Electric brush

A technology of brushes and metal brushes, applied in circuits, current collectors, electrical components, etc., can solve problems such as low operating efficiency, poor stability, and short life, and achieve low brush wear rate, improved wear resistance, and low Effect of Coefficient of Friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

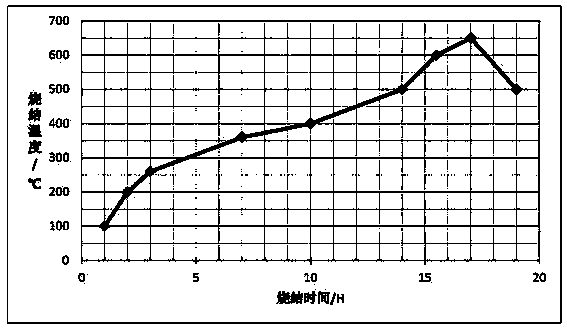

Image

Examples

Embodiment 1

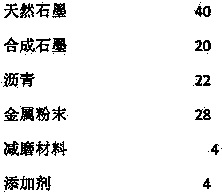

[0082] 1) Prepare materials (parts) according to the following weight ratio:

[0083]

[0084] Among them, the natural graphite is T399.9; the synthetic graphite particle size is ≤325 mesh, the carbon content is ≥99.9%, the fixed carbon content is ≥80%, the moisture content is ≤0.5%, and the ash content is ≤0.5%; the asphalt is selected from Coal tar pitch with a softening point of 95-110°C, coking value ≈ 55%, toluene insoluble matter content ≈ 25%, ash content 3 , with a particle size of ≤325 mesh; the silver powder is flaky silver powder with a purity of 99.9%, and a powder particle size of ≤80nm; the friction-reducing material is a mixture of molybdenum disulfide and tungsten disulfide, wherein the weight of molybdenum disulfide and tungsten disulfide The ratio of molybdenum disulfide and tungsten disulfide is 3:1; the particle size of molybdenum disulfide and tungsten disulfide is 3000-4000 mesh, and the purity is 99%; the additives include hexagonal boron nitride and c...

Embodiment 2

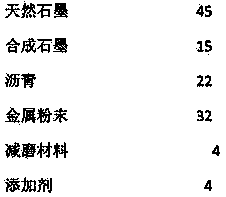

[0119] 1) Prepare materials (parts) according to the following weight ratio:

[0120]

[0121] Among them, the natural graphite is T399.9; the synthetic graphite particle size is ≤325 mesh, the carbon content is ≥99.9%, the fixed carbon content is ≥80%, the moisture content is ≤0.5%, and the ash content is ≤0.5%; the asphalt is selected from Coal tar pitch with a softening point of 95-110°C, coking value ≈ 55%, toluene insoluble matter content ≈ 25%, ash content 3 , with a particle size of ≤325 mesh; the silver powder is flaky silver powder with a purity of 99.9%, and a powder particle size of ≤80nm; the friction-reducing material is a mixture of molybdenum disulfide and tungsten disulfide, wherein the weight of molybdenum disulfide and tungsten disulfide The ratio of molybdenum disulfide and tungsten disulfide is 3:1; the particle size of molybdenum disulfide and tungsten disulfide is 3000-4000 mesh, and the purity is 99%; the additives include hexagonal boron nitride and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com