A kind of Schottky diode and its preparation method

A Schottky diode and cathode technology, which is used in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the limitation of reverse voltage withstand capability, complex process, and difficulty in withstand voltage and conduction capability of Schottky diodes and other problems, to achieve the effect of improving the conduction capacity and increasing the withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

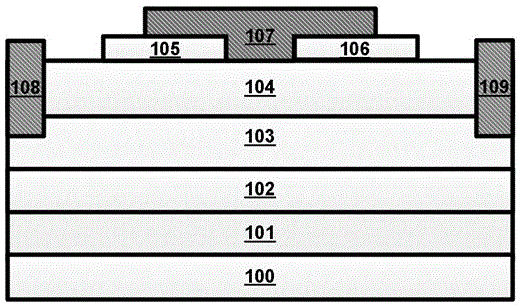

[0058] This embodiment provides a Schottky diode, including a substrate layer 100 formed of sapphire, a crystal nucleus layer 101 above the substrate layer, a buffer layer 102 above the crystal nucleus layer 101, and GaN formed on the buffer layer 102. layer 103 and the AlGaN layer 104 located on the GaN layer 103, a two-dimensional electron gas channel is formed between the GaN layer 103 and the AlGaN layer 104, and the GaN layer 103 and the AlGaN layer 104 form ohmic contacts with the cathodes 108 and 109, and the AlGaN layer 104 It forms a Schottky contact with the anode electrode; it also includes a metal field plate 107 connected to the anode electrode and annular P-GaN enhancement layers 105 and 106 filled between the metal field plate 107 and the AlGaN layer 104 .

[0059] In this embodiment, the doping concentration of the two P-GaN enhancement layers 105, 106 is between 1E13-1E20 / cm 3 In between, the doping concentration increases gradually along the direction extendi...

Embodiment 2

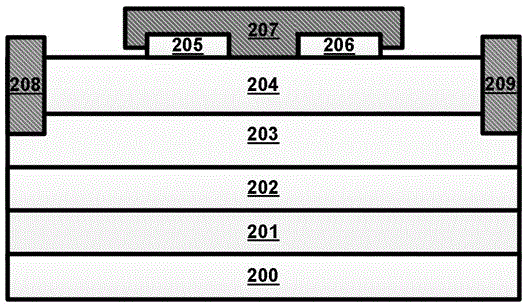

[0069]This embodiment provides a Schottky diode, including a substrate layer 200 formed of Si, a crystal nucleus layer 201 located above the substrate layer, a buffer layer 202 located above the crystal nucleus layer 201, and a GaN layer formed on the buffer layer 202. layer 203 and the AlGaN layer 204 located on the GaN layer 203, a two-dimensional electron gas channel is formed between the GaN layer 203 and the AlGaN layer 204, and the GaN layer 203 and the AlGaN layer 204 form ohmic contacts with the cathodes 208 and 209, and the AlGaN layer 204 It forms a Schottky contact with the anode electrode; it also includes a metal field plate 207 connected to the anode electrode and annular P-GaN enhancement layers 205 and 206 filled between the metal field plate 207 and the AlGaN layer 204 .

[0070] In this embodiment, the doping concentration of the two P-GaN enhancement layers 205, 206 is between 1E13-1E20 / cm 3 In between, the doping concentration increases gradually along the ...

Embodiment 3

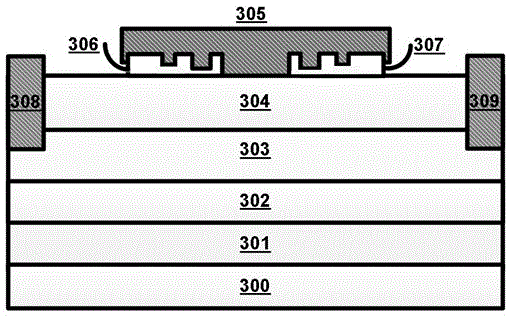

[0080] This embodiment provides a Schottky diode, including a substrate layer 300 formed of SiC, a crystal nucleus layer 301 located above the substrate layer, a buffer layer 302 located above the crystal nucleus layer 301, and a GaN layer formed on the buffer layer 302. layer 303 and the AlGaN layer 304 located on the GaN layer 303, a two-dimensional electron gas channel is formed between the GaN layer 303 and the AlGaN layer 304, the GaN layer 303 and the AlGaN layer 304 form ohmic contacts with the cathodes 308, 309, and the AlGaN layer 104 It forms a Schottky contact with the anode electrode; it also includes a metal field plate 305 connected to the anode electrode and annular P-GaN enhancement layers 307 and 307 filled between the metal field plate 305 and the AlGaN layer 304 .

[0081] In this embodiment, the doping concentration of the P-GaN enhancement layers 307, 306 is between 1E13-1E20 / cm 3 Between, more specifically, the doping concentrations of the different regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com