Patents

Literature

35results about How to "Improve reverse withstand voltage capability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

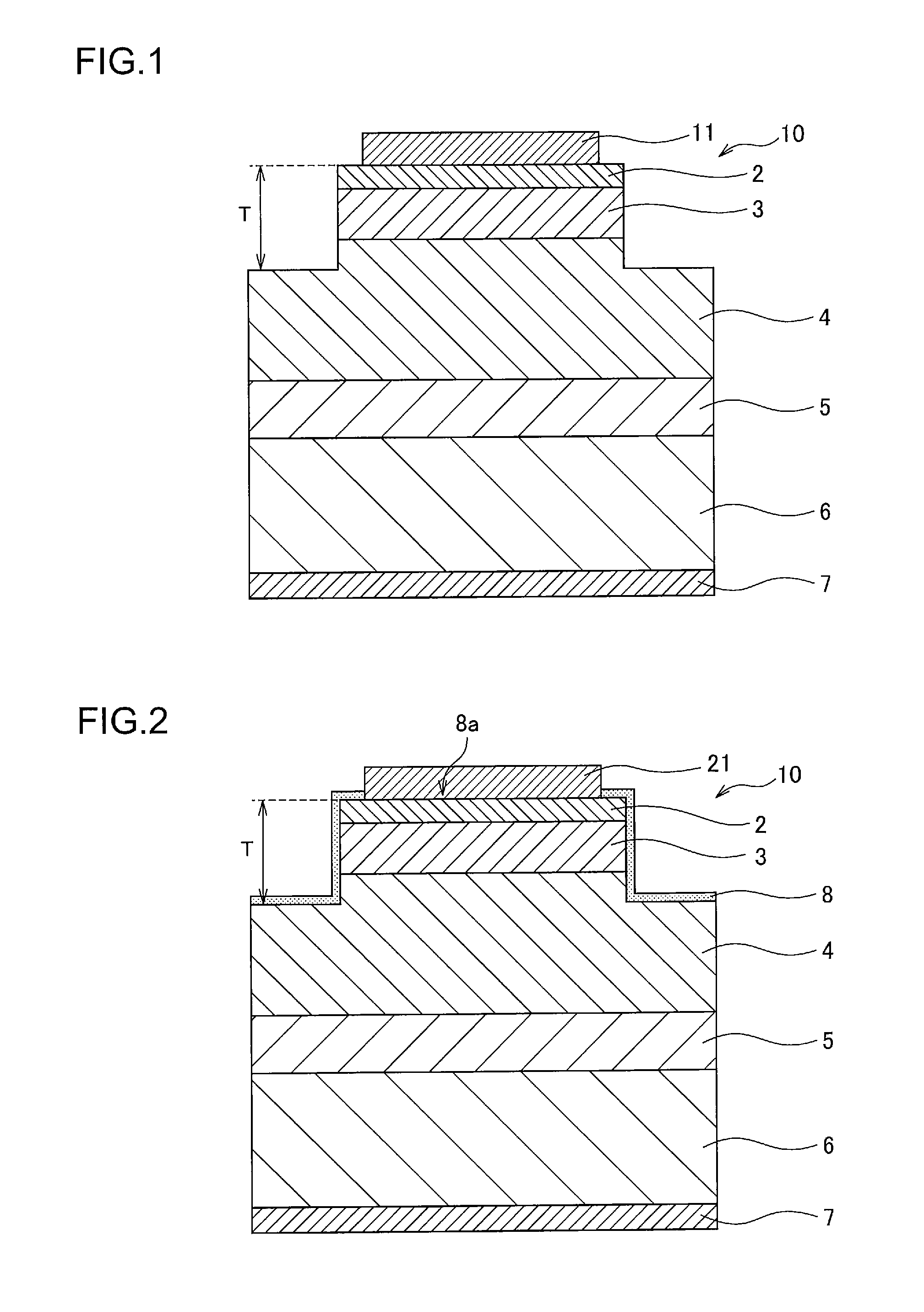

Shield grid trench MOSFET device and manufacturing method thereof

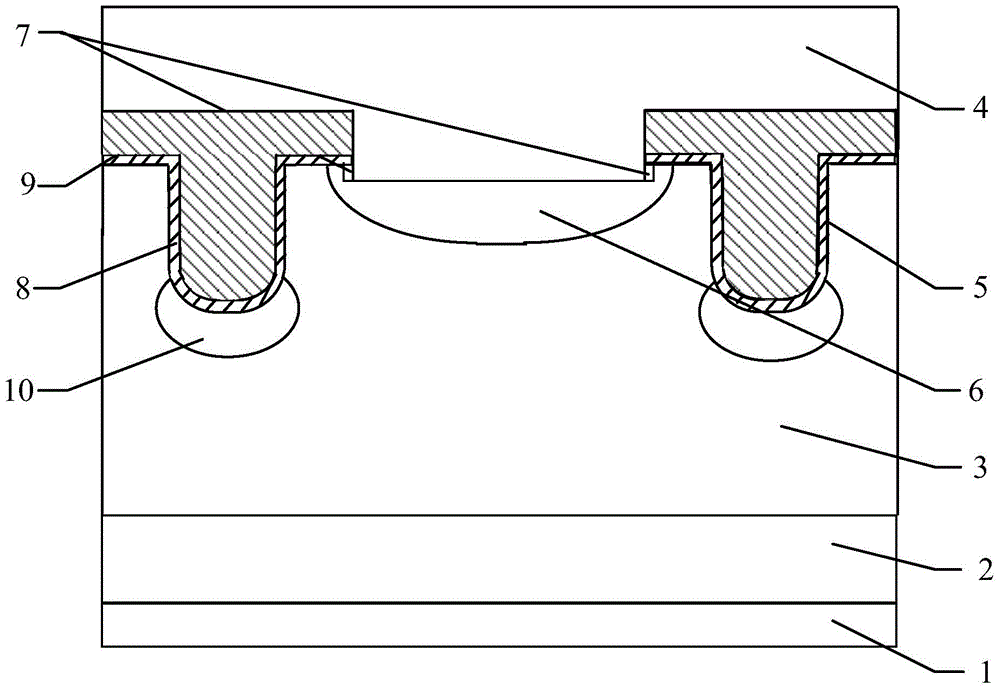

ActiveCN105702739AIncrease the doping concentrationLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetEngineering

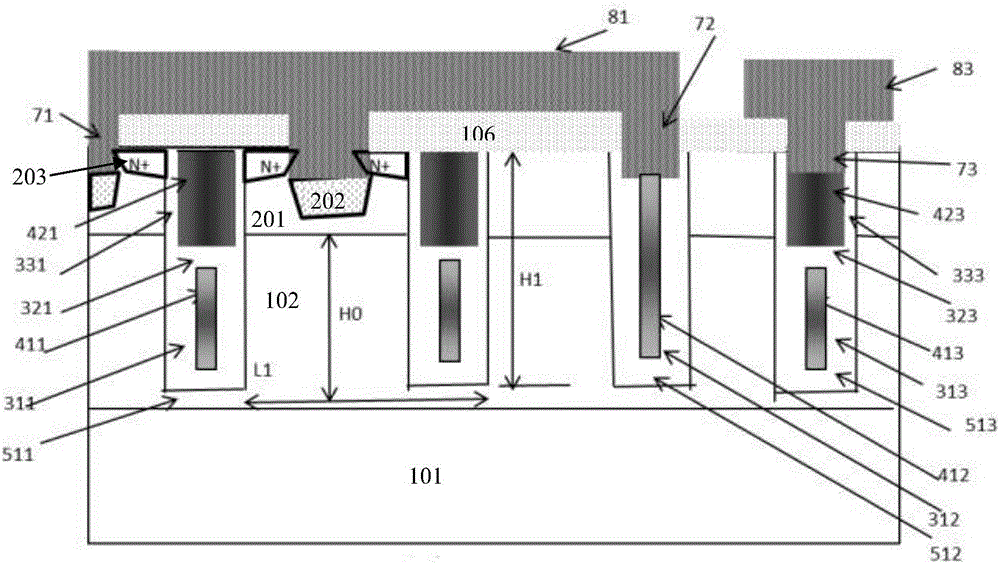

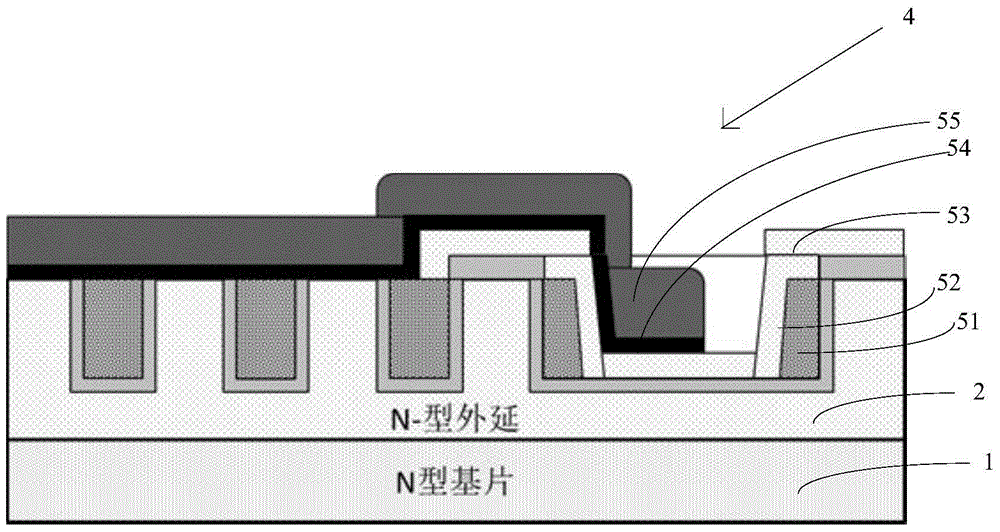

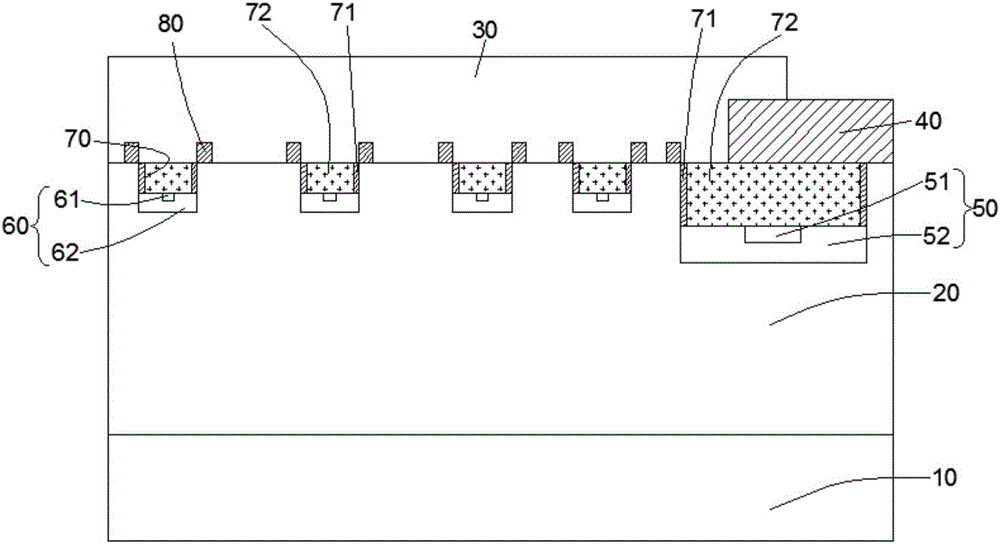

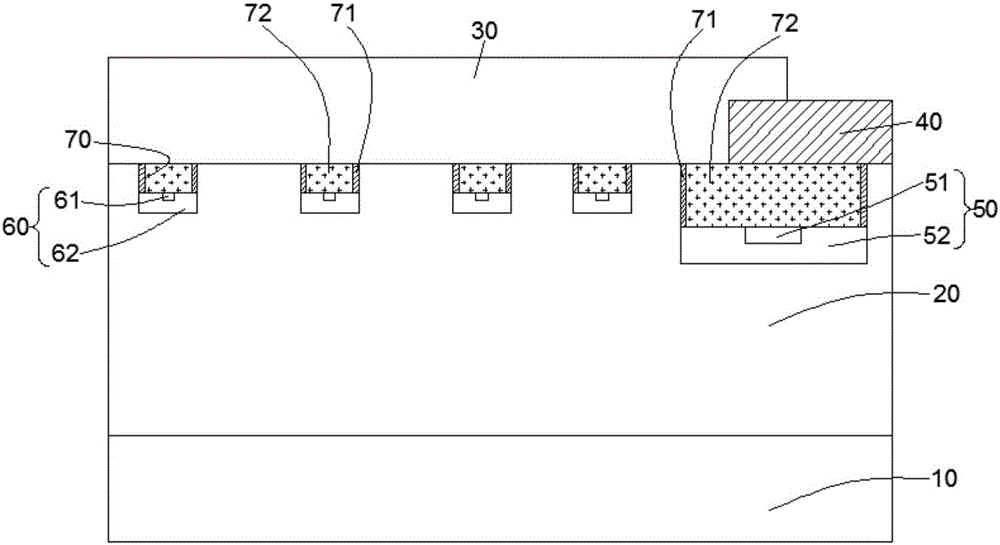

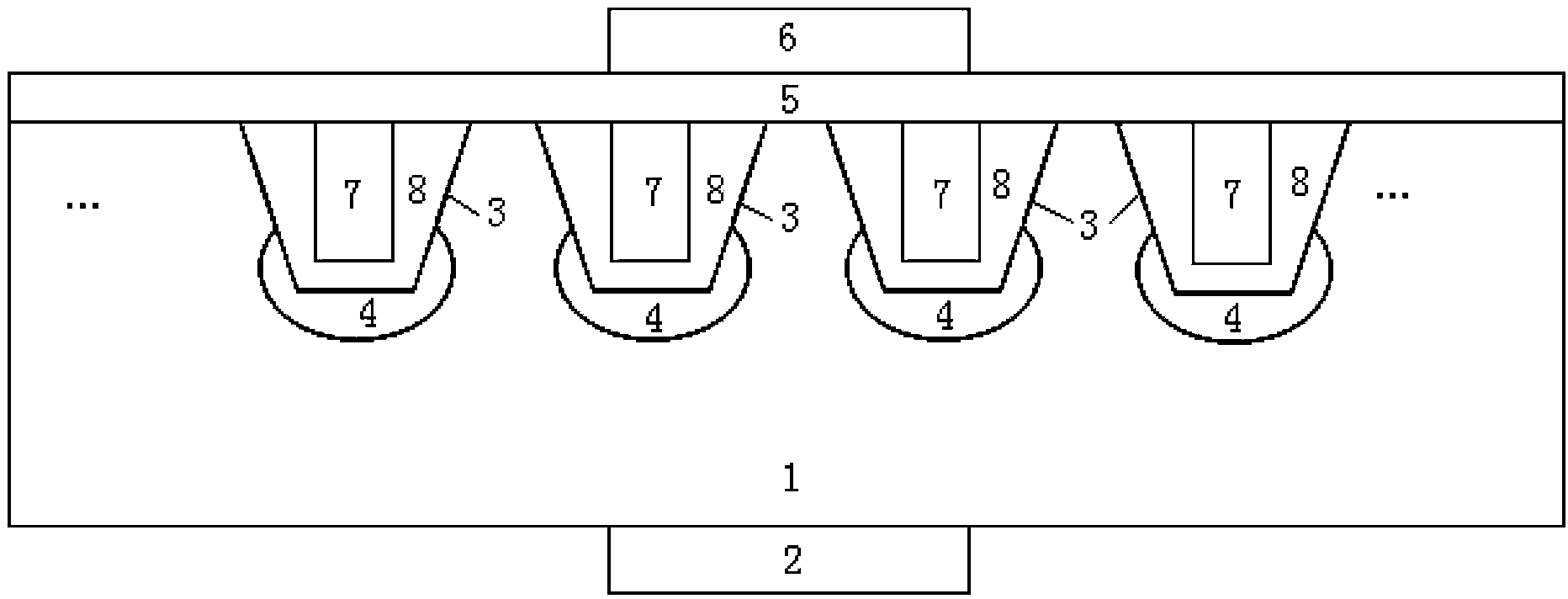

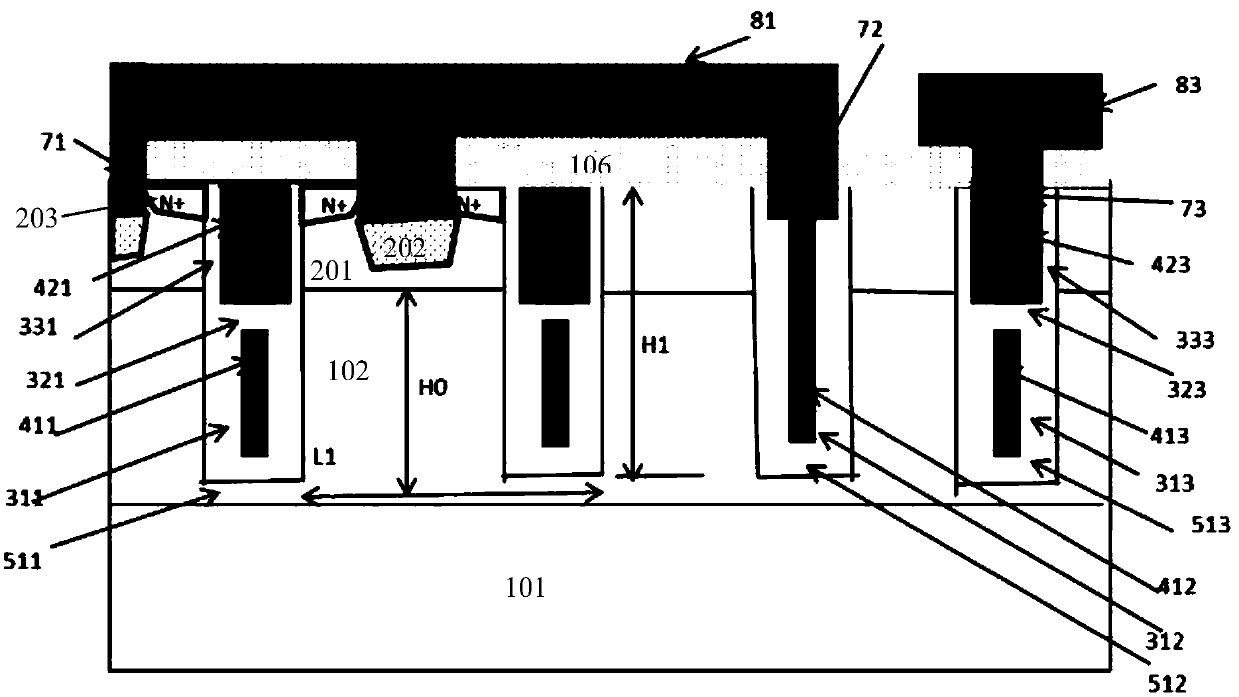

The invention discloses a shield grid trench MOSFET device.In grid electrode structures of primitive cells, shield electrodes are formed after epitaxial layers filling trenches are etched back, and trench grids are formed at the tops of the shield electrodes; the shield electrodes and adjacent drift regions make direct contact, carrier balance is achieved, the shield electrodes of the primitive cells and the drift regions form alternately-arranged structures in the transverse direction, and the shield electrodes carry out transverse exhausting on the adjacent drift regions in reverse bias of the device.The invention further discloses a manufacturing method of the shield grid trench MOSFET device.According to the shield grid trench MOSFET device and the manufacturing method, it is unnecessary to arrange dielectric films at the bottoms of the shield electrodes, stepping of device units can be reduced, the specific on-resistance of the device can be reduced, manufacturing difficulty can be lowered, and the uniformity of device performance can be improved.

Owner:SHENZHEN SANRISE TECH CO LTD

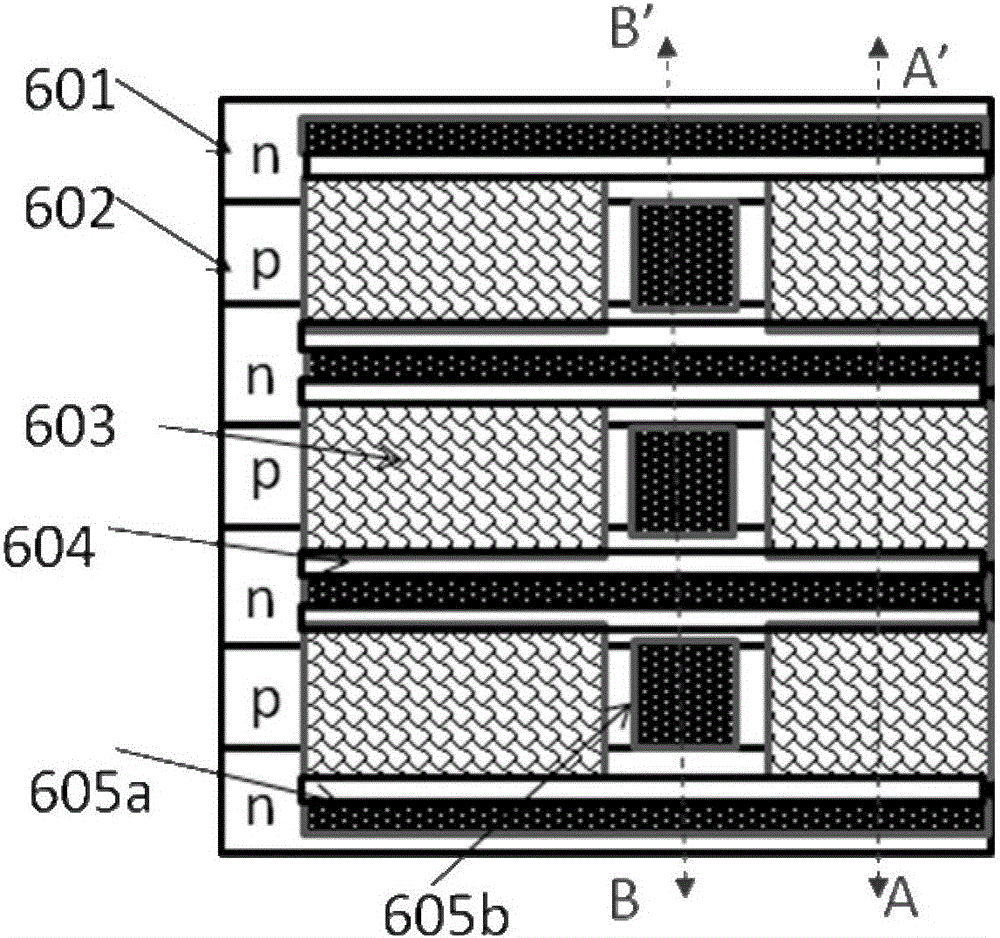

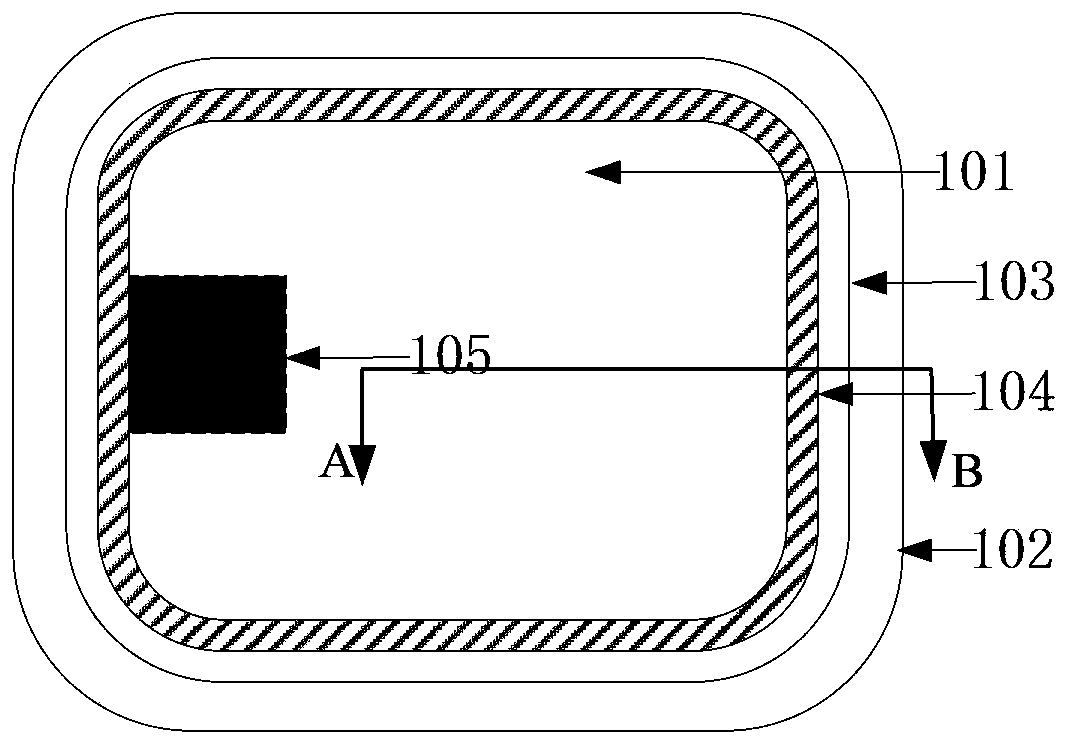

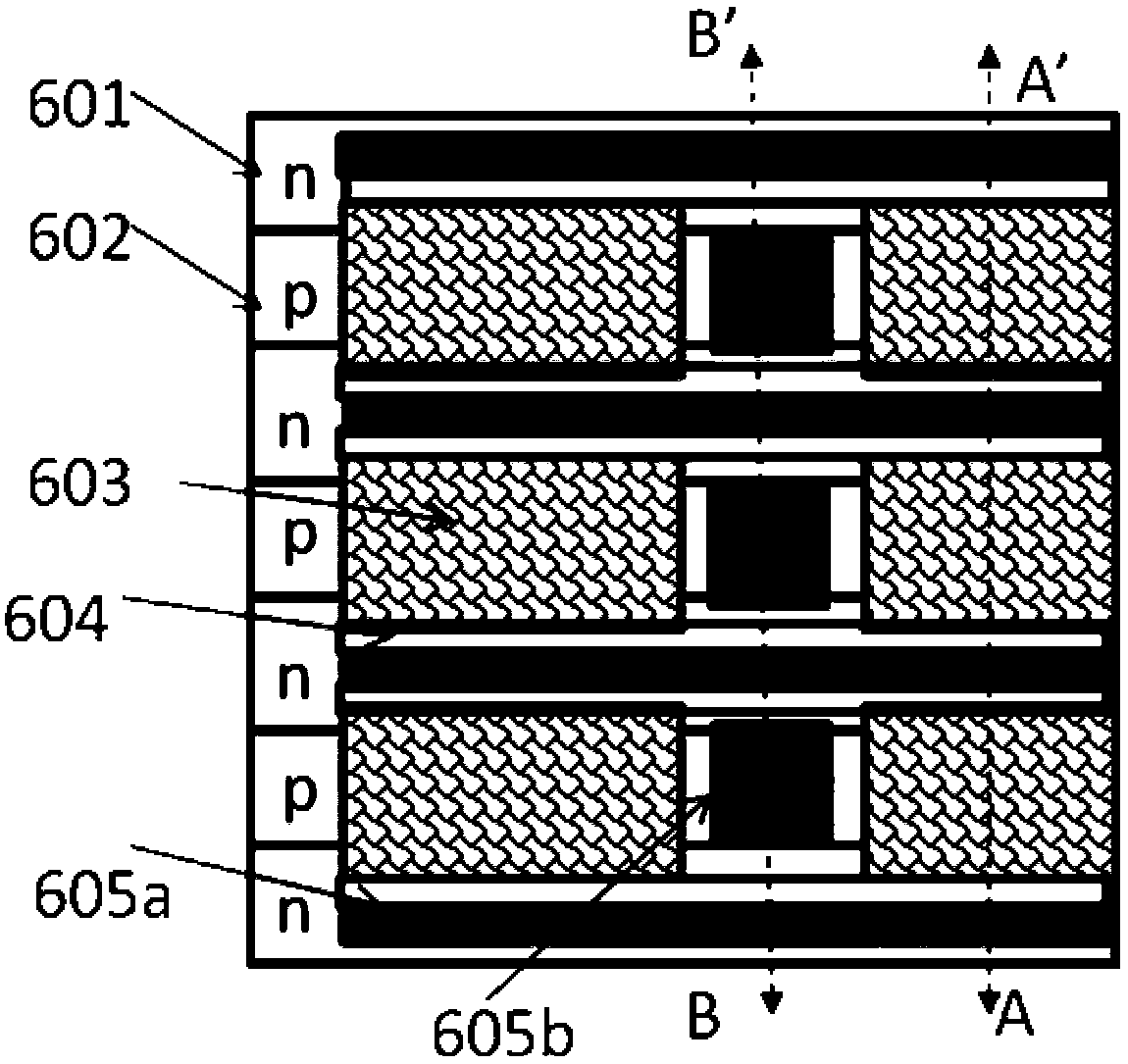

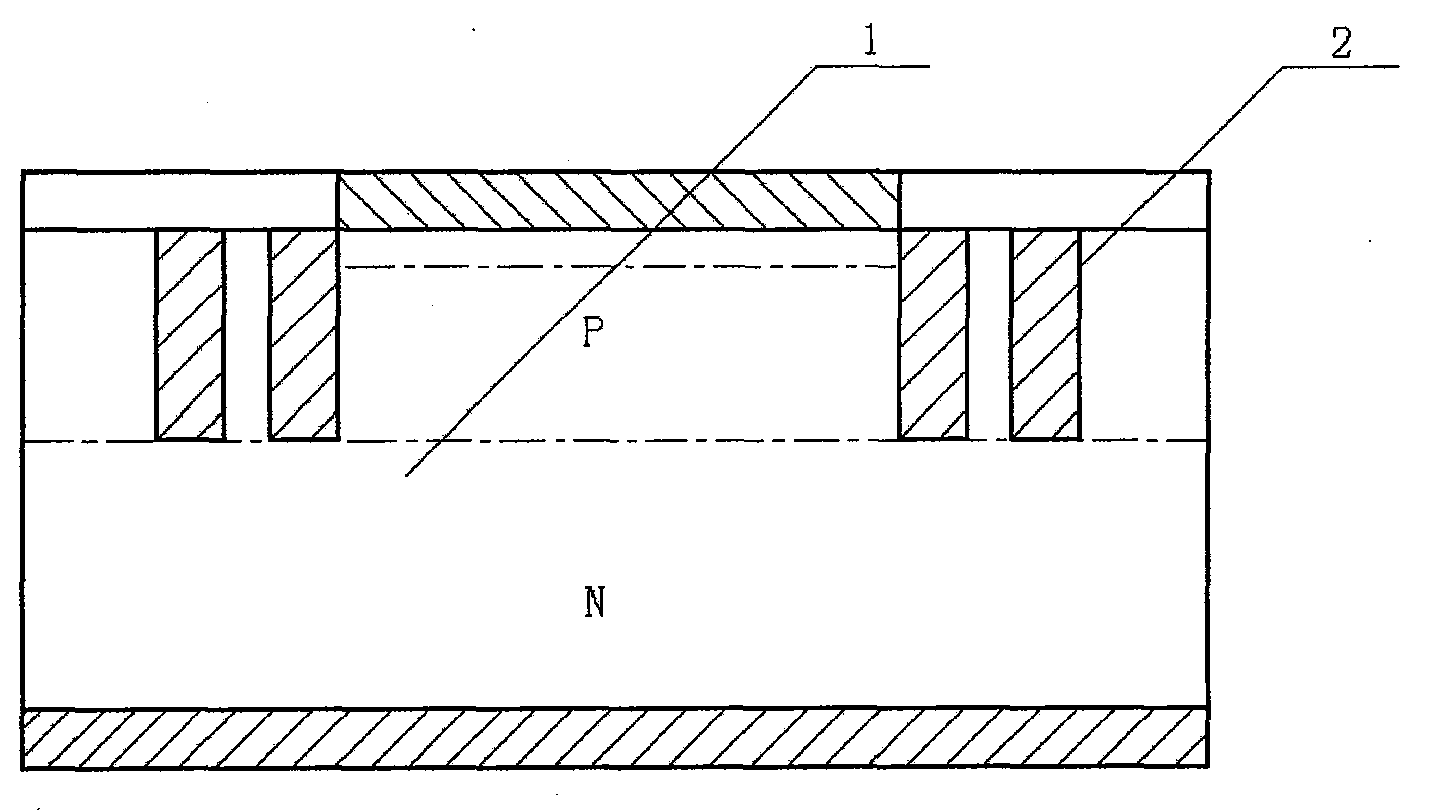

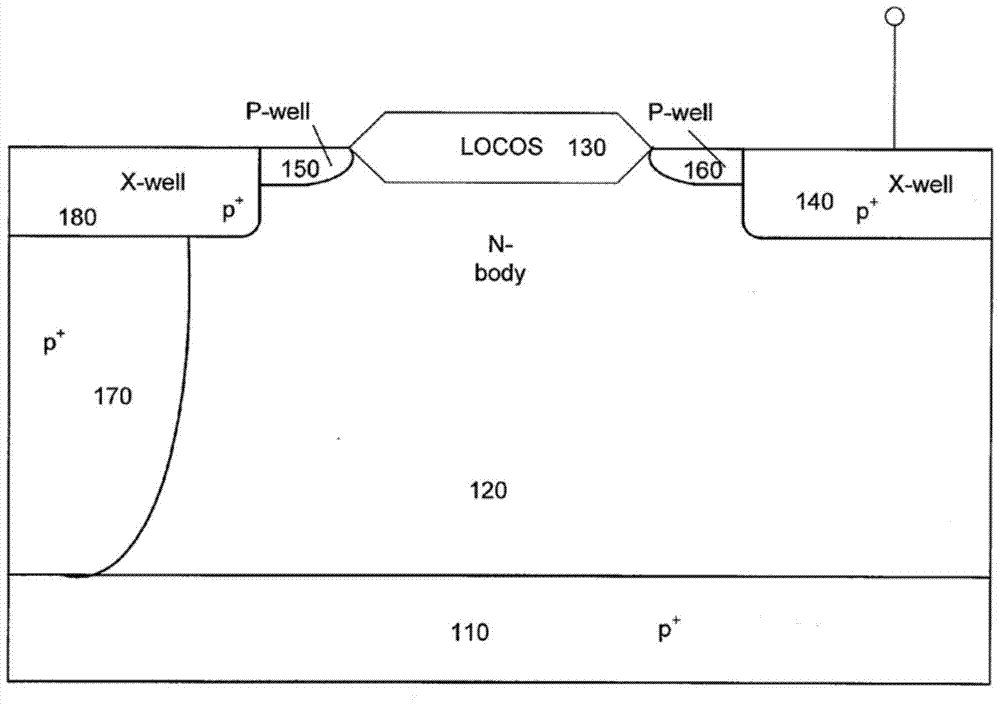

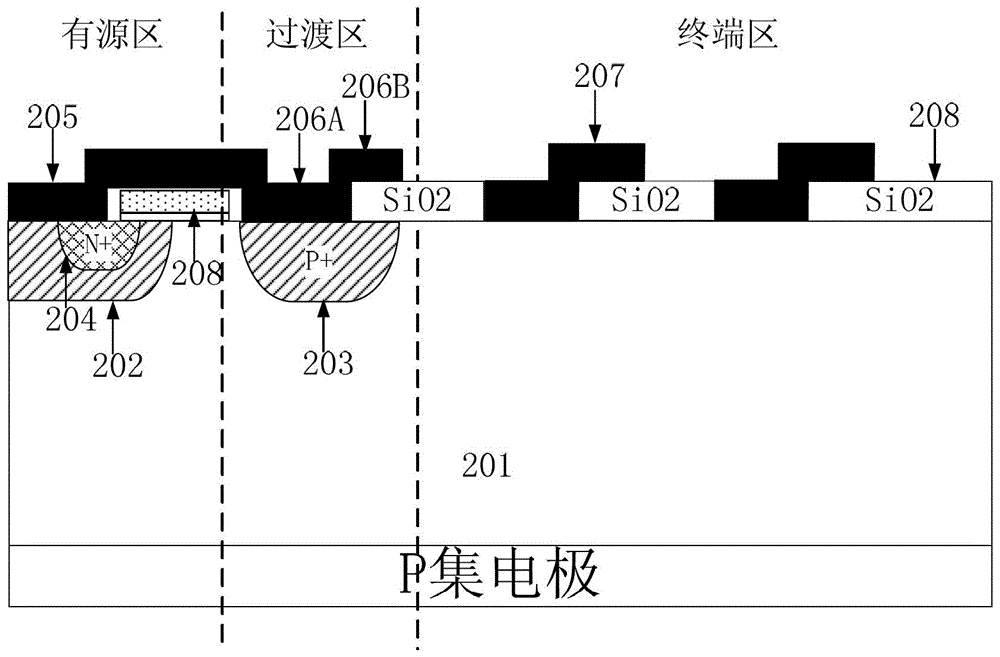

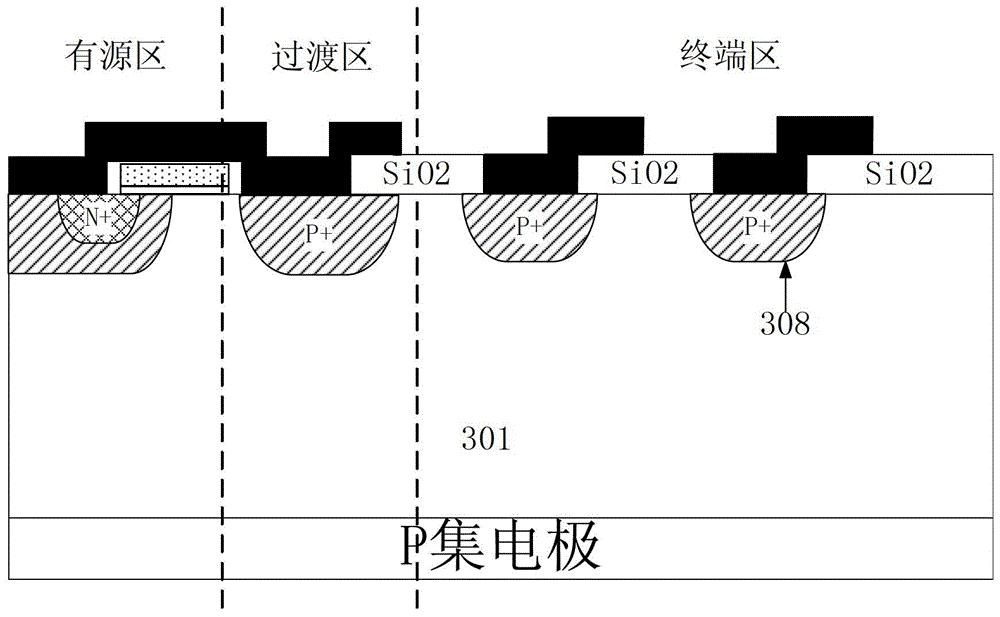

Insulated gate bipolar transistor and manufacturing method

InactiveCN104009072AEnsure balanceEnhanced ability to withstand reverse voltageSemiconductor/solid-state device manufacturingSemiconductor devicesTransistorElectrical and Electronics engineering

The invention discloses an insulated gate bipolar transistor and its manufacturing method. The insulated gate bipolar transistor comprises a collector region, a super-junction drift region positioned on the surface of the collector region, an active region positioned on the surface of the super-junction drift region, a first terminal structure which encircles the active region and a second terminal structure which encircles the super-junction drift region and the first terminal structure. Width of the second terminal structure increases progressively in a first direction. The first direction is from the collector region to the active region. The bottom of the second terminal structure is contacted with the collector region, and the top of the second terminal structure is flush with the top of the active region. As the insulated gate bipolar transistor provided by the application is equipped with the second terminal structure which is used as a reverse pressure terminal structure of the insulated gate bipolar transistor, reverse pressure resistance of the insulated gate bipolar transistor can be raised effectively.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

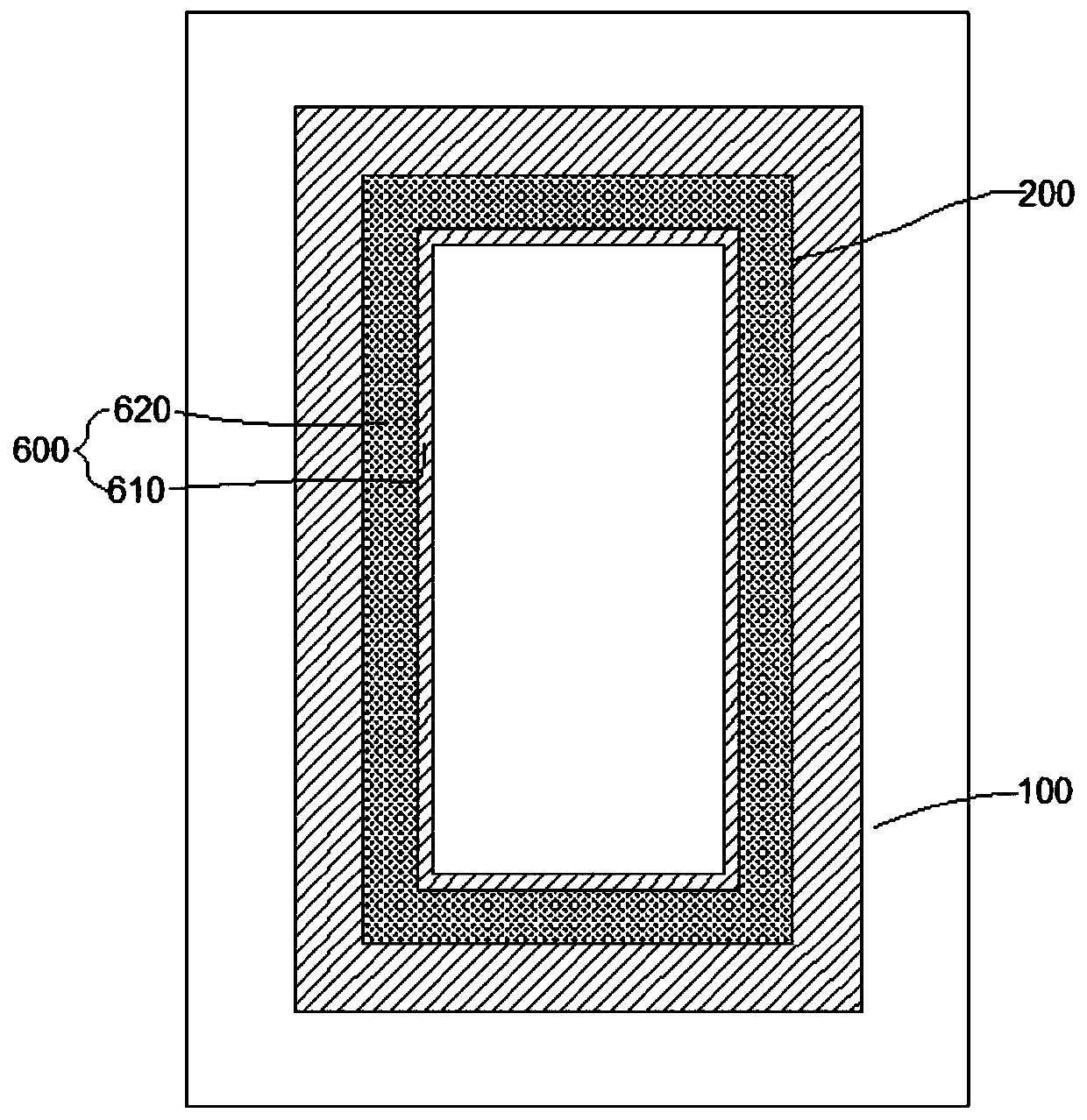

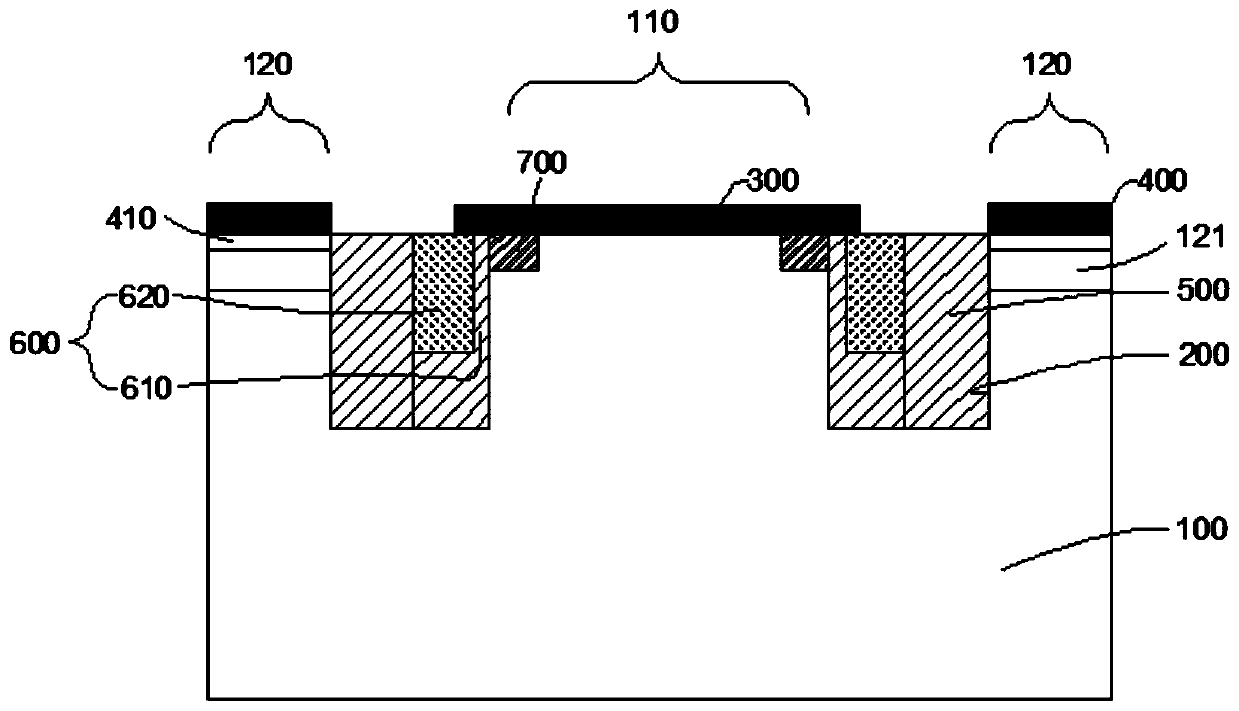

Trench Schottky diode terminal structure and preparation method thereof

InactiveCN104900719AImprove reverse withstand voltage capabilityImprove pressure resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesHorizontal and verticalSchottky diode

The present invention discloses a trench Schottky diode terminal structure which comprises an N-type silicon substrate. One side of the N-type silicon substrate is also provided with an N-type silicon epitaxial layer which is internally provided with a plurality of first trenches, and one side of the trenches is provided with a terminal ring structure. The invention also discloses a preparation method of the trench Schottky diode terminal structure. Due to the depletion of the N-type silicon epitaxial layer by the first trenches, a depletion layer is formed at the surface of the N-type silicon epitaxial layer of each of the first trenches, with the increase of reverse voltage, the depletion layers spread to the depth (horizontal and vertical directions) of a silicon surface, thus depletion layers between adjacent trenches are connected, which is equivalent to the significant increase of the depletion layer in the vertical direction, thus the reverse voltage withstand ability of a device is increased, the leakage current is reduced at the same time, and a terminal ring is added at the edge part of the device to improve the voltage withstand and reliability performance of the device.

Owner:SHANGHAI GREENPOWER ELECTRONICS

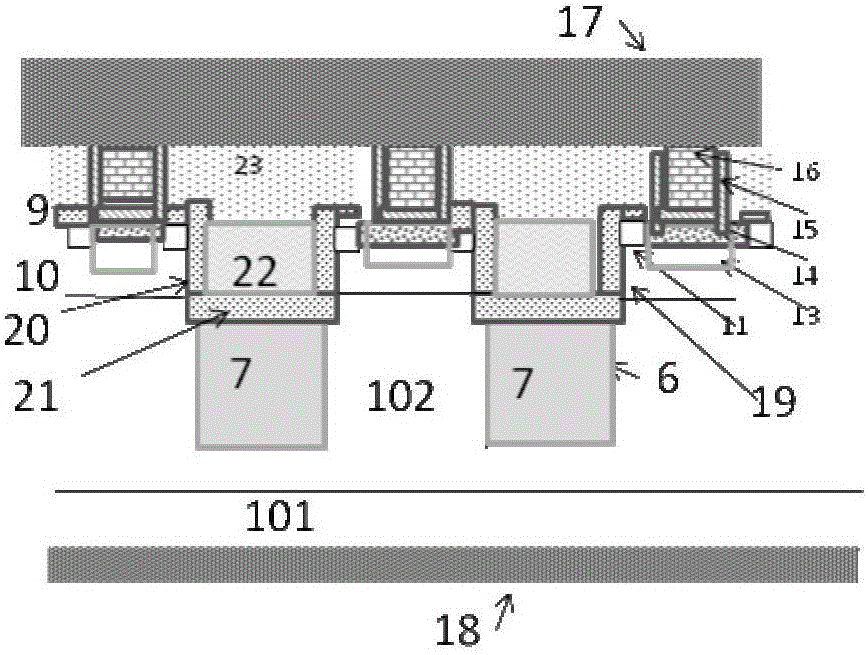

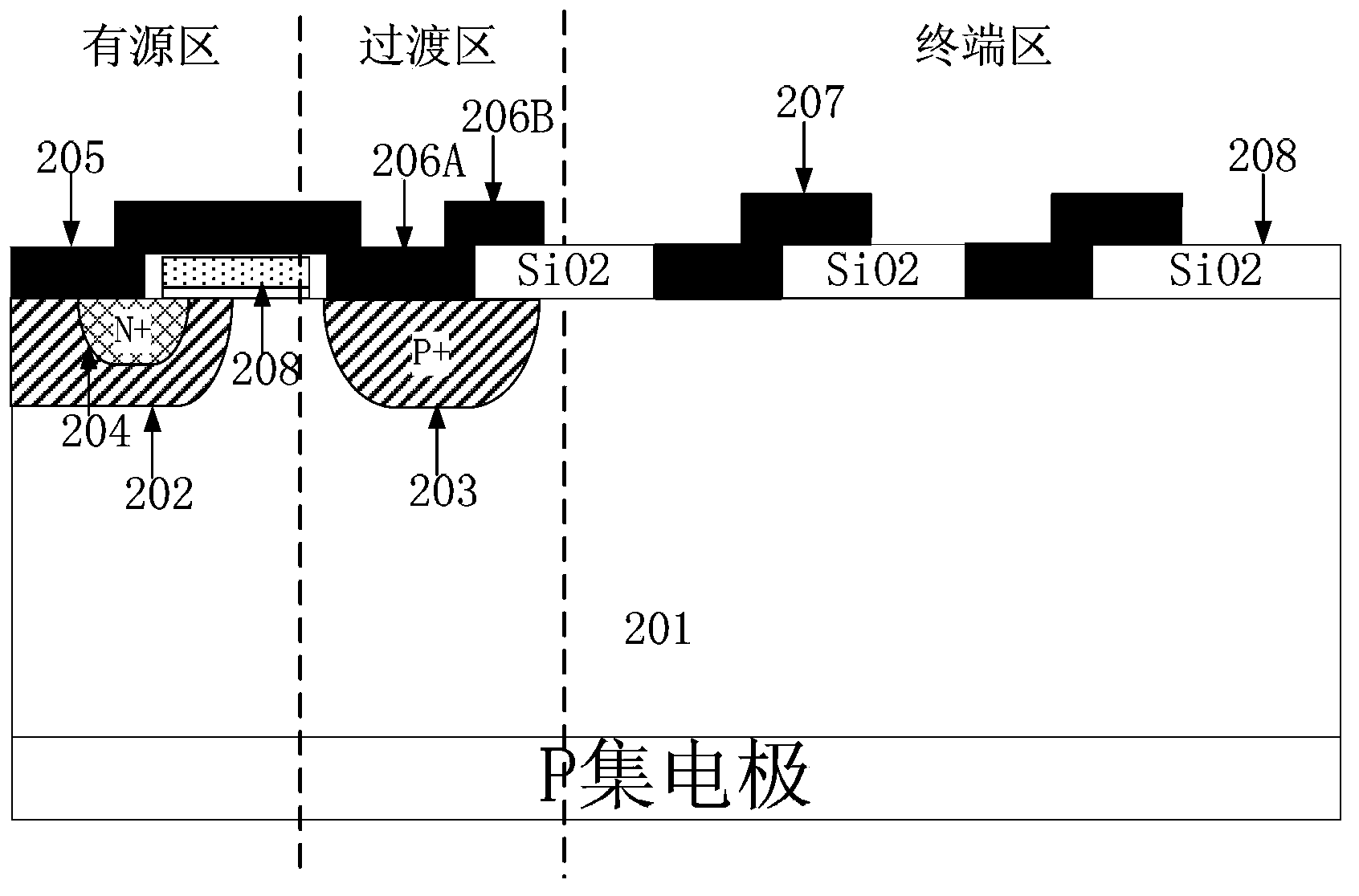

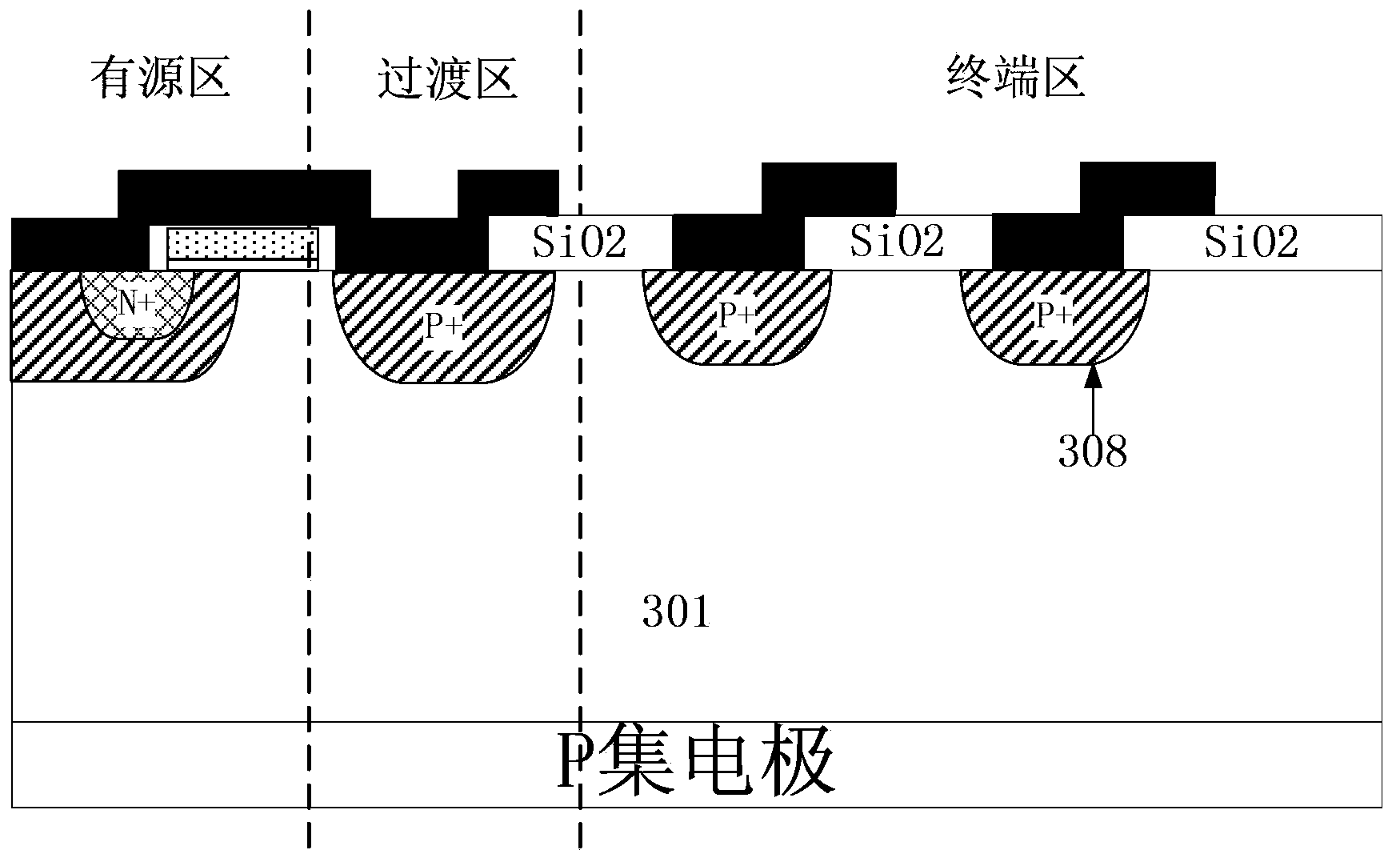

Semiconductor device and manufacturing method thereof

ActiveCN103855200AAvoid failureImprove performanceTransistorSemiconductor/solid-state device manufacturingEngineeringMetal electrodes

The invention provides a semiconductor device and a manufacturing method thereof. The semiconductor device includes a substrate, an emitter metal electrode and a first field plate; a base region and a main junction are formed in the substrate; the emitter metal electrode is formed on the surfaces of the base region and an emitting region and is electrically connected with the base region and the emitting region; and the first field plate covers the main junction and is electrically connected with the emitter metal electrode. According to the semiconductor device provided by the invention, a current path exists in the base region which is adjacent to the main junction at a transition region, such that a current release path can be provided for dynamic avalanche current which appears in switch-on and switch-off processes of the semiconductor device, and therefore, the failure of the semiconductor device caused by the dynamic avalanche current can be avoided, and the performance of the semiconductor device can be improved; and the first field plate covers the main junction and is electrically connected with the base region, the potential of the first field plate is zero constantly, and therefore, an electric field shielding effect of the first field plate can be enhanced, and therefore, a reverse voltage withstanding capacity of the semiconductor device can be improved.

Owner:SHANGHAI LIANXING ELECTRONICS +2

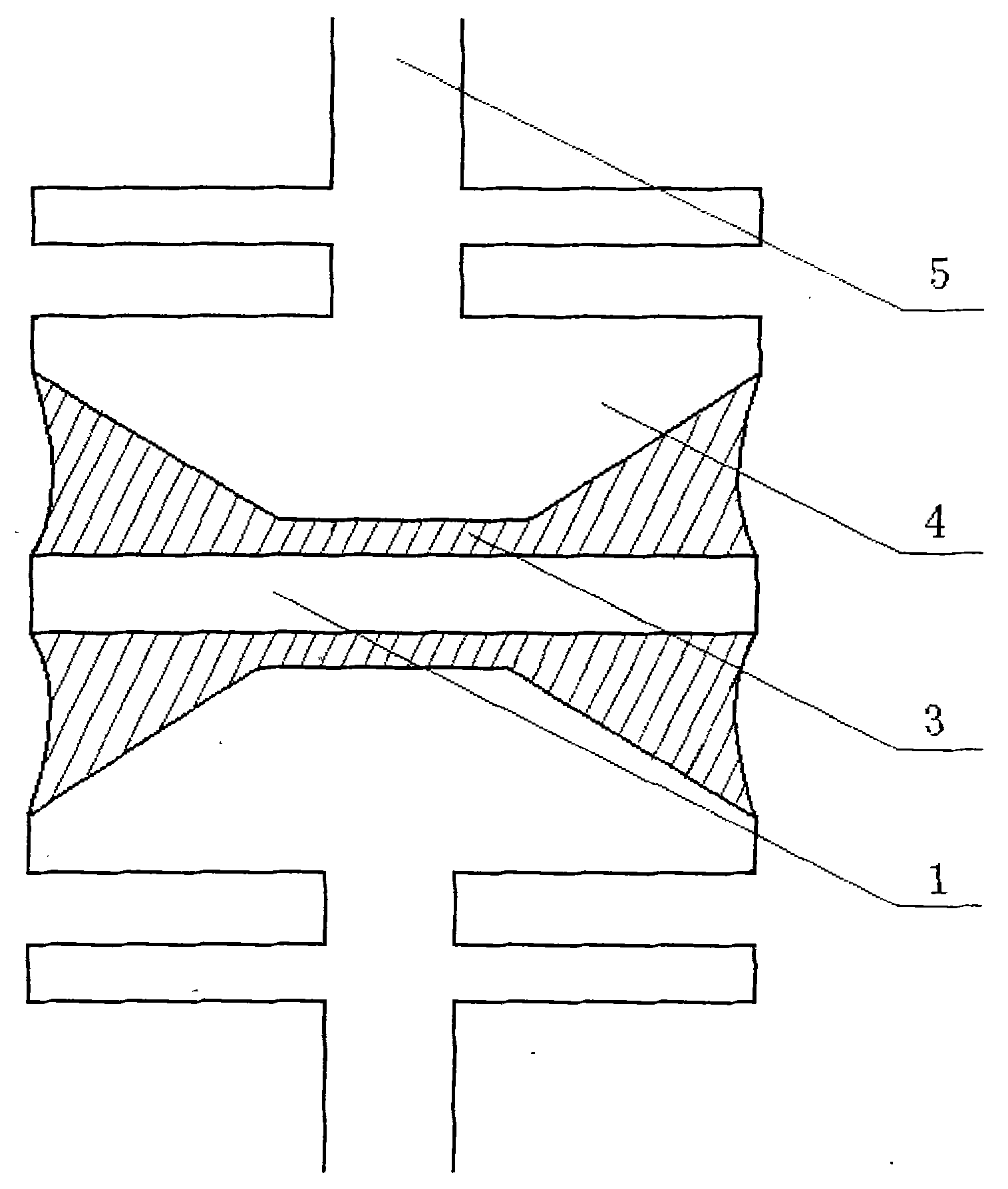

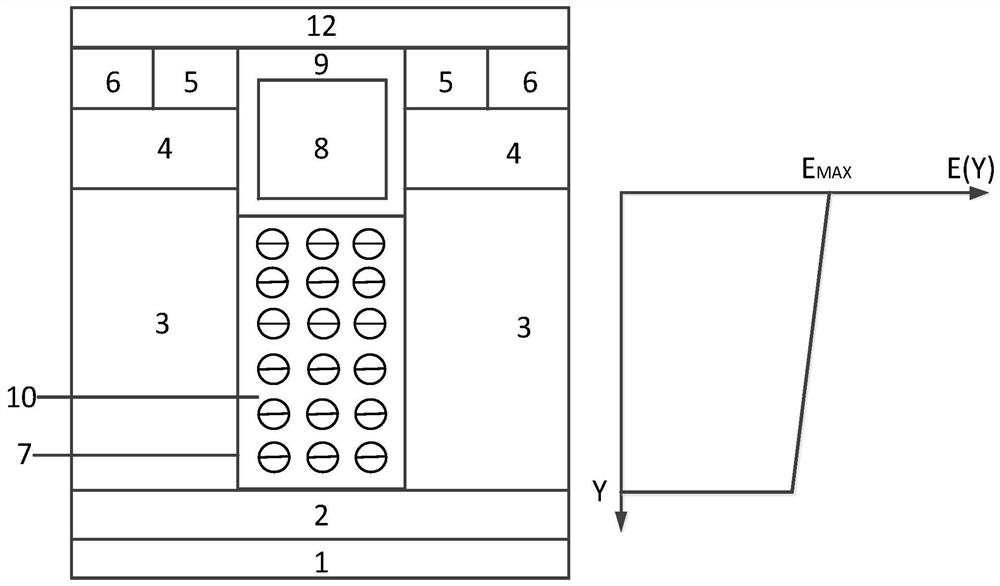

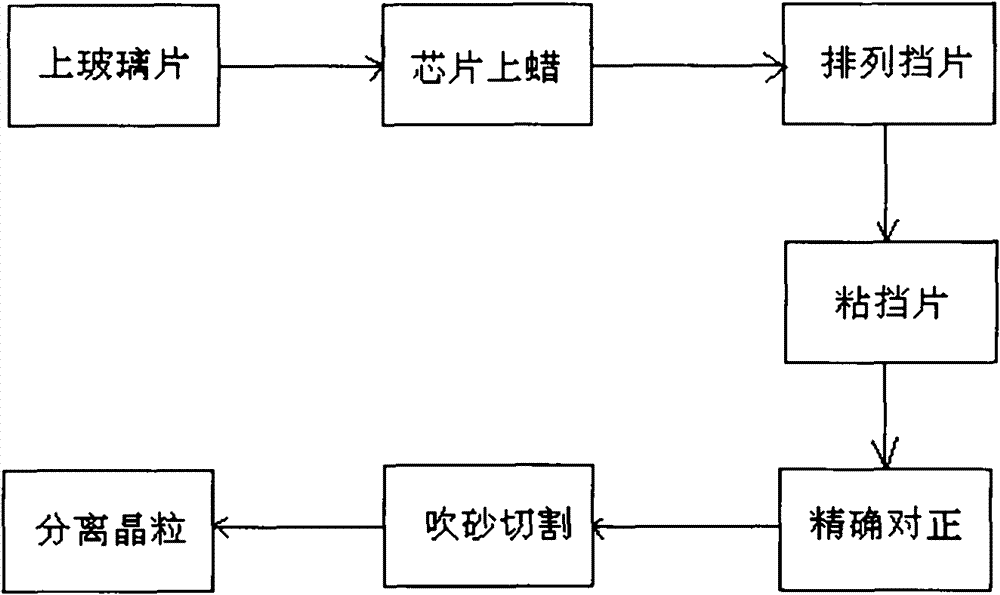

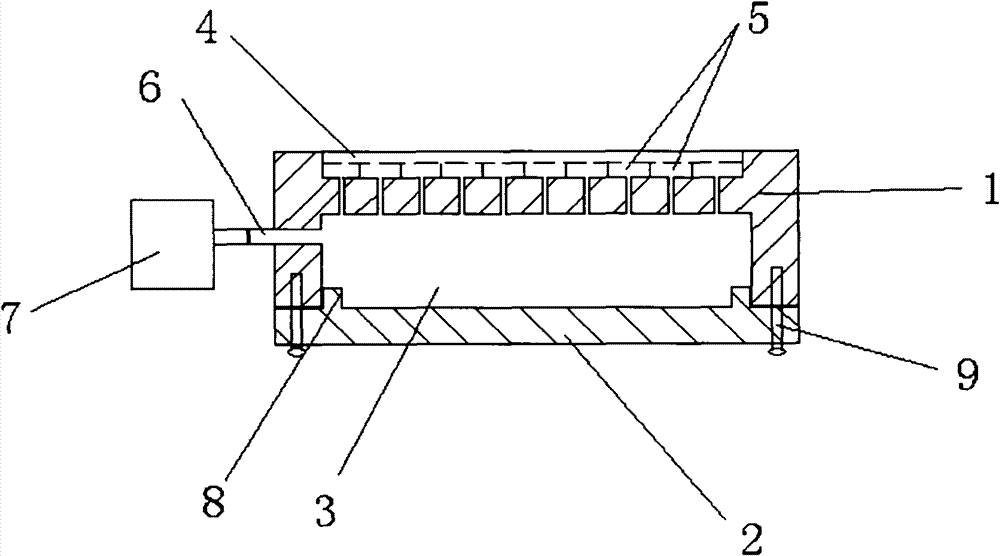

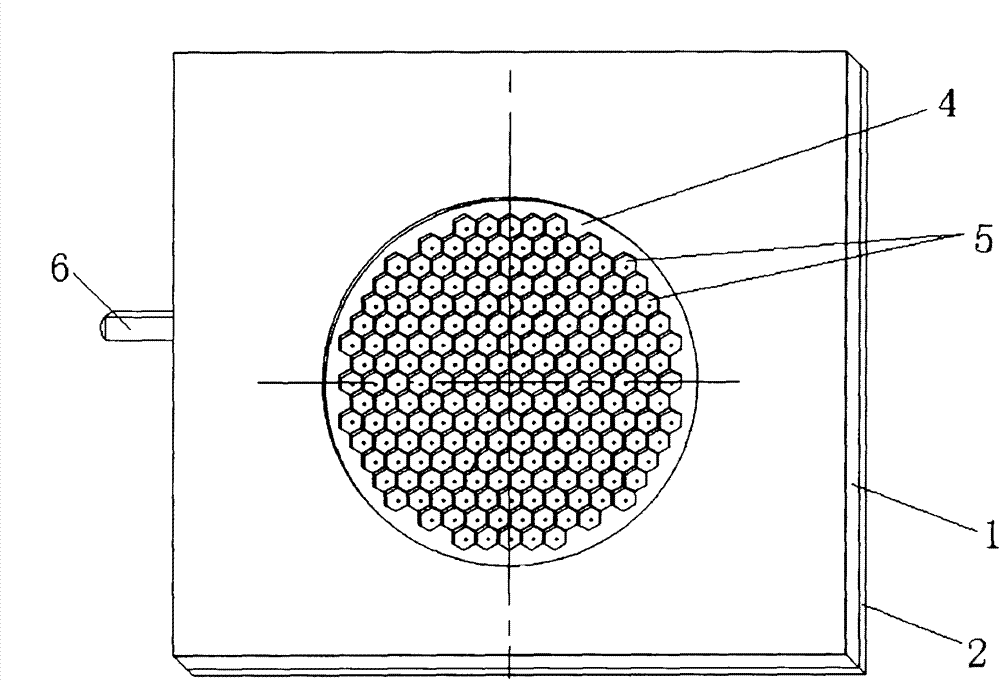

Rectifier grain, production method thereof and suction cup mould

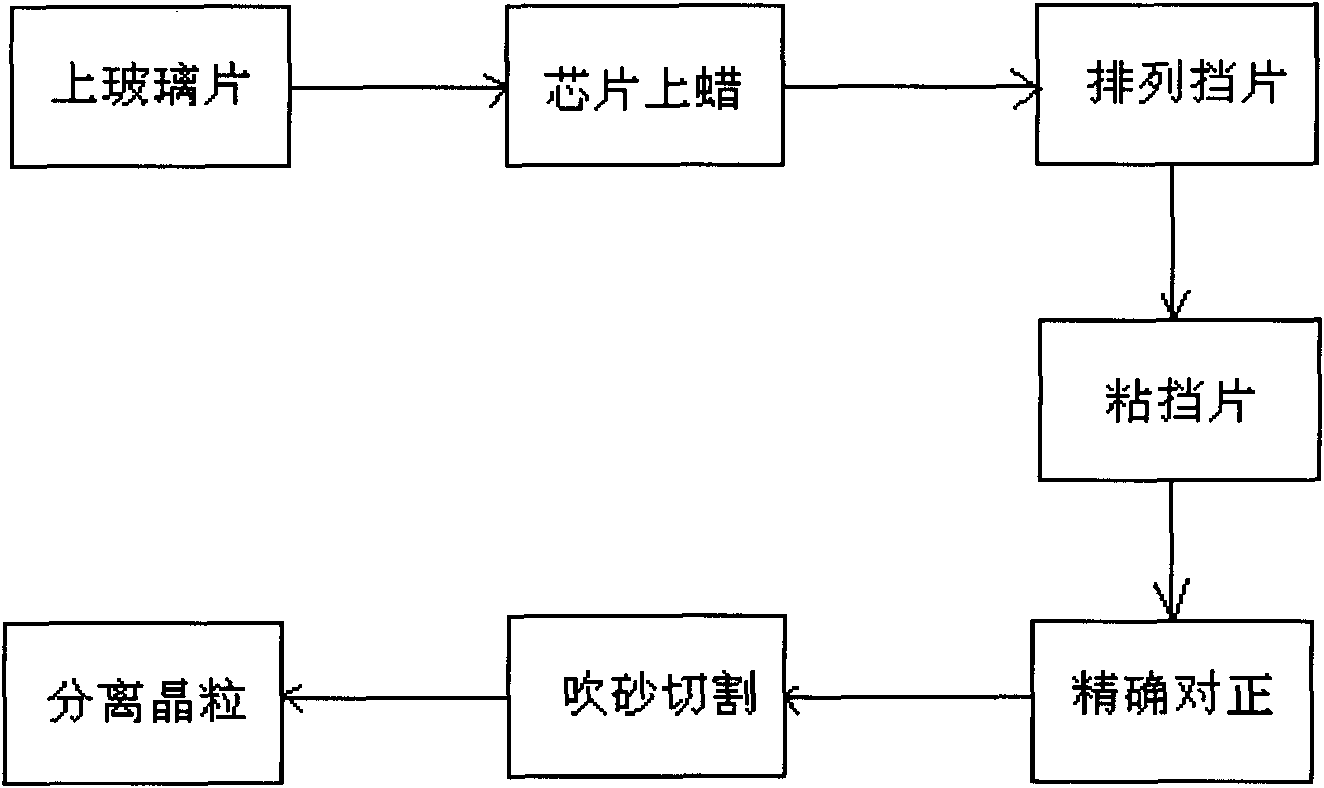

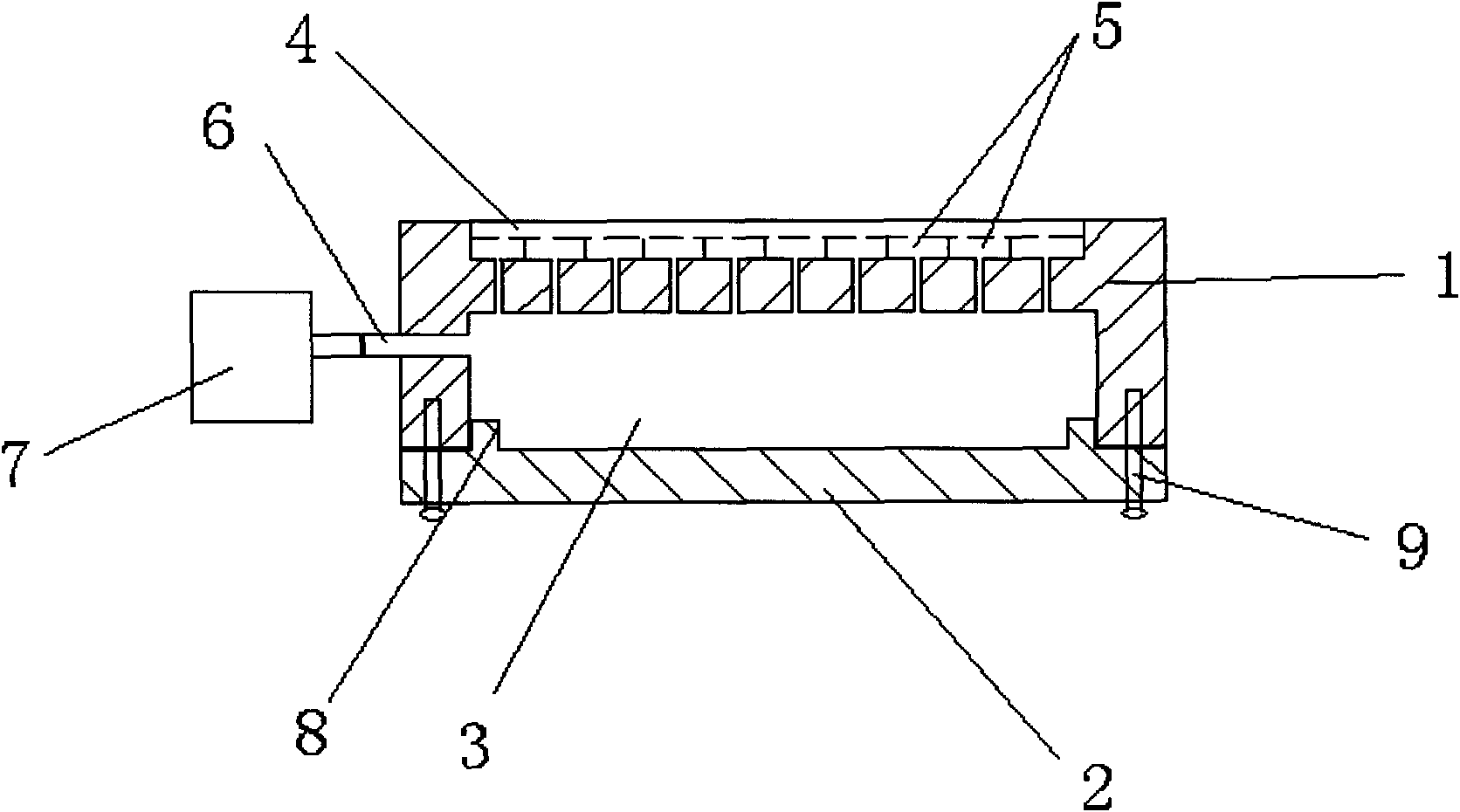

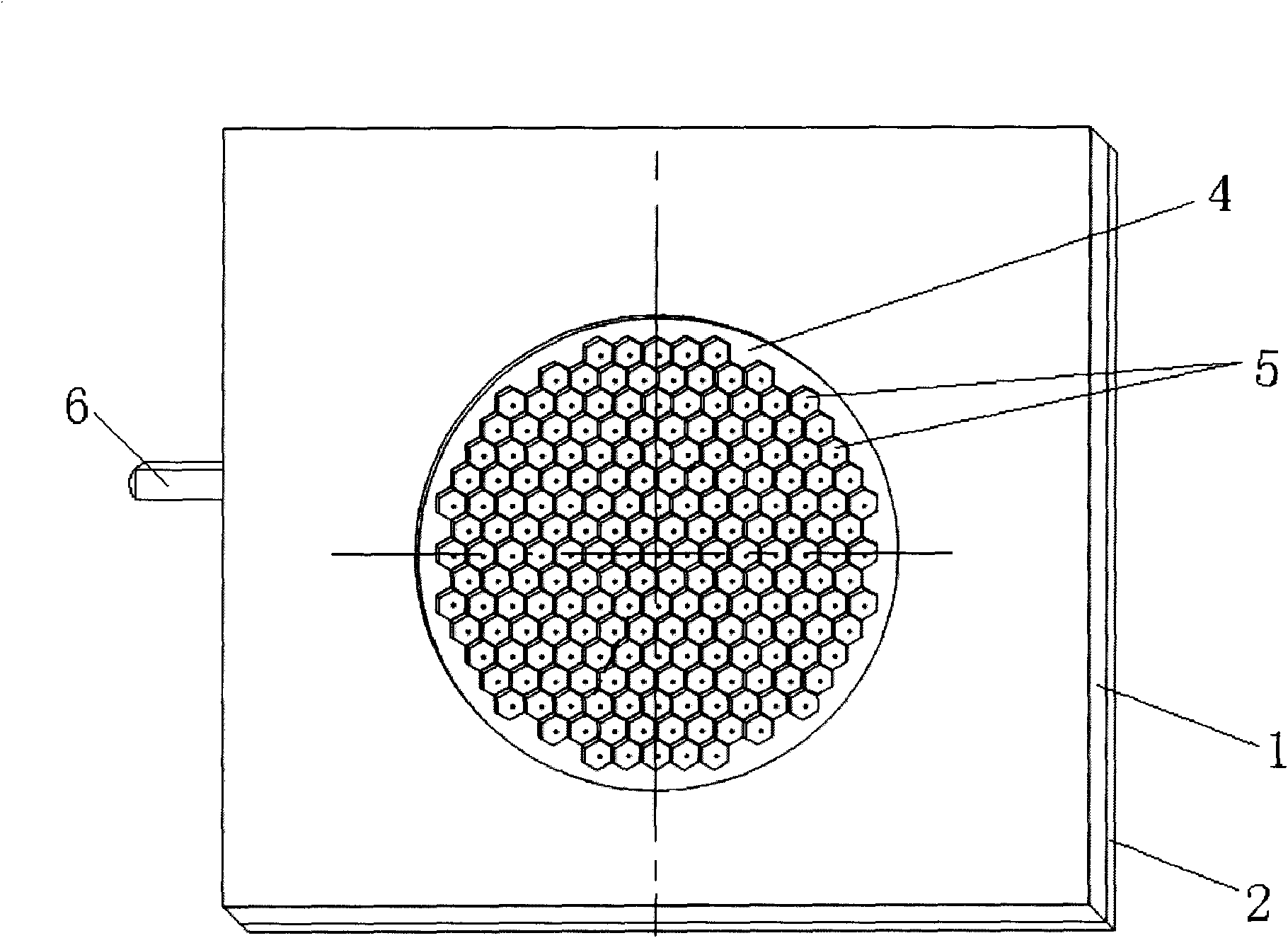

InactiveCN101819992AAvoid breakingReduce harmSemiconductor/solid-state device manufacturingSemiconductor devicesResistSand blasting

The invention discloses a rectifier grain, a production method thereof and a suction cup mould. The grain is in the shape of a regular hexagon. The production method for the grain comprises the following steps of: coating a photo-resist; adhering an MASK film; exposing; making a GPP film; arranging a glass sheet; waxing a chip; arranging a baffle; adhering the baffle; accurately aligning; cutting by sand blasting; and separating the grain. The suction cup mould comprises an upper die and a lower die, wherein the upper and lower dies are detachably connected with each other so as to form a cavity which can be vacuumized; the upper surface of the upper die is provided with a notch; the bottom surface of the notch is provided with a plurality of regularly hexagonal counter bores which are cellular and arranged closely; and each counter bore is communicated with the cavity. By using the structure and the method, the rectifier grain, the production method and the suction cup mould have the advantages that: firstly, the area utilization of the grain is improved, the product is durable, and the impact resistance is enhanced; secondly, the point discharge effect is reduced and the backward voltage resistance of the product is enhanced; and thirdly, the edge of a glass trench of the grain which is cut by the sand blasting method is tidy and the electrical performance is better protected.

Owner:GOOD ELECTRONICS WUHU

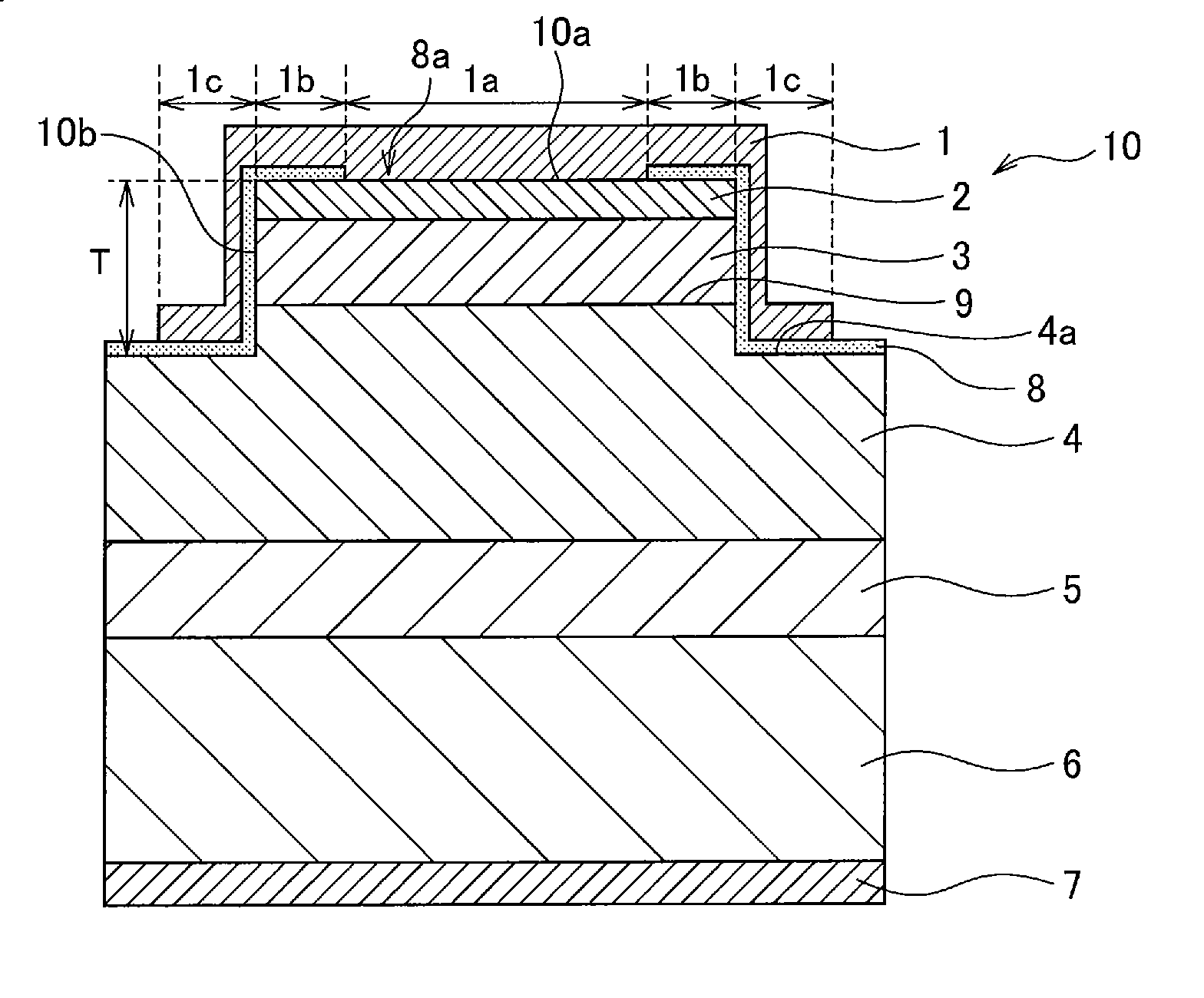

Semiconductor diode

InactiveUS20120313108A1Improve reverse withstand voltage capabilityIncreasing on-resistance of the pn-junction diodeSemiconductor devicesOhmic contactSemiconductor

To provide a semiconductor diode with a part of a semiconductor lamination portion having a mesa structure portion, which is the part where a pn-junction is formed by lamination of an n-type semiconductor layer and a p-type semiconductor layer on a substrate, comprising: a protective insulating film formed by coating a main surface of the mesa structure portion, a side face of the mesa structure portion in which an interface of the pn-junction is exposed, and an etched and exposed surface of the n-type semiconductor layer; and an anode electrode formed in ohmic-contact with the p-type semiconductor layer exposed from an opening formed on a part of the main surface of the mesa structure portion of the protective insulating film, extending from the main surface, through the side face of the mesa structure portion, to the surface of the n-type semiconductor layer.

Owner:HITACHI METALS LTD

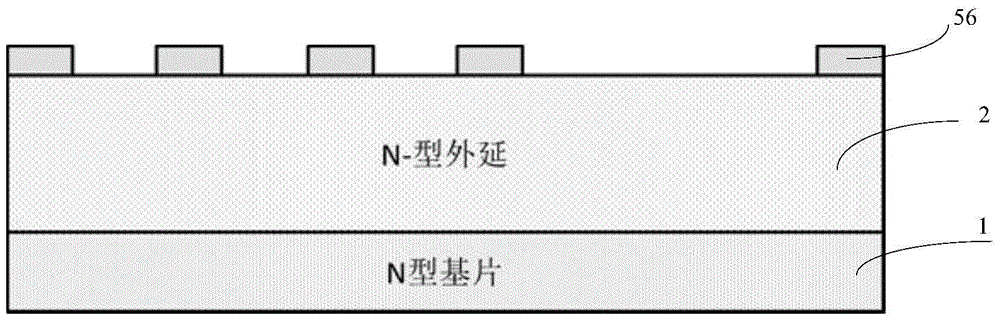

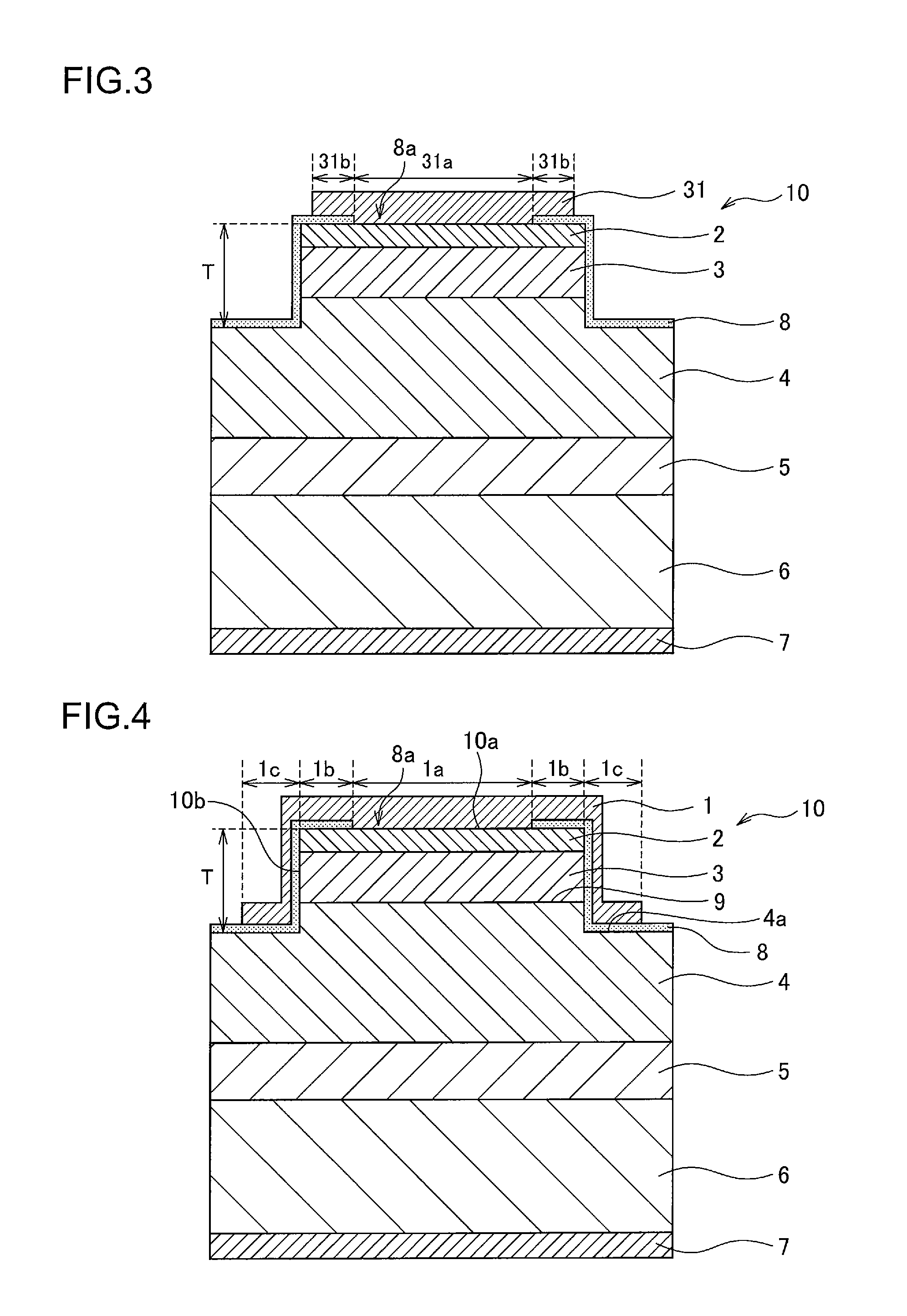

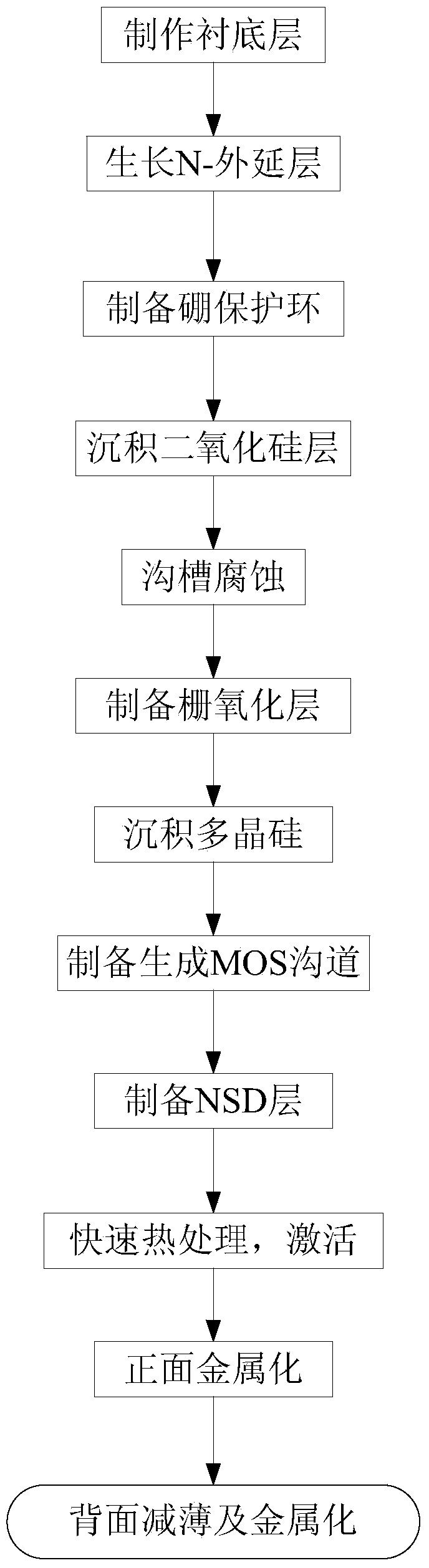

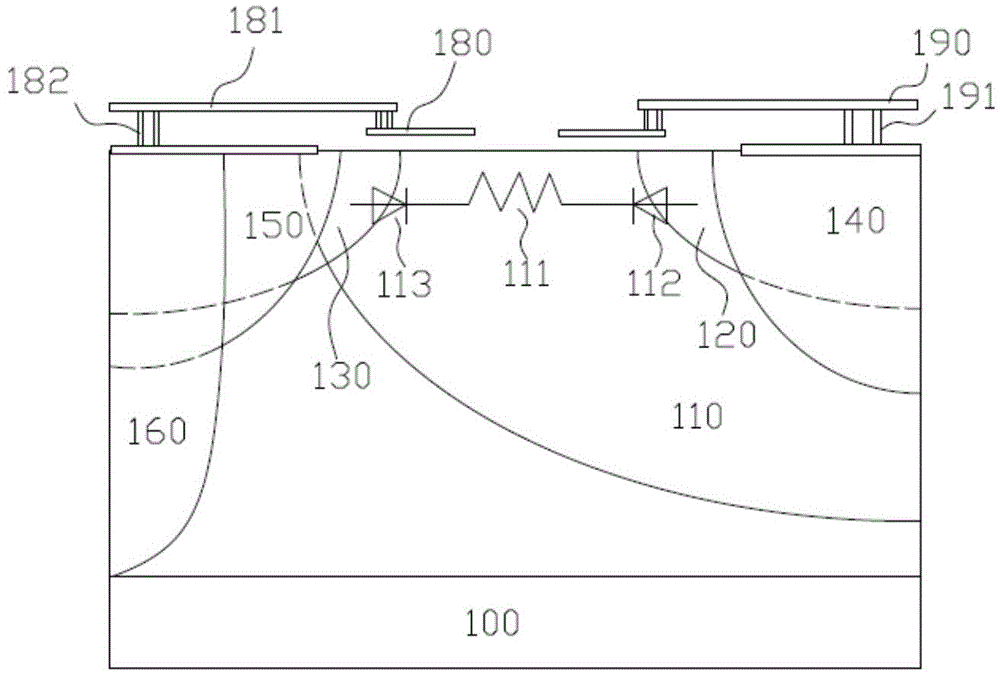

Power diode and method for manufacturing power diode

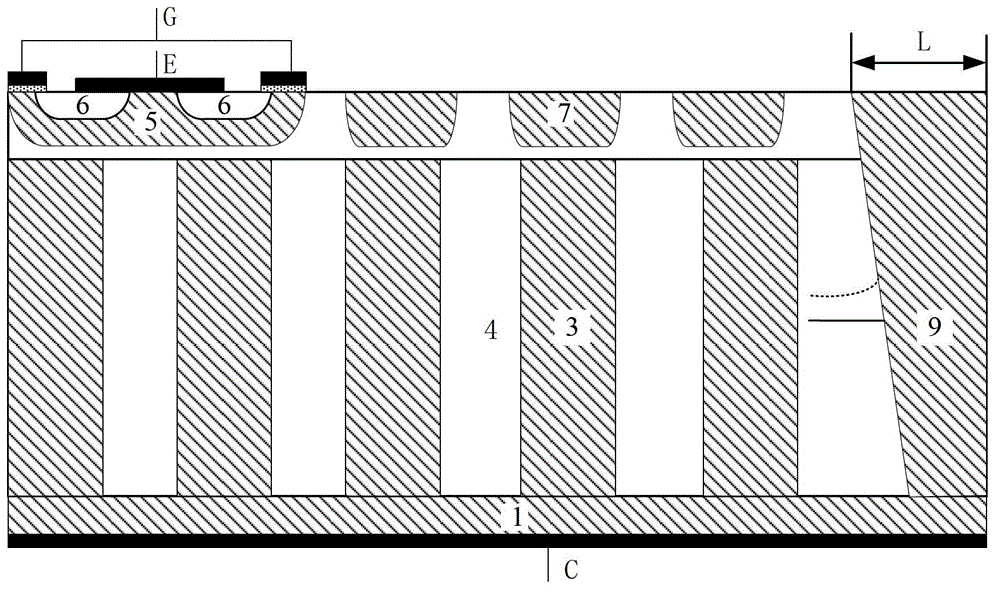

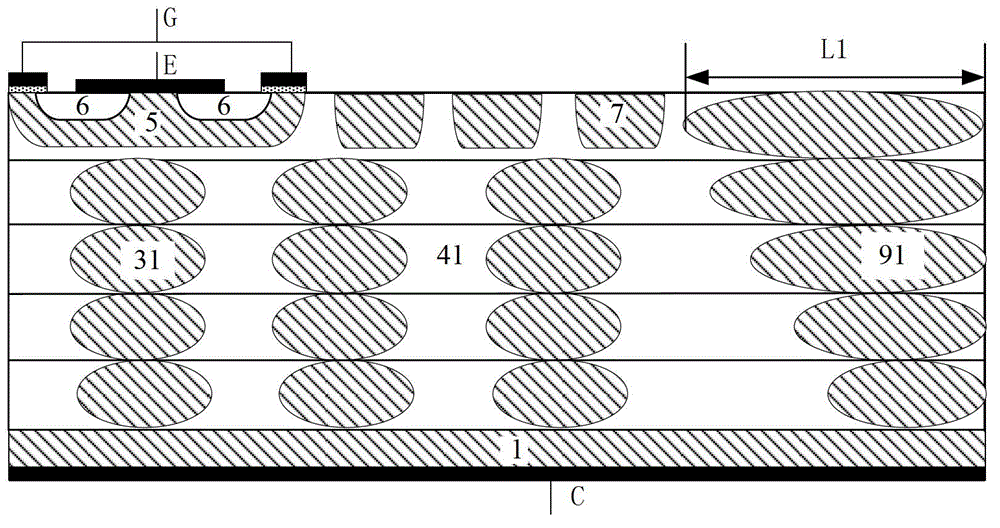

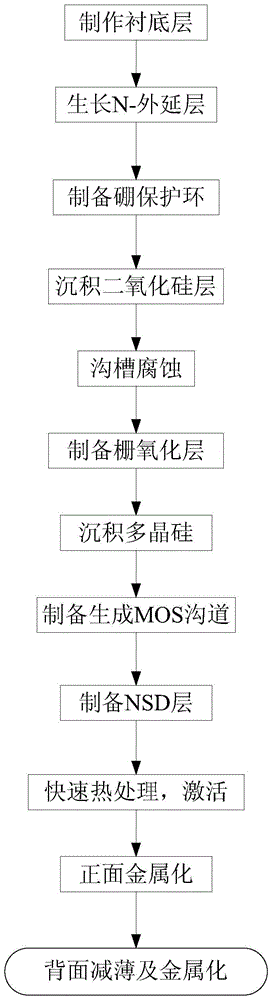

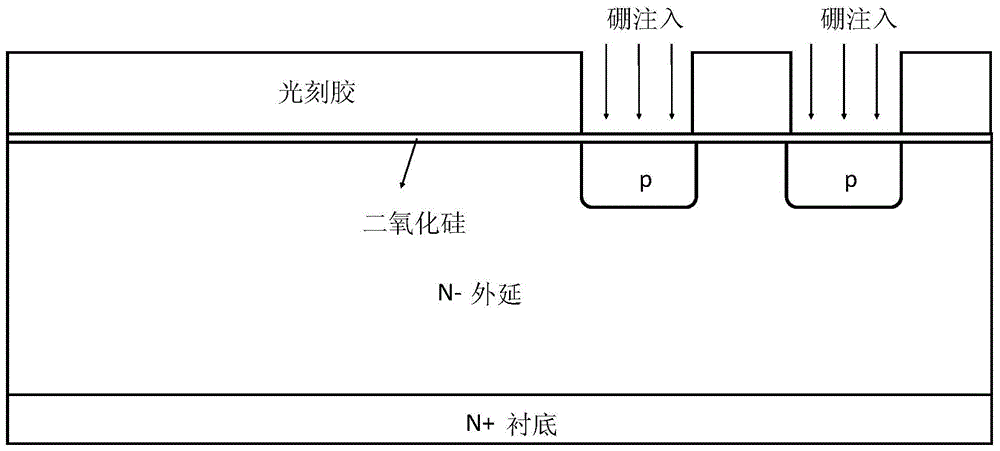

ActiveCN104051546AImprove reverse withstand voltage capabilityImprove reverse withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETElectricity

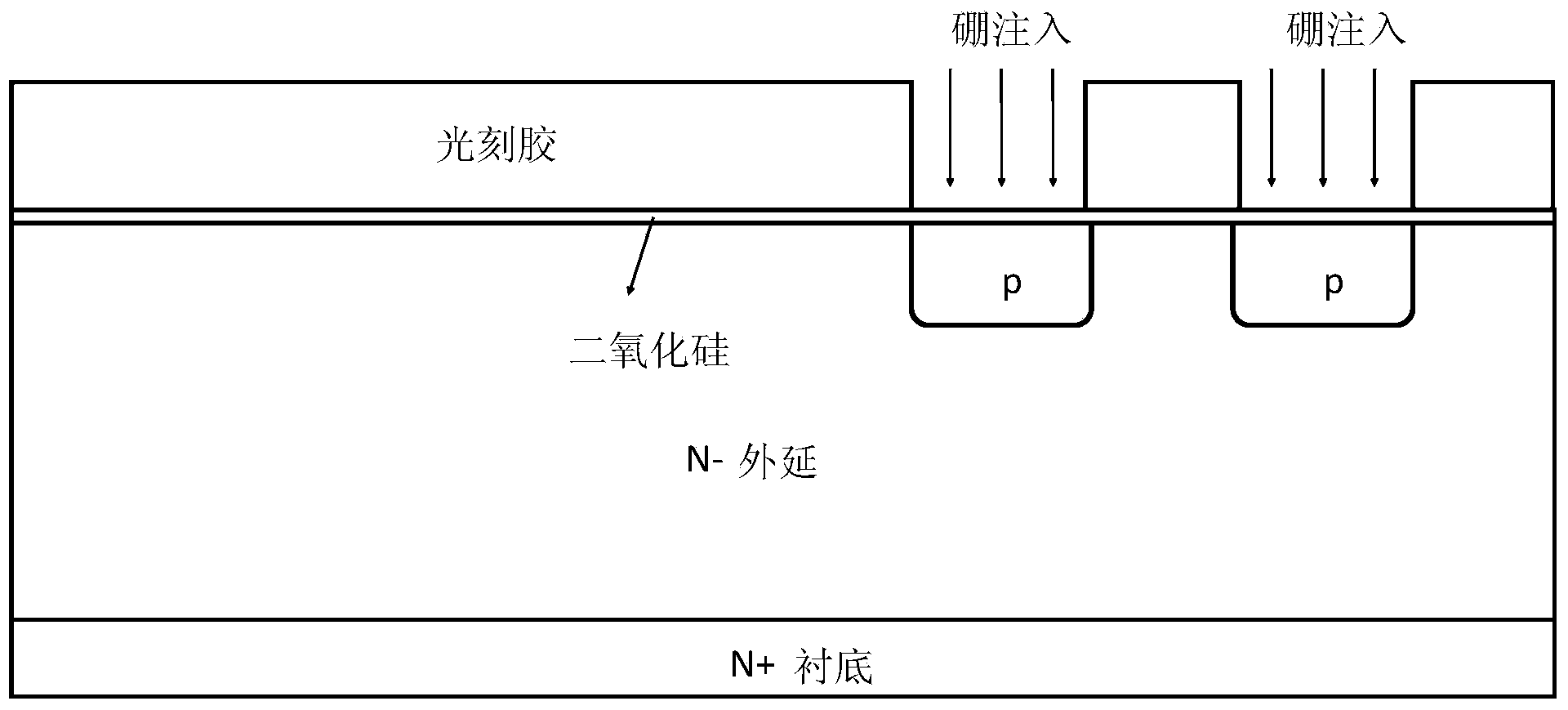

The invention relates to a power diode and a method for manufacturing the power diode. The power diode comprises a bottom electrode, a substrate layer, an N- type epitaxial layer and a top electrode, wherein the top electrode serves as the positive electrode of the power diode, the bottom electrode serves as the negative electrode of the power diode, at least two grooves are transversely formed in the upper portion of the N- type epitaxial layer in a spaced mode, and an MOS channel is formed in the portion, between every two adjacent grooves, of the N- type epitaxial layer. The power diode is made of silicon materials and can be obtained through an existing silicon semiconductor integrated circuit; special metal materials are not needed, and the method for manufacturing the power diode is compatible with an existing semiconductor production technology; the backward voltage resistance of the device is improved through p+ regions injected into the grooves; when backward voltage is applied to the device, the p+ exhaustion regions in the grooves expand and are connected, a backward current channel is cut off, and the voltage resistance of the device is improved; when the power diode operates in the forward direction, electricity is conducted through parasitic mosfet, and the forward starting voltage of the device is reduced.

Owner:无锡橙芯微电子科技有限公司

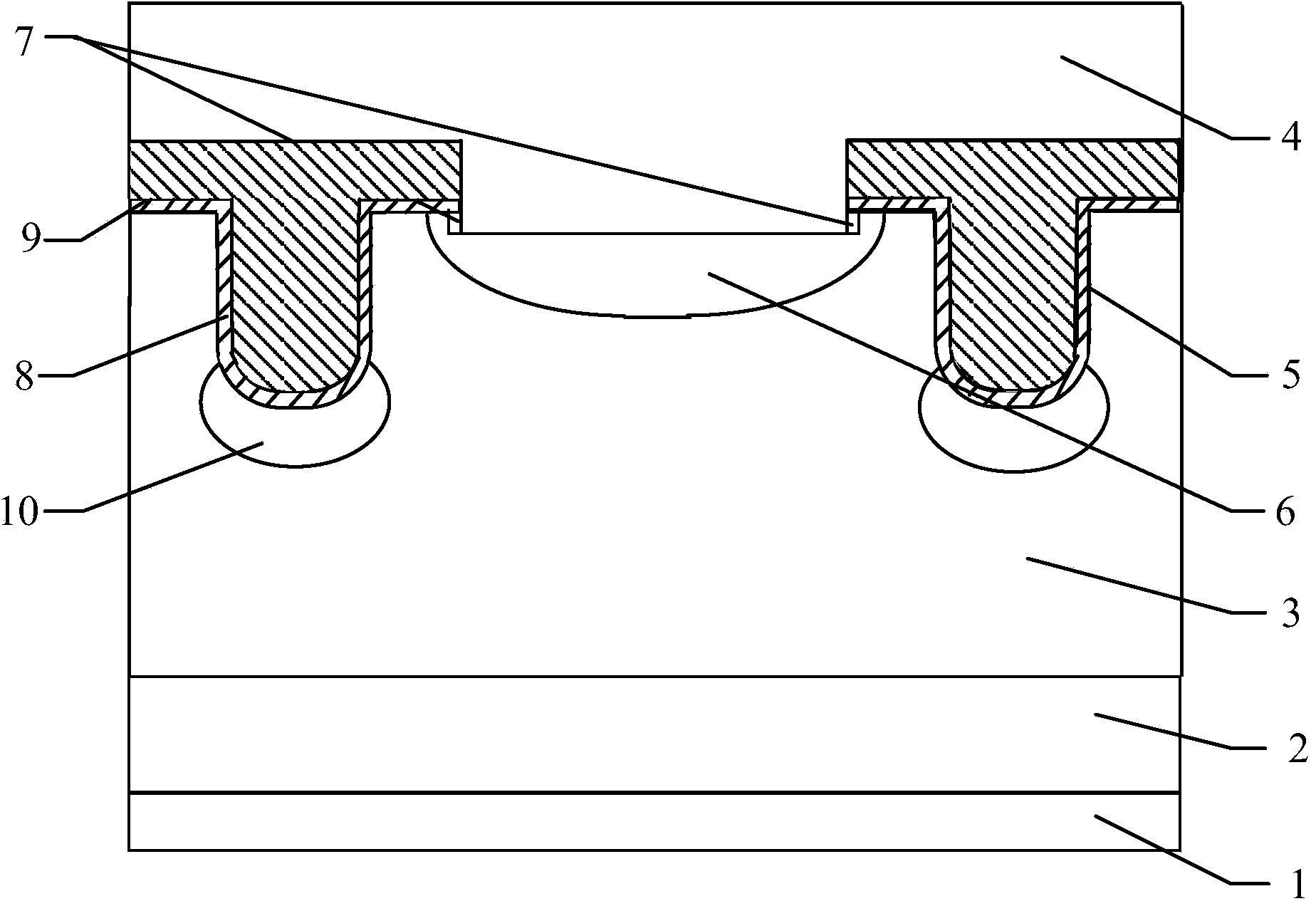

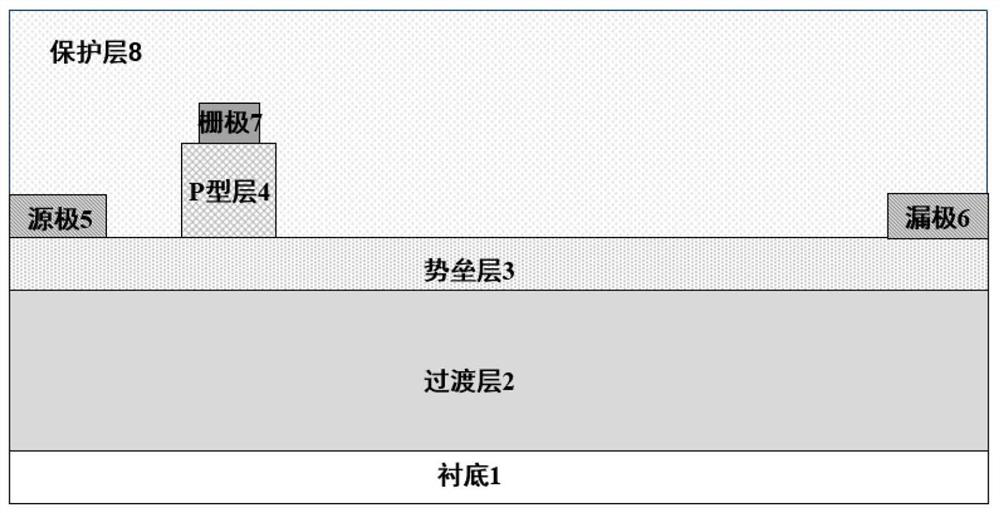

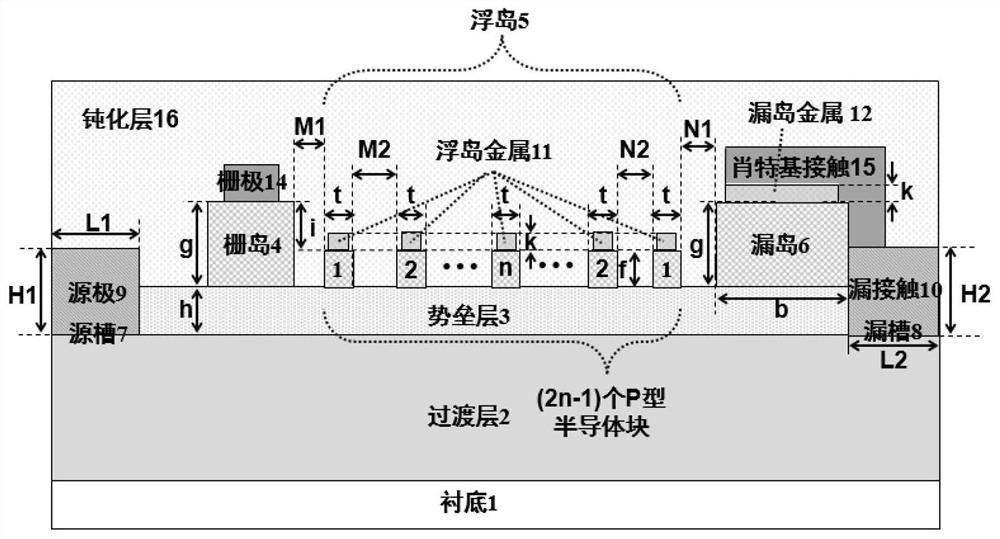

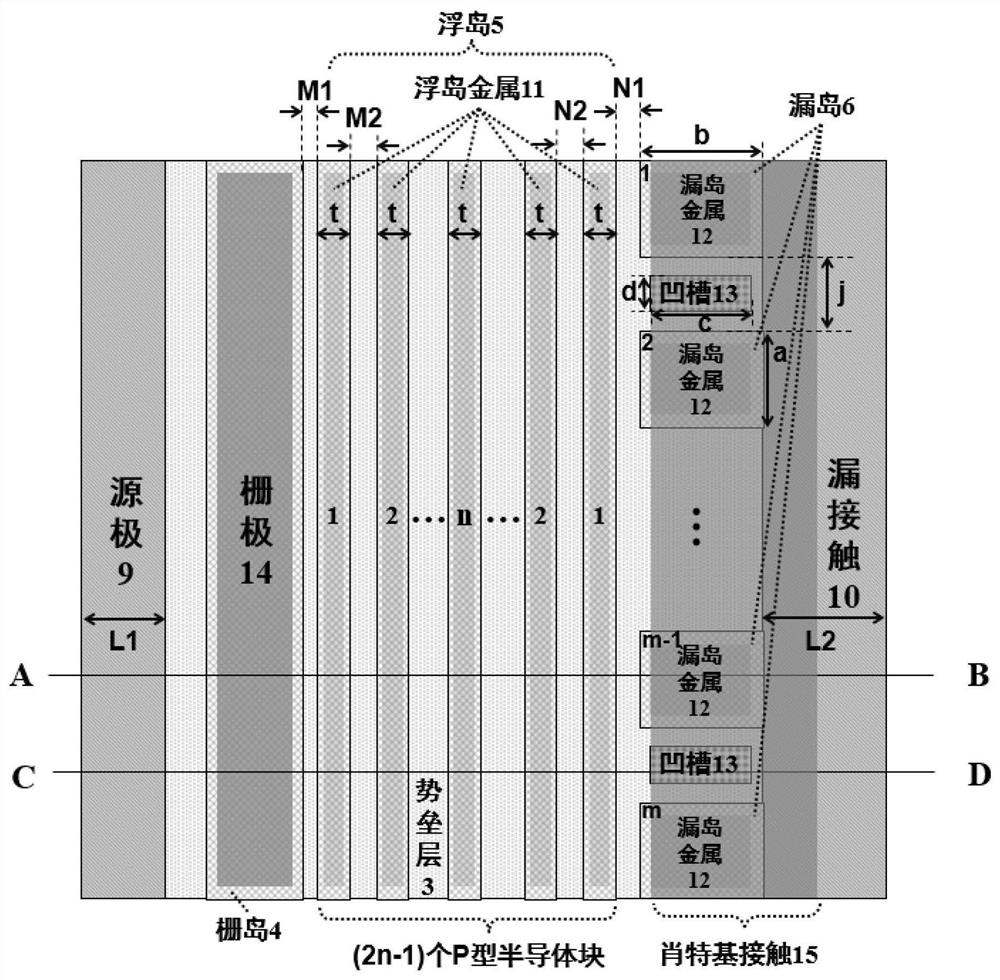

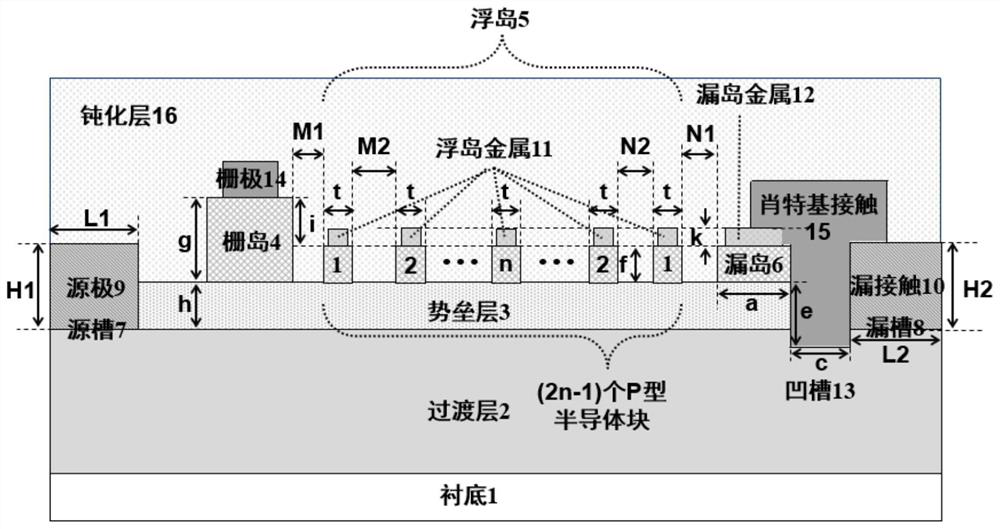

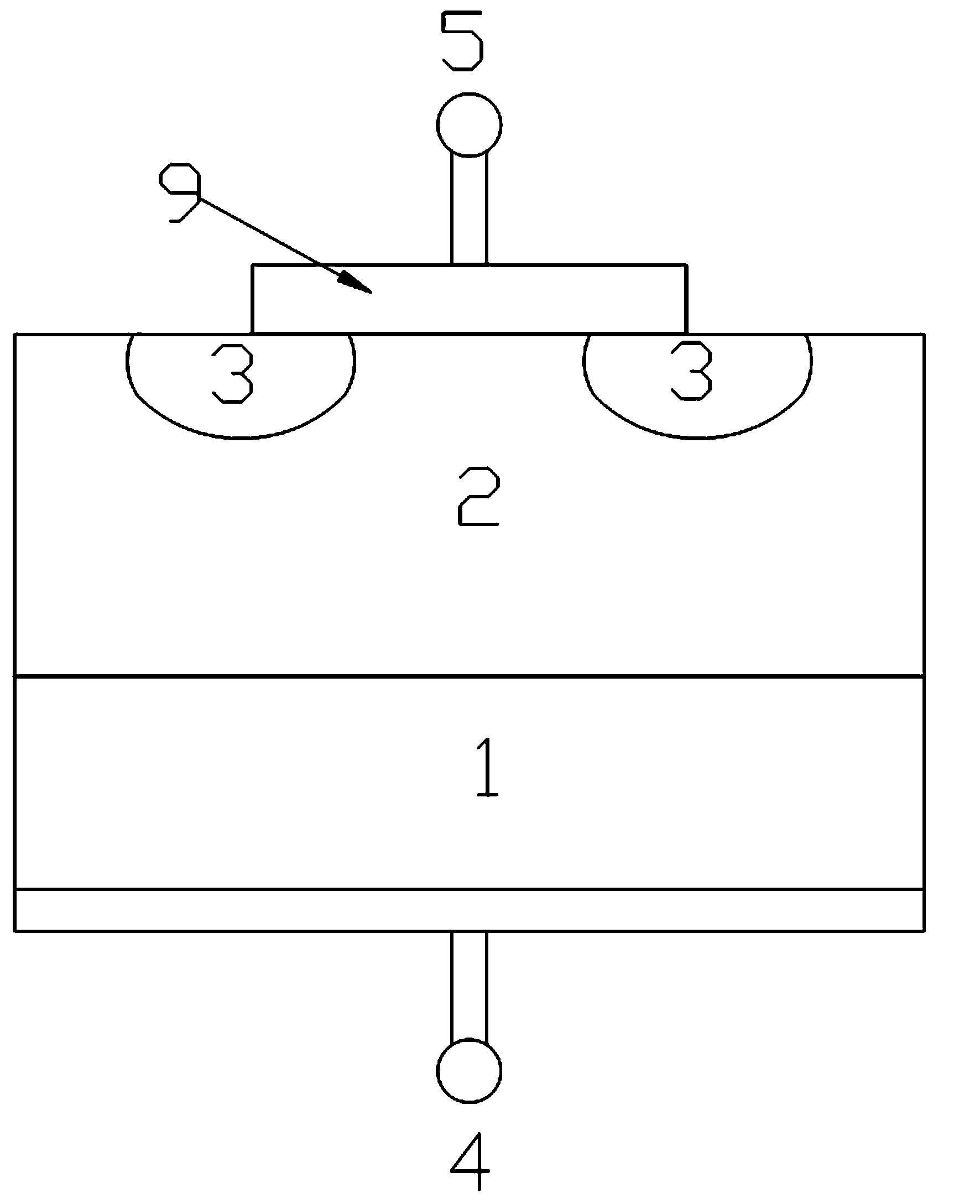

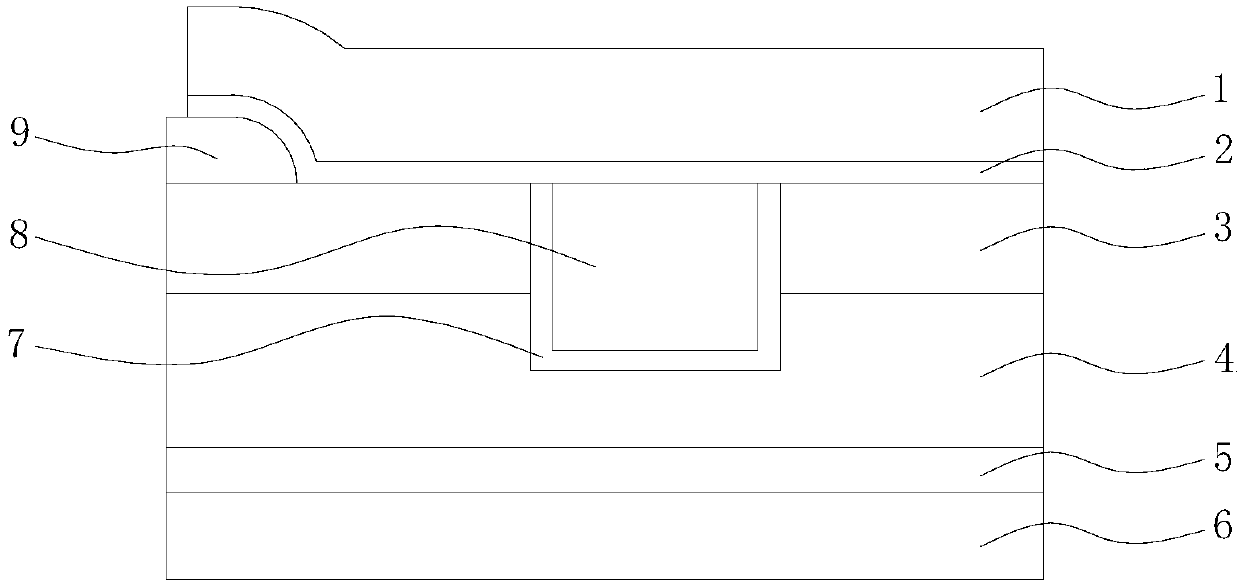

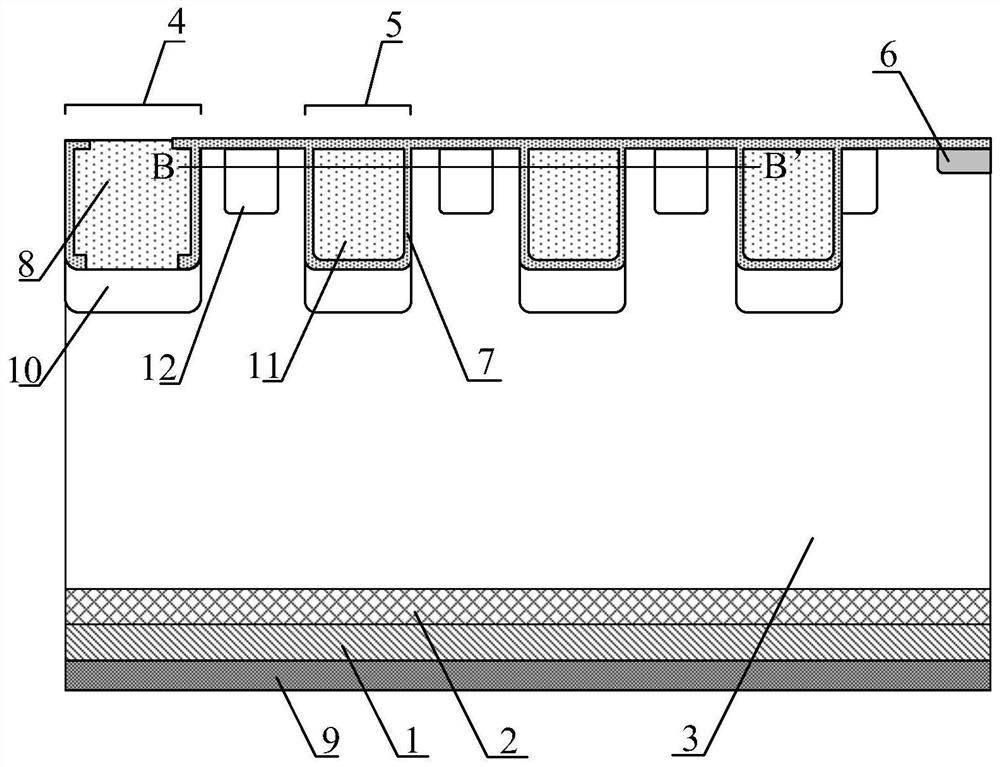

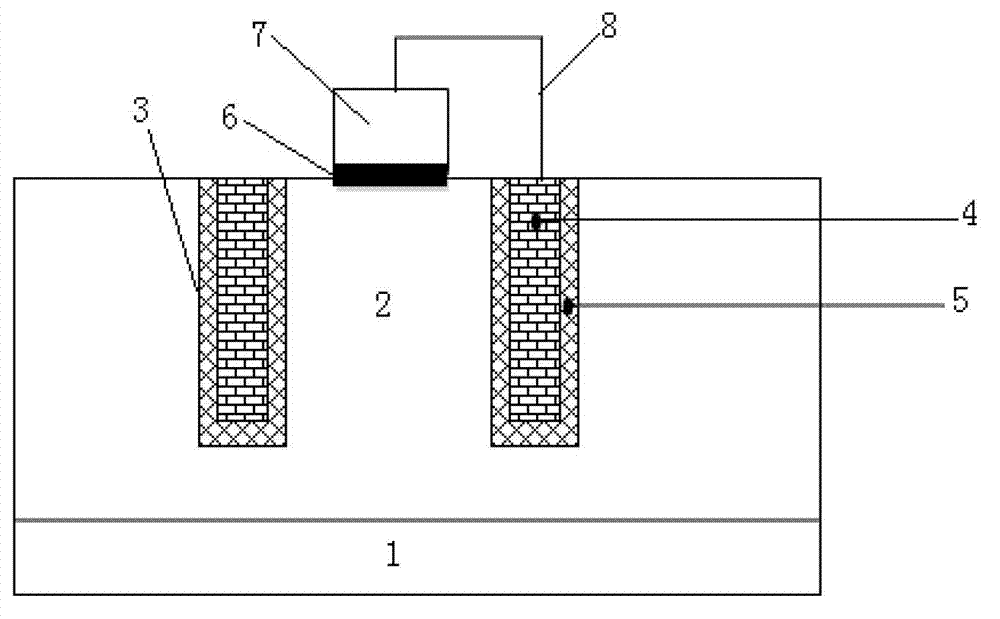

Heterojunction power device and manufacturing method thereof

ActiveCN112768505AInhibition of current collapse effectImprove reverse withstand voltage capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionEngineering

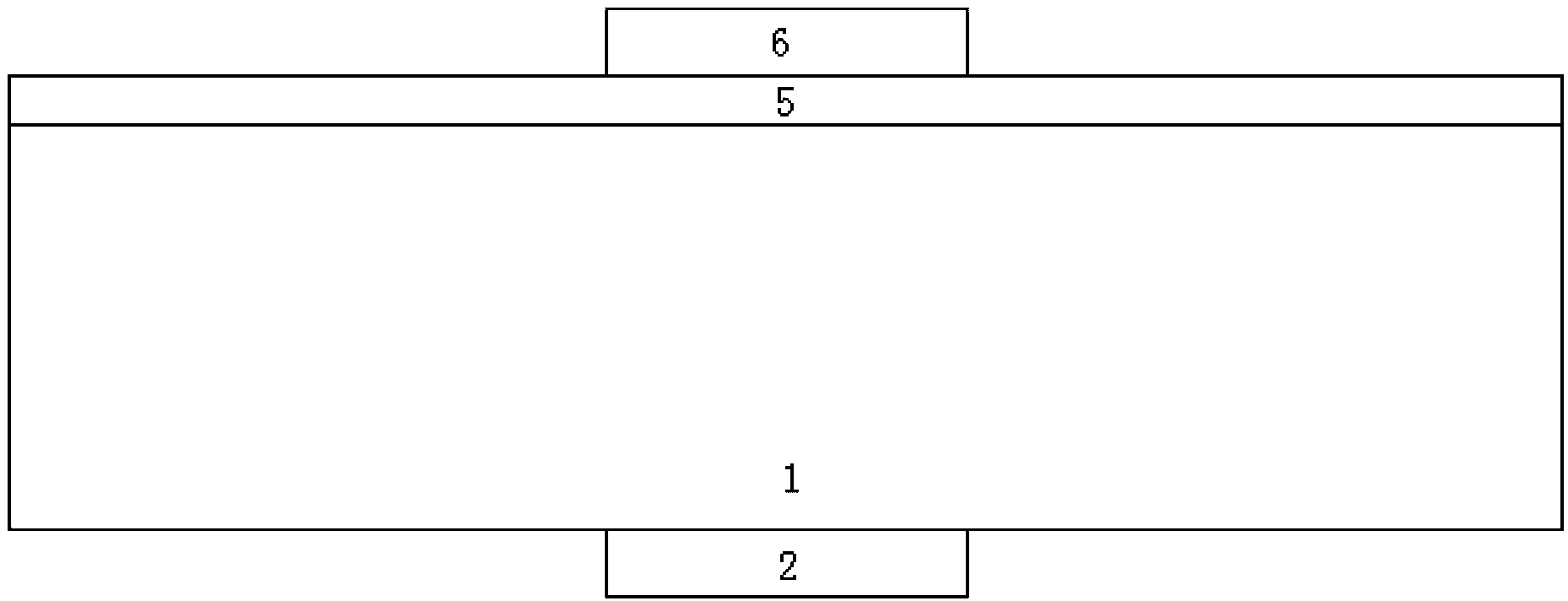

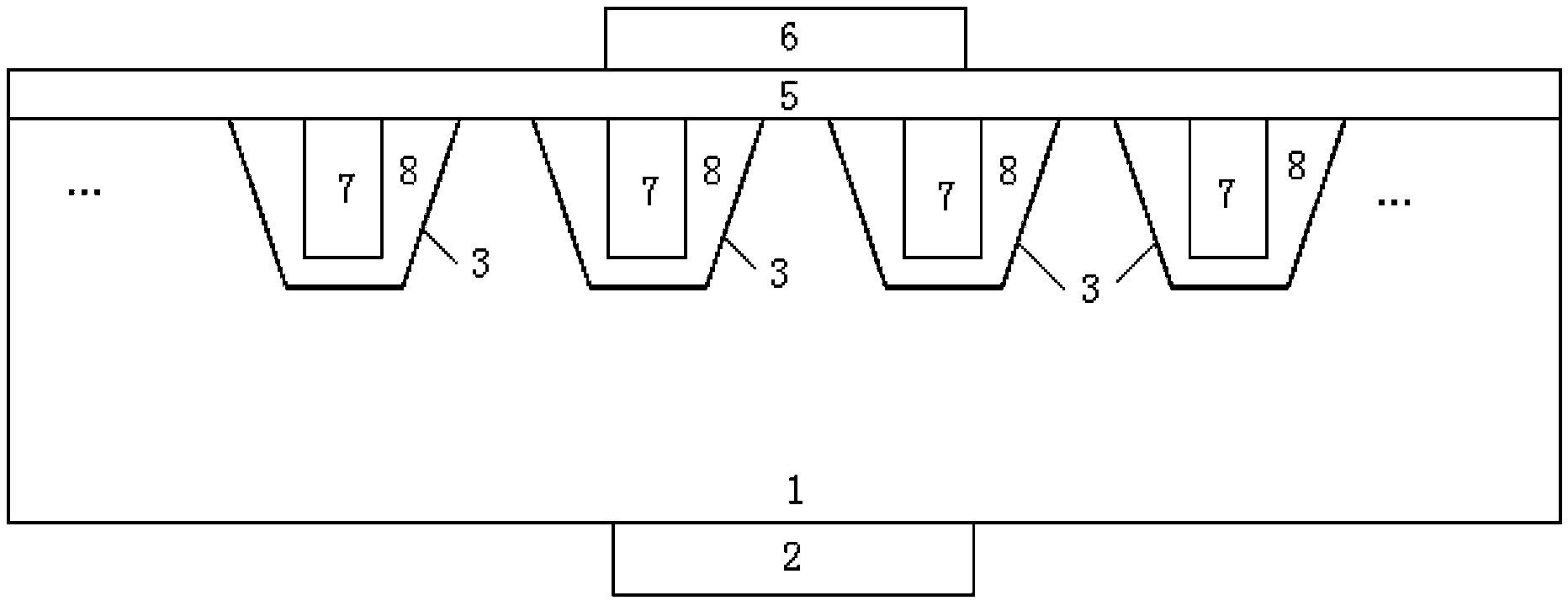

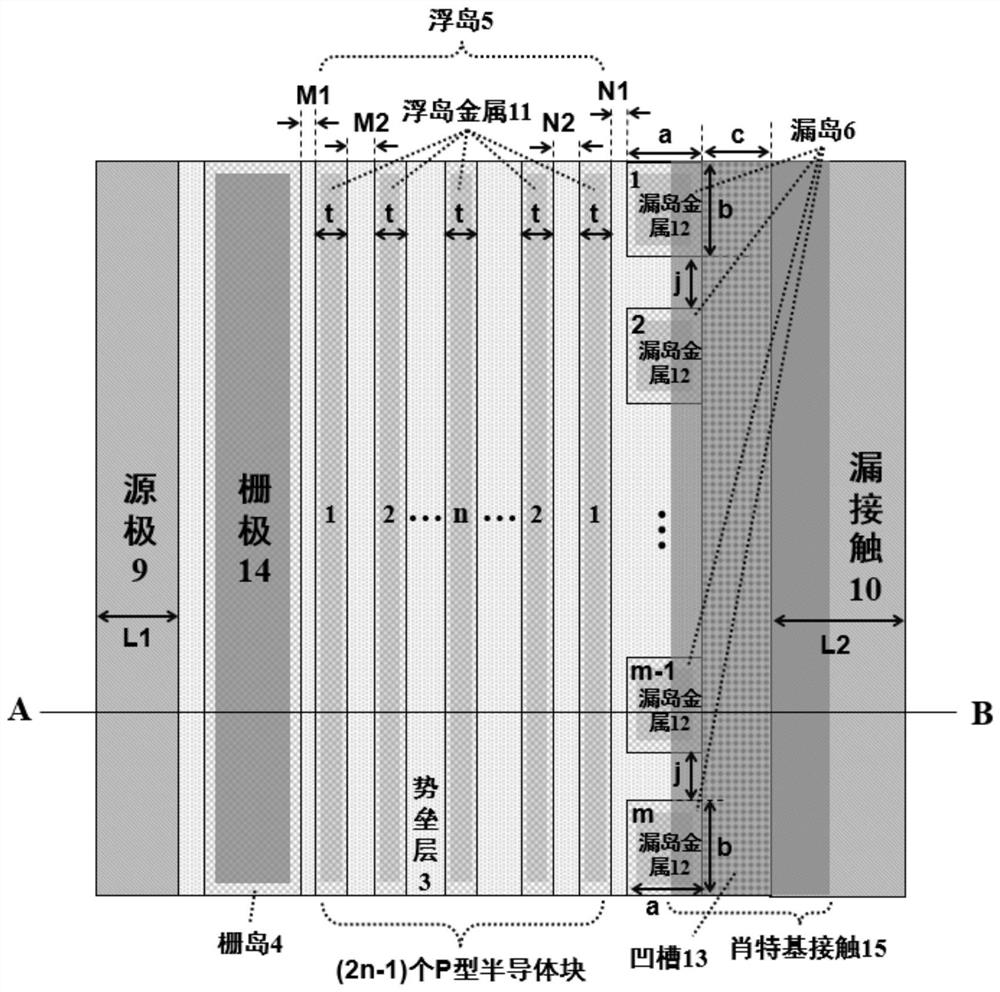

The invention discloses a heterojunction power device and a manufacturing method thereof, and mainly solves the problems of current collapse phenomenon and low breakdown voltage of the existing gallium nitride-based device. The heterojunction power device comprises a substrate (1), a transition layer (2), a barrier layer (3), a source groove (7), a drain groove (8), a source electrode (9), a drain contact (10), floating island metal (11), drain island metal (12), a grid electrode (14) and a passivation layer (16), wherein a gate island (4), a floating island (5) and a drain island (6) are sequentially arranged on the barrier layer from left to right; the floating island (5) is composed of 2n-1 independent P-type semiconductor blocks, the drain island (6) is composed of m P-type semiconductor cuboid blocks, and a groove (13) is formed between every two cuboid blocks; and metal is deposited on the inner portion, the front side, the rear side and the right side of the groove to form Schottky contact (15). Current collapse can be restrained, breakdown voltage is improved, forward blocking and reverse blocking are good, and the heterojunction power device can be used for a basic device of a power electronic system.

Owner:XIDIAN UNIV

JBS (Junction Barrier Schottky) diode

The invention relates to the technical field of semiconductors, in particular to a JBS (Junction Barrier Schottky)-structured diode. The JBS diode comprises a first conductive type substrate, a first conductive type semiconductor layer, an anode metal layer, an insulating layer, a terminal protection region and a second conductive type semiconductor region, wherein multiple grooves are formed in the upper surface layer of the first conductive type semiconductor layer at certain intervals; the terminal protection region and the second conductive type semiconductor region are formed below the grooves; insulated side walls are formed on side walls of the grooves; the grooves are filled with conductive materials. According to the JBS diode, the improvement function of a PN junction of the JBS diode on voltage withstanding performance of the diode is effectively improved.

Owner:南通旺峰电子科技有限公司

Schottky clamping diode with groove structure and terminal structure

InactiveCN103855226AEase withstand voltageImprove reverse withstand voltage capabilitySemiconductor devicesEngineeringP type doping

The invention discloses a Schottky clamping diode with a groove structure. The diode comprises an N-type epitaxial layer serving as the negative electrode of the Schottky clamping diode with the groove structure, multiple grooves formed in the N-type epitaxial layer, P-type doping areas formed on the bottom of each groove, and a metal layer formed at the upper end of the N-type epitaxial layer and at the upper end of a groove area, wherein an oxidation layer is formed in each groove, polycrystalline silicon is arranged above each oxidation layer to enable the corresponding groove to be filled up, the multiple grooves and the oxidation layers and polycrystalline silicon inside form the groove area, the bottom of each groove is wrapped in the corresponding P-type doping area, the P-type doping areas are not mutually connected, and the N-type epitaxial layer and the groove area are connected through the metal layer to serve as the positive electrode of the Schottky clamping diode with the groove structure. The invention further discloses a terminal structure matched with the Schottky clamping diode with the groove structure. According to the Schottky clamping diode with the groove structure and the terminal structure, the pressure resistance of the bottom of each groove can be improved, so that reverse pressure resistance of products is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Power diode device and preparation method thereof

ActiveCN102779858BInhibit injectionImprove reverse withstand voltage capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesPower diodeEngineering

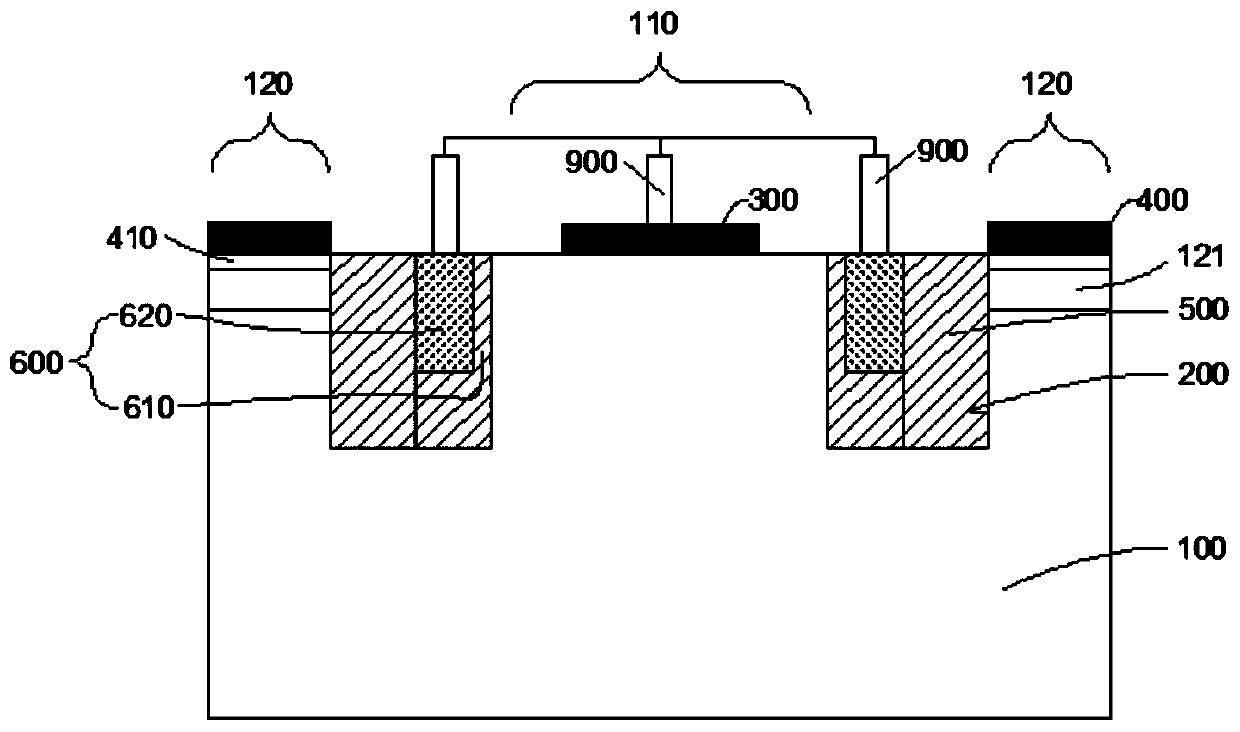

The invention discloses a power diode device, which comprises a stacked substrate, a buffer layer, an epitaxial layer, an ALN layer, a field limiting ring, an annular field plate, and a metal layer forming a Schottky junction. The epitaxial layer and the metal layer form a Schottky junction The cathode is electrically connected, and the metal layer is connected to the anode. A plurality of annular concave-convex portions are formed on the annular field plate, the highest point of the convex portion of the annular field plate gradually rises from the inner side to the outer side of the power component, and the lowest point of the annular field plate gradually rises from the inner side to the outer side of the power component. Elevated, the projection of the annular field plate closest to the center of the power diode device to the epitaxial layer is located in the field limiting ring closest to the center, and the metal layer covers the recess of any annular field plate.

Owner:JIANGSU CORENERGY SEMICON CO LTD

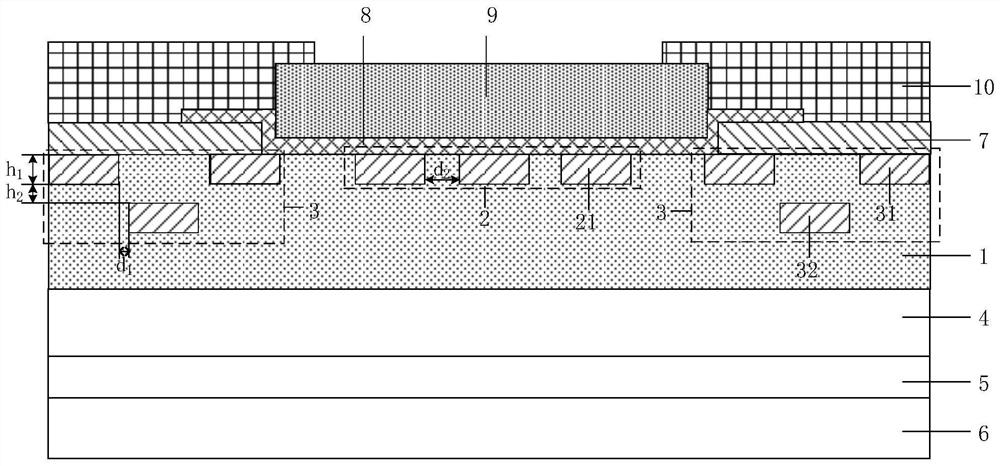

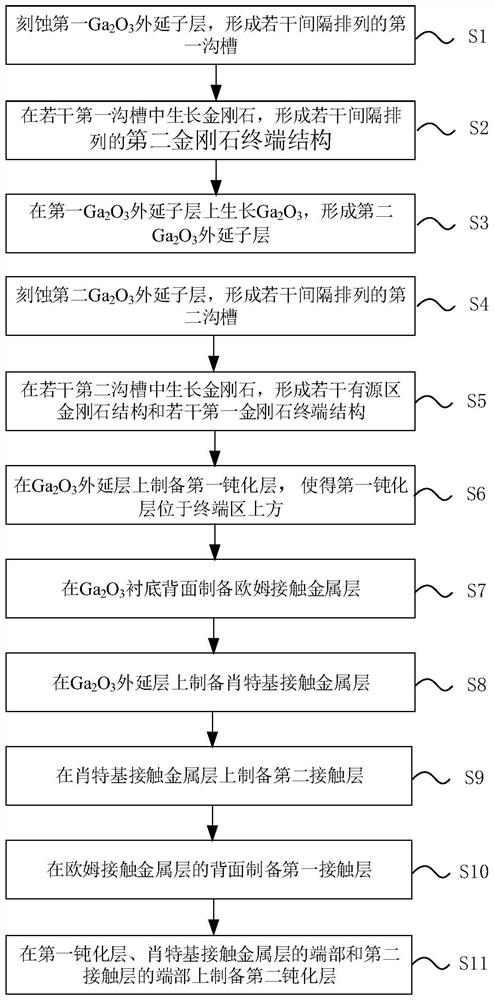

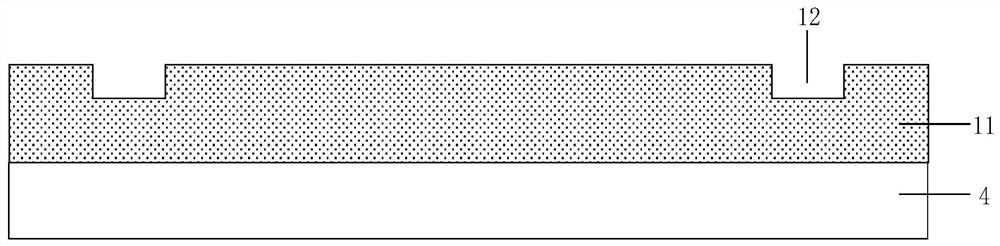

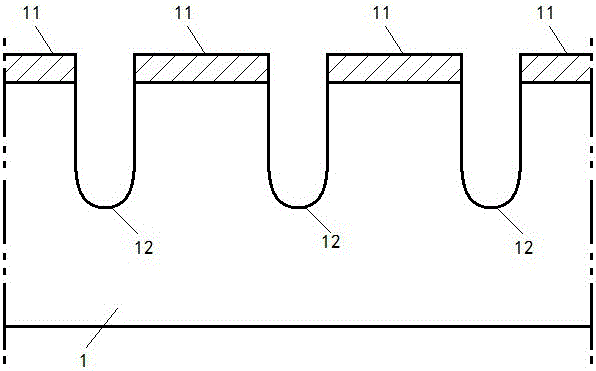

Ga2O3 Schottky diode based on diamond terminal structure and manufacturing method

ActiveCN113555446AHigh breakdown field strengthReduce leakage currentFinal product manufactureSemiconductor/solid-state device manufacturingPhysical chemistryEngineering

Owner:ZHEJIANG XINKE SEMICON CO LTD

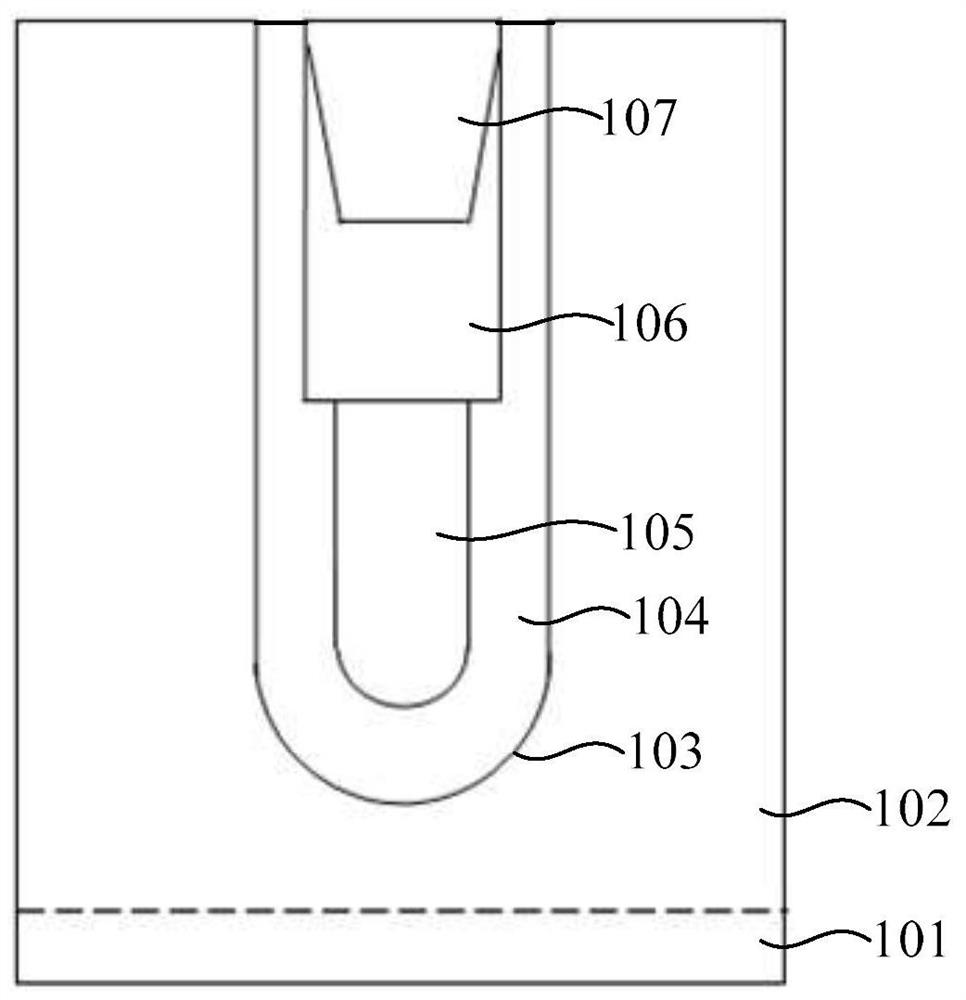

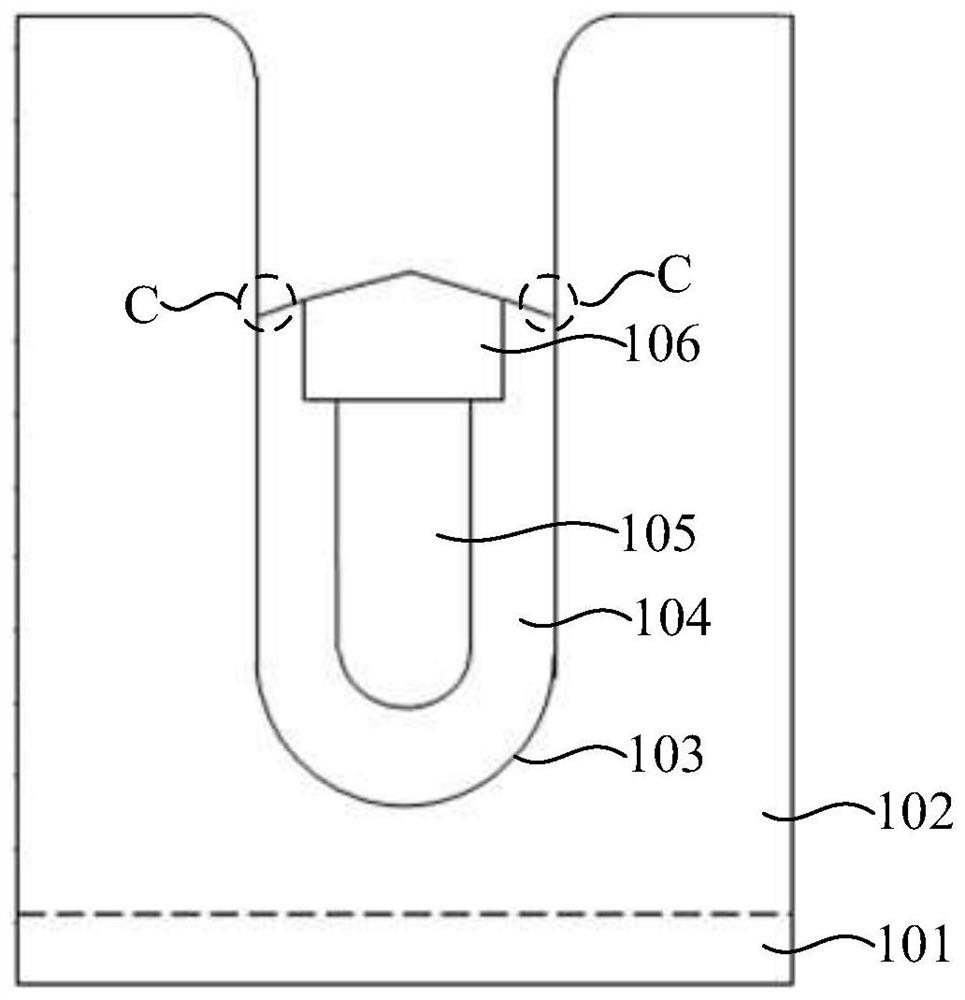

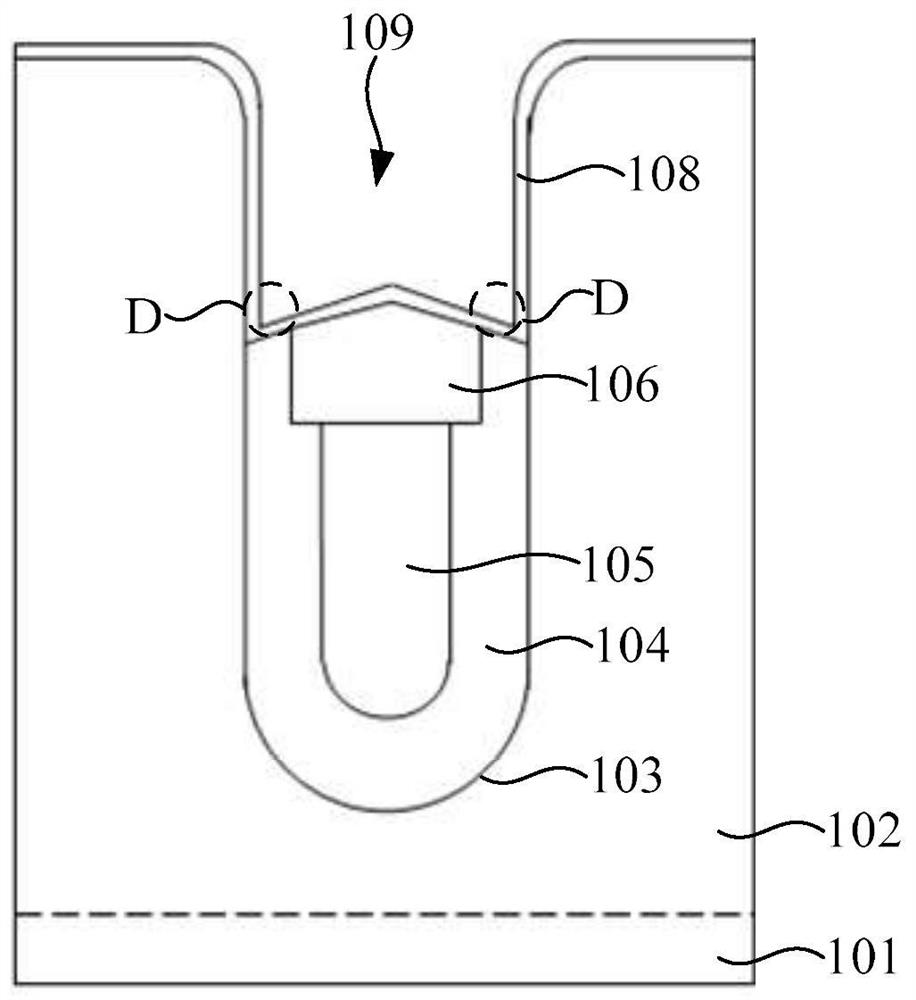

Groove-type MOS Schottky rectifier with deep grooves and T-POLY structure and manufacturing method thereof

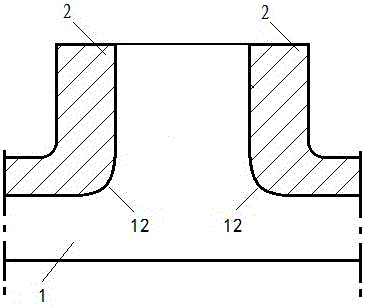

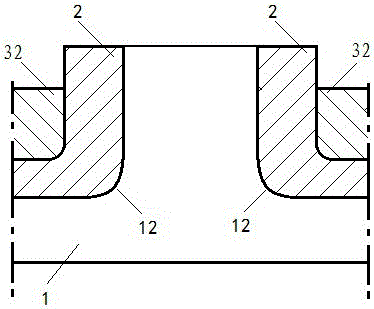

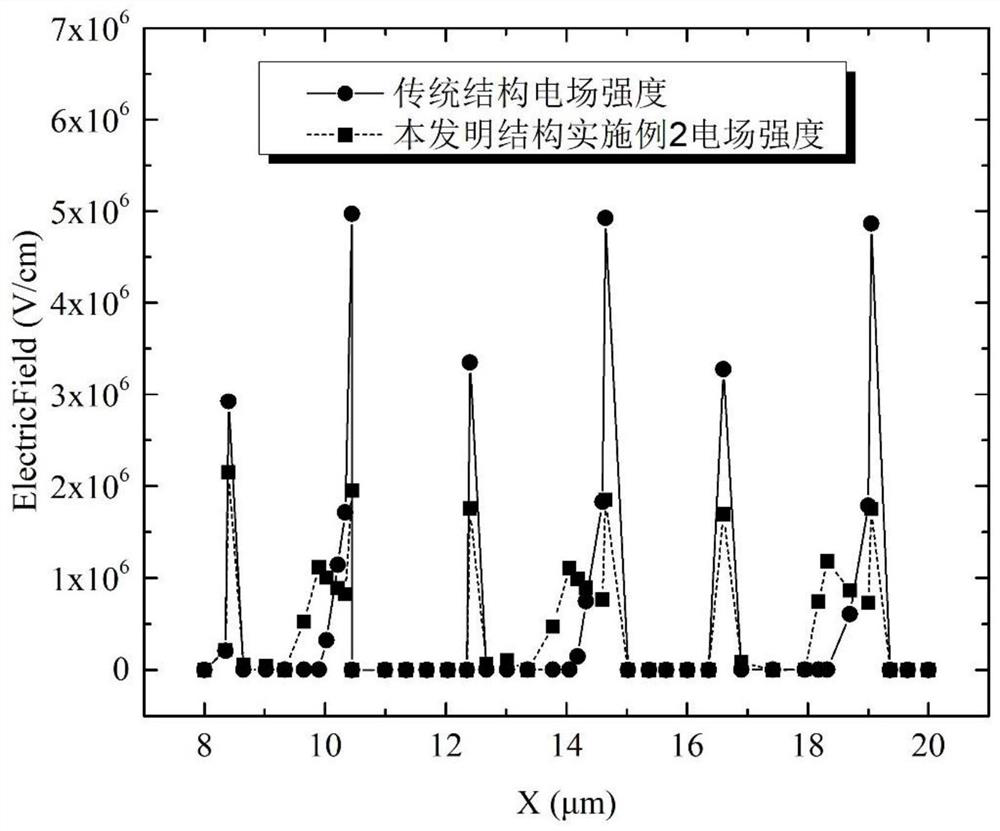

InactiveCN106328690ALower forward voltage dropReduce electric field strengthSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringReverse bias

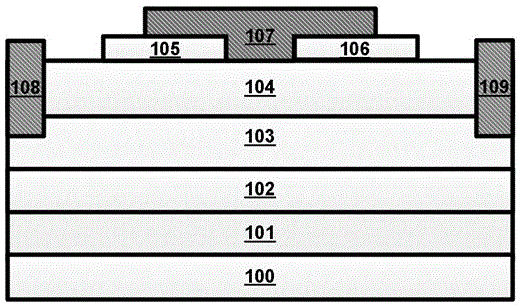

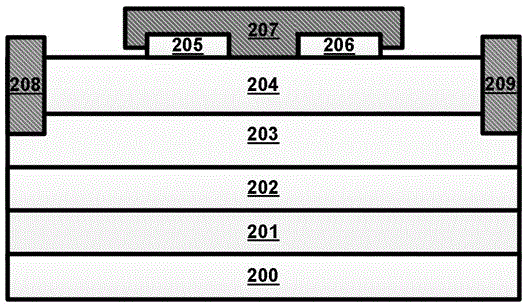

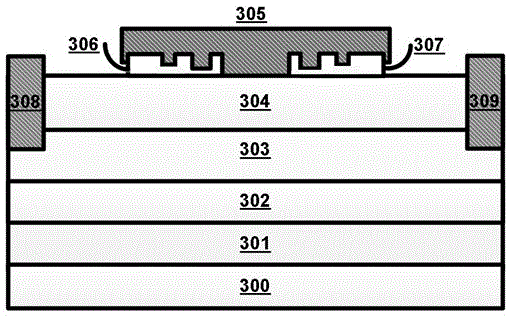

The invention relates to a groove-type MOS Schottky rectifier with deep grooves and a T-POLY structure and a manufacturing method thereof. The groove-type MOS Schottky rectifier comprises an epitaxial layer, wherein the epitaxial layer is etched at intervals along the transverse direction to form a plurality of longitudinal grooves, the grooves extend downwards from the upper surface of the epitaxial layer, the thickness of the epitaxial layer is D, D is greater than 0, and the depth of the grooves ranges from 1 / 2[D(1-20%)] to 1 / 2[D(1+20%)]; the bottom part and two inner side walls of each groove are provided with an insulating medium, and the insulating medium at the two inner side walls is of a stepped shape; polycrystal is deposited in each groove, the polycrystal is of a T-shaped structure and composed of a horizontal shoulder portion and a longitudinal extending portion, the upper surface of the horizontal shoulder portion is flush with the upper surface of the epitaxial layer, and the lower surface of the horizontal shoulder portion extends to the upper surface of the longitudinal extending portion; and the thickness of the horizontal shoulder portion is one third to half of the depth of the corresponding groove. Under high reverse bias, the groove-type MOS Schottky rectifier provided by the invention increases the potential longitudinal landing space, improves electric field distribution near corners of the bottom part of each groove and inside an oxide, and reduces the electric field intensity near barrier metal.

Owner:厦门吉顺芯微电子有限公司 +2

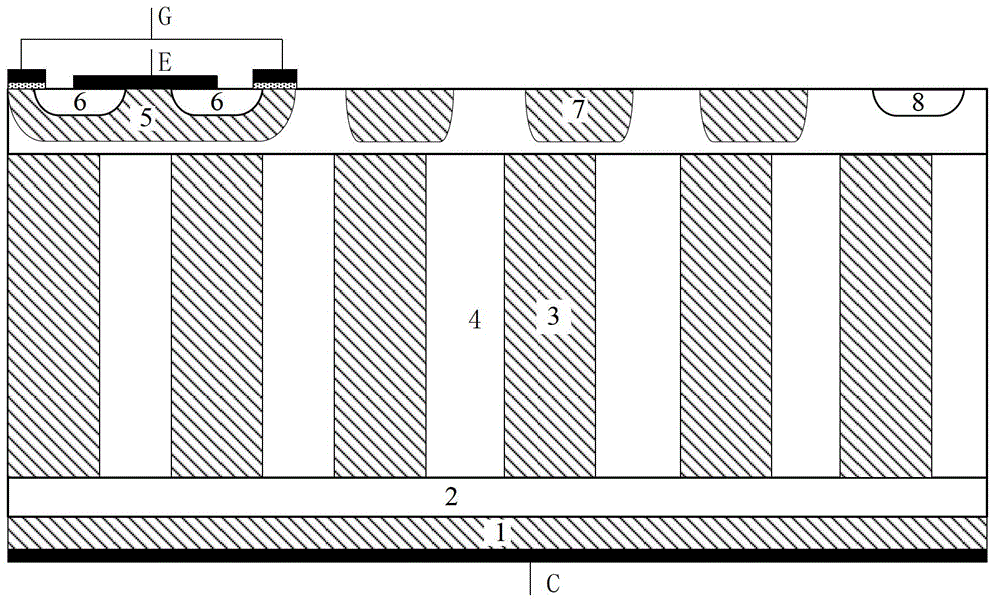

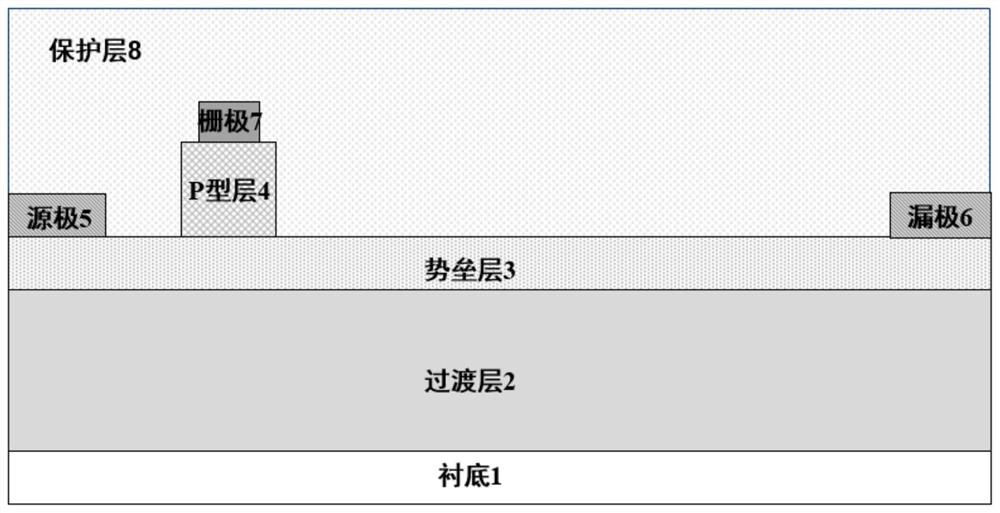

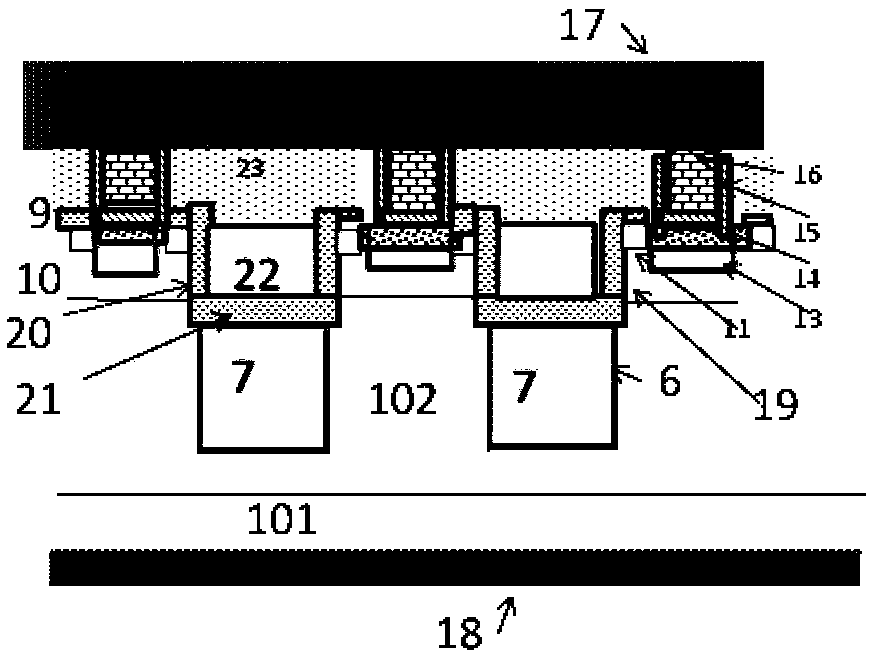

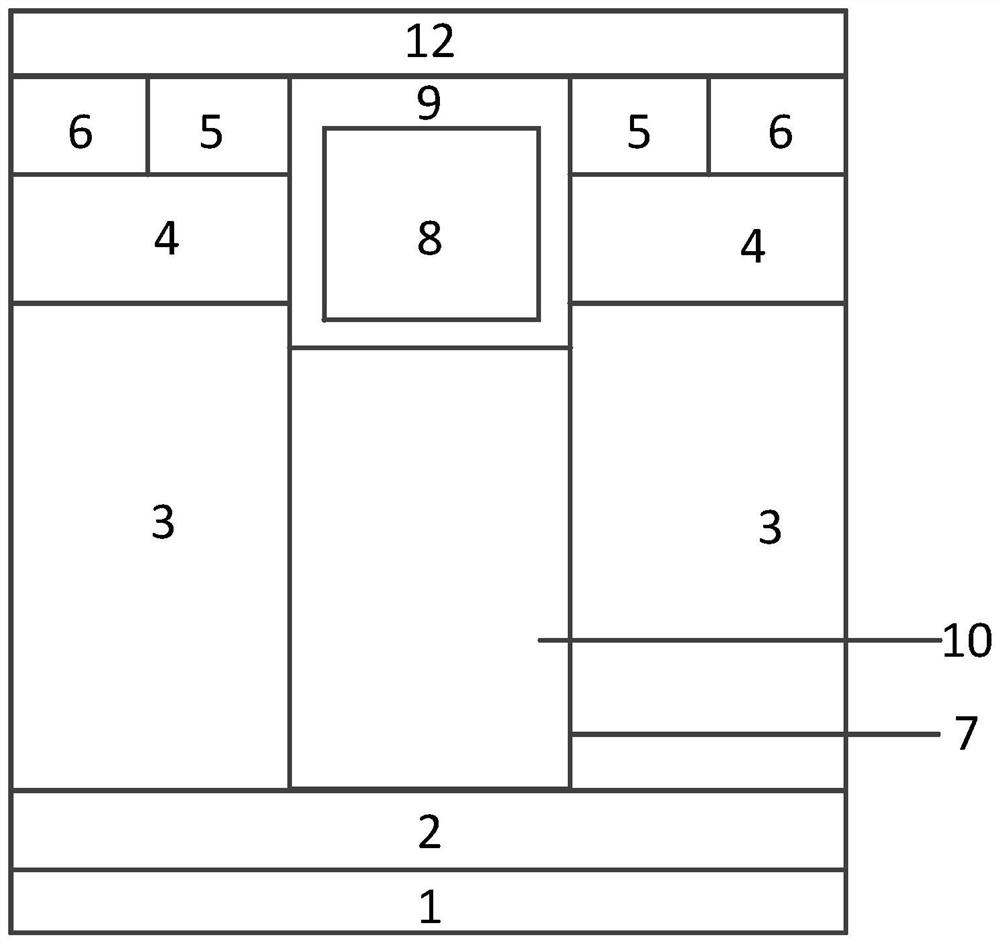

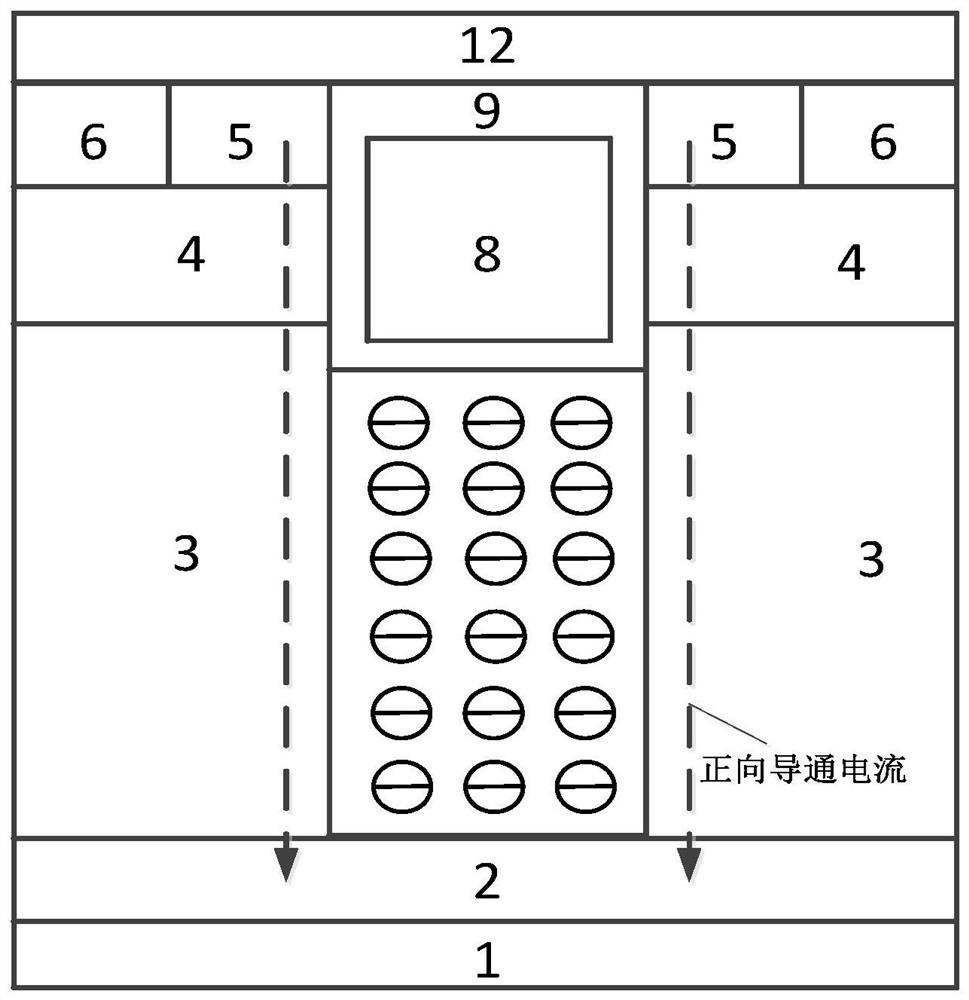

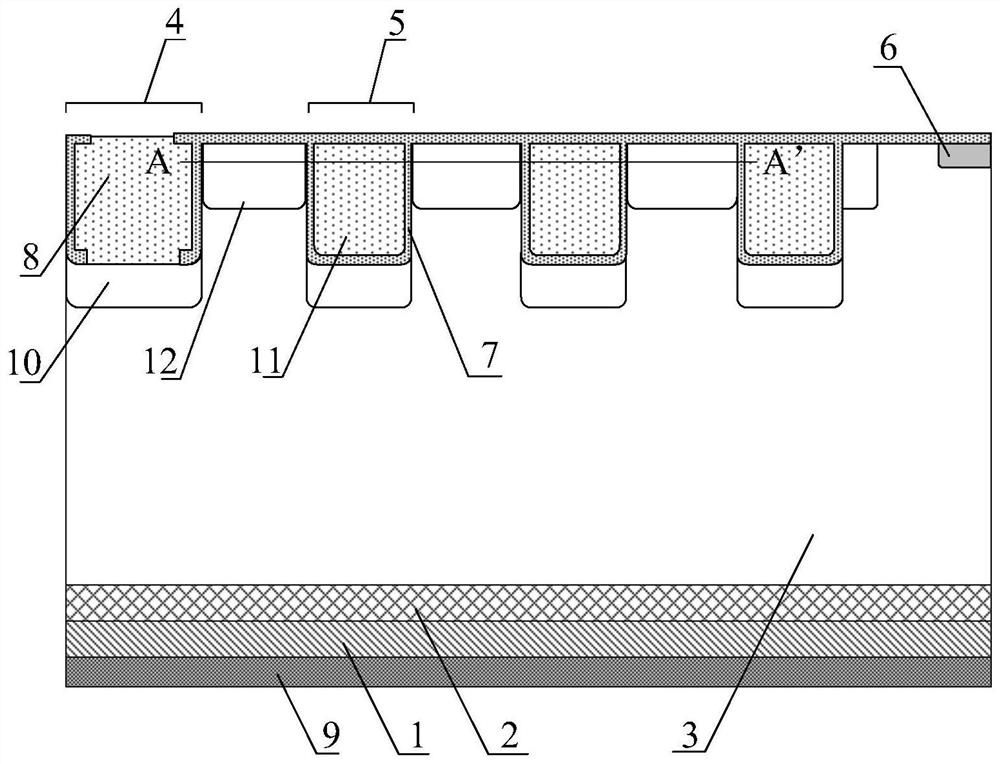

GaN-based high-electron-mobility transistor and manufacturing method thereof

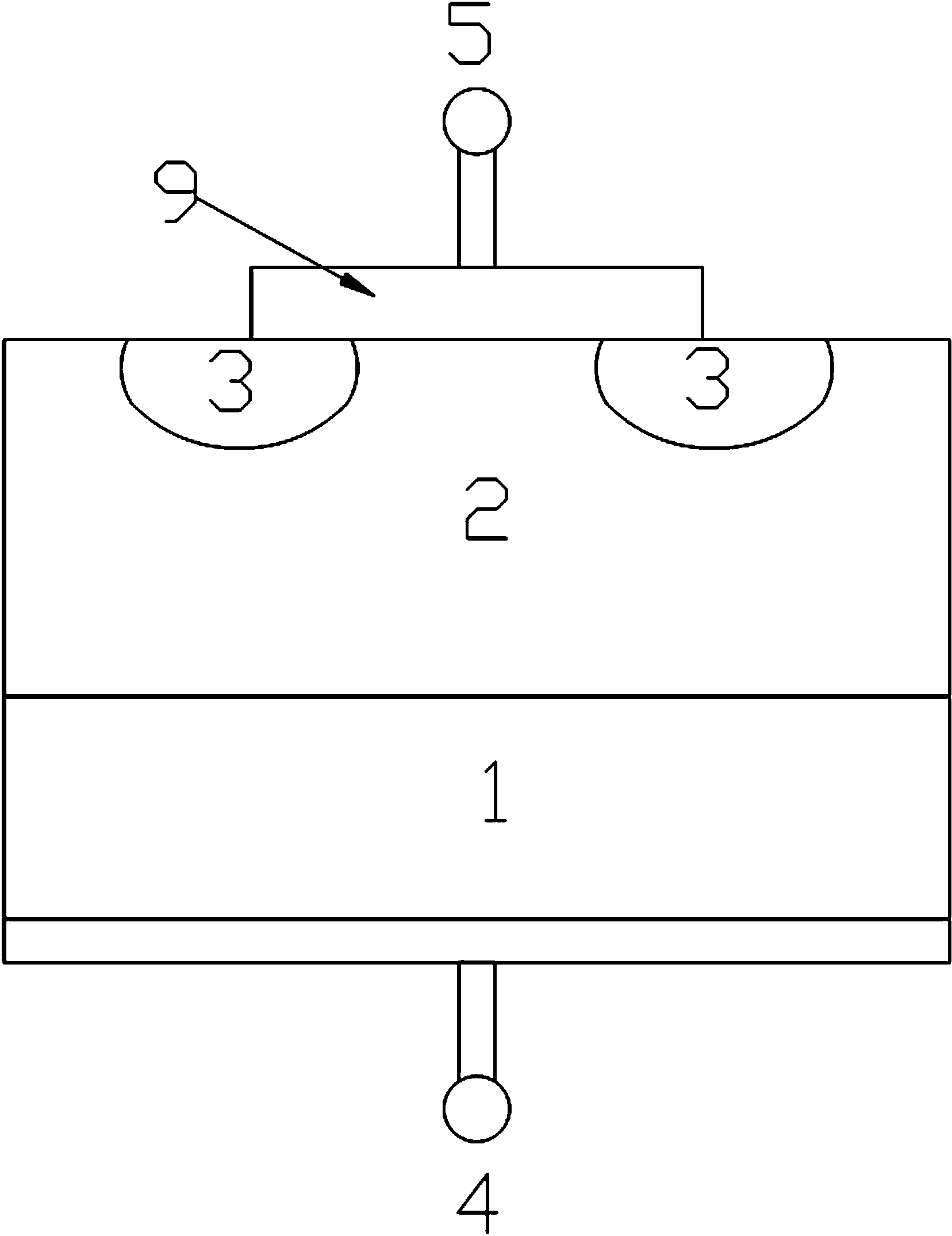

InactiveCN112736130AInhibition of current collapse effectImprove reverse withstand voltage capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideElectron system

The invention discloses a GaN-based high-electron-mobility transistor and a manufacturing method thereof, and mainly solves the problems of current collapse of an existing GaN-based device and complex process when high breakdown voltage is realized. The transistor comprises a substrate (1), a transition layer (2) and a barrier layer (3), a source groove (7) is formed in the left edge of the barrier layer, a source (9) is deposited at the upper part of the barrier layer, a drain groove (8) is formed in the right edge of the barrier layer, a drain contact (10) is deposited at the upper part of the barrier layer, a gate island (4) is arranged at the upper part of the barrier layer, and a gate (14) is deposited at the upper part; a floating island (5) and a drain island (6) are arranged on the barrier layer on the right side of the gate island, floating island metal (11) is deposited on the upper portion of the floating island, drain island metal (12) is deposited on the upper portion of the drain island, a groove (13) is arranged between the floating island and the drain contact, and Schottky contacts (15) are deposited inside and on the upper portion of the groove. The transistor is good in forward blocking and reverse blocking, strong in inhibition of current collapse, and can be used as a basic device of a high-reliability power electronic system.

Owner:XIDIAN UNIV

Shielded gate trench mosfet device and manufacturing method thereof

ActiveCN105702739BIncrease the doping concentrationLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetReverse bias

Owner:SHENZHEN SANRISE TECH CO LTD

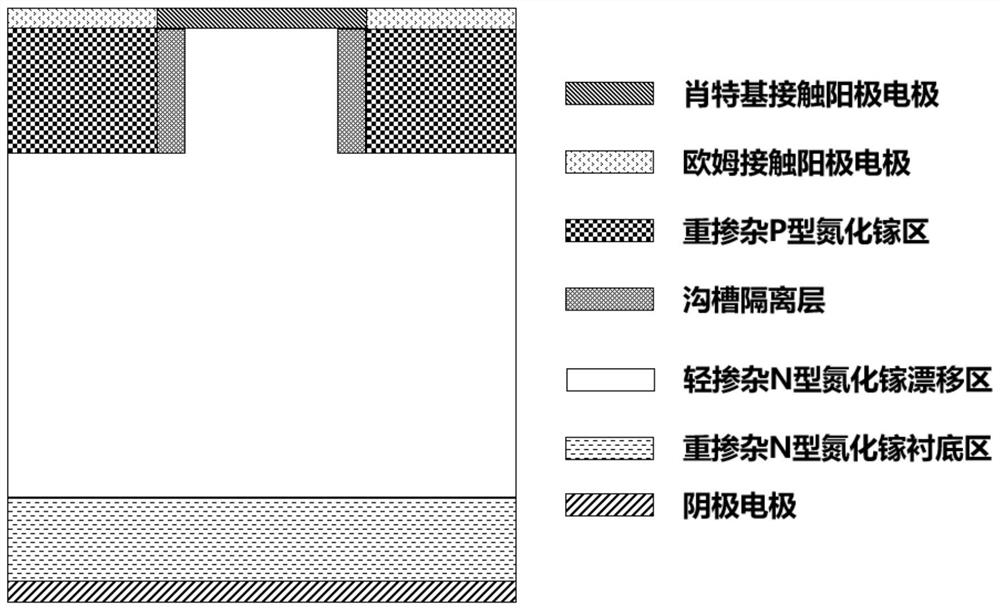

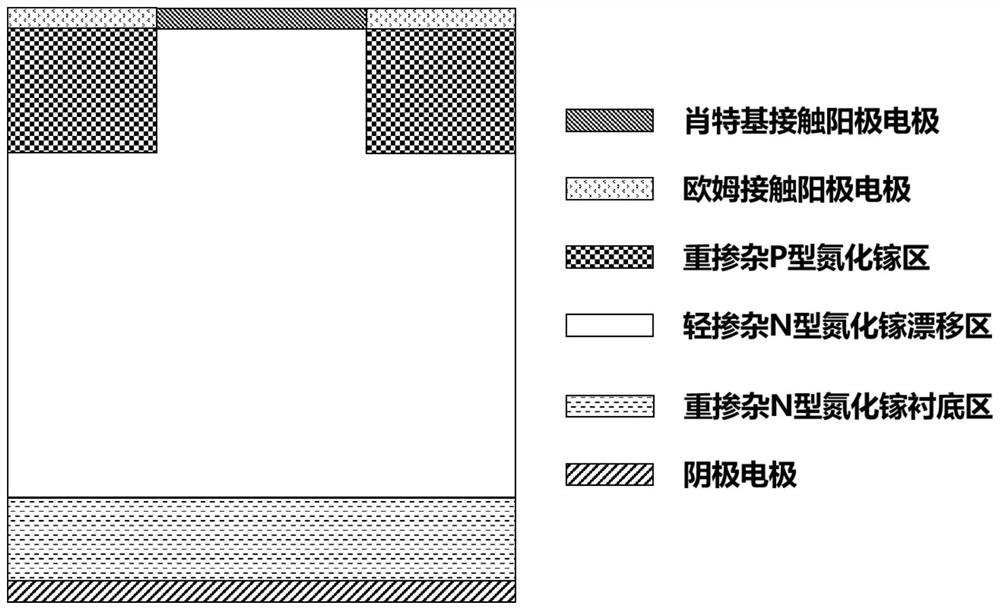

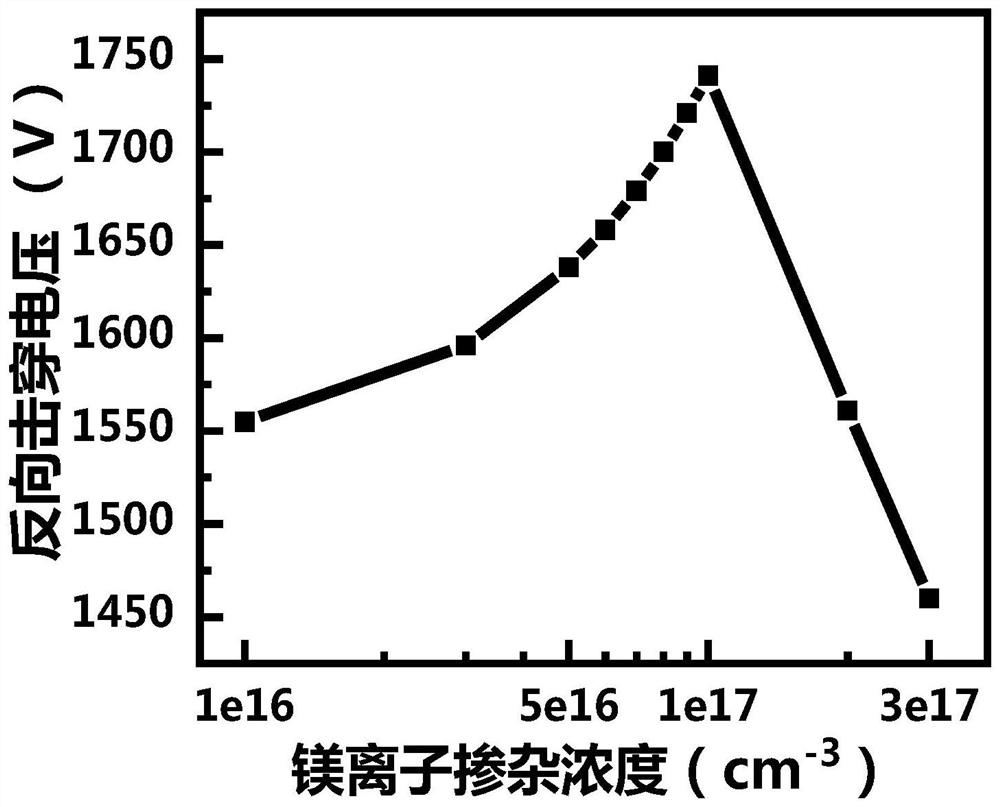

Vertical III-nitride power semiconductor device structure with trench isolation layer and preparation method of vertical III-nitride power semiconductor device structure

PendingCN114220871AGood reversing performanceHigh critical breakdown electric field strengthSemiconductor/solid-state device manufacturingDiodePower semiconductor deviceEngineering

The invention provides a vertical III-nitride power semiconductor device structure with a trench isolation layer, which sequentially comprises a cathode electrode, a heavily doped N-type nitride substrate region, a lightly doped N-type nitride drift region, a heavily doped P-type nitride region and an anode electrode from bottom to top, and an isolating layer is arranged between the vertical contact surfaces of the heavily doped P-type nitride region and the lightly doped N-type nitride drift region. The arrangement of the trench isolation layer structure optimizes the electric field distribution in the device, effectively improves the reverse performance of the device, and guarantees the excellent forward characteristic.

Owner:SHANDONG UNIV

Efficient energy-saving Schottky diode

InactiveCN101728350BImprove protectionReduce leakage currentSemiconductor/solid-state device detailsSolid-state devicesEnergy sourceCorrosion

The invention provides a Schottky diode. By adopting an electrode layer protection ring technique of a Schottky diode chip, a reverse insulating ability is improved. A reverse leakage current of the Schottky diode is less than or equal to 15 muA and a reverse voltage-during ability is more than or equal to 50 V. The manufacturing process and flow are simplified, the raw materials and energy sources are saved, the manufacturing efficiency is improved and the manufacturing cost is lowered. Corrosion chemicals which will pollute environment are forbidden to use so the environment is protected. A ladder-shaped conical cylinder design of a lead head of the Schottky diode can increase a welding area, as well as decrease a contact area of the Schottky diode chip, reduce the short circuit phenomenon caused by welding and improve the weldability. The Schottky diode chip and the lead head can be effectively and reliably welded, so the extending and bending resistant properties of the Schottky diode are enhanced, the service life thereof is prolonged and the superior product rate is increased.

Owner:陈湘义

Power diode device and preparation method thereof

ActiveCN102790097BInhibit injectionImprove reverse withstand voltage capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesPower diodeEngineering

The present invention discloses a power diode device that includes the substrate, buffer layer, extension layer, circular field board, and the metal layer of the phase stacking settings.There are multiple field limited loops on the top, and there are multiple circular bumps on the ring plate. The highest point of the convex part of the ring field board gradually increases from the inside of the power component.The inner side of the power component gradually increases, and the circular field board that is closest to the center of the power diode device to the outward layer is located in the restricted ring closer to the center.The layer is connected to the cathode, and the metal layer is connected to the anode.

Owner:JIANGSU CORENERGY SEMICON CO LTD

A kind of Schottky diode and its preparation method

ActiveCN102903762BImprove pressure resistanceImprove conduction performanceSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactEngineering

The invention provides a Schottky diode which comprises a substrate layer as well as a series of III-family nitride layers formed above the substrate layer, a metal field plate connected with the anode electrode and at least one P-type doped III-family nitride reinforcement layer which is filled between the metal field plate and a III-family nitride layer at the uppermost layer. Two-dimensional electron gas channels are formed between the adjacent III-family nitride layers by utilizing a heterogeneous structure; the III-family nitride layers and a cathode electrode are in ohmic contact; and the III-family nitride layers and an anode electrode are in Schottky contact. According to the Schottky diode provided by the inventio, the reverse withstand voltage capability and the forward withstand voltage capability are improved at the same time.

Owner:SUZHOU YINGNENG ELECTRONICS TECH

A Schottky diode

ActiveCN106784024BIncrease reverse compression capacityLower forward conduction resistanceSemiconductor devicesInsulation layerSemiconductor materials

The invention relates to a Schottky diode. The Schottky diode comprises a semiconductor material, a groove dividing the semiconductor material into an anode zone and a cathode zone, an anode metal layer contacted with the semiconductor material in the anode zone and a cathode metal layer contacted with the semiconductor material in the cathode zone, wherein the groove is annular, the part, close to the cathode zone, in the groove is filled with an insulating medium, one side, close to the anode zone, in the groove forms a gate structure, the gate structure consists of a first gate insulation layer formed by the inner wall of the groove and conductive polycrystalline silicon arranged in the groove, and the conductive polycrystalline silicon is electrically connected with the anode metal layer. The Schottky diode effectively solves the problems of lower reverse bias and larger reverse leakage current.

Owner:SHENZHEN HUAKE SEMICON

A deep trench dmos device

ActiveCN107316905BLower on-resistanceImprove reverse withstand voltage capabilitySemiconductor devicesPower semiconductor deviceGate dielectric

The invention provides a deep groove DMOS device and belongs to the technical field of power semiconductor devices. The present invention includes a metallized source electrode, a drift region, a substrate, and a metallized drain electrode arranged from top to bottom; wherein the drift region has deep grooves and body regions located on both sides or the periphery thereof, and the deep grooves include gate electrodes, The gate dielectric layer and the strained insulating dielectric region, the lower surface of the strained insulating dielectric region is in contact with the upper surface of the substrate. In the present invention, by introducing a strained insulating dielectric region with compressive or tensile properties into the deep groove structure, stress is applied to the semiconductor material where the multi-subcurrent flow path is located, thereby increasing the mobility of carriers and reducing the on-resistance; At the same time, the strained insulating dielectric region is doped with charges to form a lateral electric field with the drift region, assisting in depleting the drift region, and achieving the purpose of improving the reverse withstand voltage of the device.

Owner:HANGZHOU SILICON-MAGIC SEMICON TECH CO LTD

Rectifier grain, production method thereof and suction cup mould

InactiveCN101819992BAvoid breakingReduce harmSemiconductor/solid-state device manufacturingSemiconductor devicesResistSand blasting

The invention discloses a rectifier grain, a production method thereof and a suction cup mould. The grain is in the shape of a regular hexagon. The production method for the grain comprises the following steps of: coating a photo-resist; adhering an MASK film; exposing; making a GPP film; arranging a glass sheet; waxing a chip; arranging a baffle; adhering the baffle; accurately aligning; cuttingby sand blasting; and separating the grain. The suction cup mould comprises an upper die and a lower die, wherein the upper and lower dies are detachably connected with each other so as to form a cavity which can be vacuumized; the upper surface of the upper die is provided with a notch; the bottom surface of the notch is provided with a plurality of regularly hexagonal counter bores which are cellular and arranged closely; and each counter bore is communicated with the cavity. By using the structure and the method, the rectifier grain, the production method and the suction cup mould have theadvantages that: firstly, the area utilization of the grain is improved, the product is durable, and the impact resistance is enhanced; secondly, the point discharge effect is reduced and the backward voltage resistance of the product is enhanced; and thirdly, the edge of a glass trench of the grain which is cut by the sand blasting method is tidy and the electrical performance is better protected.

Owner:GOOD ELECTRONICS WUHU

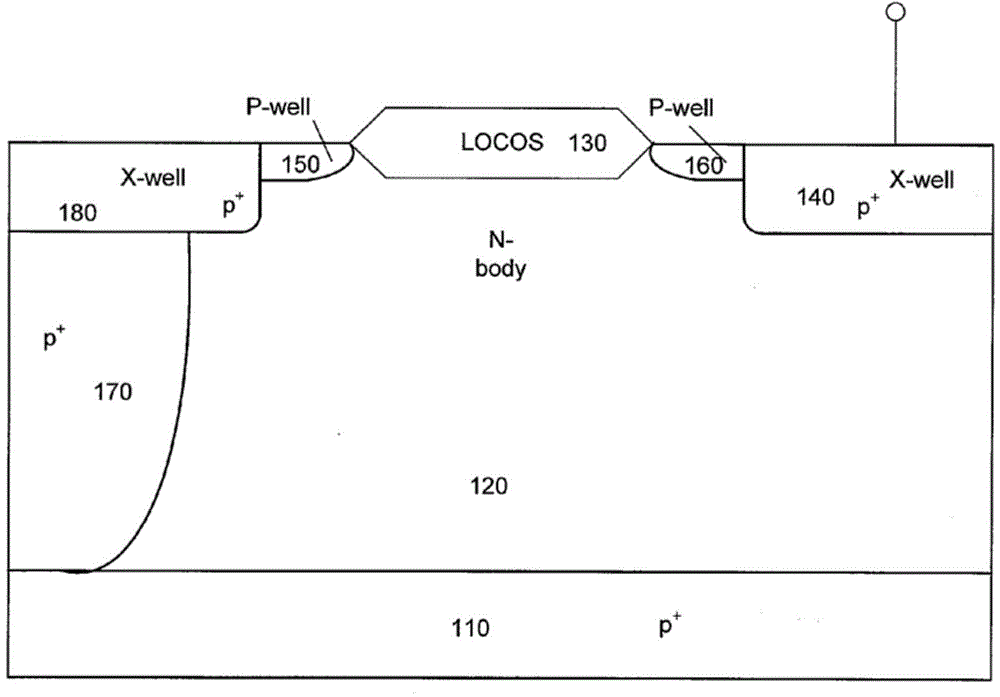

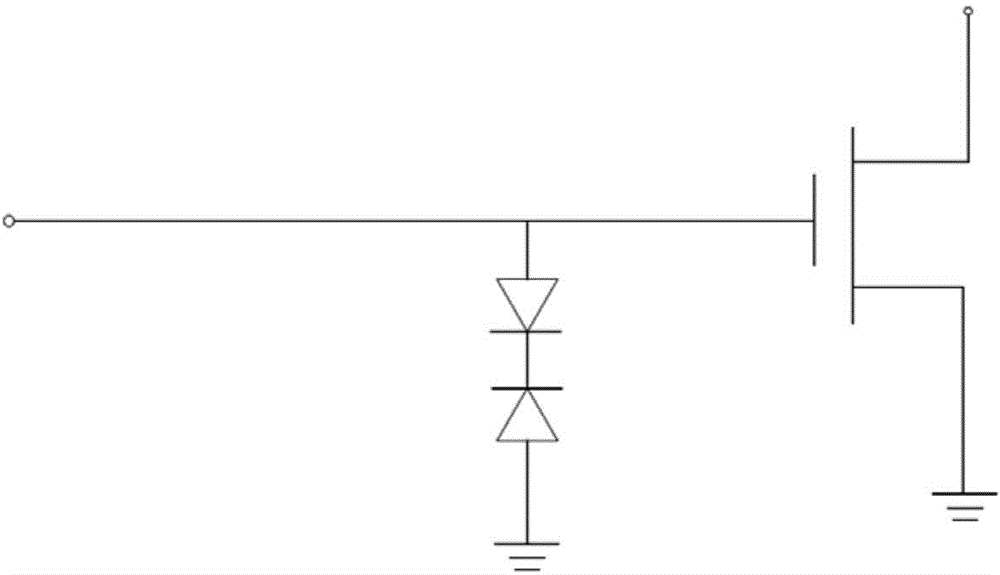

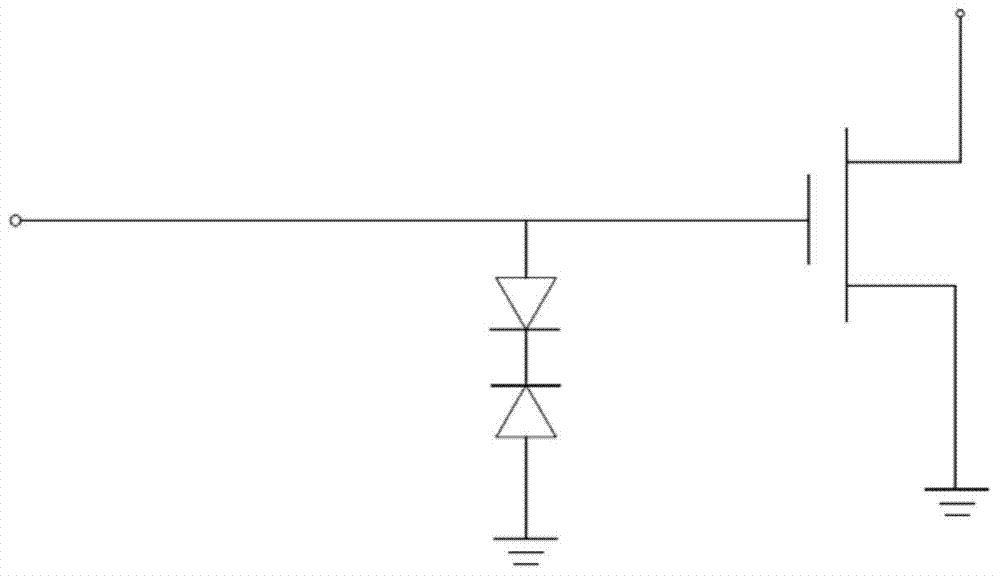

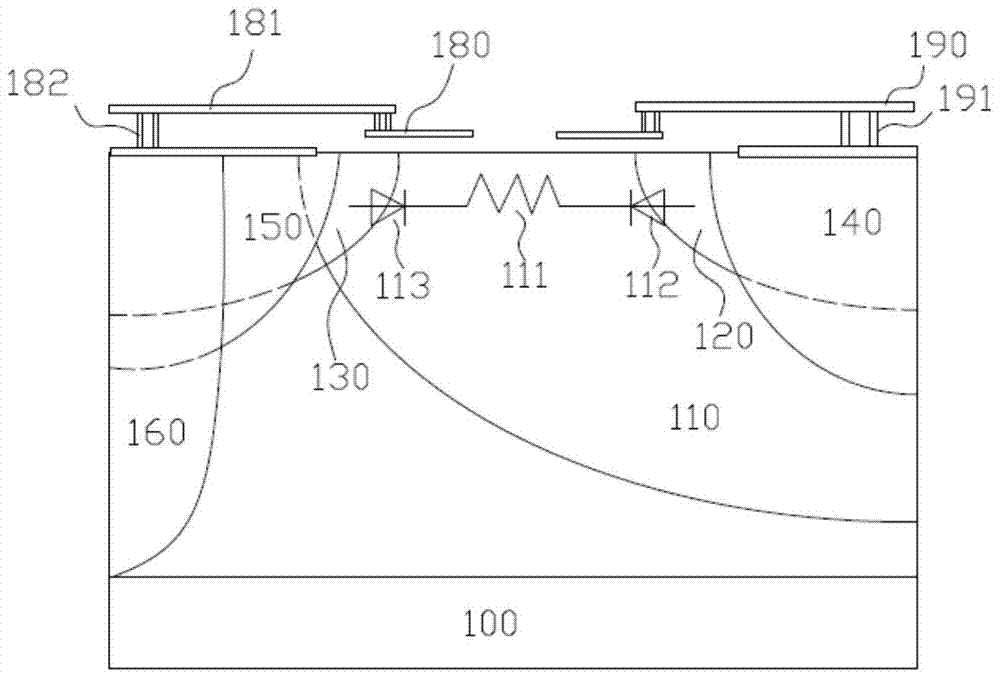

Electrostatic discharge protection structure in semiconductor device, and semiconductor device

ActiveCN105448893AImprove reverse withstand voltage capabilityImprove breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor devicePower flow

The invention discloses an electrostatic discharge protection structure in a semiconductor device, and the semiconductor device. The structure is provided with a pair of opposite diodes. A field plate which is always grounded is disposed above the node region of one diode. A depletion layer of the node region is increased through an internal electric field between the field plate and an N-type trench region, so as to improve the breakdown voltage. Because there is no oxidation layer, a conduction resistance Rdson is reduced, thereby enabling a withstand current value to be increased, and effectively solving a problem of conflict between the breakdown voltage and the withstand current.

Owner:INNOGRATION SUZHOU

Diode device and manufacturing process thereof

InactiveCN109962097AIncrease the turn-on voltageImprove reverse withstand voltage capabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSputteringMetal

The invention provides a diode device. The diode device includes an oxide layer, a doped polysilicon region, and cathode metal, N-type heavily doped region, N-type lightly doped region, P-type doped region, a barrier layer and anode metal which are arranged in sequence and are electrically conductive. The invention also provides a manufacturing process of the diode device, which includes the following steps: epitaxially growing the P-type doped region on the N-type lightly doped region; inward etching from the P-type doped region to the N-type lightly doped region to form a trench region; forming the oxide layer on the surfaces of the P-type doped region and the N-type lightly doped region; filling the trench region covered with the oxide layer with doped polysilicon; and sputtering metalon the P-type doped region to form the barrier layer and depositing the anode metal on the barrier layer. In forward electrification, low on-voltage is realized by Schottky contact of the P-type dopedregion and the barrier layer. In reverse electrification, high reverse withstand voltage is realized by a PN junction formed by the P-type doped region and the N-type lightly doped region.

Owner:BYD SEMICON CO LTD

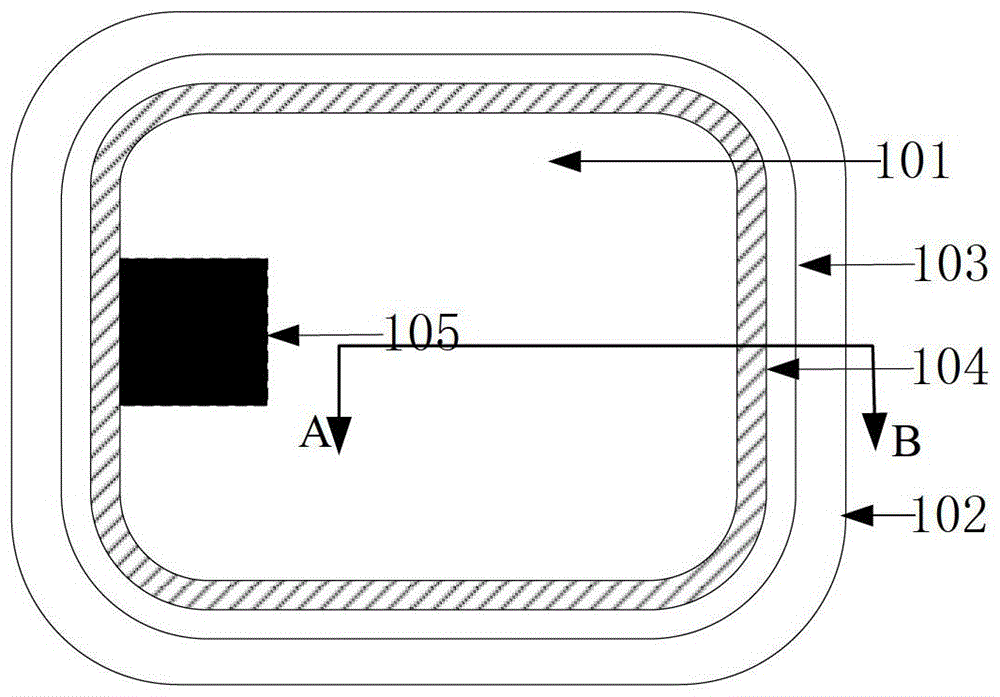

A trench type semiconductor power device terminal protection structure and power device

ActiveCN110416284BIncrease the electric field strengthReduced pressure resistanceSemiconductor devicesElectrical field strengthSplit ring

A trench type semiconductor power device terminal protection structure and power device, the power device structure includes a first conductivity type substrate, a first conductivity type buffer layer, a first conductivity type drift region, and in the first conductivity type drift region There is a primary cell area and a terminal protection area, and a main voltage divider ring, a secondary voltage divider ring, and a first conductivity type cut-off ring are provided outside the primary cell area, and a second conductivity type shielding protection layer is provided under the voltage divider ring. The structural feature is that a well region of the second conductivity type is provided between adjacent voltage divider rings, and each voltage divider ring is isolated from the well region of the second conductivity type by a drift region of the first conductivity type. At the same time as the best layer assists in withstand voltage, it can avoid the potential influence between adjacent voltage divider rings, effectively reduce the electric field strength in the voltage divider epoxy layer, and improve the withstand voltage capability of the terminal protection structure, and the structure is compatible with The original manufacturing process is compatible, and the overall performance of the device is improved while keeping the cost unchanged.

Owner:SOUTHEAST UNIV

Schottky diode

InactiveCN103035751AReduced conduction power consumptionImprove reverse withstand voltage capabilitySemiconductor devicesOptoelectronicsPolycrystalline silicon

The invention discloses a schottky diode which comprises an N-type epitaxy arranged on an N-type substrate and deep grooves formed in the N-type epitaxy. A silica layer is arranged in each deep groove and a polycrystalline silicon area is arranged at the inner side of the silica layer. A schottky contact area is arranged on the N-type epitaxy between deep grooves, and a metal layer is arranged on the schottky contact area, wherein the depth of the silica layer is larger than 1000 angstroms and the polycrystalline silicon area is connected with the metal layer through a metal wire. When the depth of silica layer filling each deep groove is larger than 1000 angstroms, the schottky diode can endure the high pressure of over 80 V.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Electrostatic discharge protection structure in semiconductor device and semiconductor device

ActiveCN105448893BImprove reverse withstand voltage capabilityImprove breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesBreakdown voltageElectrostatic discharge protection

An electrostatic discharge protection structure of a semiconductor device and a semiconductor device, the electrostatic discharge protection structure has a pair of back-to-back diodes, a field plate is always grounded above one of the diode junction regions, and the field plate and the N-type channel region are used The internal electric field between them increases the depletion layer in the junction region to increase the breakdown voltage. At the same time, because there is no field oxide layer, the on-resistance Rdson decreases, so that the withstand current value also increases. , effectively solve the contradiction between breakdown voltage and withstand current.

Owner:INNOGRATION SUZHOU

Shield gate trench field effect transistor and preparation method thereof

ActiveCN113035715AOther operating parameters influenceImprove reverse withstand voltage capabilityTransistorSemiconductor/solid-state device detailsEtchingPhysical chemistry

The invention provides a shield gate trench field effect transistor and a preparation method thereof. The method mainly comprises the steps: providing a substrate, forming an epitaxial layer on the upper surface of the substrate, forming a deep trench in the epitaxial layer, and forming a shielding oxide layer, shield polysilicon, a first isolation oxide layer and a second isolation oxide layer on the inner wall of the deep trench, wherein the density of the first isolation oxide layer is greater than that of the second isolation oxide layer; removing the second isolation oxide layer, a part of the first isolation oxide layer and the shielding oxide layer through wet etching, so that an obtuse angle is formed between the upper surface of the shielding oxide layer and the side wall of the deep trench; forming a gate oxide layer and gate polysilicon on the inner wall of the deep trench; and forming other structures of the field effect transistor. According to the method, the reverse voltage endurance capability of the gate oxide layer can be effectively improved, and other working parameters of the field effect transistor cannot be influenced; and the preparation method provided by the invention is easy to realize in process manufacturing and mass production.

Owner:CHINA RESOURCES MICROELECTRONICS (CHONGQING) CO LTD

A kind of preparation method of power diode

ActiveCN104051546BImprove reverse withstand voltage capabilityImprove reverse withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETMetallic materials

Owner:无锡橙芯微电子科技有限公司

A semiconductor device and method of making the same

ActiveCN103855200BAvoid failureImprove performanceTransistorSemiconductor/solid-state device manufacturingElectricityEngineering

The invention provides a semiconductor device and a manufacturing method thereof. The semiconductor device includes a substrate, an emitter metal electrode and a first field plate; a base region and a main junction are formed in the substrate; the emitter metal electrode is formed on the surfaces of the base region and an emitting region and is electrically connected with the base region and the emitting region; and the first field plate covers the main junction and is electrically connected with the emitter metal electrode. According to the semiconductor device provided by the invention, a current path exists in the base region which is adjacent to the main junction at a transition region, such that a current release path can be provided for dynamic avalanche current which appears in switch-on and switch-off processes of the semiconductor device, and therefore, the failure of the semiconductor device caused by the dynamic avalanche current can be avoided, and the performance of the semiconductor device can be improved; and the first field plate covers the main junction and is electrically connected with the base region, the potential of the first field plate is zero constantly, and therefore, an electric field shielding effect of the first field plate can be enhanced, and therefore, a reverse voltage withstanding capacity of the semiconductor device can be improved.

Owner:SHANGHAI LIANXING ELECTRONICS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com