Shield grid trench MOSFET device and manufacturing method thereof

A technology of shielded gate and trench, which is applied in the manufacture of shielded gate trench MOSFET devices, and in the field of shielded gate trench MOSFET devices, can solve the problems that the device unit cannot be effectively reduced, the consistency of the device is deteriorated, and the manufacturing process is complicated. Achieve the effects of easy control, reduced stepping, and reduced manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

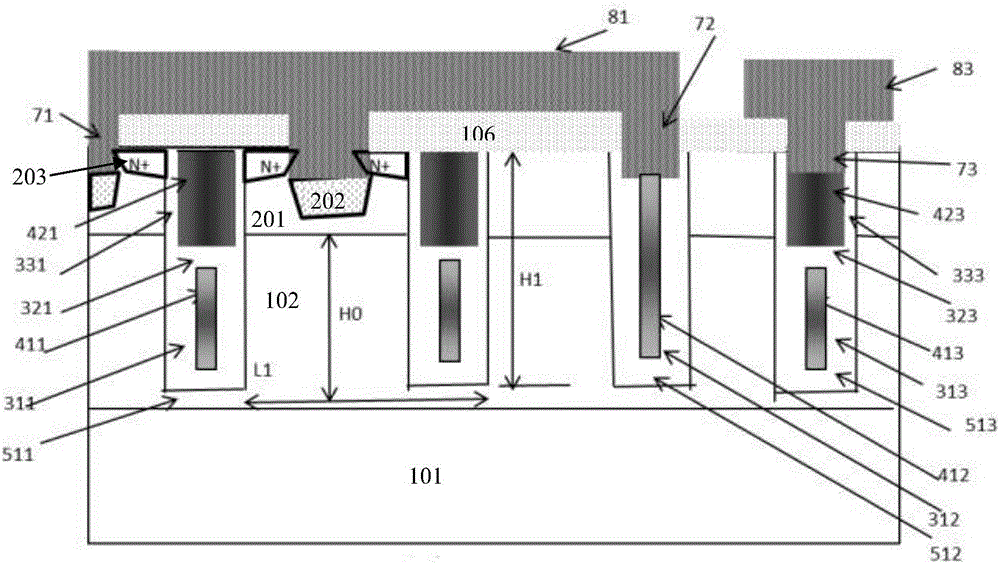

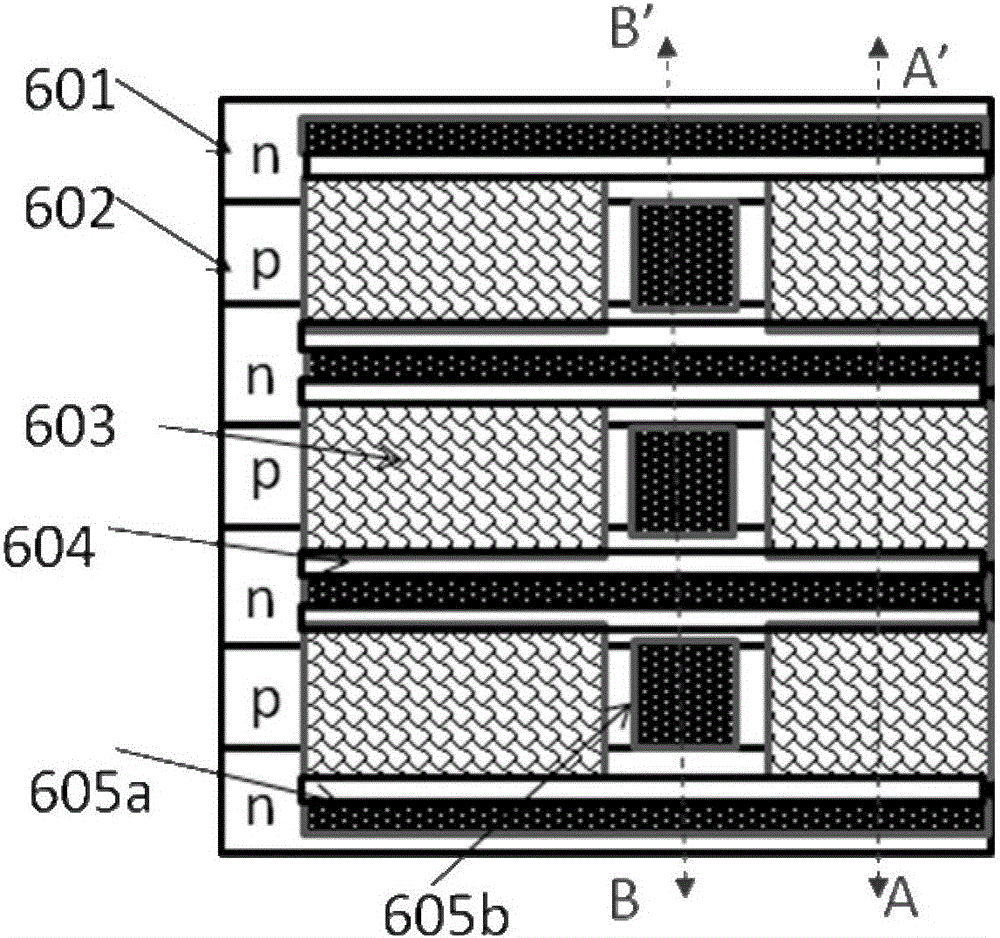

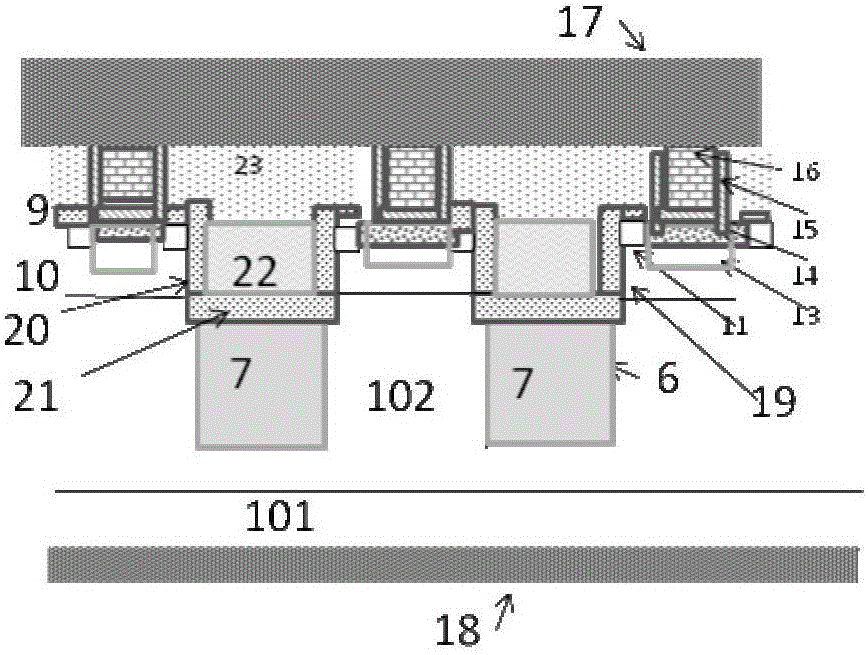

[0064] Such as figure 2 Shown is the layout of the shielded gate trench MOSFET device in the first embodiment of the present invention; as Figure 3A Shown is the first embodiment of the present invention shielded gate trench MOSFET device along figure 2 The section view of the BB' position in ; such as Figure 3B Shown is the first embodiment of the present invention shielded gate trench MOSFET device along figure 2 The cross-sectional view of the AA' position in the figure; the shielded gate trench MOSFET device in the first embodiment of the present invention is described by taking an N-type device as an example, that is, in the first embodiment of the present invention, the first conductivity type is N-type, and the second The conductivity type is P-type; the structure of the P-type device can be obtained by exchanging the doped conductivity type of the device between N-type and P-type, and the description of the present invention does not describe the P-type device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com