A ground brush and a preparation method thereof

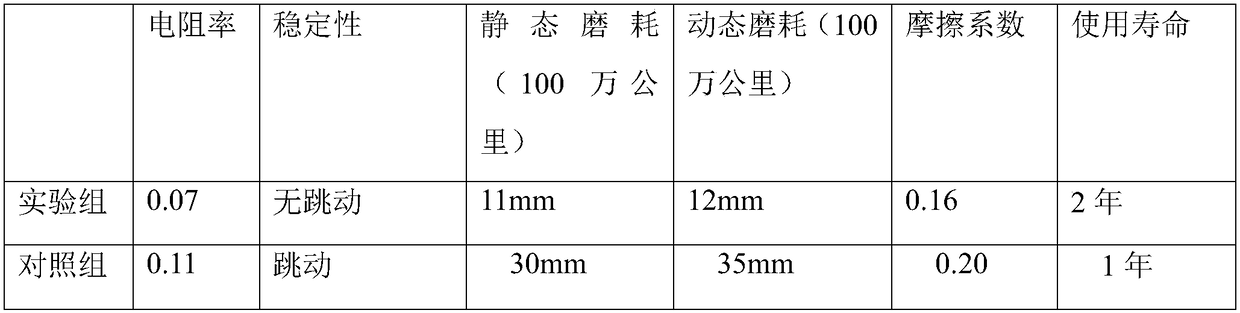

A grounding brush, graphite powder technology, applied in the direction of brush manufacturing, circuit, connection, etc., can solve the problems of lead-containing is not environmentally friendly, short service life, poor stability, etc., to achieve long service life, good wear resistance, make up a reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a grounding brush and a preparation method thereof, the formula and preparation method are as follows:

[0034] 1. Formula:

[0035] The grounding brush is prepared from the following raw materials in parts by weight: 10 parts of graphite powder, 70 parts of copper powder, 2 parts of tin powder, 5 parts of zinc carbonate, 0.1 part of silicon carbide and 0.1 part of washing oil; wherein: graphite powder has a particle size of 300 mesh natural graphite powder (flaky graphite powder), and the carbon content in the graphite powder is ≥99%, the ash content is ≤1%; the average particle size of silicon carbide is 300 mesh; the bulk density of copper powder is 0.9g / cm 3 ;

[0036] 2. The preparation method of the grounding brush is carried out according to the following steps:

[0037] 1) Weighing: Weigh graphite powder, copper powder, tin powder, zinc carbonate, anti-wear agent and washing oil respectively;

[0038] 2) Mixing: put graphite powder, a...

Embodiment 2

[0042] This embodiment provides a grounding brush and a preparation method thereof, the formula and preparation method are as follows:

[0043] 1. Formula:

[0044] The grounding brush is prepared from the following raw materials in parts by weight: 20 parts of graphite powder, 75 parts of copper powder, 8 parts of tin powder, 11 parts of zinc carbonate, 0.5 part of anti-wear agent and 0.2 part of washing oil; wherein: graphite powder is the particle size It is 300 mesh natural graphite powder (flaky graphite powder), and the carbon content in the graphite powder is ≥99%, the ash content is ≤1%; the average particle size of silicon carbide is 300 mesh; the bulk density of copper powder is 0.9g / cm 3 ;

[0045] 2. The preparation method of the grounding brush is carried out according to the following steps:

[0046] 1) Weighing: Weigh graphite powder, copper powder, tin powder, zinc carbonate, anti-wear agent and washing oil respectively;

[0047] 2) Mixing: put graphite powder...

Embodiment 3

[0051] This embodiment provides a grounding brush and a preparation method thereof, the formula and preparation method are as follows:

[0052] 1. Formula:

[0053] The grounding brush is prepared from the following raw materials in parts by weight: 14 parts of graphite powder, 75 parts of copper powder, 5 parts of tin powder, 8 parts of zinc carbonate, 0.3 part of anti-wear agent and 0.1 part of washing oil; wherein: graphite powder is the particle size It is 300 mesh natural graphite powder (flaky graphite powder), and the carbon content in the graphite powder is ≥99%, the ash content is ≤1%; the average particle size of silicon carbide is 300 mesh; the bulk density of copper powder is 0.9g / cm 3 ;

[0054] 2. The preparation method of the grounding brush is carried out according to the following steps:

[0055] 1) Weighing: Weigh graphite powder, copper powder, tin powder, zinc carbonate, anti-wear agent and washing oil respectively;

[0056] 2) Mixing: put graphite powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com