferromagnetic films are pinned with their magnetic moments oriented parallel to an air bearing surface (ABS) of the magnetic head. The ferromagnetic film magnetostatically couples to the free layer which causes the free layer to be in a single magnetic domain state. Accordingly, when the free layer is subjected to magnetic incursions from a rotating disk in a disk drive, the free layer maintains a stable magnetic condition so that resistance changes of the free layer are not altered by differing magnetic conditions of the free layer.

Owner:IBM CORP

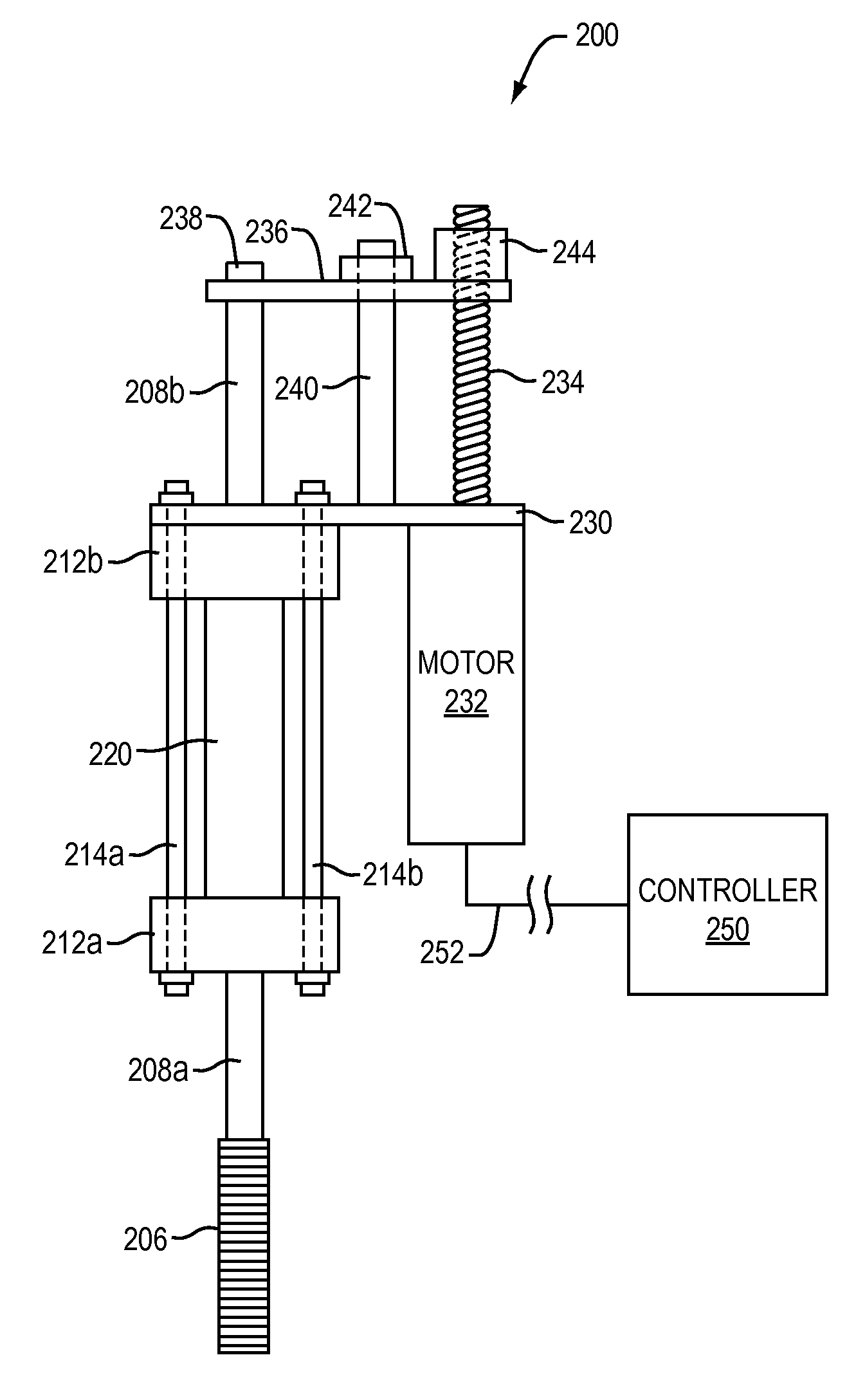

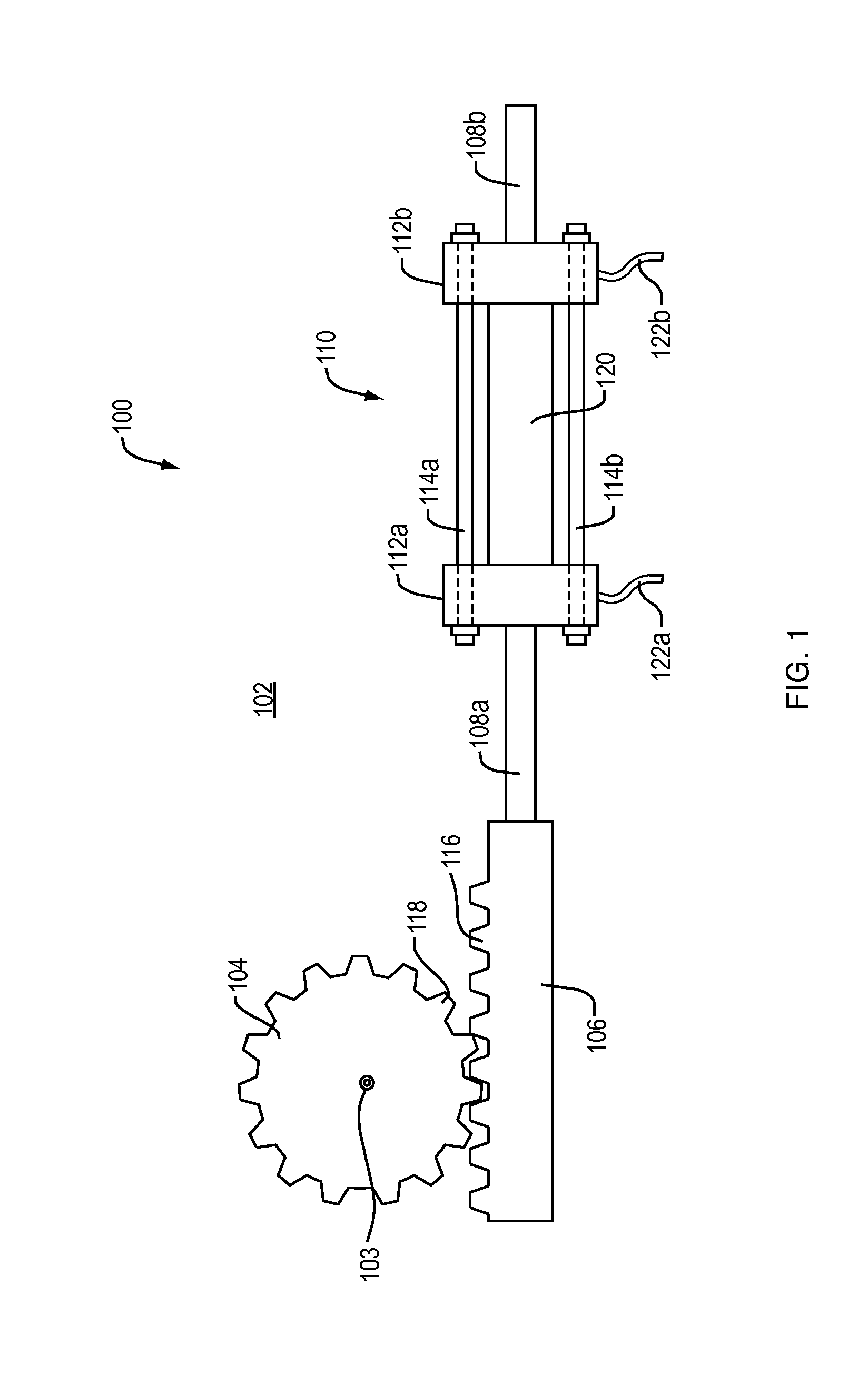

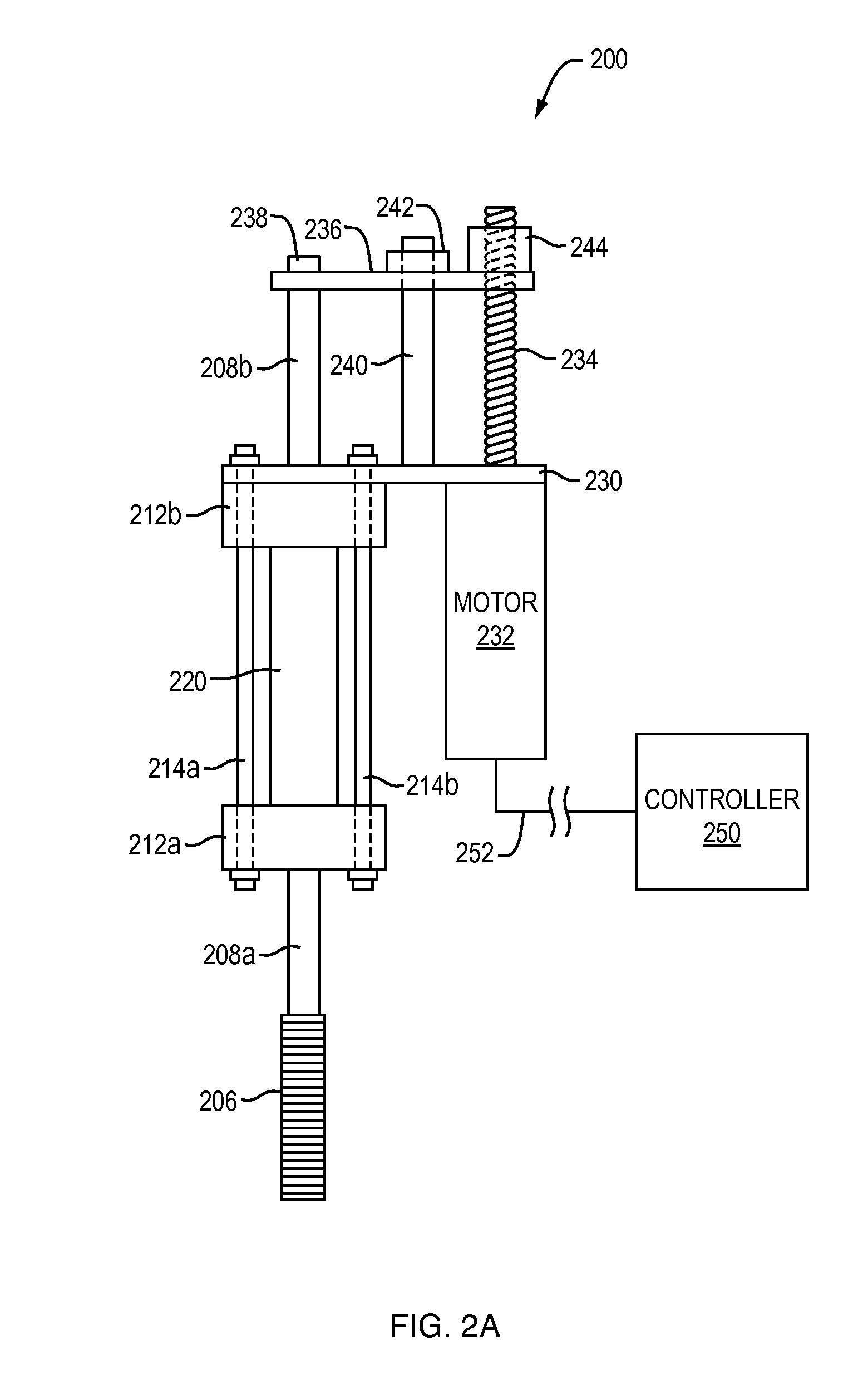

Electronic Retrofit Controller for Hydraulically Adjusted Printing Press

InactiveUS20100194216A1Reduce amountQuick calibrationPlaten pressesWave amplification devicesLinear motionHydraulic fluid

A retrofit kit for a printing press adjustment hydraulic actuator. The hydraulic actuator is maintained to benefit from its mounting position and alignment, but the hydraulic fluid is removed. A hydraulic actuator shaft is attached to a mechanism that converts the rotary motion of an electric motor to linear motion. The electric motor provides faster and more accurate control of the hydraulic actuator shaft than the hydraulic fluid, providing for faster adjustment of the printing press.

Owner:INNOVATIVE MOTOR CONTROLS

Light emitting diode drive device, illumination device, in-vehicle cabin illumination device, and vehicle illumination device

ActiveUS8362639B2Small stepSimple circuit configurationDischarge tube incandescent screensElectric discharge tubesIn vehicleVoltage drop

A light emitting diode drive device includes a drive circuit section that applies a direct-current voltage to a light source including a plurality of light emitting diodes connected in series to allow the light source to light up, a voltage detection circuit section that detects a voltage across the light source, and a malfunction determination circuit section that determines that the light emitting diode is short-circuited when the voltage detection circuit section detects a voltage drop and a potential between the voltage before being dropped and the voltage after being dropped is equal to or more than a predetermined threshold value. Thus, it is possible to detect a fact that a light emitting diode, which lights up, is short-circuited or is not short-circuited, with a simple circuit configuration.

Owner:PANASONIC CORP

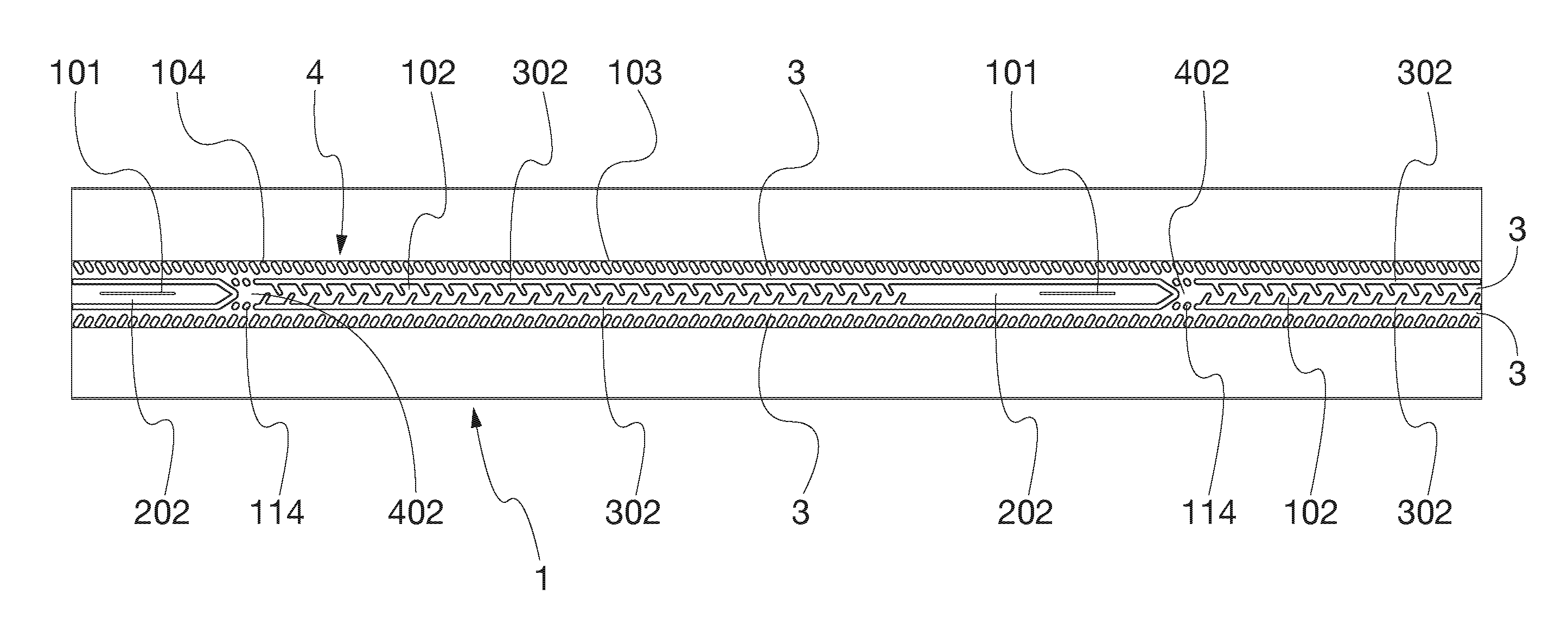

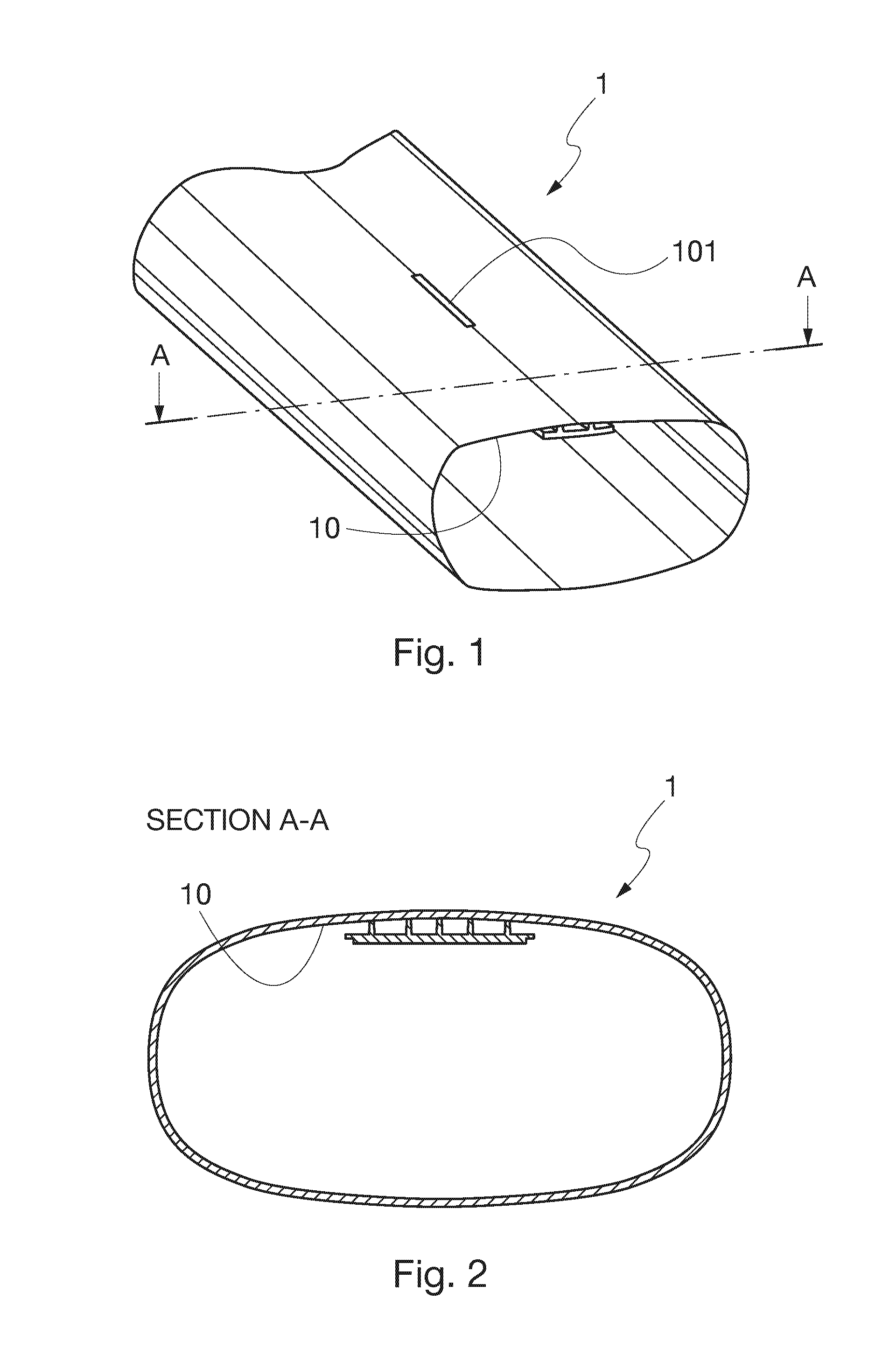

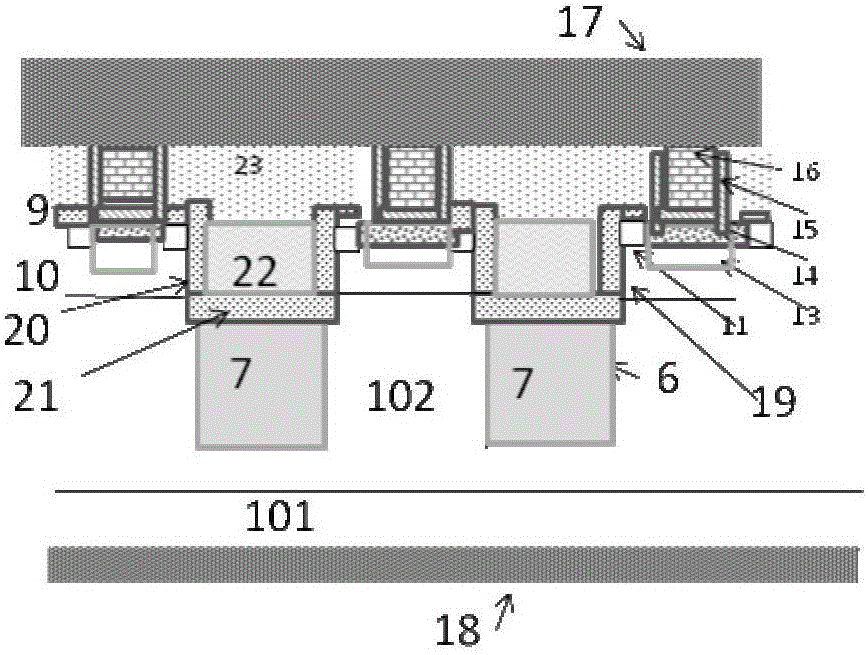

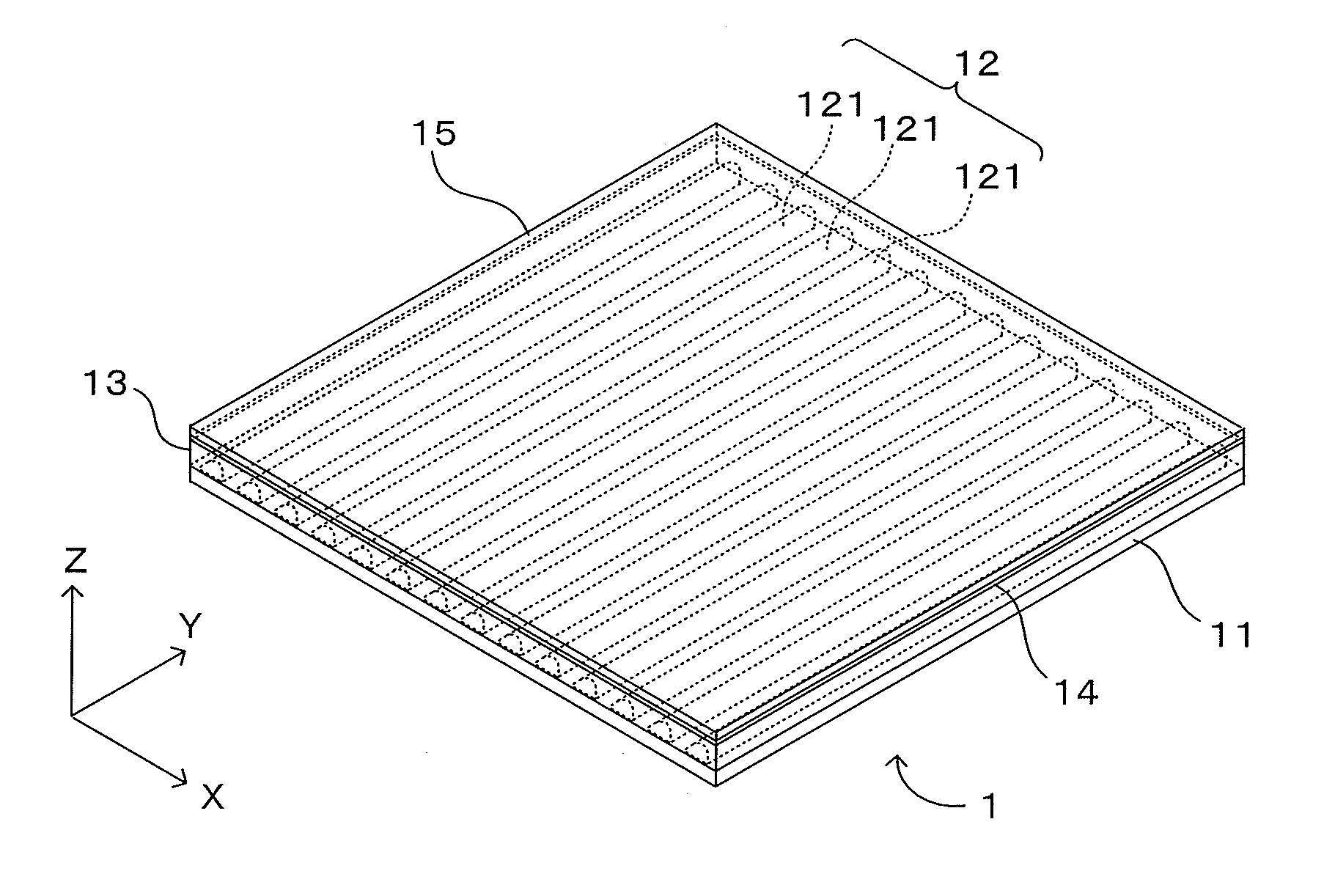

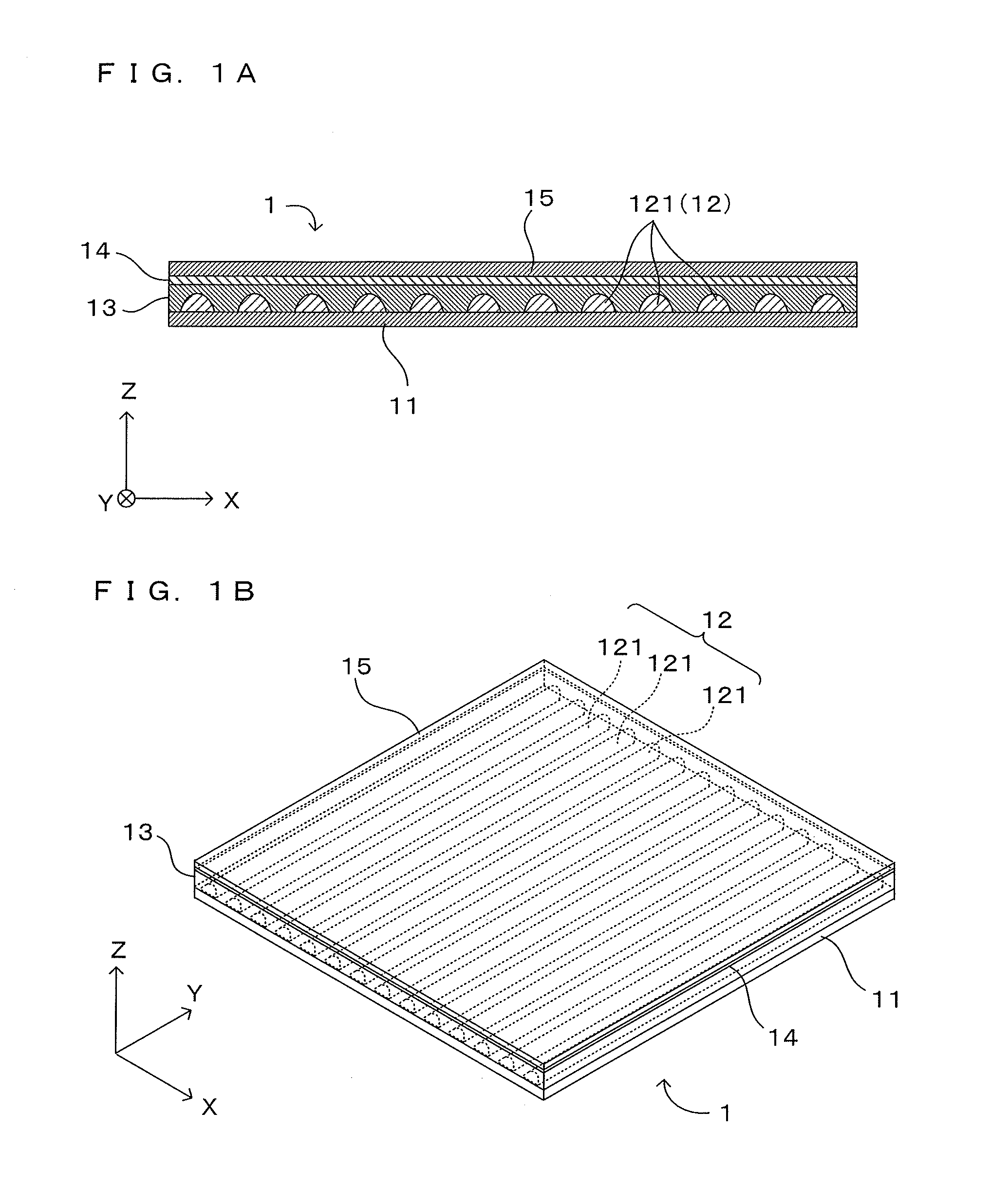

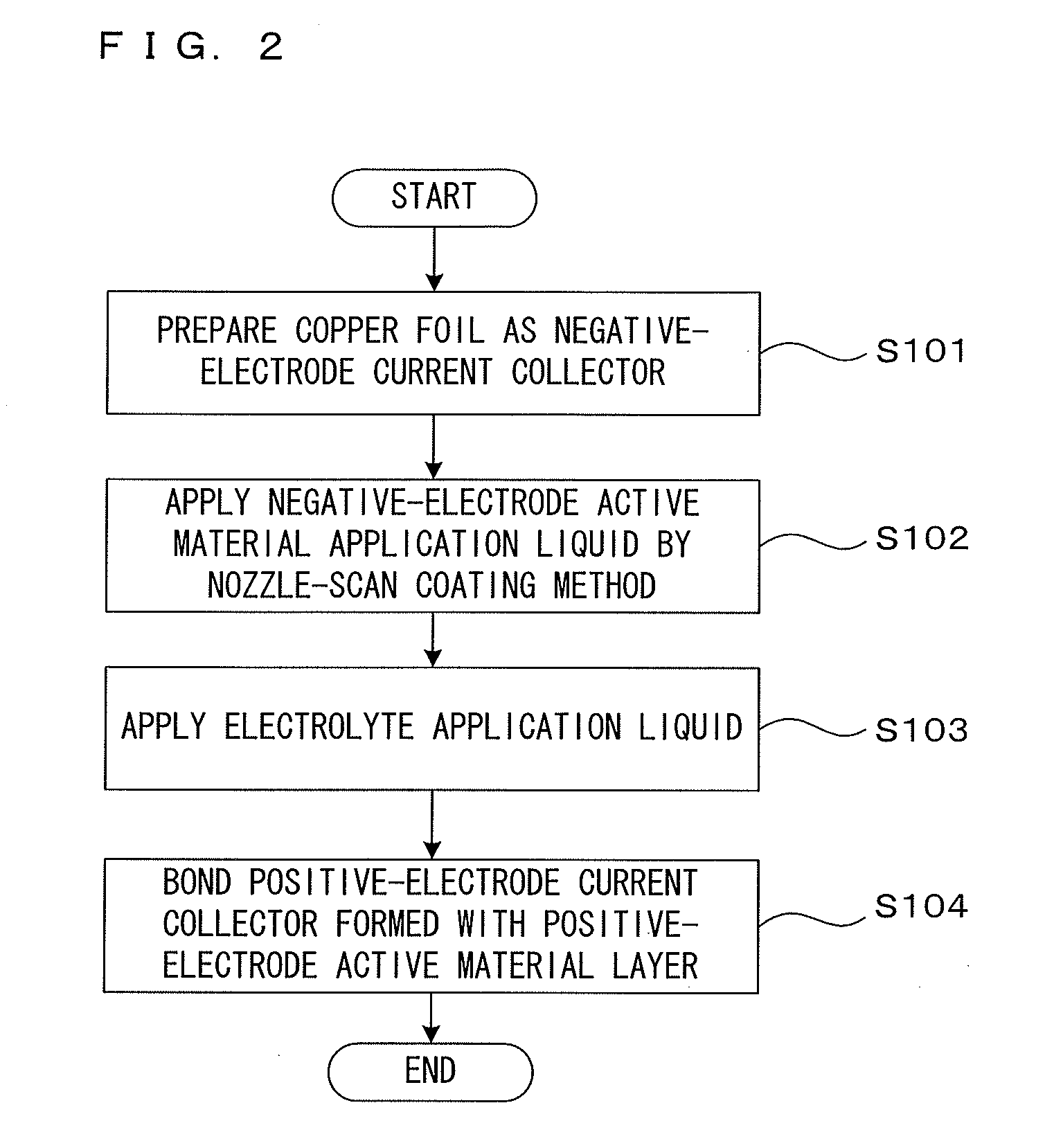

Lithium-ion secondary battery, vehicle, electronic device and manufacturing method of lithium-ion secondary battery

InactiveUS20120077093A1Small sizeImprove electrochemical performanceFinal product manufactureElectrode carriers/collectorsLithiumPolyethylene oxide

A negative-electrode active material layer 12 contains Li4Ti5O12 as a negative-electrode active material, and a positive-electrode active material layer 14 contains LiCoO2 as a positive-electrode active material. A solid electrolyte layer 13 contains polyethylene oxide and polystyrene as an electrolyte material. Gradients of surfaces of stripe-shaped pattern elements 121 forming the negative-electrode active material layer 12 are smaller than 90° when viewed from a surface of the negative-electrode current collector 11. By such a construction, it is possible to construct a battery having a high capacity in relation to the used amount of the active materials and good charge and discharge characteristics.

Owner:DAINIPPON SCREEN MTG CO LTD

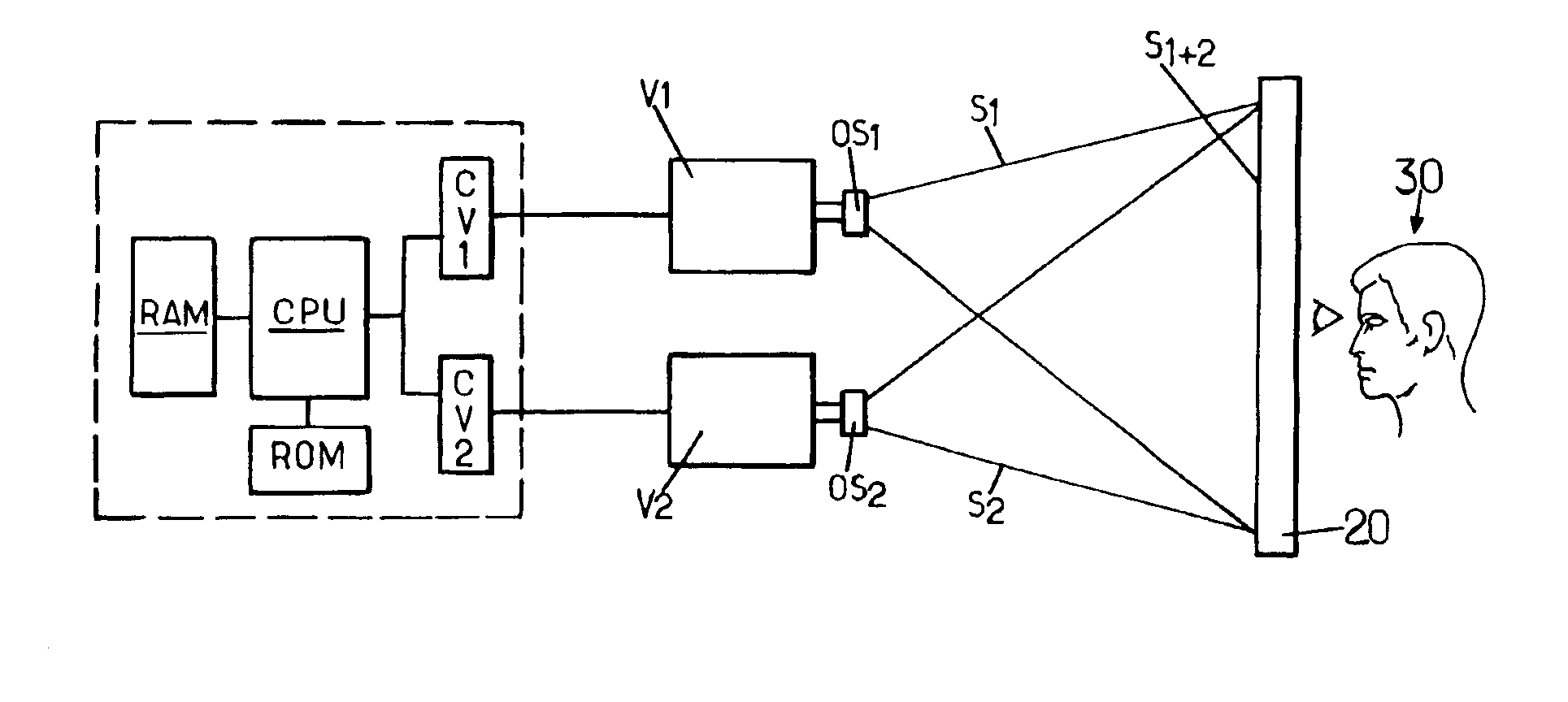

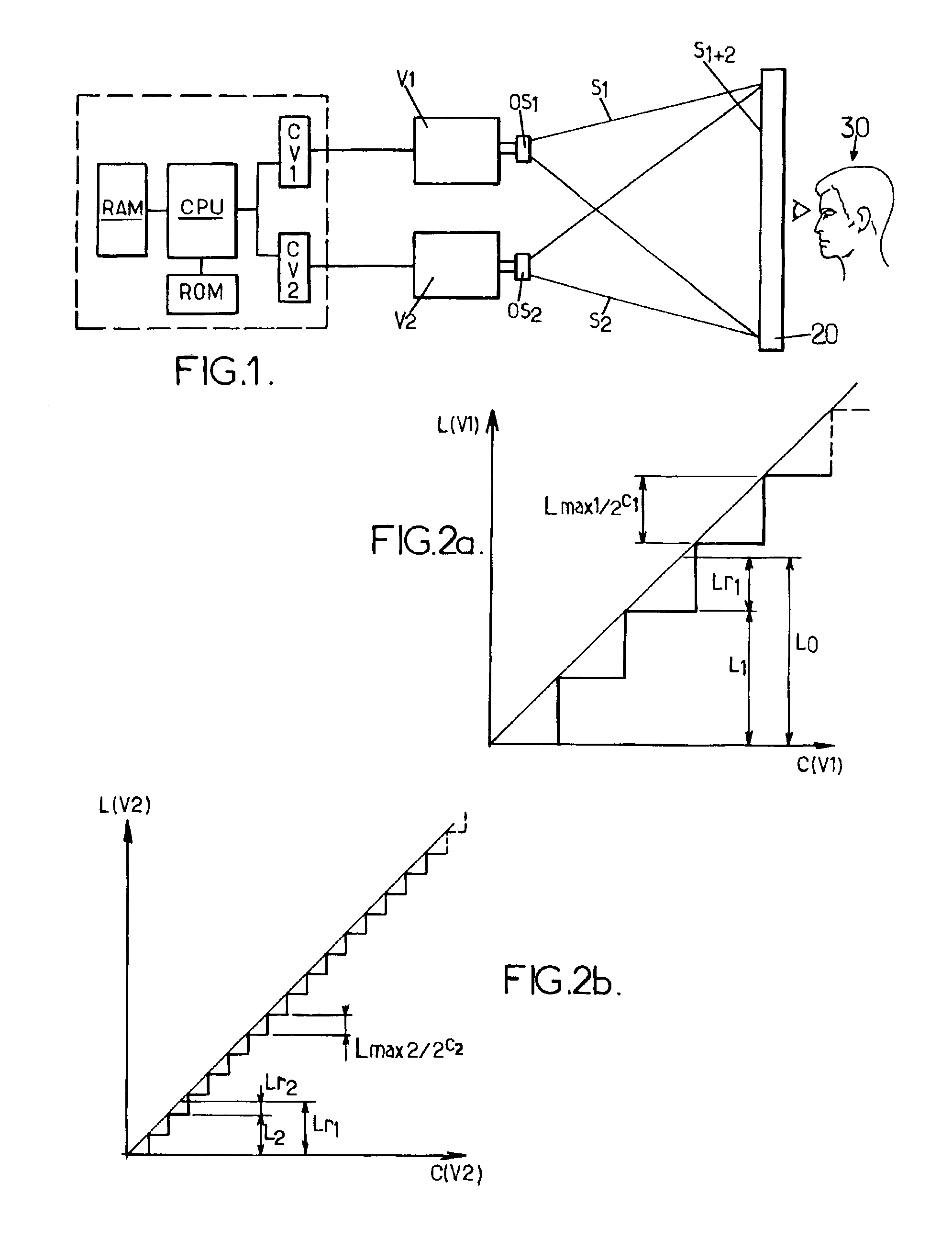

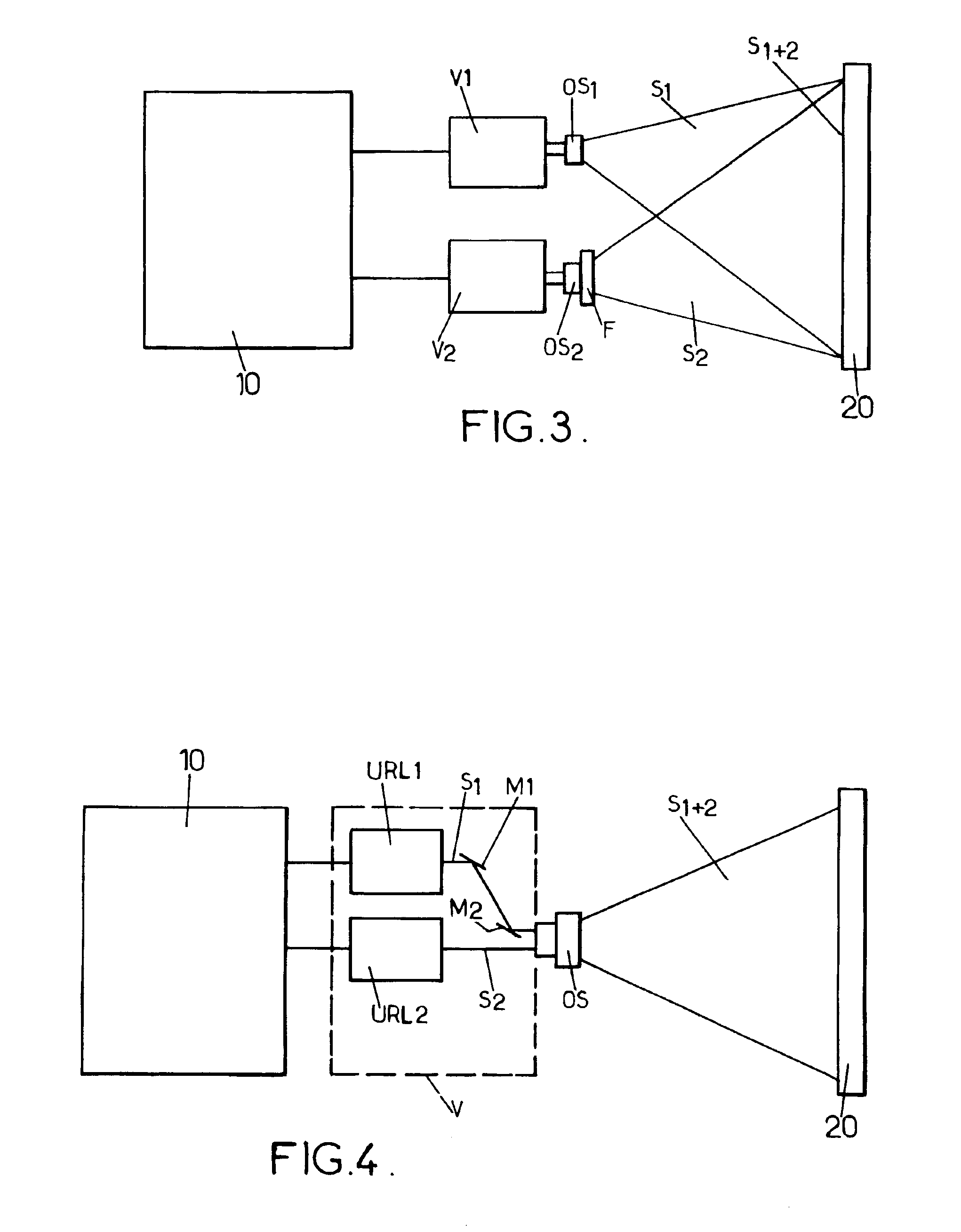

Method and device for restoring a light signal

InactiveUS6911977B2Improve finenessSmall brightness stepTelevision system detailsColor signal processing circuitsDigital dataImage resolution

A method for restoring a light signal from digital data defining a colorimetric coordinate of the light signal in a specific colorimetric system, comprises the step of generating a first light signal using a first light restoration unit, the step of generating a second light signal using a second light restoration unit, and the step of generating a third light signal obtained by superimposing the first and second light signals. The second light restoration unit covers a brightness dynamics less than the brightness dynamics covered by the first restoration light unit. The second light restoration unit has a brightness resolution finer than the first light restoration unit.

Owner:CENT SCI & TECHN DU BATIMET

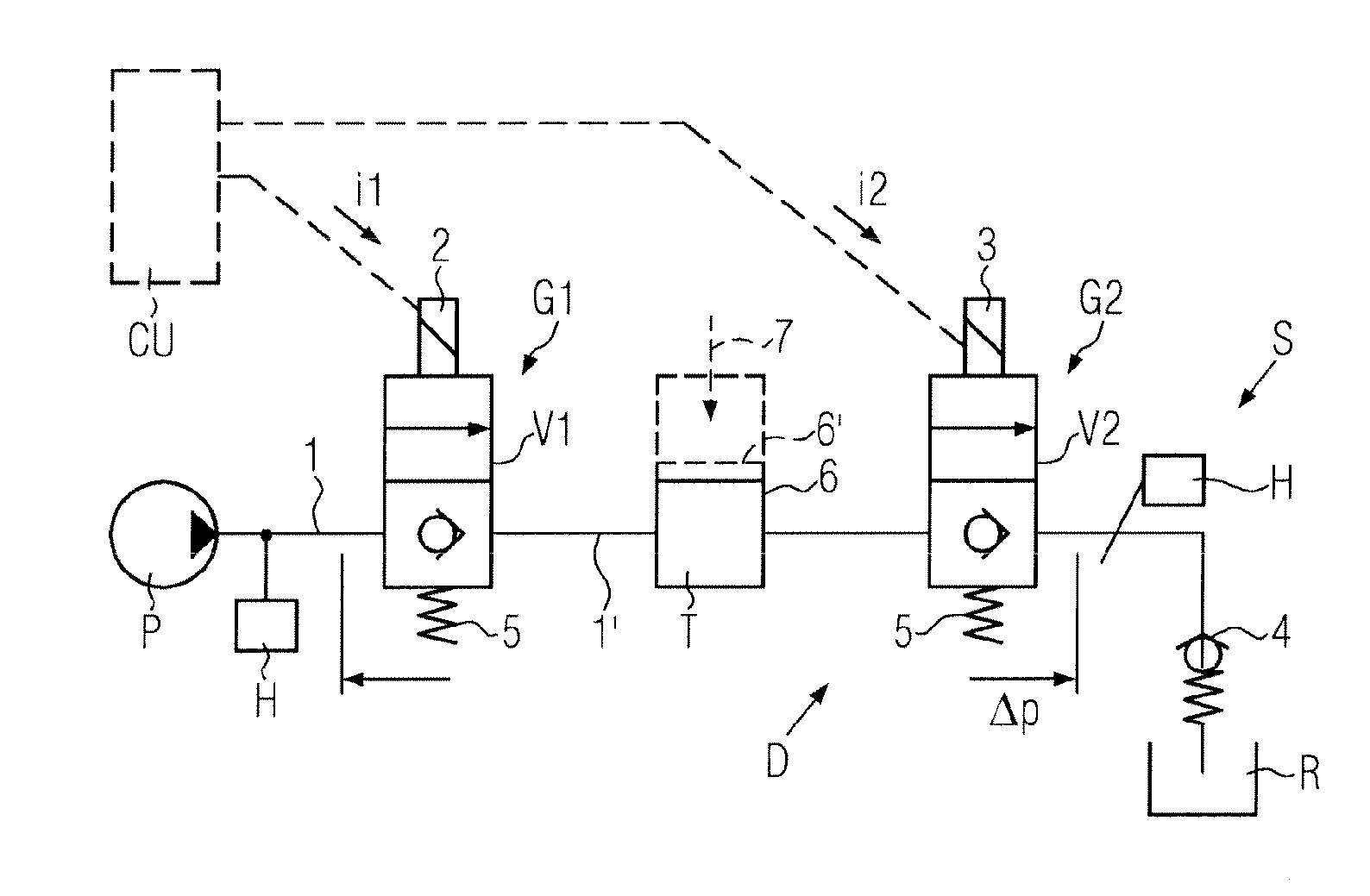

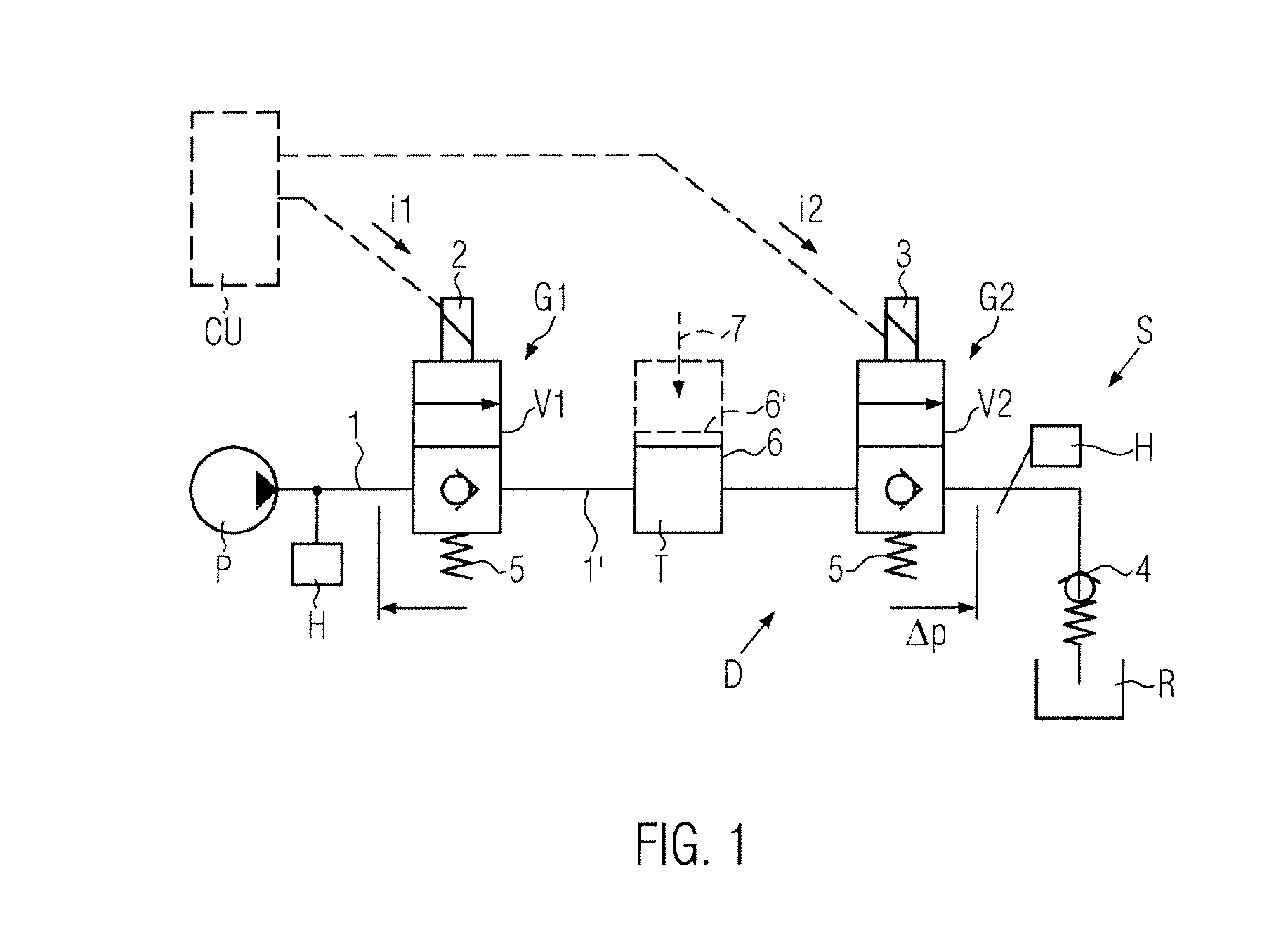

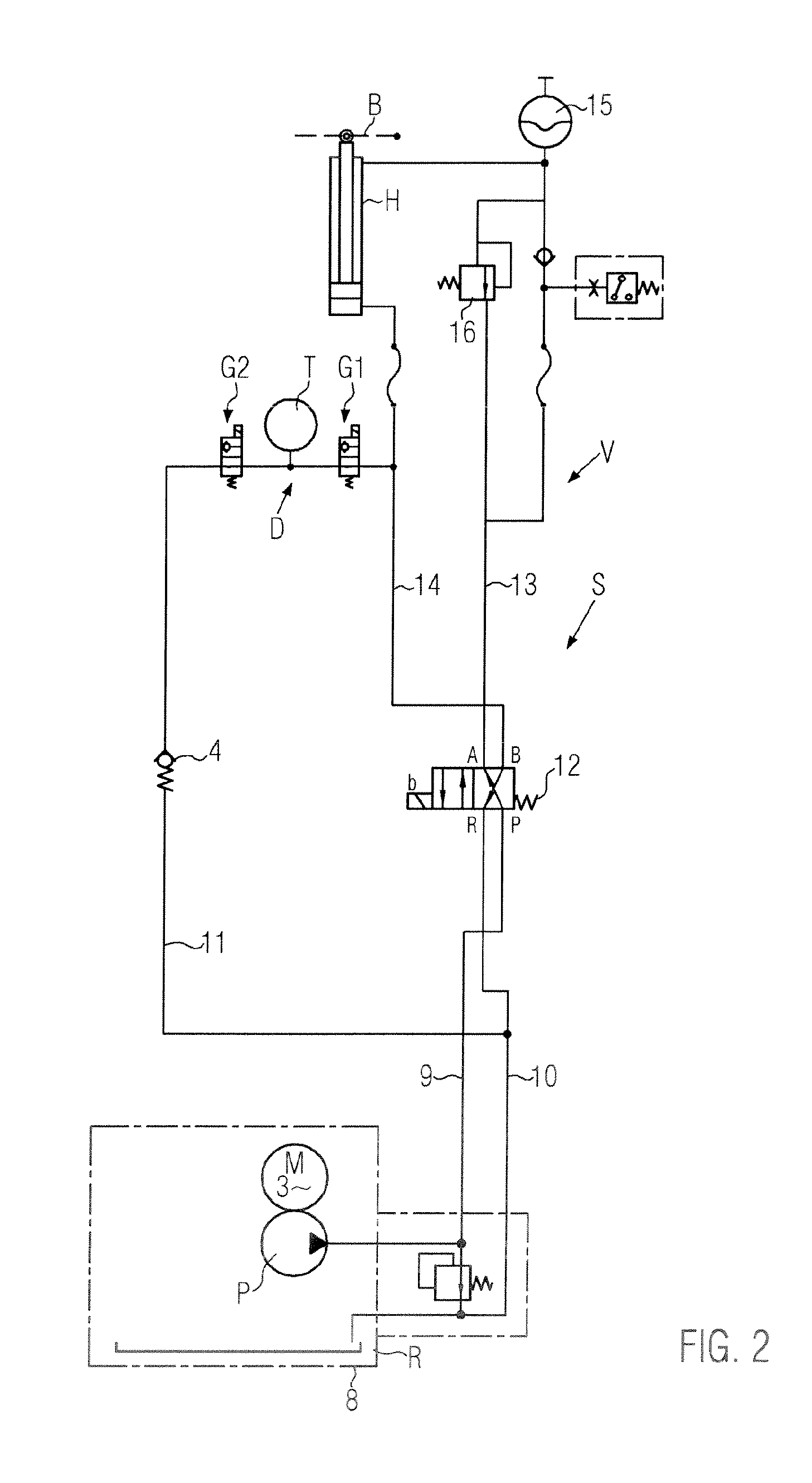

Hydraulic control device

InactiveUS20090235921A1Small movement stepLow costSolar heating energyFluid couplingsHydraulic pumpEngineering

A hydraulic control device for moving at least one hydraulic consumer comprises at least one supply line, a discharge line or bypass line to which the hydraulic consumer is connected, and at least one pressure source and, optionally, a directional control valve. The line contains a dosing device for measuring a hydraulic medium dose by using a given compressibility of the hydraulic medium. The measured hydraulic medium dose either is supplied from the dosing device into the hydraulic consumer connected downstream or is discharged from the hydraulic consumer connected upstream into the dosing device. The dosing device comprises from upstream to downstream in series first and second blocking members which respectively can be switched into a leakage-free blocking position and into a through flow position, and a dead space between the blocking members. For dosing the hydraulic medium dose the blocking members are switched several times alternatingly.

Owner:HAWE HYDRAULIK SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com