A semiconductor device and method of making the same

A semiconductor and device technology, applied in the field of semiconductor devices and their production, can solve the problems of semiconductor device failure and poor performance, and achieve the effect of improving performance and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

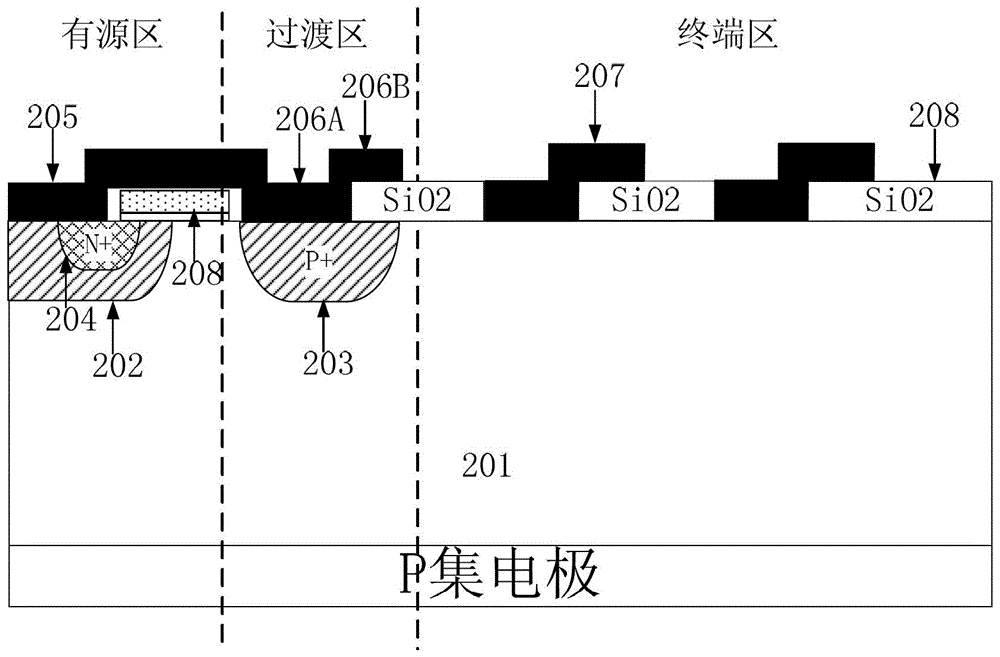

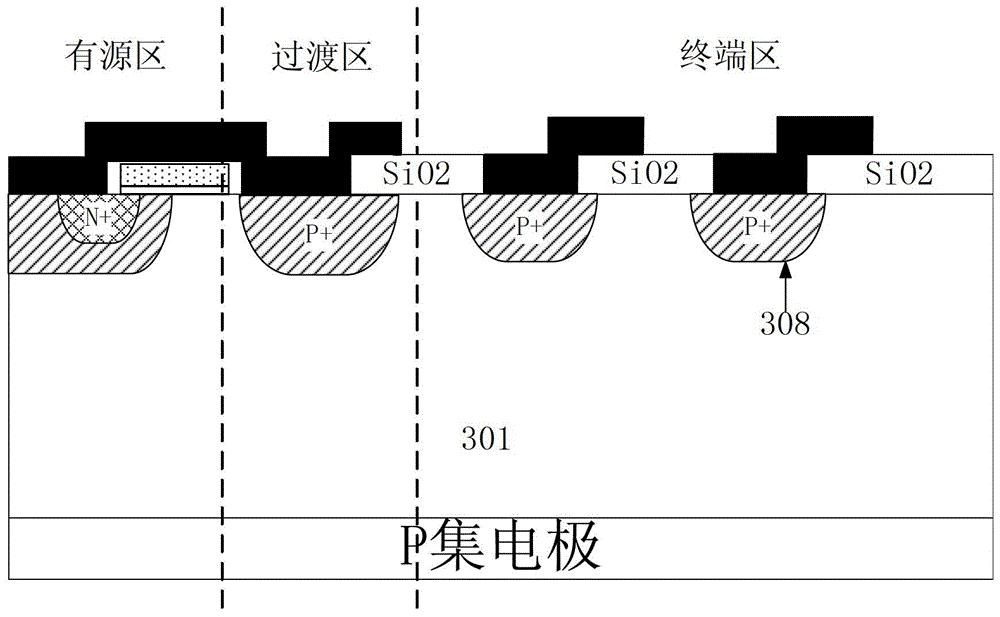

[0027] As mentioned in the background section, semiconductor devices in the prior art are prone to failure and have poor performance.

[0028] The inventors found that there are two main reasons why existing semiconductor devices are prone to failure: on the one hand, during the turn-on and turn-off processes of the semiconductor device, the base region close to the main junction in the active region of the semiconductor device is prone to latch-up Lock-in effect, causing semiconductor devices to fail. On the other hand, when the semiconductor device is subjected to a reverse voltage, the main junction of the semiconductor device is prone to premature breakdown, resulting in failure of the semiconductor device.

[0029] The inventors have found that the main reason for the latch-up effect to occur easily in the base region close to the main junction in the active region of the semiconductor device is that there will be a large dynamic avalanche current during the turn-on and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com