Carbon brush used for locomotive traction motor

A traction motor and carbon brush technology, applied in circuits, current collectors, electrical components, etc., can solve the problems of commutation performance limitation, carbon brush temperature rise, carbon brush temperature rise, etc., to improve wear resistance and uniform performance. , the effect of improving orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] 1. Preparation of soft carbon black powder

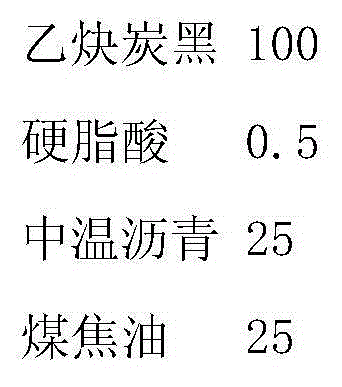

[0084] 1-A) Prepare materials according to the following weight ratio (kg):

[0085]

[0086] 1-B) Add acetylene carbon black and stearic acid to a double paddle mixing pot preheated to 150°C, close the lid and mix for 20 minutes, then add medium-temperature pitch and coal tar, close the lid and mix for 60 minutes, turn off the power to obtain a mixture material.

[0087] 1-C) Take out the mixed material, cool it naturally to 80° C., and press it into a material column; wherein, the pressure of the pressing treatment is 5 MPa.

[0088] 1-D) Put the material column in the roasting furnace, isolate the air and roast, the maximum temperature is 1200 ° C for 10 hours, and the roasting curve is 288 hours; after cooling out of the furnace, put the roasted material column into the graphitization furnace, and use pitch As a filler, it can be rapidly graphitized when electrified (the temperature can be raised freely), and it can ...

Embodiment 2

[0119] 1. Preparation of soft carbon black powder

[0120] In addition to step 1-A) according to the following weight ratio preparation (kg):

[0121] Acetylene Black 95

[0122] Stearic acid 0.4

[0123] Medium temperature asphalt 24

[0124] Except coal tar 24, all the other are identical with embodiment 1.

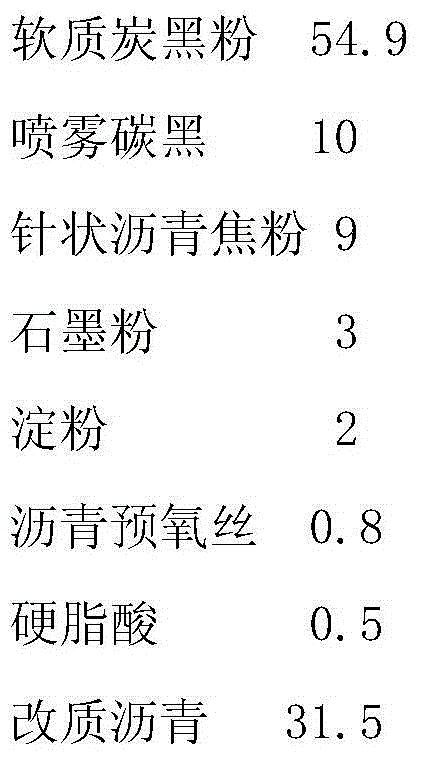

[0125] 2. Preparation of carbon brush blanks

[0126] 2-A) Prepare raw materials (kg) according to the following weight ratio:

[0127]

[0128] 2-B) Mixed extrusion treatment

[0129] Preheat the second-ninth section of the twin-screw extrusion mixer cavity to 110°C, add the raw materials in step 2-A) to the first section of the twin-screw extrusion mixer at a constant speed, and continue Raise the temperature to 200°C and carry out mixing and extrusion treatment to obtain the mixed material;

[0130] 2-C) The first grinding treatment

[0131] The mixed material was pulverized to 74 μm in a Raymond mill, and then pulverized to 48 μm in a fluidized bed jet mi...

Embodiment 3

[0143] 1. Preparation of soft carbon black powder

[0144] In addition to step 1-A) according to the following weight ratio preparation (kg):

[0145] Acetylene carbon black 105

[0146] Stearic acid 0.6

[0147] Medium temperature asphalt 26

[0148] Except coal tar 26, all the other are identical with embodiment 1.

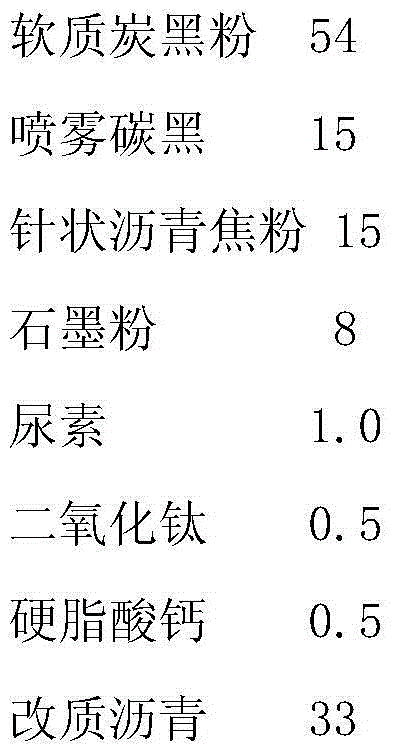

[0149] 2. Preparation of carbon brush blanks

[0150] 2-A) Prepare raw materials (kg) according to the following weight ratio:

[0151]

[0152] 2-B) Mixed extrusion treatment

[0153] Preheat the second-ninth section of the twin-screw extrusion mixer chamber to 130°C, add the raw materials in step 2-A) to the first section of the twin-screw extrusion mixer at a uniform speed, and continue Raise the temperature to 210°C and carry out mixing and extrusion treatment to obtain the mixed material;

[0154] 2-C) The first grinding treatment

[0155] The mixed material was pulverized to 74 μm in a Raymond mill, and then pulverized to 48 μm in a fluidized be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com