Vertical III-nitride power semiconductor device structure with trench isolation layer and preparation method of vertical III-nitride power semiconductor device structure

A technology of power semiconductor and device structure, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of unfavorable device forward conduction, large forward conduction resistance, etc., to optimize electric field distribution and improve reverse resistance. voltage capability and the effect of reducing forward on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

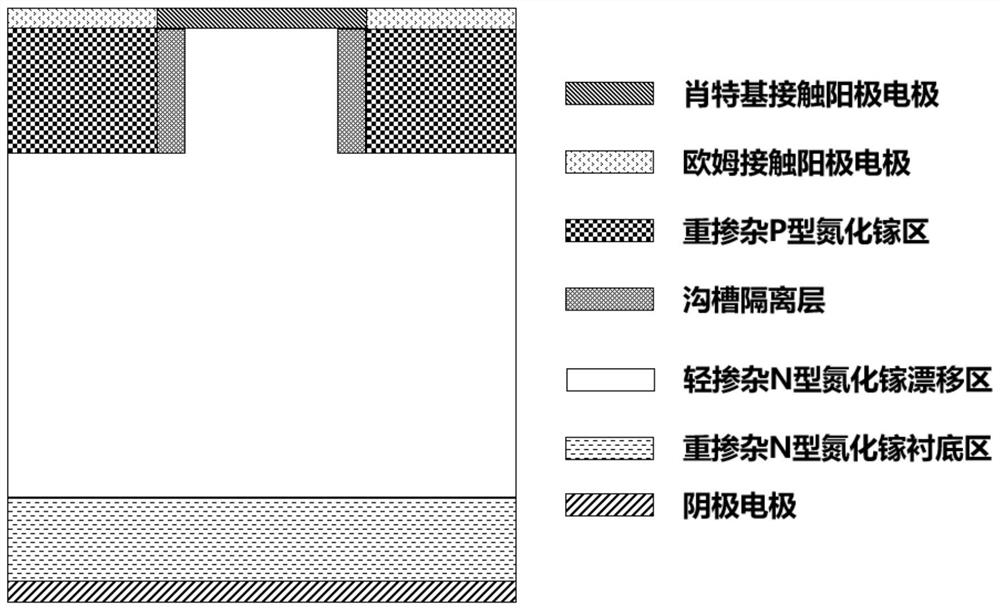

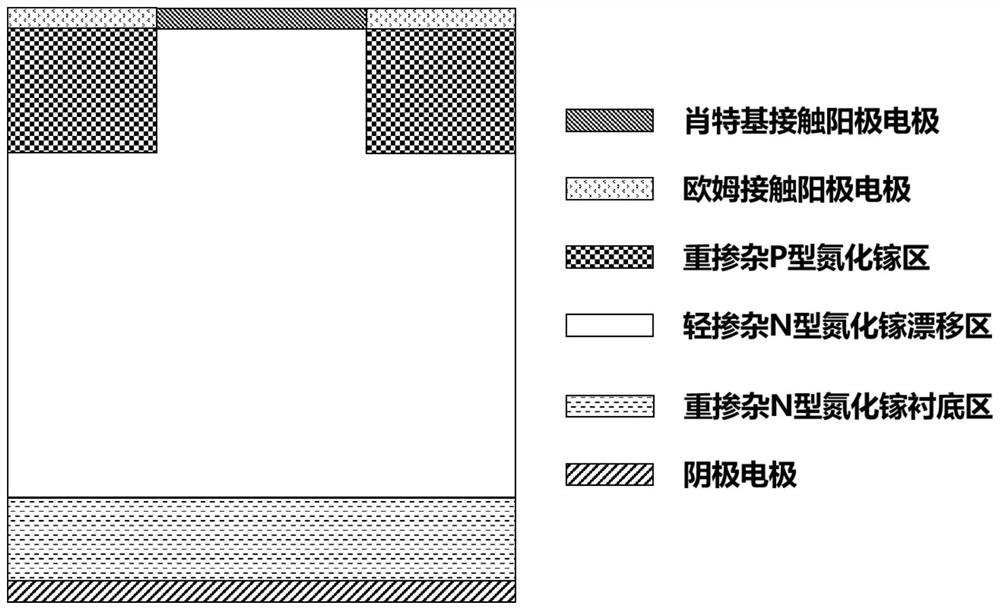

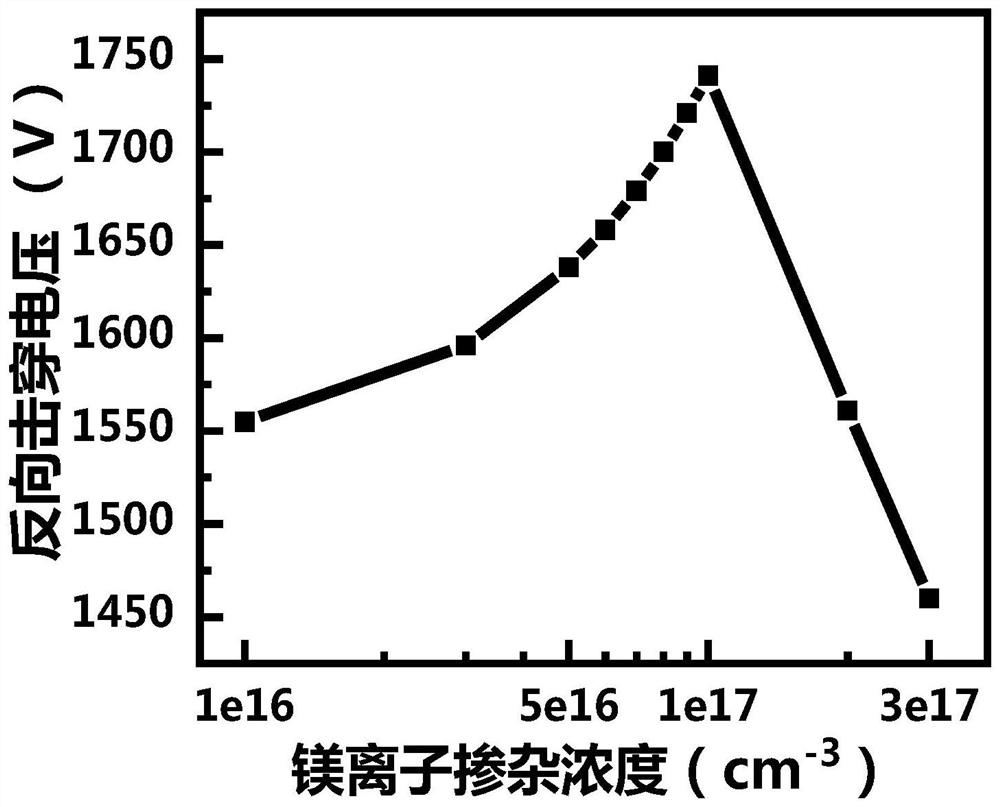

[0055] A vertical type III gallium nitride power semiconductor device structure with a trench isolation layer, the structure is as follows figure 1 As shown, it includes a cathode electrode, a heavily doped N-type GaN substrate region, a lightly doped N-type GaN drift region, a heavily doped P-type GaN region, and an anode electrode from bottom to top; heavily doped An isolation layer of silicon dioxide is arranged between the two vertical contact surfaces of the doped P-type GaN region and the lightly doped N-type GaN drift region, and the lateral thickness of each isolation layer is 50nm. The height is 1.5 μm.

[0056] The doping element of the lightly doped N-type gallium nitride drift region is silicon, and the doping concentration is 2e16cm -3 . The lightly doped N-type GaN drift region is composed of a lightly doped N-type GaN drift layer and a lightly doped N-type GaN protrusion; the lightly doped N-type GaN protrusion has a cuboid structure, The lightly doped N-type...

Embodiment 2

[0063] A method for preparing a vertical Group III GaN power semiconductor device structure with a trench isolation layer described in Embodiment 1, using a secondary epitaxy process to grow a heavily doped P-type GaN region, comprising the following steps:

[0064] (1) Using trimethylgallium (TMGa), ammonia (NH 3 ) as Ga source and N source, SiH 3 CH 3 As an N-type impurity source, H 2 As a carrier gas, a 2μm-thick low-defect, low-dislocation heavily doped N-type gallium nitride substrate region is realized in MOCVD, and the doping concentration of silicon is 5e18cm -3 ;

[0065] (2) Using trimethylgallium (TMGa), ammonia (NH 3 ) as Ga source and N source, SiH 3 CH 3 As an N-type impurity source, H 2 As a carrier gas, a layer of lightly doped N-type GaN drift region with a thickness of 15 μm is homoepitaxially deposited on the surface of the heavily doped N-type GaN substrate region by MOCVD method, and the doping concentration of silicon is 2e16cm -3 ;

[0066] (3) ...

Embodiment 3

[0074] A preparation method of the vertical type III gallium nitride power semiconductor device structure with a trench isolation layer described in embodiment 1, as described in embodiment 2, the difference is: in step (6), use multiple The process of epitaxy plus ion implantation grows heavily doped P-type gallium nitride region, the specific steps are as follows:

[0075] ① Use silicon dioxide as a hard mask to block the top surface of the unetched lightly doped N-type GaN drift region and the upper surface of the isolation layer, use ammonia as the nitrogen source, SiH 3 CH 3 As the dopant source, trimethylgallium (TMGa) was used as the Ga source, H 2 As a carrier gas, a layer of N-type GaN with a thickness of 0.3-0.6 μm is homoepitaxially deposited on both sides of the isolation layer and on the upper surface of the lightly doped N-type GaN drift region by MOCVD method, and the doping concentration of silicon is 2e16cm -3 ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com